FDX3543RP

-2-

COMPONENTS AND CHARACTERISTICS

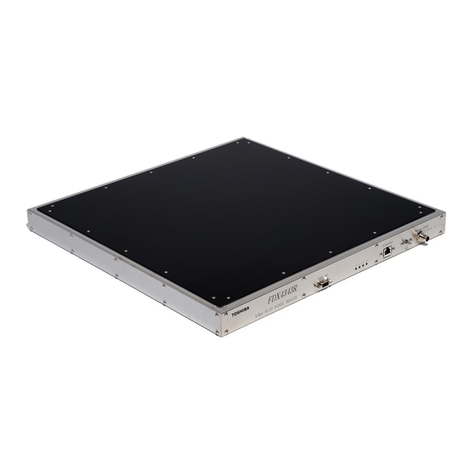

Flat Panel Sensor Unit:

Sensor Protection Plate....................................................................................... Carbon Fiber Plate

Cooling ................................................................................................................ Natural Air Cooling

Input....................................................................................................... DC15V (from Interface Box)

Power Consumption .................................................................................................. Maximum 10W

Overall Dimensions................................................................ 384×460×15mm (W(H)×D(V)×(H))

Weight ......................................................................................................................... 3 kg (approx.)

Interface Box:

Input........................................................................................................... AC100 to 240V, 50/60Hz

Output.................................................................................................................. DC15V 2.6A 30VA

Overall Dimensions................................................................ 115×185×85mm (W(H)×D(V)×(H))

Weight ......................................................................................................................... 1 kg (approx.)

Dimensional Outline:

Refer to pages 24 to 25.

Environmental:

Under delivery and stock

Temperature ............................................................................................................ -15 ~55 ℃

Humidity........................................................................................ 10 ~90 %(Non-Condensing)

Pressure ................................................................................................................ 50 ~106 kPa

Under operating

Temperature ........................................................................................................... +10 ~35 ℃

Humidity....................................................................................... 10 ~85 % (Non-Condensing)

Pressure ................................................................................................................ 70 ~106 kPa

ACCESSORIES

Cables:

AC Cable ............................................................................................................................ 1.8 m×1

GND Cable ............................................................................................................................ 3 m×1

CD:

CD(Defect map, SDK)............................................................................................................. 1 pcs

OPTION ACCESSORIES

Sensor Unite Cable (Sensor Unit - Interface Unit)

ECB-F035A-09/G......................................................................................................................... 9 m

ECB-F035A-14/G....................................................................................................................... 14 m