Table of Contents

PNEG-2170 PLC Controller 3

Contents

Chapter 1 Introduction ..........................................................................................................................................5

General Safety Statements ................................................................................................................... 5

Scope .................................................................................................................................................... 6

Ordering Parts ....................................................................................................................................... 6

Replacement Parts ................................................................................................................................ 6

Chapter 2 General Information .............................................................................................................................7

System Description ............................................................................................................................... 7

Optional Features .................................................................................................................................. 7

Chapter 3 Safety .....................................................................................................................................................8

Safety Guidelines .................................................................................................................................. 8

Cautionary Symbol Definitions .............................................................................................................. 9

Safety Cautions ................................................................................................................................... 10

Safety Sign-Off Sheet ......................................................................................................................... 13

Chapter 4 Installation ..........................................................................................................................................14

Receiving Inspection ........................................................................................................................... 14

Pre-Installation Preparation ................................................................................................................. 14

Controller Location .............................................................................................................................. 14

System Wiring ..................................................................................................................................... 14

Chapter 5 Operations and Adjustments ............................................................................................................15

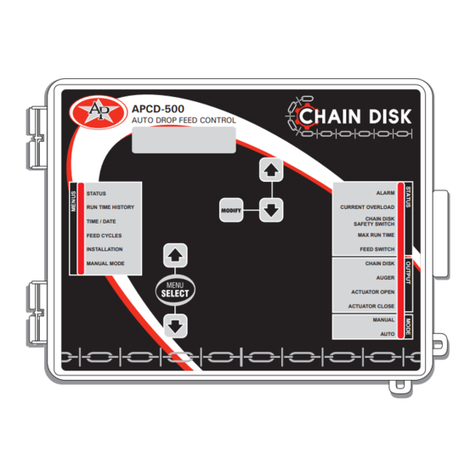

Control Components and their Functions ............................................................................................ 15

Chapter 6 Operations Mode and Description ....................................................................................................20

Operation Modes ................................................................................................................................. 20

Chapter 7 PLC Settings for PS, PS-XP and HD-PP Sampler Operation ..........................................................24

Sampler Operation Description ........................................................................................................... 24

PS, PS-XP and HD-PP Sampler Operating Components ................................................................... 24

PS, PS-XP and HD-PP Sampler Program Mode ................................................................................ 24

PS, PS-XP and HD-PP Sampler Timer Settings ................................................................................. 25

Chapter 8 PLC Settings for PT, PTG, LF, GS, GP and PDP Sampler Operation ............................................26

Sampler Operation Description ........................................................................................................... 26

PT, PTG, LF, GS, GP and PDP Sampler Operating Components ...................................................... 26

PT, PTG, LF, GS, GP and PDP Sampler Main Fuse (Refer to Certified Drawing) ............................. 26

PT, PTG, LF, GS, GP and PDP Sampler Program Mode ................................................................... 26

PT, PTG, LF, GS, GP and PDP Sampler Timer Settings .................................................................... 27

Chapter 9 PLC Settings for GSS and GSS-U Sampler Operation ....................................................................28

Sampler Operation Description ........................................................................................................... 28

GSS and GSS-U Sampler Operating Components ............................................................................. 28

GSS and GSS-U Sampler Main Fuse (Refer to Certified Drawing) .................................................... 28

GSS and GSS-U Sampler Program Mode .......................................................................................... 28

GSS and GSS-U Sampler Timer Settings ........................................................................................... 29

Chapter 10 PLC Settings for GT, GRES and RS Sampler Operation ..............................................................30

Sampler Operation Description ......................................................................................................... 30

GT, GRES and RS Sampler Operating Components ........................................................................ 30

GT, GRES and RS Sampler Main Fuse (Refer to Certified Drawings) .............................................. 30

GT, GRES and RS Sampler Program Mode ..................................................................................... 30