NTEGRA Spectra Probe NanoLaboratory. (Inverted Configuration with Solar TII spectrometer)

NTEGRA Spectra Probe NanoLaboratory. Inverted Configuration

with Solar TII spectrometer

Table of Contents

1. OVERVIEW .............................................................................................................................................5

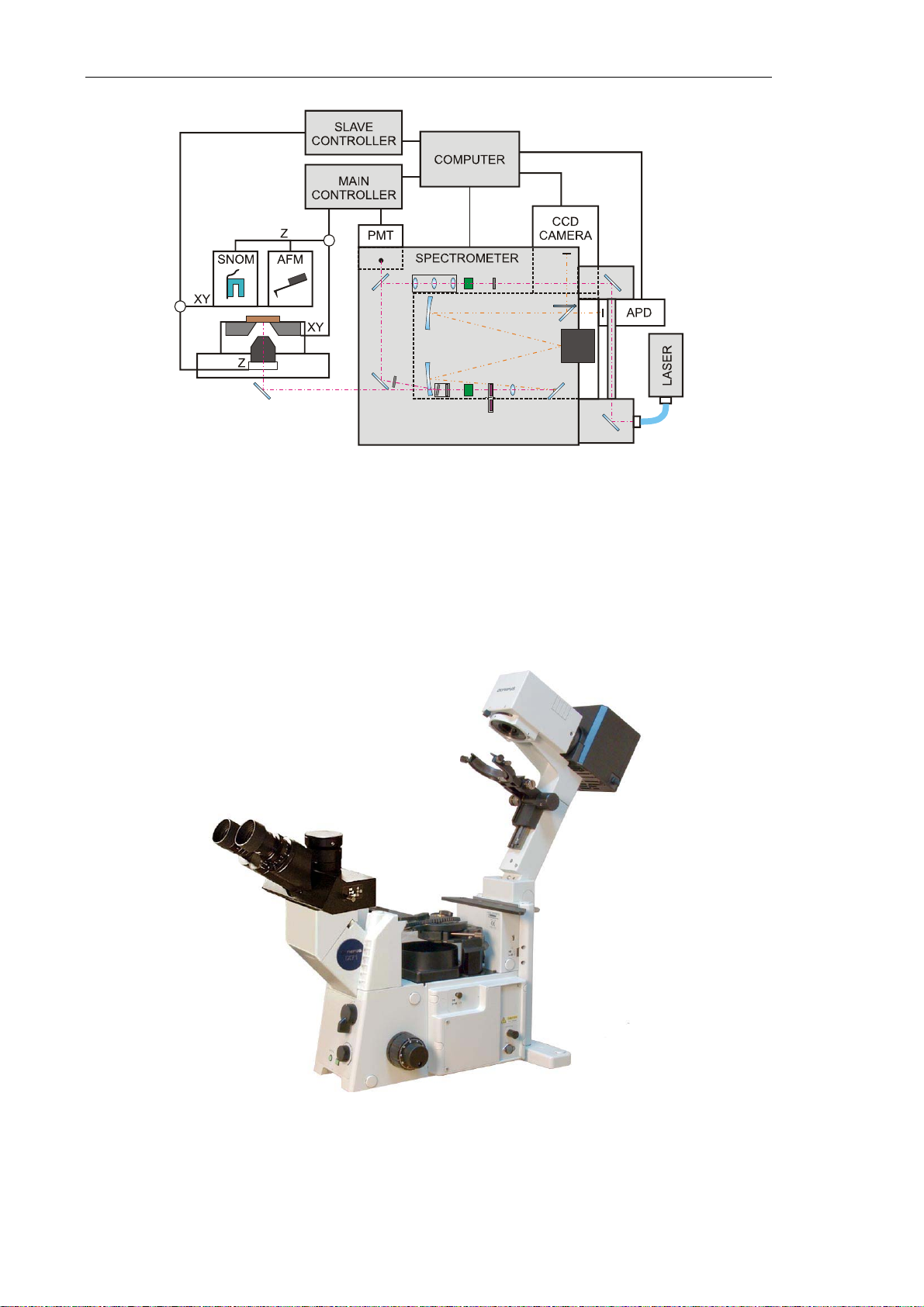

2. DESIGN.....................................................................................................................................................7

2.1. INVERTED OPTICAL MICROSCOPE .................................................................................................... 8

2.2. NTEGRA BASE UNIT....................................................................................................................... 9

2.3. XY SCANNING OPTICAL EXCHANGEABLE MOUNT......................................................................... 10

2.4. MEASURING HEADS........................................................................................................................ 12

2.5. SPECTROMETER .............................................................................................................................. 16

2.6. DETECTORS .................................................................................................................................... 16

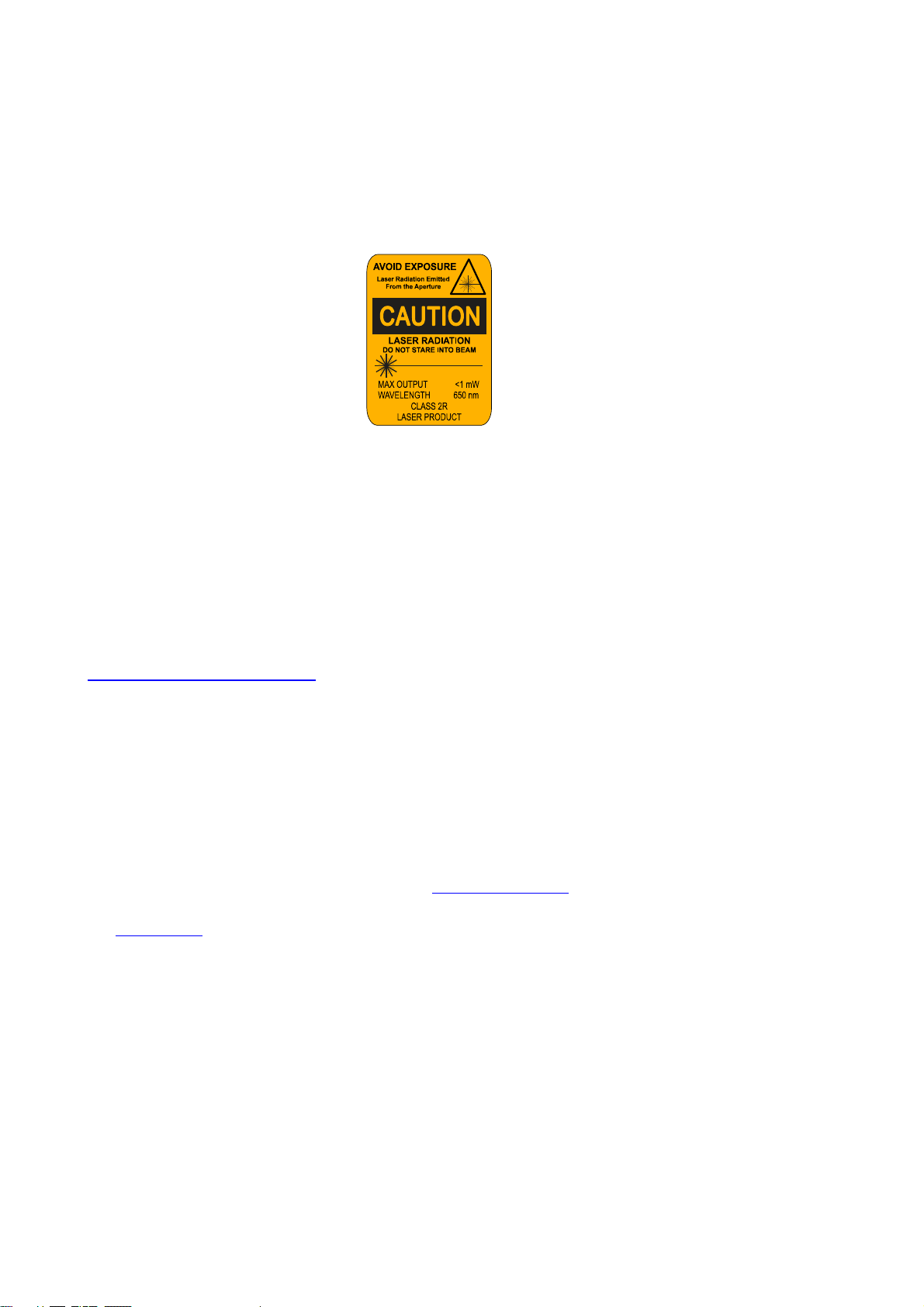

2.7. LASER............................................................................................................................................. 20

2.8. OPTICAL FIBER TRANSPORT SYSTEM ............................................................................................. 21

2.9. ADDITIONAL CABLES ..................................................................................................................... 22

2.10. CONTROLLERS................................................................................................................................23

2.11. COMPUTER ..................................................................................................................................... 24

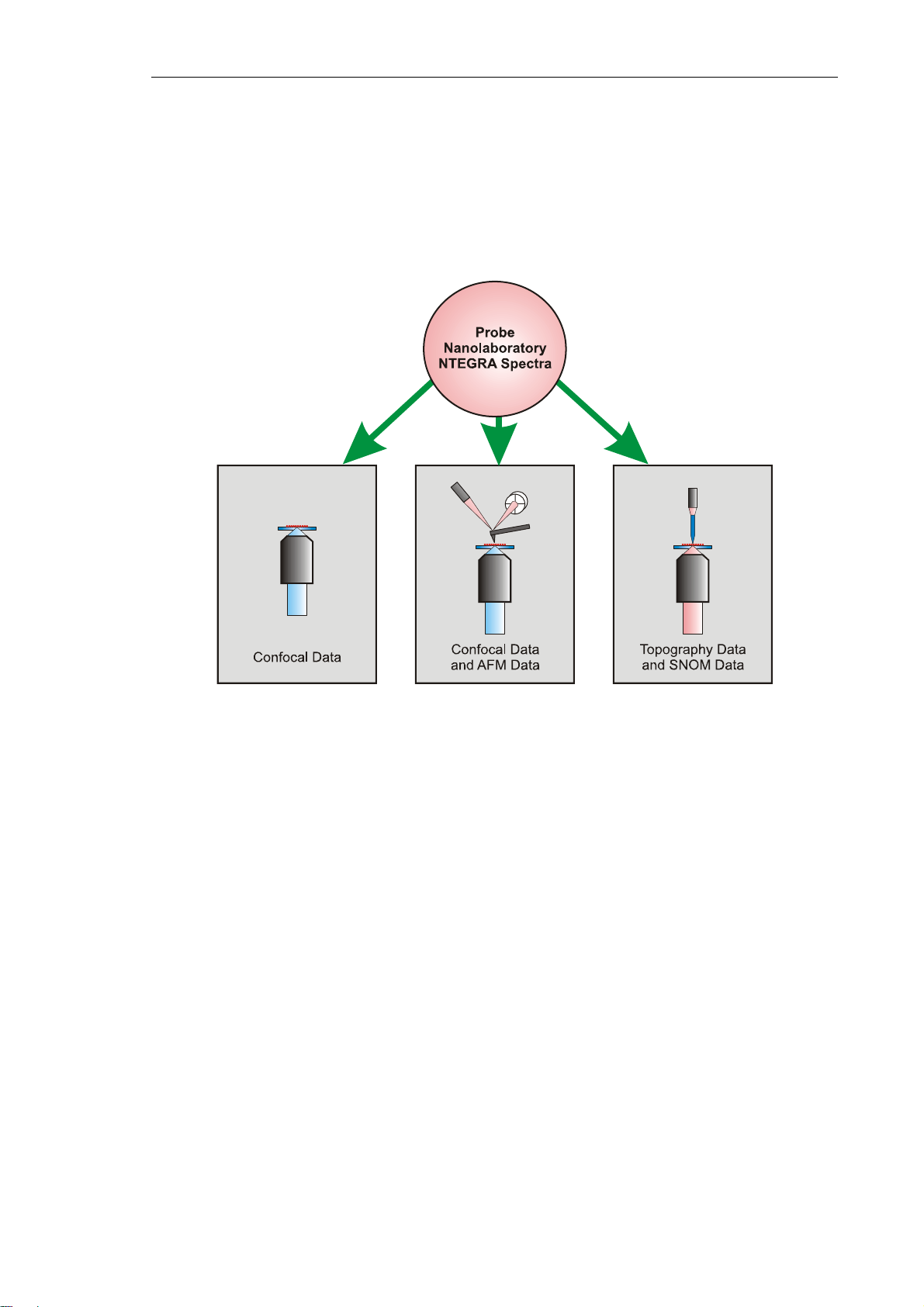

3. PRINCIPLE OF OPERATION OF THE NTEGRA SPECTRA PNL..............................................25

4. BASIC SAFETY MEASURES..............................................................................................................28

5. OPERATING CONDITIONS...............................................................................................................31

6. STORAGE AND TRANSPORT REGULATION ...............................................................................33

7. GENERAL REQUIREMENTS ON INSTALLATION......................................................................34

8. SETUP AND INSTALLATION............................................................................................................35

8.1. PREPARING THE SPECTROMETER .................................................................................................... 35

8.1.1. Installing and Aligning the Optical Fiber Transport System........................................... 35

8.1.2. Installing the Spectrometer and the Optical Microscope ................................................ 38

8.2. CONNECTING THE ELECTROMECHANICAL UNITS............................................................................ 39

8.3. POWERING SEQUENCE .................................................................................................................... 41

9. PREPARING FOR OPERATION........................................................................................................44

9.1. LAUNCHING THE CONTROL PROGRAM............................................................................................ 44

9.2. VERIFYING ADJUSTMENT OF THE DISPLACEMENT SENSORS........................................................... 45

9.3. ADJUSTING THE SPECTRAL UNIT .................................................................................................... 46

9.4. MOUNTING THE SAMPLE ................................................................................................................ 50

10. MEASURING WITH THE CONFOCAL MICROSCOPY MODE..................................................51

10.1. FOCUSING THE LASER BEAM .......................................................................................................... 51

10.2. ADJUSTING CHANNELS OF DETECTION........................................................................................... 52

10.2.1. Adjusting Detection Parameters of the CCD-camera ..................................................... 52

10.2.2. Adjusting Detection Parameters of the PMT Module...................................................... 57

10.2.3. Adjusting Detection Parameters of the APD Module...................................................... 59

10.3. ADJUSTING SCAN PARAMETERS ..................................................................................................... 61

10.4. ADDITIONAL ADJUSTING FOR SCANNING WITH AFM HEAD ........................................................... 63

10.5. SCANNING ...................................................................................................................................... 68

10.5.1. Scanning with Recording by the CCD-Camera............................................................... 68

10.5.2. Scanning with Recording by the PMT Module ................................................................ 71

10.5.3. Scanning with Recording by the APD Module ................................................................ 72

10.6. SAVING DATA................................................................................................................................. 73

10.7. FINISHING THE WORK..................................................................................................................... 73

11. AFM AND SNOM MEASUREMENTS ...............................................................................................75