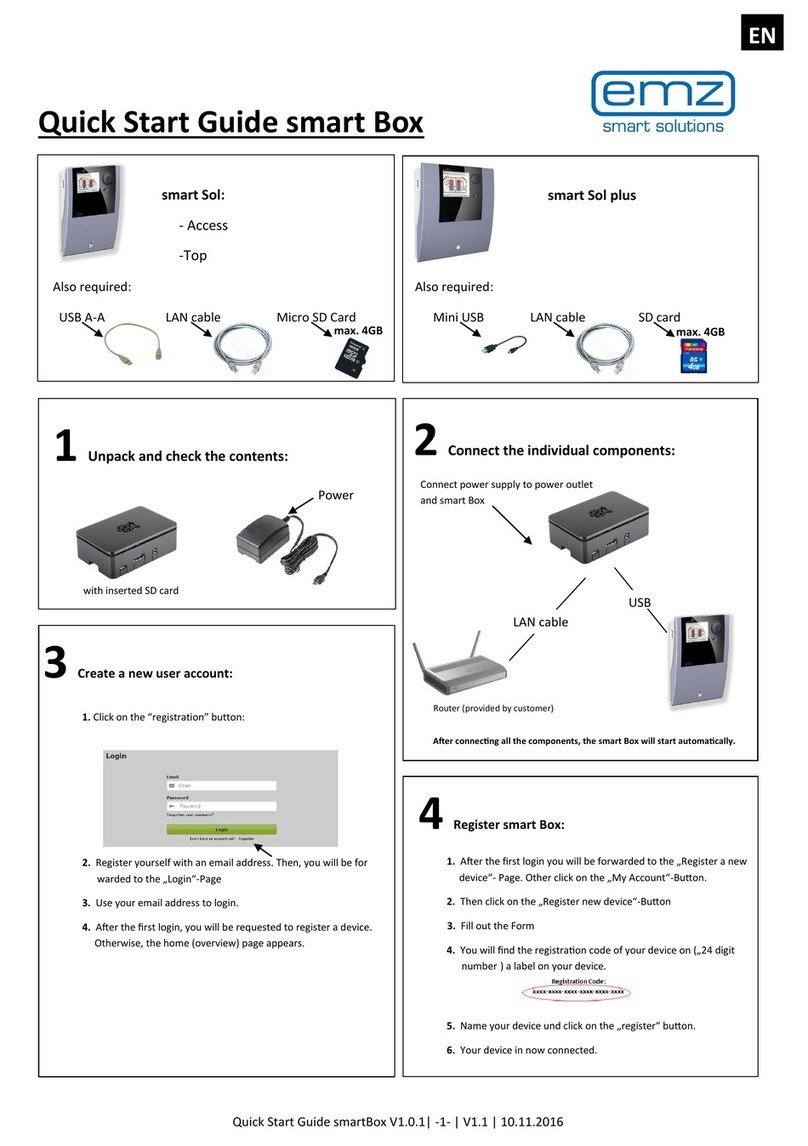

emz smart Sol User manual

DIFFERENTIAL TEMPERATURE CONTROLLER FOR MEDIUM-SIZED

SOLAR THERMAL PLANTS USED FOR HEATING DOMESTIC WATER AND

SUPPORTING THE HEATING SYSTEM.

COMFORT

OPERATING INSTRUCTIONS

These Assembly and Operating Instructions are an integral part of the product.

> Read Assembly and Operating Instructions carefully before using the product.

> Keep them in a safe place during the product‘s service life.

Translation from the German original edition ©emz 2015 - Subject to modications.

The contents and representations of these Assembly and Operating

Instructions are the intellectual property of emz-Hanauer GmbH & Co.KGaA.

Non-authorized disclosure, reproduction, divulgation or editing of this

documentation, as well as exploitation, utilization or publication, are prohibited.

The rights to the word and design marks ›emz - smart solutions‹ and ›smart Sol‹

are the exclusive property of emz-Hanauer GmbH & Co.KGaA.

The rights to any cited brands, names or logos are the property

of their appropriate developers / of the licensees in question.

Page 3

Table of contents Page

Important fundamental information 4

Symbols used 5

Description 6

Dimensions 7

Technical Data 8

Designation of the components 10

Operation of the controller 11

Display 12

Opening the terminal cover 13

Wall-mounting 14

Connection to power supply 15

Hydraulic systems 20

Functions for boiler control 41

Thermostat functions 44

Commissioning mode 45

Automatic mode 60

Operation mode 62

Malfunction 78

Replacement of fuse 84

Professional mode 85

Disassembly/Disposal 108

Warranty and liability 109

Commissioning report 110

Service request 111

EC Declaration of conformity 112

Index 113

TABLE OF CONTENTS

Page 4 IMPORTANT FUNDAMENTAL INFORMATION

These instructions describe installation, commissioning, operation, repair

and disassembly of the differential temperature controller smart Sol for

solar thermal plants.

For operation of the entire plant, the technical documentation of all the

components used such as solar collectors, boiler, tank, pumps, mixers

and valves etc. must be complied with.

The controller is handled by the operator of the entire solar

thermal plant, i. e. as a rule by technical non-experts.

Make sure not to use the controller until you have thoroughly read and

understood these Assembly and Operating Instructions and the safety provisions.

Comply with all safety provisions and involve a specialist in case of doubt.

Keep these Assembly and Operating Instructions and all reference

documents so that they are available if required.

When relocating or when selling the device, hand the documents over to your successor.

Important!

The tter installing the controller must inform the plant operator about

operation, functioning and the method of action of the smart Sol!

Danger!

The device in operation may only be made accessible to

adults disposing of appropriate knowledge and experience!

Danger!

The controller by no means replaces the safety

components required under plant engineering aspects!

Danger!

Assembly, connection, commissioning, repair and disassembly of

the controller may only be performed by a qualied specialist!

Page 5

SYMBOLS USED

When handling the differential temperature controller smart Sol

and the entire plant, please make sure that the following safety provisions

in the Assembly and Operating Instructions are complied with!

Note!

Useful information regarding handling of the device and the plant!

Important!

Important information compliance with which is essential!

Danger!

Immediate danger for assets, life and limb!

Page 6 DESCRIPTION

The differential temperature controller smart Sol is an independent electronic

controller for surface-mounting which is used for the control of solar thermal plants.

The controller is equipped with a robust three-part plastic housing

which can only be opened by means of tools (screw driver PH2).

Operation is effected by means of only two control elements;

indications appear against a backlit colour display.

Before connection of the electrical system, the controller

must be mounted rmly to a perpendicular, robust surface (wall).

For its own supply and the supply of the outputs, the controller must be connected

to an electrical energy supply system in accordance with the technical data.

Assembly, connection, commissioning, repair and disassembly

of the controller are only admissible in a specialist workshop.

To ensure correct operation, temperature sensors type Pt 1000

must be used - the sensor design does not affect function.

Each temperature sensor has two connectors which are equivalent,

i. e. interchangeable. Thus, polarity reversal is not an issue.

The sensor lines can be extended up to a length of 100 m, to

this effect, a cable cross section of 2 x 1.5 mm2is recommended.

Note!

The electrical equipment of the device must be installed rmly and

connected to the power supply via a disconnector ensuring complete

isolation from the power supply according to the erection regulations!

Important!

Make sure that only a dry or slightly moistened cloth is used for cleaning

and servicing of the housing, the control elements and the display.

The surfaces must never get into contact with cleaning products

or solvents - mat, brittle or slightly dissolved plastic parts must

be replaced immediately!

A device with damaged housing must not be operated!

Page 7

5 mm

57,5 mm

115 mm

dmax 5mm/9mm

120 mm

27 mm

26 mm

57,5 mm

46 mm

173 mm

DIMENSIONS

Page 8

Intended Use

The differential temperature controller may be used exclusively as controller for the con-

trol of solar thermal plants. It must be operated within the scope of all the specications

described. Installation and set-up of the controller may only be performed by specialists.

The tter must have read and understood the operating manual.

The tter explains all the relevant functions to the operator.

For operation, it is essential that the housing is closed and free of damage.

Scope of supplies

1 Differential temperature controller smart Sol

1 Instruction manual

Differential temperature controller smart Sol

Type of mounting Wall-mounting

Housing Plastics, in several parts

Mode of operation Type 1

Type of protection IP 20

Dimensions Width x Height x Depth [mm] 115 x 173 x 46

Weight [g] Basic version 370

Storage/operating temperature [°C] 0-40, non-condensation

Handling via rotary encoder and pushbuttons

Display TFT colour display 47 x 35 mm, backlit

Power reserve of real time clock,

at least [h] 8

Connection to power supply

Design 3 spring-type terminals PE, N and L

Service voltage [VAC] 230 ±10%

Line frequency [Hz] 50 ±1%

Auxiliary consumption typ. [W] 1,74

Power consumption max. [W] 3.5

Fuse Micro fuse, type 5 x 20 mm, T2A/250 V

Rated pulse voltage [V] 2500

TECHNICAL DATA

Page 9

Max. cross sections to be connected

Cable end sleeve: 0.25 to 0.75 mm2

Single-wire 0.50 to 1.50 mm2

Fine-wired 0.75 to 1.50 mm2

Interfaces TS1 / TS2 / TS3 / TS4

Design 2 spring-type terminals each

Assignment as inputs

Admissible temperature probe Temperature sensor Pt 1000

Optional assignment of

TS3 / TS4 to the impeller sensor DFZ 1-100 pulses/litre

Optional assignment as

output on TS4 PWM signal 100Hz...2kHz or

analogue output 0...10V, max. 10mA

Triac outputs RO1 / RO2

Design 3 spring-type terminals each, PE, N and L

Output voltage [VAC] 230 ±10%

Output power max.

per output [VA] 200

Output current max.

per output [A] 1

Switching output REL: Floating change-over contact

Design 3 spring-type terminals

Switching voltage max. [V] 253

Switching capacity max. [VA] 230

Switching current max. [A] 1

TECHNICAL DATA

Page 10 DESIGNATION OF THE COMPONENTS

Drillhole for

securing bolt

Fuse

Housing base

Terminals

Spare fuse

esc button

Display

Rotary encoder

with OK button

Housing cover

Terminal cover

Screw fastening

of terminal cover

Break-out segments

Screw connection

strain relief device

Strain relief device

Page 11

OPERATION OF THE CONTROLLER

The entire set-up and operation of the differential temperature controller

smart Sol is effected via only two control elements on the device front.

All settings and interrogations are effected via the rotary encoder.

To nd a required menu item, turn the rotary encoder to ›scroll‹

through the menu - the selectable option appears on a coloured

background on the display.

To conrm the selected menu item, press the rotary encoder.

An appropriate submenu is called up, or selection is activated.

Press the esc button to make the menu return by one level from any subitem.

If no input is made within the preset time (30-255 s),

the controller returns automatically to the initial level.

Page 12 DISPLAY

Schema 1

04. 07. 2015 10:35

1.3.2 Röhrenkollektor

04. 07. 2015 10:35

Aktivierung

Start

n-solar 1

t-ein

T-ein

80%

10min

20.0°C

Display elements; example: information screen

For indication of the operating mode and for communication in case of set-up,

malfunction, modication and evaluation, the differential temperature controller

smart Sol is equipped with a coloured full graphics display which is permanently backlit.

The display is active as long as there is supply voltage on the controller.

After a preset time (30 - 255 s), backlighting is dimmed to 10%.

Active system

with current

temperatures

Date and time

Display elements; example: communication screen

Activatable

menu item

Selection menu

Scroll arrow

Check box

Sub menu arrow

Date and time

Professional mode

Manual mode

Message

Number and name of menu

Page 13

OPENING THE TERMINAL COVER

Danger!

Mortal danger due to electrocution! Whenever work is performed on the

open terminal cover, all poles of the power supply must be

disconnected reliably and protected against being switched on again!

1Release the lock screw.

2Swing terminal cover

forward ...

3... push it upwards ...

4... and remove it.

Store the terminal cover

carefully and protect

it against damage!

To close the terminal cover,

reverse the opening procedure.

Page 14 WALL-MOUNTING

1Fasten the top securing bolt so

that a space of 2 to 3 mm is

created between the wall and

the screw head.

2Move the device so that the

upper fastening port is located

above the screw head ...

3... and push it downwards.

4Fasten the lower securing bolt.

If necessary, use dowel

pins for wall-mounting!

Important!

The device corresponds to protection type IP 20 - make sure the

appropriate prerequisites exist on the envisaged place of installation.

Do not use the housing base as drill template.

A device with damaged housing must not be operated!

Page 15

CONNECTION TO POWER SUPPLY

Danger!

Mortal danger due to electrocution! Whenever work is performed

on the open terminal cover, all poles of the power supply must be

disconnected reliably and protected against being switched on again!

Terminal block

RO2/RO1/Power

Terminal

block REL

Terminal block

TS1-TS4

The differential temperature controller smart Sol is connected to the

power supply via three groups of spring-type terminals which are

visible once the terminal cover is opened.

To introduce the cables, release the three screws on the strain relief device;

if necessary, remove the strain relief device.

In case of ush mounting of the cables, the break-out segments in the housing

base can be removed carefully and the cables routed through these ports.

The central terminal block is the interface to a potential-free change-over contact

- here, it may be necessary to route electrical resistors into the

spring-type terminals and to connect part of the cables via luster terminals.

The spring-type terminals for the power supply, RO1, RO2 and REL, and for TS1,

TS2, TS3 and TS4 can accommodate solid wires up to a cross section of 1.5 mm2.

Appropriate stranded wires must be preassembled with cable end sleeves.

For the strain relief device function, TS1 to TS4 and REL require

cable cross sections of at least 5mm, for Power, RO1, RO2 at least 7mm.

The strain relief xture can be slightly reworked to t larger cable diameters without

producing sharp edges.

Page 16 CONNECTION TO POWER SUPPLY

Connection of a pump to REL

Connection diagram for a pump to REL:

L

N

PE

L

N

PE

Pump

Connection of a switching valve to RO1/RO2

Connection diagram for a switching Connection diagram for a switching

valve without power supply to RO2: valve with power supply to RO2:

Valve

L

N

PE L

Valve

L‘

N

L

Connection of a switching valve to REL

Connection diagram for a switching Connection diagram for a switching

valve without power supply to REL: valve with power supply to REL:

Valve

L

N

PE

L

N

PE

L

N

PE

Valve

L‘

L

N

Page 17

CONNECTION TO POWER SUPPLY

High-efciency pump:

A high-efciency pump can be connected via RO1 or RO2.

The appropriate control signal is issued at TS4.

Thus, TS4 is no longer available as input.

The control signal may be an analog voltage 0 - 10V or a PWM signal.

For further details, please refer to the pump specication.

For denition and settings, the professional mode under 1.3.7 has been provided.

RO1 or RO2:

230V supply of the

high-efciency pump

TS4: PWM-control signal

for the high-efciency

pump

Left-hand terminal: GND

Right-hand termin.: Signal

Volumetric ow sensor:

Measurement of solar radiation (heat quantity):

The solar yield is calculated from the ow rate and the differential temperature.

The differential temperature is the difference in the temperature of the collector

sensor and the solar circuit return line sensor.

An impeller sensor can be connected to TS3 or TS4 and must be adjusted during

installation. The temperature sensor for the solar return line must be set

in the menu ›1.1.4 Heat quantities‹. Solar radiation measurement using an

impeller sensor is possible for plant layouts 1, 2, 3, 4, 5, 7, 10, 12 and 14.

Page 18 CONNECTION TO POWER SUPPLY

Important!

Depending on whether HE

pumps are used as solar or

heating pumps, they are

supplied with proportional or

inverted control signals. (Both

analogue and PWM control.)

100%

10V analog/

100% PWM

0

Inverted

(heating pump)

Proportional

(Solarpump)

For connection, press the actuation pushbutton

of the spring-type terminal using a screwdriver and

insert the wire to its stop in the appropriate port.

Release the actuation pushbutton and

pull the cable slightly to ensure that it

is safely clamped.

Important!

Before closing the terminal cover, make

sure the strain relief device is tightened safely.

Check once more that all cables are in good

condition and connected correctly.

The strain relief device can only ensure solid

clamping if the cables are not stripped to a length

of over 35 mm.

Insulation of the individual wires must be

removed over a length of 9 - 10 mm to ensure

safe electric contact in the spring-type terminal.

Stranded wires must be provided with cable end sleeves!

9-10 mm

max.

35 mm

Page 19

Page 20 HYDRAULIC SYSTEMS

Boiler with disable

recharge feature,

efciency optimization

Boiler with disable

recharge feature

time-/temperature-

controlled, in combination

Boiler, e. g. using fossil

fuels/ solid fuels/

heat pump etc.

Hydraulic

heat exchanger

Temperature probes

Switching valve

Solar collector panel

Secondary yield

Solar collector panel

Main yield

Swimming pool

Warm water /

buffer tank with

heat exchangers

Warm water /

buffer tank without

heat exchanger

Heating pump

Return line

Supply line

Note!

Dene structure and design of the plant already when planning

the entire solar thermal system and align the design with the

one of the hydraulic systems of the controller!

If you want to complete an existing system or replace

the existing controller, please make sure that

smart Sol is compatible with the existing conguration!

The sensors are connected to TS1 to TS4, the order not being

signicant; pumps and valves are connected to RO1 / RO2 - The

interfaces are assigned to the functions in question on commissioning.

Other manuals for smart Sol

2

Table of contents

Other emz Controllers manuals