Bioscreen C Microbiology Reader User's Manual

_______________________________________________________________________________________________

________

_______________________________________________________________________________________________

________

4

2. SYSTEM DESCRIPTION

2.1 Overview

The Bioscreen C Microbiology Reader is a fully automated system developed to perform a wide range of

microbiology experiments. The system consists of:

Bioscreen C reader

BioScreener software

Honeycomb microplates (consumables)

PC (not provided by Growth Curves Ltd.)

All microorganisms (bacteria, mold, yeast, etc.) increase the turbidity of liquid growth medium when growing

and multiplying in it. Bioscreen C monitors this growth by measuring the turbidity of the medium in the wells of

a microplate. These measurements are done kinetically, and recorded as optical density (OD)

measurements. All functions are controlled by BioScreener software according to the parameters entered by

the user. OD values are recorded automatically by the software.

Bioscreen C is an open system: the user can decide what is studied in the the wells. Any microorganism,

broth or chemical can be pipetted into the wells for monitoring growth kinetically and automatically. Most of

the conventional test tube tests where the turbidity or color change occurs can be run with the "mini-tubes" in

a Honeycomb microplate with Bioscreen C.

For vertical light photometry, all visible light wavelengths can be used. The eight standard filters provided in

the filter wheel of Bioscreen C are: 405, 420, 450, 492, 540, 580, 600 nm and a wide band (420-580 nm)

filter. Filters with special wavelengths are available by request.

2.2 Bioscreen C Reader

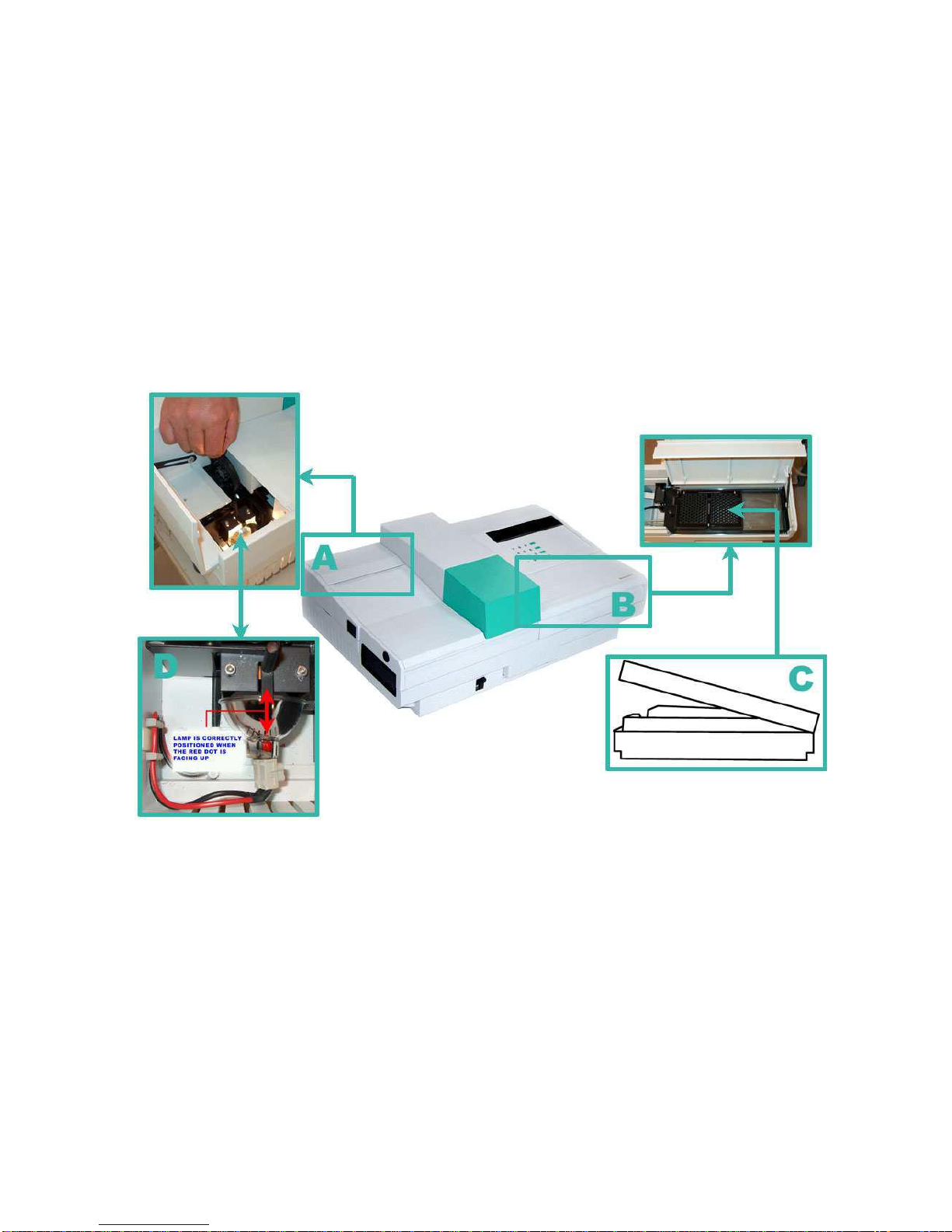

The reader includes three interrelated systems: mechanical transport, incubator and optical system (for the

elements, see Figure 1). These three systems work in a coordinated way to provide automated

heating/cooling, sample indexing and OD readings.

2.2.1 Mechanical transport

The incubator tray assembly holds the Honeycomb microplates. The assembly shuttles from the microplate

loading section into the measurement compartment, where light is passed through each well of the

microplate and the detector makes the OD readings.

2.2.2 Incubator

The incubator consists of the incubator tray (fixed, non-removable), the incubator cover (on hinges) and a

temperature control system. After filling the microplate with experimental materials, the incubator cover is

placed manually on top of the incubator tray and properly closed. During the incubation and measuring, the

incubator cover remains in place.

The temperature control system maintains the incubation temperature set by the program. Ethylene glycol

and water mixture (1:1) is used as a heat transfer liquid. The liquid circulates continuously in the incubator

tray to keep the temperature stable and at a selected value. The temperature is continuously monitored and

saved by the software.

2.2.3 Optical system

The changes in turbidity or color in the culture medium, due to the growth of microorganisms, is measured

kinetically with a vertical photometer.