22-9240rev2.0 Inovonics Wireless Receiver Installation Instructions 6 / 2009

© 2009 CSG Security Corporation / Société Sécurité CSG Page 4of 6

Guardall

5201 Explorer Drive, Mississauga, Ont., Canada. L4W-4H1

salesna@guardall.com +1 905.206.8434 | supportna@guardall.com +1 905.206.8436 | Fax: +1 905.629.4970

www.guardall.com | +1 877.249.9993

Programming:

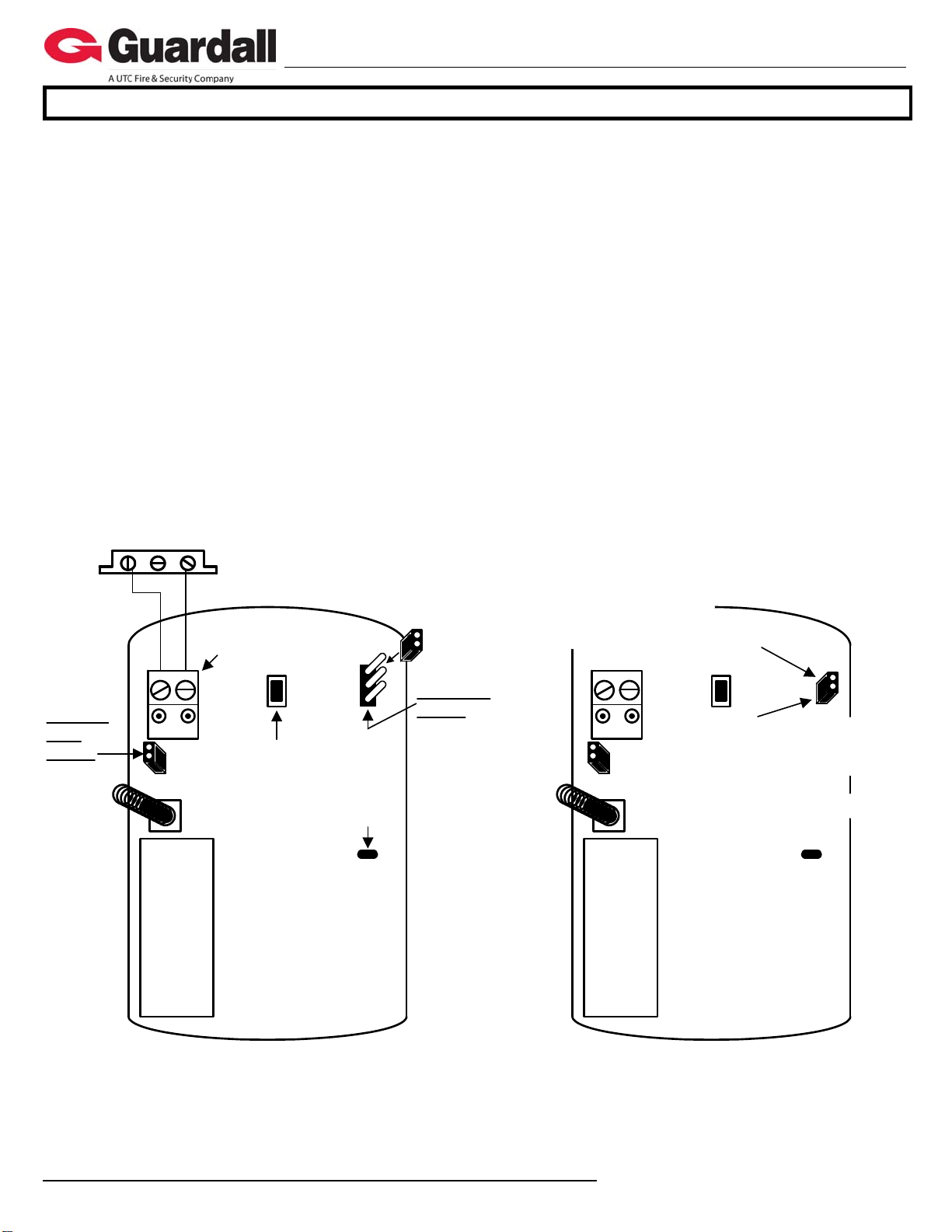

Wireless (2) Receiver Module

Compatible with Chubb/Monitor AFx, ISM, xL security

system main panel firmware and Director Software

version 4.1 and greater.

The wireless module learns wireless sensors.

Only Inovonics wireless sensors can be used with the

Inovonics receiver module.

The wireless module does not support wireless keypads

and it is not necessary to reserve input point numbers

for keypad ‘panic’ buttons.

Wireless Receiver Module Programming

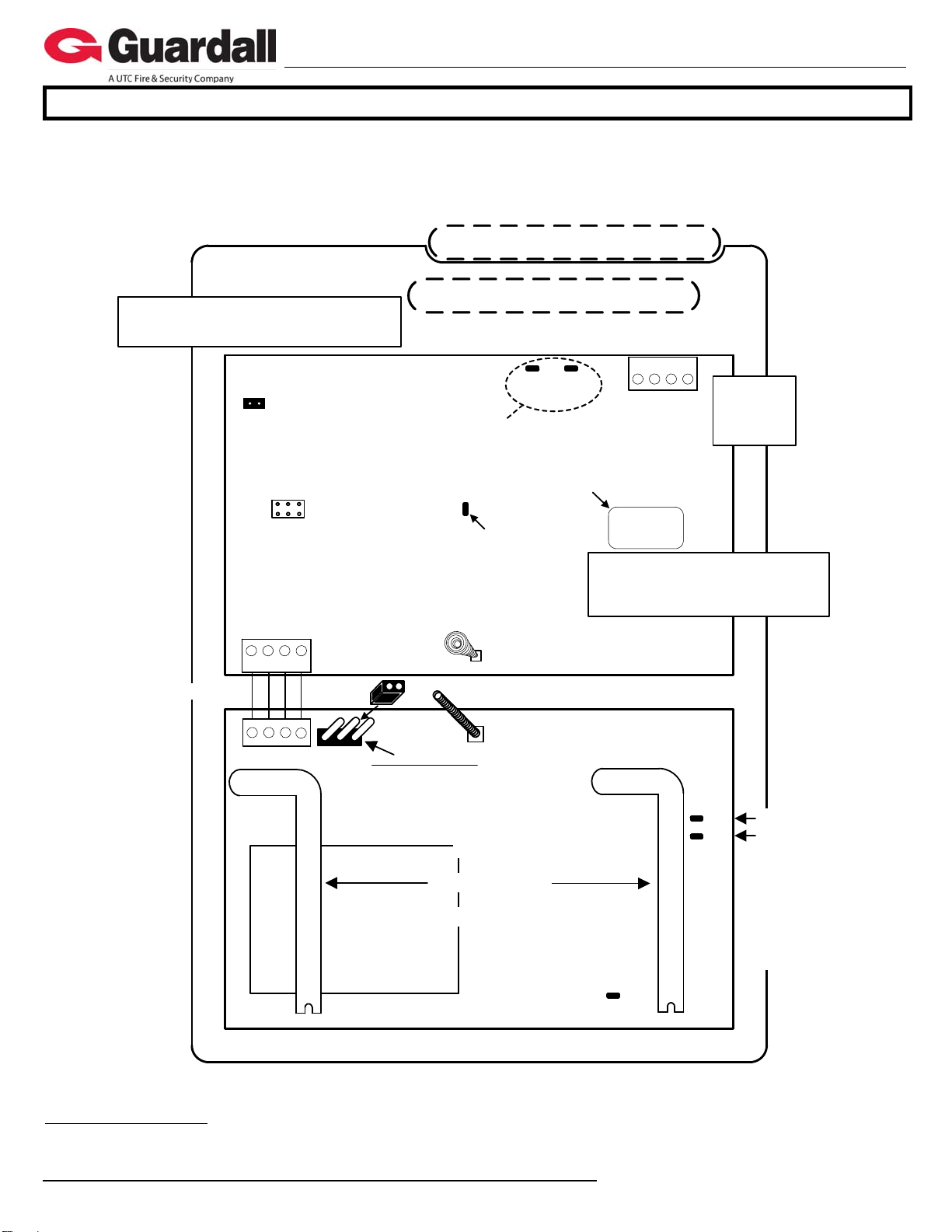

The wireless module has a 5-digit module serial

number, which is programmed into the system module

programming. For systems with a Feature Set of 5 or

above, local configuration programming at an LCD

keypad cannot be done. Module enrollment, input point

assigning, must be done using the Director software and

sent to the panel. Wireless transmitter sensors are

learned into the system using the LCD keypad.

If for some reason the serial number sticker is missing,

the wireless module will display its serial number when it

is first powered. Using the yellow and green Diagnostic

LEDs beside the module bus terminal block, the number

of pulses on the yellow LED while the green LED is ON,

gives the digit value. E.g. green on, count 3 pulses on

yellow, green off, first digit is “3”. Green turns on, yellow

pulses 9 times, green off, second digit is “9”. Etc. etc.

until the entire serial number is displayed, one digit at a

time. It takes several seconds to compete the entire

process. NOTE: “0” is indicated by the green on and NO

pulses of the yellow LED.

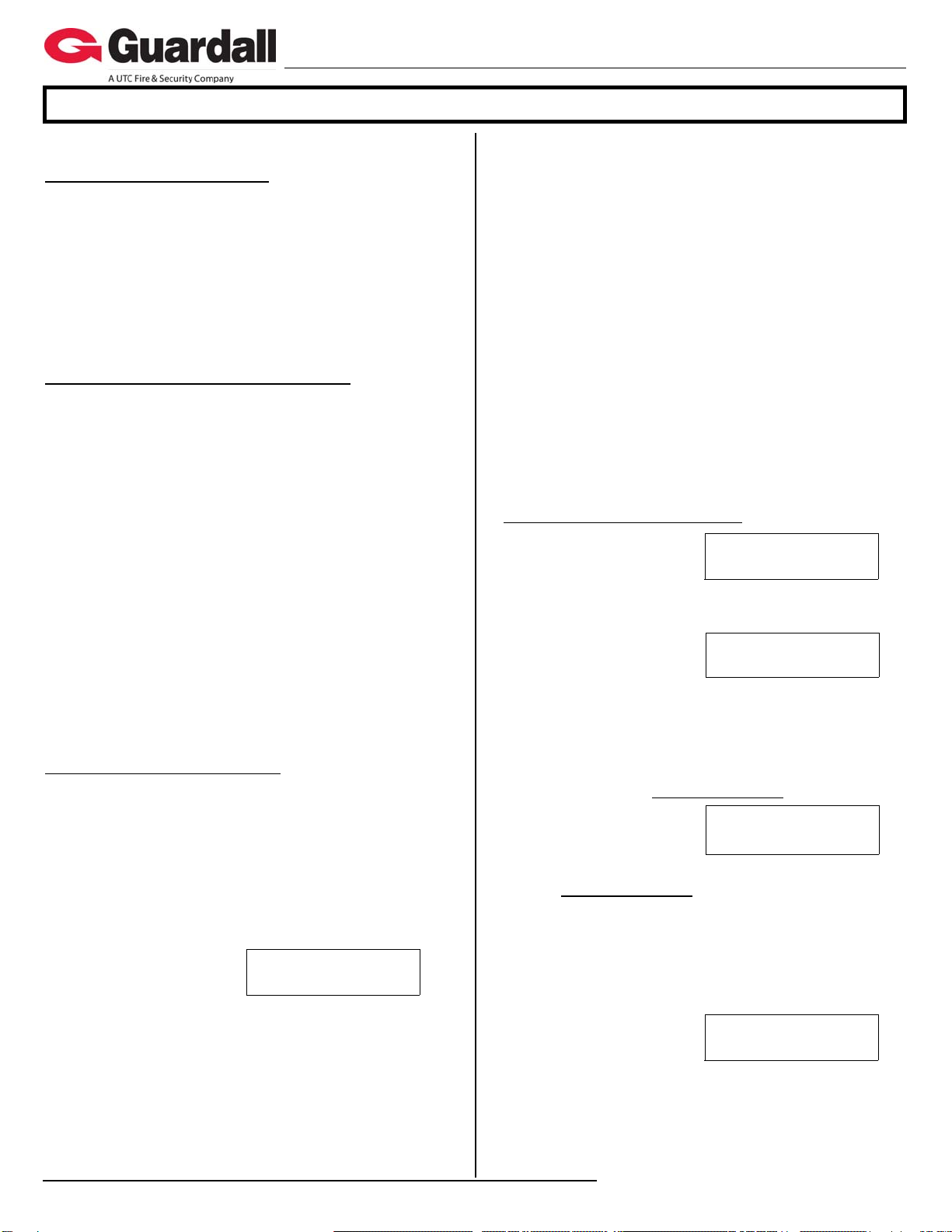

Receiver Module Programming

Program the wireless module serial # into the module

configurations. Assign the number of input points

required (4 to 32). The wireless module does not have

outputs. Leave the wireless module’s outputs defaulted

or change them to “0” or none so the outputs can be

assigned some where else. After making these

selections, press the button below ‘Save’ in the LCD

keypad’s module enrollment screen, or send the module

info to the panel from the Director Software.

AllSVN:3 Force:2

Save

The next screen will look

like this. It can only be

programmed through the

system’s LCD keypad. If the module config was sent

to the panel by the Director, go to an LCD keypad

on the system and log on as a service user. Select

‘Config/Advanced’ and the first Module

Configurations screen for this module number: e.g.

M0050. Press the ‘Save’ button from that screen

to get to this one.

AllSVN: Wireless Module Supervision Timeouts. The

time allowed before a supervision signal is transmitted

from the wireless module because it has not received a

trigger or supervisory signal from any of the sensors

assigned to it.

Selections: 1 = 2 Hrs, 15 Min

2 = 6 Hrs, 35 Min

3 = 12 Hrs (default)

4 = 25 Hrs, 15 Min

0 (None) cannot be entered.

Force: The number of times any sensors should be

triggered before the wireless module will Force learn it

into the system. This can be helpful if in a big system

with e.g. wireless PIRs that are being periodically

tripped by people, the force count is increased to avoid

false ‘force’ enrolment of a sensor.

The default is 2 triggers but can be changed from 1 to 9

triggers.

When these selections are acceptable, press the

‘Save’ button. Pressing the button will display the

module type, its input range and its module serial

number.

Repeater Module Programming

No Sensor Learn

Save Rp01

Pressing the Save button

will display the screen for

Repeater Programming.

Rp01 is the Repeater number and Mrepresents

Module Programming.

Enroll.R

Stp Tmp Fc

With the Repeater

powered, press the keypad

right arrow key to learn the

Repeater. The Enrollment screen appears. The

tamper switch or reset button on the Repeater’s

circuit board is pressed to assign the Repeater. (see

Enroll.R(press Reset button) Stp (Stop),

Tmp (Tamper) and Fc (Force) descriptions

under the following Input Configuration section.)

SV:0.TM:

Save Del

The screen will change to

the following.

SV is the Supervisory

Timeouts. See the same description and selections

under Input Configuration, (SV:) and enter the

selection with the cursor under the “0”.

TM represents whether the module’s tamper will be

monitored. With the cursor under the ““, press any

key on the keypad to toggle the selection from

tamper enabled to a box ““: no tamper.

Del can be pressed to delete the module.

TFF:0013B2 Edit

Save Rp01

Press Save and the

screen will first display

‘Programming...‘ and

then change to this screen.

TFF:0013B2 is the Repeater’s unique identifying

code.

The right arrow key can be pressed to return to the

previous screen to Edit the Repeater programming or

press Save to proceed to programming another Repeater.