Building instructions

Thank you for choosing a quality product MADE IN GERMANY.

Please read these building instructions and suggestions prior to construction, then carefully

proceed with the step by step construction.

PRESENTATION OF THE MODEL

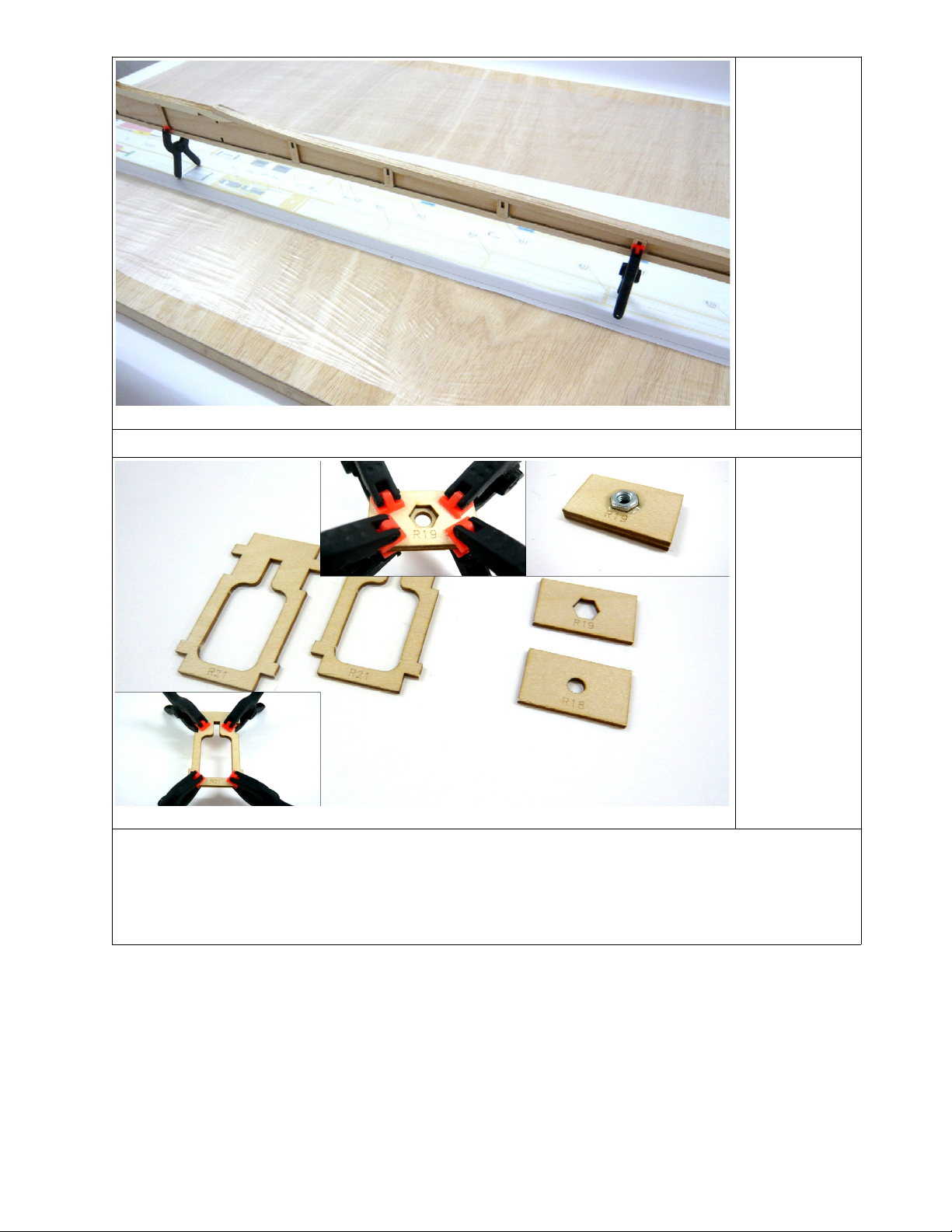

The wings are constructed in three sections with carbon tube spars.

The wing joiners are built into the spars.

The wing profile used is the AG35.

The fuselage sides are reinforced with braces and stiffeners.

Wing ribs are precut to accept the carbon spars.

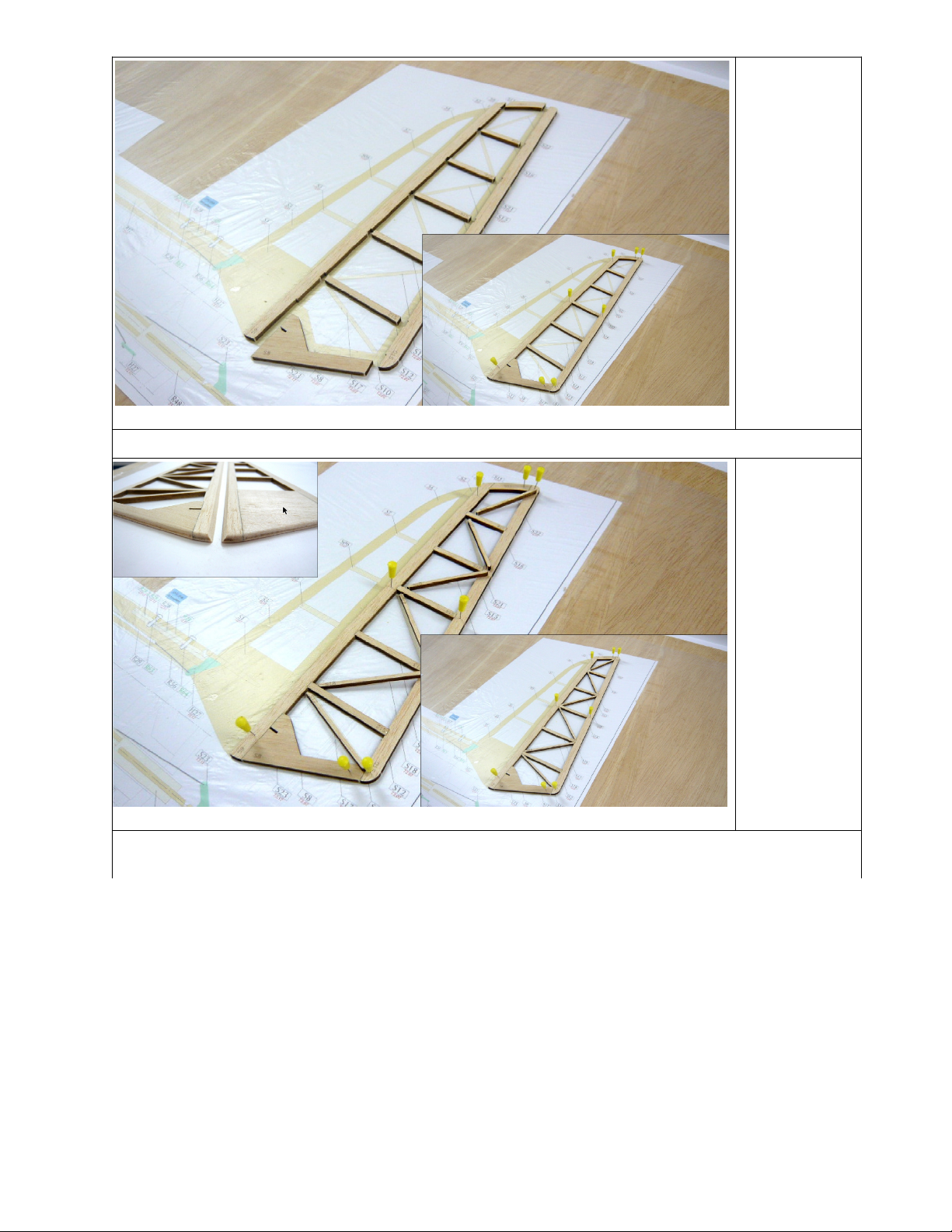

The tail feathers are builtup from trussed balsa parts.

The system is designed to use ORACOVER for the wings and fuselage, and ORALIGHT2 for the

tail feathers.

Due to the long nose and lightweight drive components, balancing the tail is as easy as possible.

Specific glue icons are shown in the relevant sections of the building instructions (NOTE: In this

English translation, the type of glue is specified between parentheses instead). For superglues

we recommend using normal cyanoacrylate (CA) and thick cyanoacrylate (thick CA, with a

slower set time).

TOOLS AND ADHESIVES

●Modelling knife, small balsa plane, sanding paper 00 and 80 grit, small round file, small

drill and Ø2.0 and 5.0 mm bits, fine metal saw, soldering iron, covering iron.

●Thin CA (ZAP)

●Thick CA (SLOZAP)

●5 minutes twocomponents epoxy (ex. UHU plus Schnellfest)

●90 minutes twocomponents epoxy (ex. UHU Plus Endfest)

DRIVE

Motor: (Premium) Hacker A2022L evo, (Standard) Roxxy 2834/ 2

Battery: 3S 300mAh, 0 g

Propeller: x6 CAM Carbon foldingprop