Safety for Blade Welders

WELDING FUMES.

PREVENT FIRES.

PERSONAL PROTECTIVE EQUIPMENT.

ABRASION INJURIES.

ELECTRIC & MAGNETIC FIELDS (EMF).

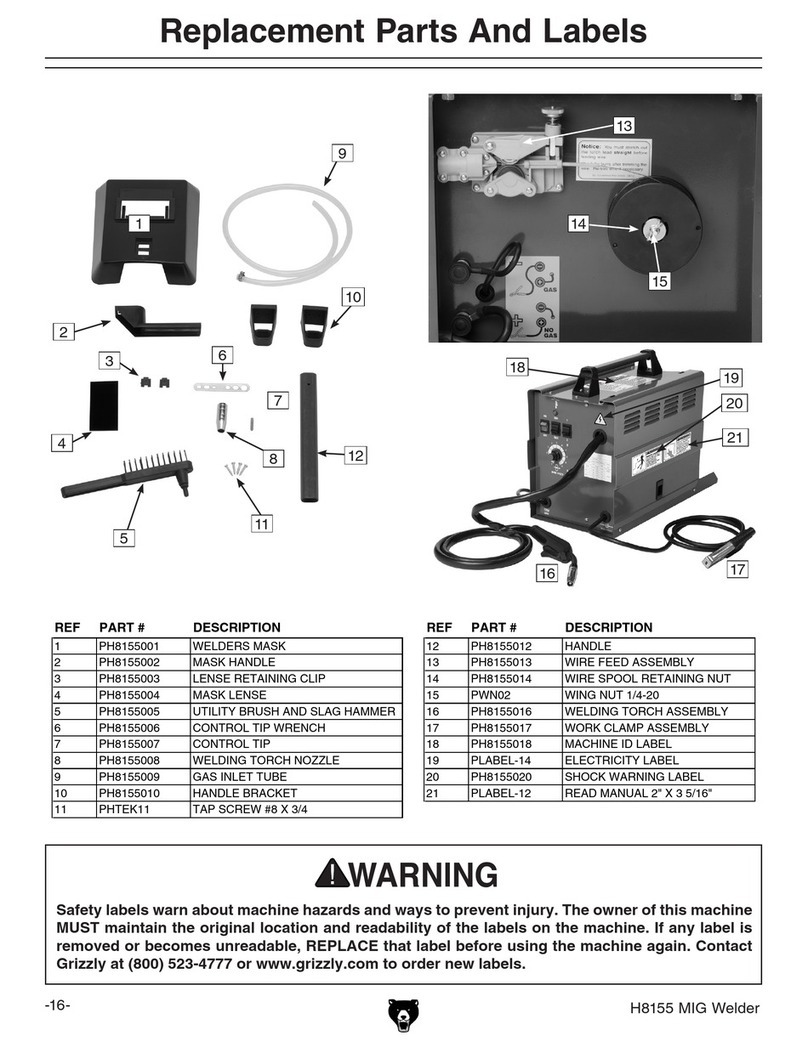

EQUIPMENT MAINTENANCE.

STABLE WORK SURFACE.

BLADE BREAKAGE.

If you have never used this type of welder before, WE STRONGLY RECOMMEND that you read

books, trade magazines, or get formal training before beginning any projects. Regardless of the

content in this section, Grizzly Industrial will not be held liable for accidents caused by lack of

training.