10182 E 06 - 2005

Technical information: MODULAR VALIDATOR XV 2

1. INTRODUCTION AND DESCRIPTION OF COMPONENTS.............................................3

1.1 MODELS IN THE XV RANGE ..............................................................................3

1.2 PHYSICAL CHARACTERISTICS...........................................................................4

1.3 TECHNICAL CHARACTERISTICS......................................................................... 5

1.4 DESCRIPTION OF COMPONENTS ....................................................................... 8

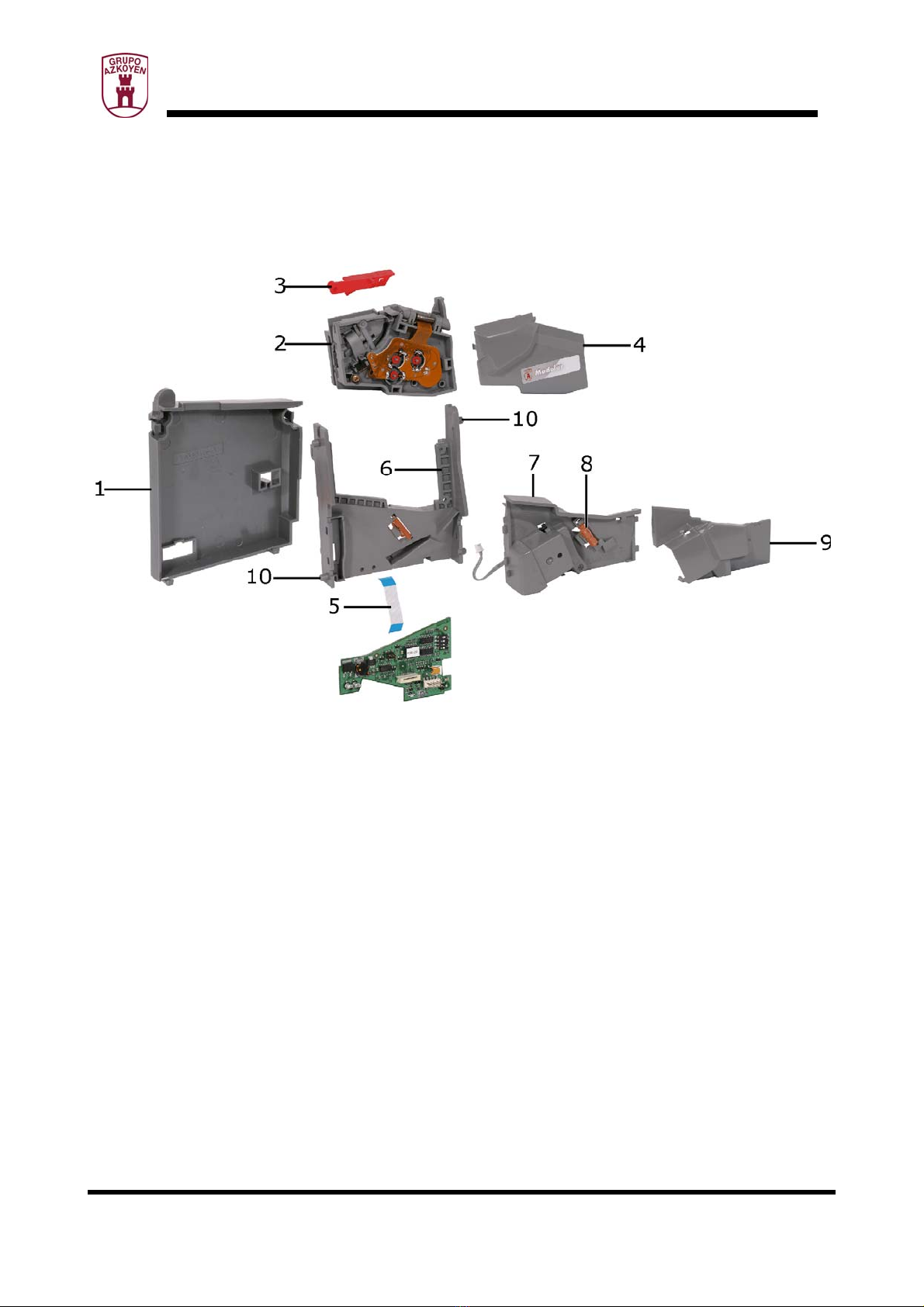

1. Cover ............................................................................................................8

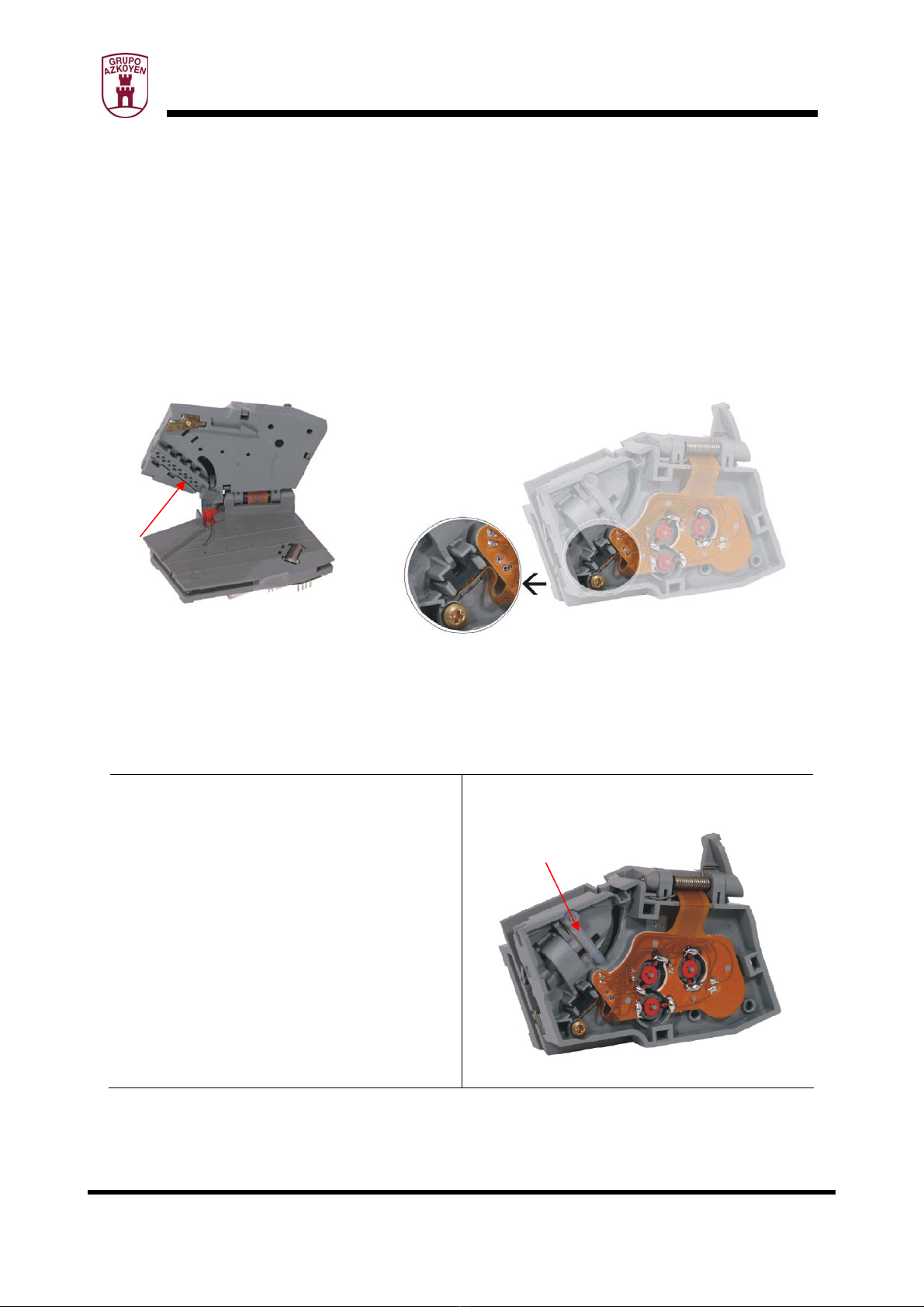

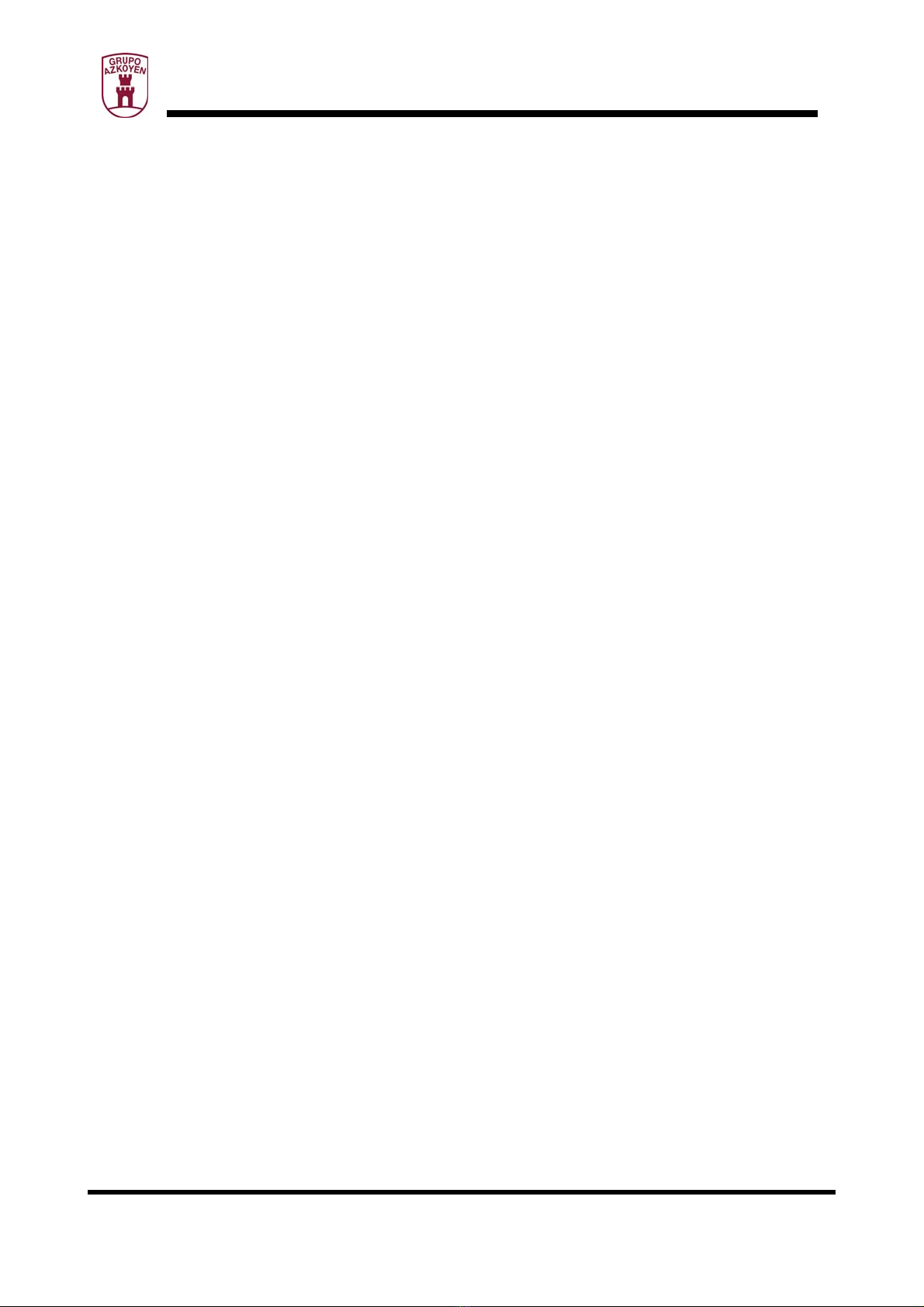

2. Sensor module ............................................................................................... 9

3. Recuperation lever ........................................................................................ 12

4. Sensor module cover ..................................................................................... 12

5. Communication bus for the entry and sensor modules ........................................ 12

6. Outlet module .............................................................................................. 12

7. Acceptance gate ........................................................................................... 13

8. Anti return ................................................................................................... 13

9. Acceptance gate cover ................................................................................... 13

10. Anchorage pivots ....................................................................................... 13

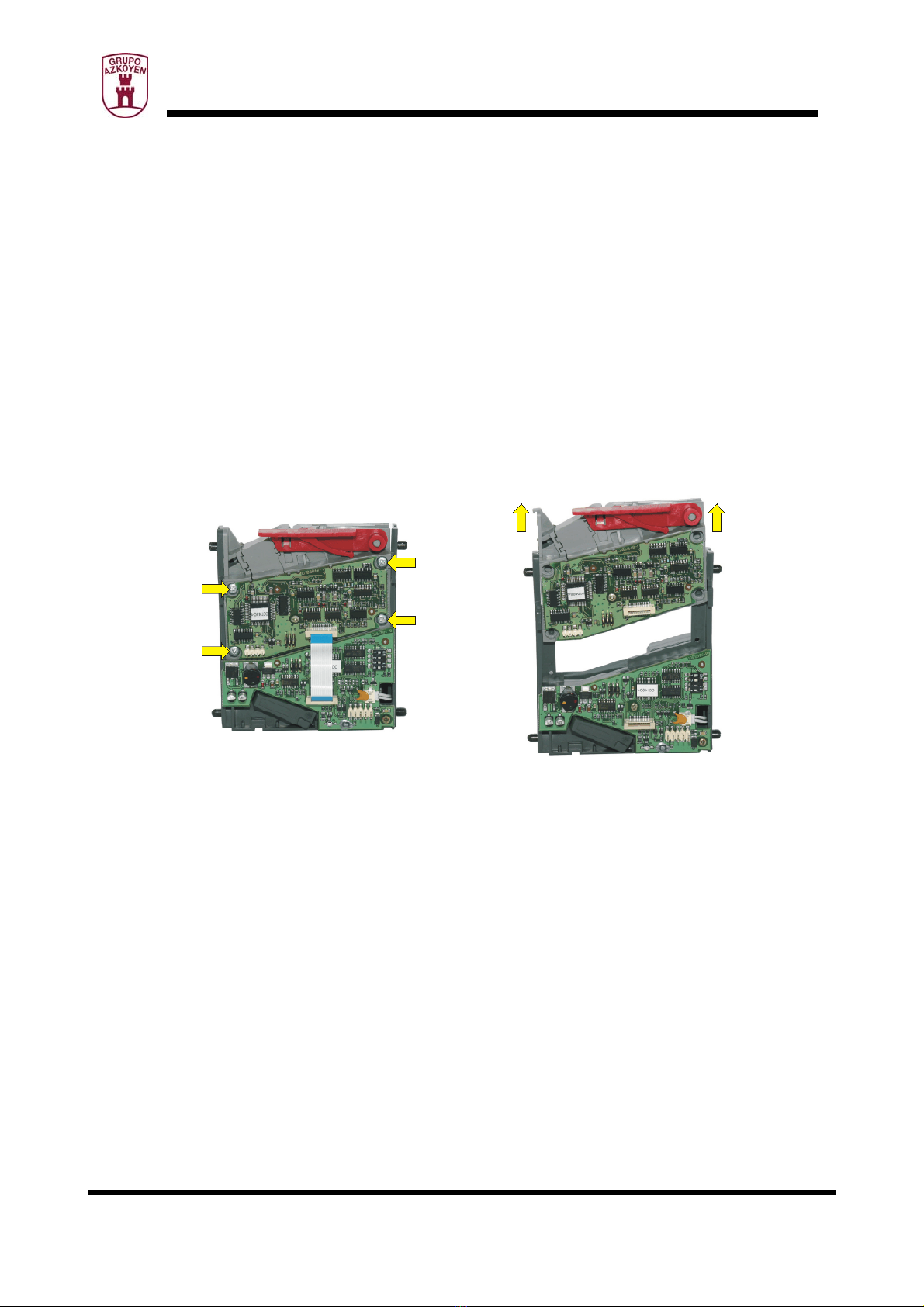

2. FUNCTIONING PRINCIPLES................................................................................ 14

2.1 Parallel mode ............................................................................................... 14

2.2 Timing mode ................................................................................................ 15

2.3 Credit mode ................................................................................................. 17

3. WORKING CONDITIONS AND NORMS.................................................................. 19

4. CLEANING AND MAINTENANCE .......................................................................... 20

5. DIMENSIONS................................................................................................... 21

6. PIN OUT.......................................................................................................... 22

7. ACCESSORIES ................................................................................................. 24

7.1 Funnels ....................................................................................................... 24

8. Large funnel .................................................................................................... 24

9. Medium funnel ................................................................................................. 24

10. Small funnel .................................................................................................... 24