PRODUCT

SAFETY

GUIDELINES

FOR

ALL

PRODUCTS

CAUTION:

DoNOT

modify

any

circuit

Service

work

should

be

performed

only

after

youare

thoroughly

familiar

with

allofthe

following

safety

checks.

Risk

of

potential

hazards

and

injury

to1he

user

increases

if

safety

checks

arenot

adhered

to

SAFETY

CHECKS

SUBJECT:

Fire

&

Shock

Hazard

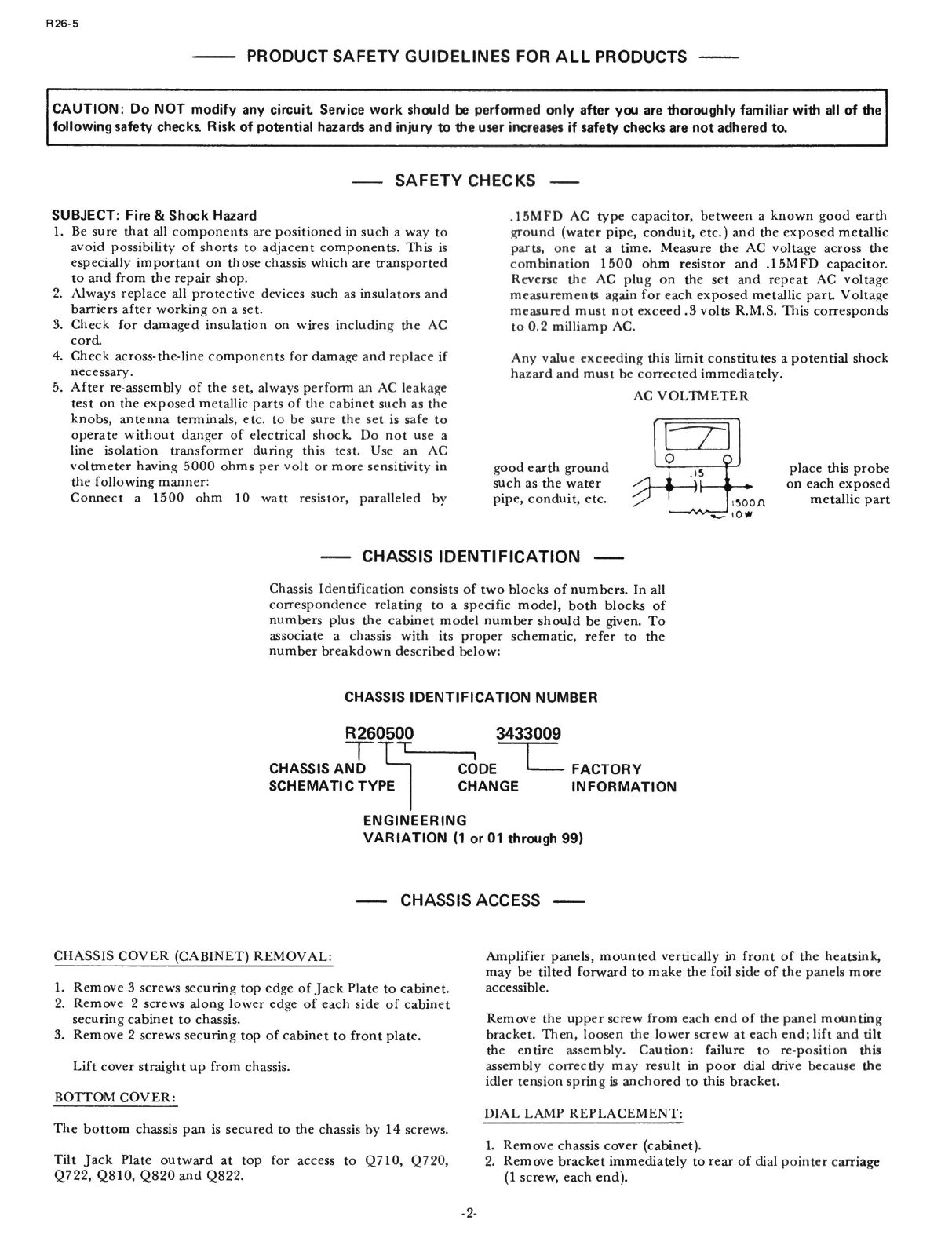

1.

Besurethatallcomponentsarepositionedinsucha wayto

avoidpossibilityofshortstoadjacentcomponents.Thisis

especiallyimportantonthosechassis

which

aretransported

toandfromtherepairshop.

2.Alwaysreplaceallprotectivedevicessuchasinsulatorsand

barriers

afterworkingona set.

3.CheckfordamagedinsulationonwiresincludingtheAC

cord.

4.Checkacross-the-linecomponentsfordamageandreplaceif

necessary.

5.

Afterre-assemblyoftheset,alwaysperformanACleakage

testontheexposedmetallic

parts

ofthecabinetsuchasthe

knobs,

antennaterminals,etc.tobesurethesetissafeto

operate

without

dangerofelectricalshock.Donotusea

line

isolationtransformerduringthistest.UseanAC

voltmeterhaving5000ohmsper

volt

ormoresensitivityin

the

following

manner:

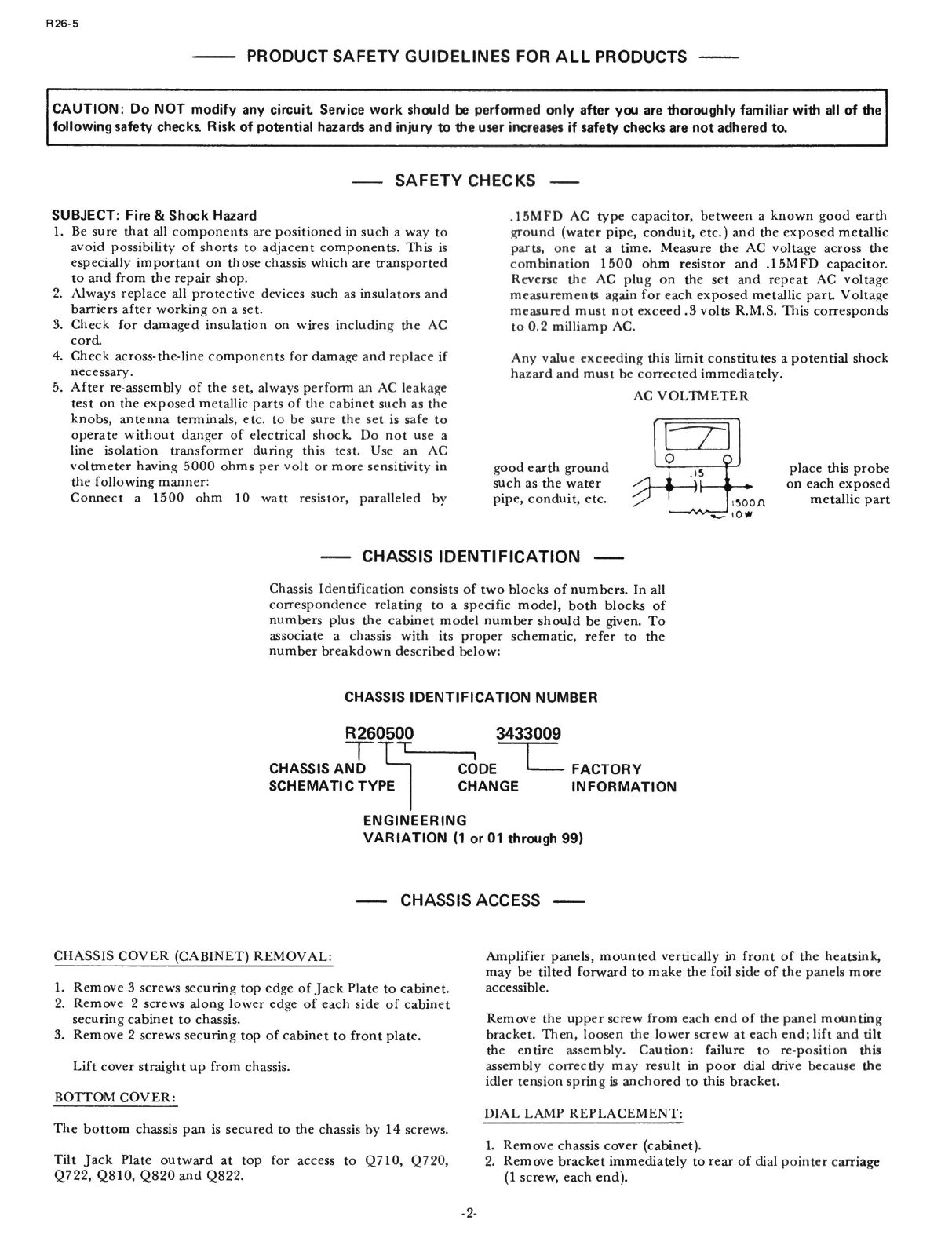

Connecta 1500ohm10wattresistor,paralleledby

.15MFD

ACtypecapacitor,

between

a

known

goodearth

ground

(waterpipe,conduit,etc.)andtheexposedmetallic

parts,

oneata time.MeasuretheACvoltageacrossthe

combination1500ohmresistorand.15MFDcapacitor.

Reverse

theACplugonthesetandrepeatACvoltage

measurementsagainforeachexposedmetallic

part

Voltage

measured

mustnotexceed.3volts

R.M.S.

Thiscorresponds

to0.2milliampAC.

Anyvalueexceedingthislimitconstitutesa potentialshock

hazard

andmustbecorrectedimmediately.

AC

VOLTMETER

goodearthground

suchasthewater

pipe,

conduit,etc.

place

thisprobe

oneachexposed

metallic

part

CHASSIS

IDENTIFICATION

CHASSIS

IDENTIFICATION

Chassis

Identificationconsistsoftwoblocksofnumbers.Inall

correspondencerelatingtoa specificmodel,bothblocksof

numbers

plusthecabinetmodelnumbershouldbegiven.To

associate

a chassis

with

itsproperschematic,refertothe

numberbreakdowndescribed

below:

CHASSIS

ACCESS

CHASSIS

COVER

(CABINET)

REMOVAL:

1.

Remove3 screwssecuringtopedgeof

Jack

Platetocabinet.

2.Remove2 screwsalong

lower

edgeofeachsideofcabinet

securingcabinettochassis.

3.Remove2 screwssecuringtopofcabinettofrontplate.

Lift

coverstraightupfromchassis.

BOTTOM

COVER:

The

bottomchassispanissecuredtothechassisby14screws.

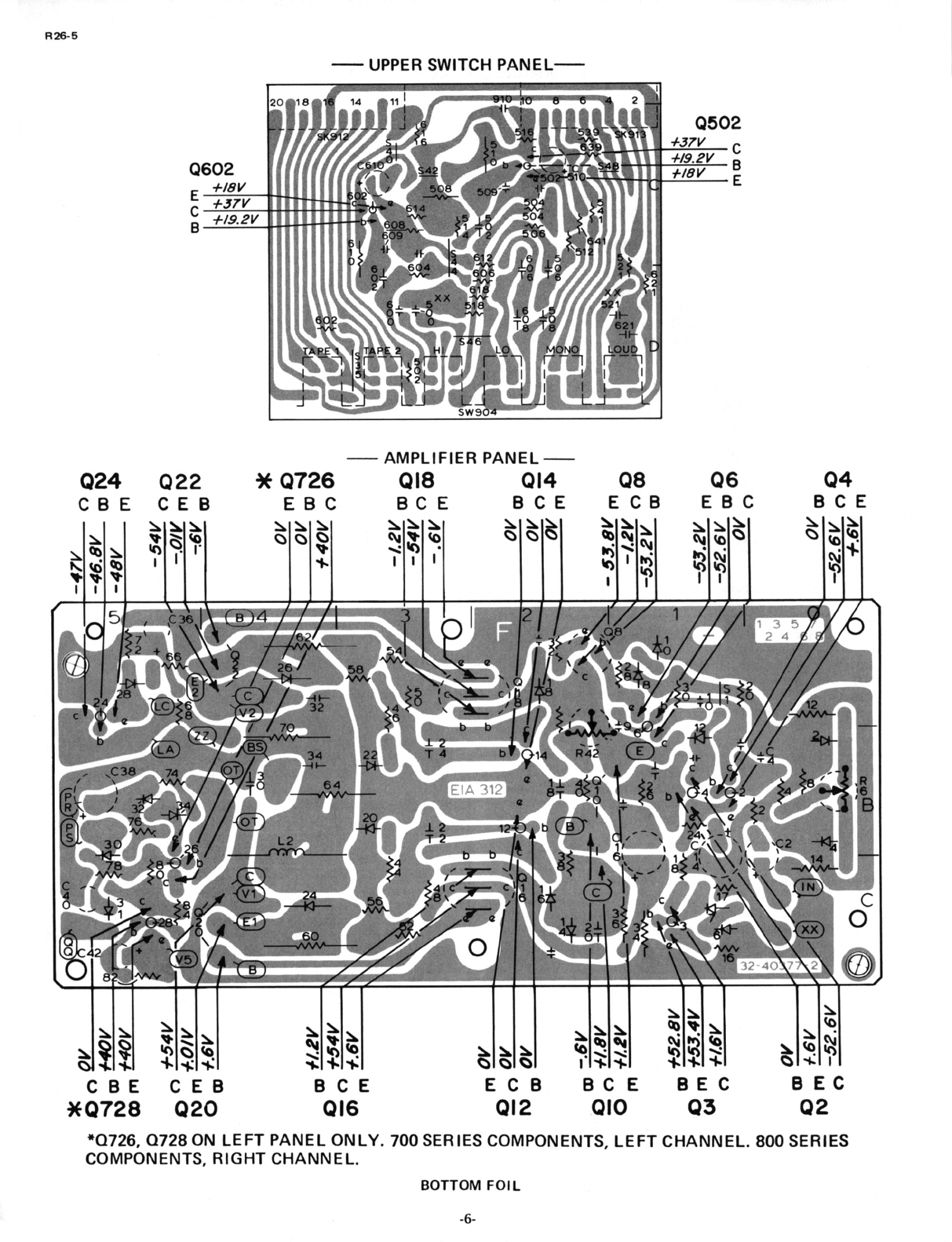

Tilt

Jack

PlateoutwardattopforaccesstoQ710,Q720,

Q722,

Q810,Q820andQ822.

Amplifierpanels,mountedverticallyinfrontoftheheatsink,

maybetiltedforwardtomakethe

foil

sideofthepanelsmore

accessible.

Removetheupperscrewfromeachendofthepanelmounting

bracket.

Then,

loosen

the

lower

screwateachend;liftand

tilt

theentireassembly.Caution:failuretore-positionthis

assembly

correctlymayresultinpoordialdrivebecausethe

idlertensionspringisanchoredtothisbracket.

DIAL

LAMP

REPLACEMENT:

1.

Removechassiscover(cabinet).

2.Removebracketimmediatelyto

rear

ofdialpointer

carriage

(1

screw,eachend).