FAA

Aircraft Certification Service SPECIAL AIRWORTHINESS

INFORMATION BULLETIN

SAIB: CE-09-37

SUBJ: Stabilizer: True Flight (Grumman American) AA-5 Date: July 1, 2009

This is information only. Recommendations aren’t mandatory.

Introduction

This Special Airworthiness Information Bulletin (SAIB) alerts you, owners and operators of True

Flight Aerospace LLC (Grumman American) Model AA-5 airplanes, of an issue concerning the

horizontal stabilizer forward spar attachment and surrounding structure in the aft fuselage area.

At this time, this airworthiness concern is not an unsafe condition that would warrant AD action

under Title 14 of the Code of Federal Aviation Regulations (14CFR) part 39.

Background

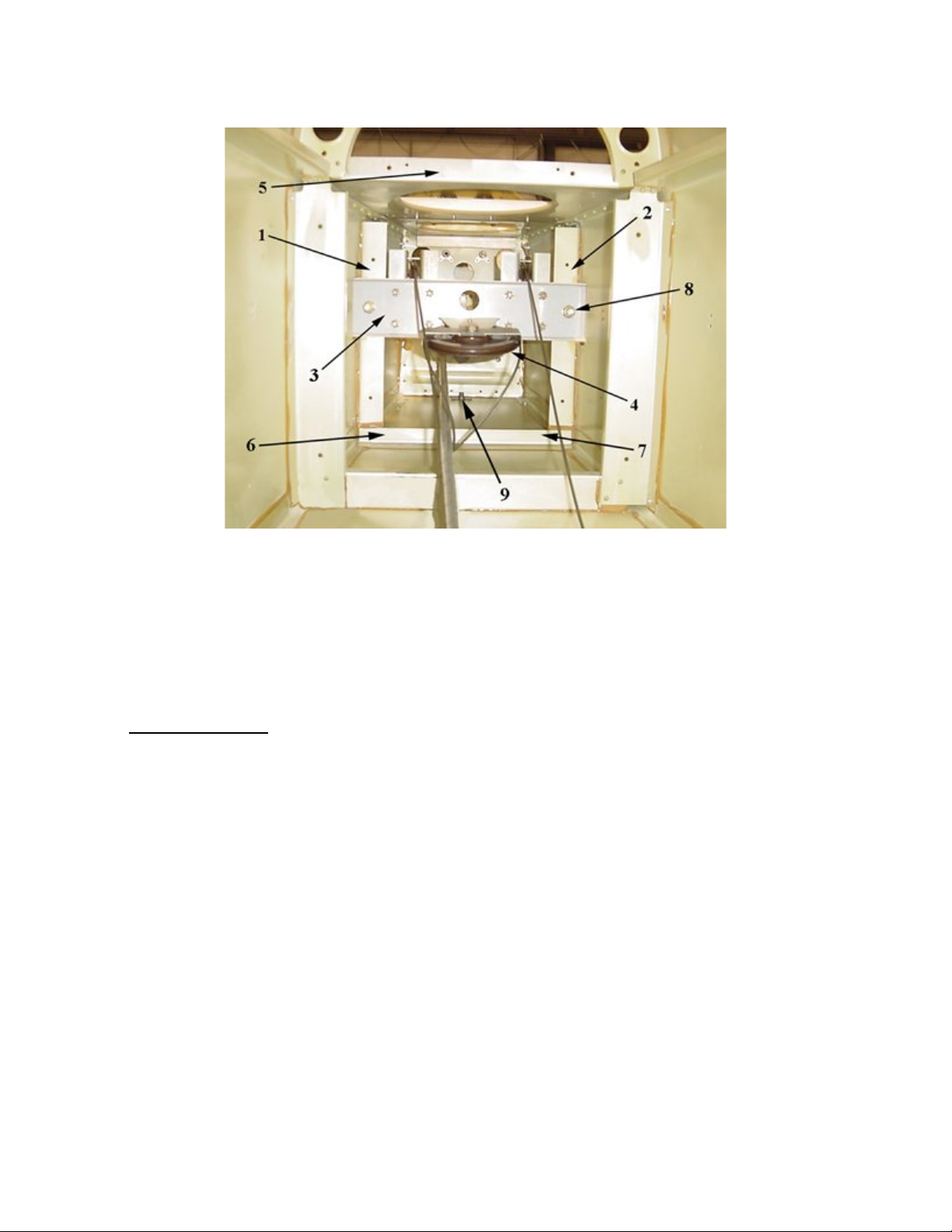

During a routine inspection, maintenance personnel found cracked and deformed structure in the aft

fuselage area including horizontal stabilizer forward spar attachment structure, spar support angles,

and stiffeners. While there are no previous reports of similar damage in the AA-5 airplanes, there

have been reports for the AA-5A and AA-5B models. In 2003, the FAA issued SAIB CE-04-34 to

inform owners of this potential issue on the AA-5A and AA-5B models and the SAIB included an

inspection of this area of the airplane. In 2003, the type certificate owner issued an update to the

maintenance manual to add instructions for this inspection for the AA-5A and AA-5B airplanes.

There are currently no clear instructions in the maintenance manual for inspecting this area of the

AA-5 model.

Recommendation

We encourage owners and maintenance personnel to perform detailed visual inspections of the

horizontal stabilizer forward spar attachment structure, and surrounding area, of the AA-5 airplanes at

the following times:

•At every annual/100 hour inspection

•After hard landings, tail strikes, or any other notable impact or force in tail area.

We’ve included a copy of the inspection instructions from the maintenance manual that were only

applicable to the AA-5A and AA-5B models for your use on the AA-5 airplane. While the structure

of the AA-5 is somewhat different in this area, True Flight Aerospace informs us that the basic

inspection points should be applicable to all of the AA-5 series models.

If you find cracks or deformation, it is always helpful to the FAA if you submit a Malfunction or

Defect Report to the FAA’s website at http://www.faa.gov/aircraft/safety/report/.

For Further Information Contact

Cindy Lorenzen, Program Manager, FAA, Central Region, Atlanta Aircraft Certification Office, One

Crown Center, 1895 Phoenix Boulevard, Suite 450, Atlanta, GA 30349; phone (770) 703-6078; fax