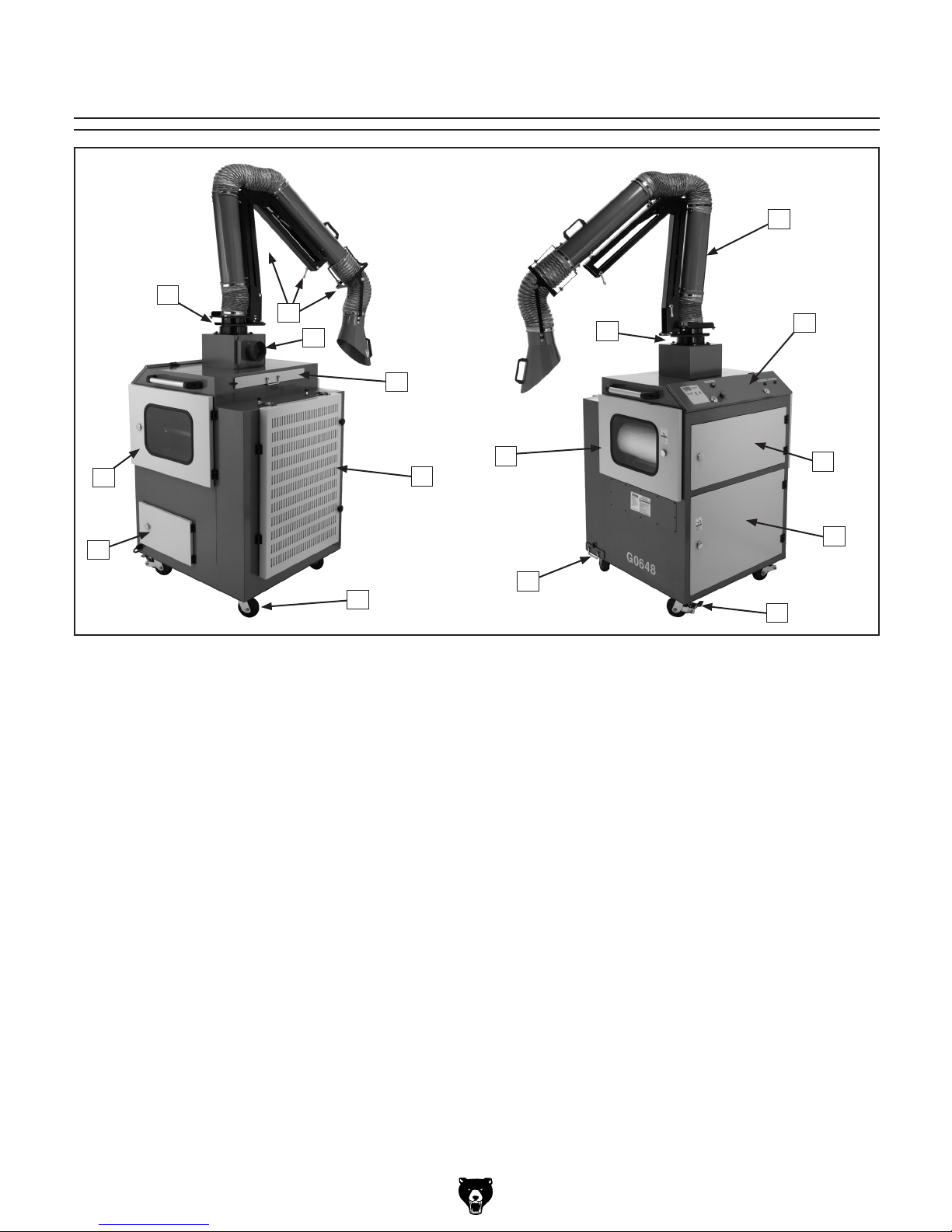

Additional Safety Instructions for

Welding Fume Extractors

5. WELDING IN A CONFINED SPACE CAN

BE HAZARDOUS.

6. PREVENT FIRES.

7. EXPERIENCING DIFFICULTIES.

1.WELDING FUMES.

2. PROTECT BODY FROM ARC BURNS,

SPARKS, AND SPATTER.

3. EQUIPMENT MAINTENANCE.

4. WORKING AREA.

No list of safety guidelines can be complete.

Every shop environment is different. Always

consider safety first, as it applies to your

individual working conditions. Use this and

other machinery with caution and respect.

Failure to do so could result in serious per-

sonal injury, damage to equipment, or poor

work results.

Like all machinery there is potential danger

when operating this machine. Accidents are

frequently caused by lack of familiarity or

failure to pay attention. Use this machine

with respect and caution to lessen the pos-

sibility of operator injury. If normal safety

precautions are overlooked or ignored, seri-

ous personal injury may occur.