3

TABLE OF CONTENTS

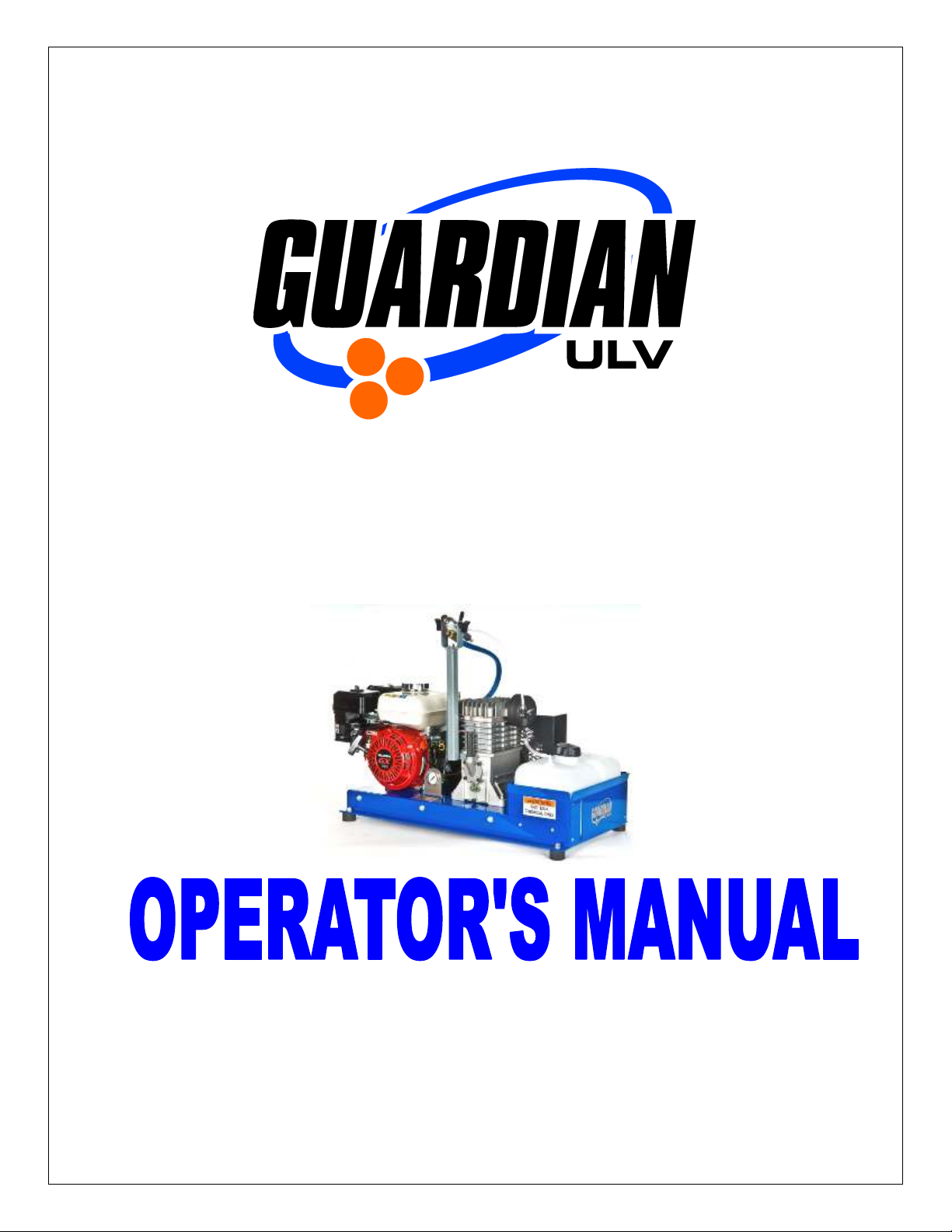

MODEL 55 ES

Contents

SPECIFICATIONS ............................................................................................................................................ 5

INTRODUCTION......................................................................................................................................... 7

SERVICING THE ENGINE ............................................................................................................................ 7

DIRECTION REFERENCE ............................................................................................................................. 8

SAFETY INFORMATION.................................................................................................................................. 9

SIGNAL WORDS ......................................................................................................................................... 9

BEFORE OPERATION CONSIDERATIONS.................................................................................................. 10

OPERATION CONSIDERATIONS ............................................................................................................... 12

MAINTENANCE AND STORAGE ...................................................................................................................13

FAMILIARIZATION .......................................................................................................................................14

OPERATOR CONTROLS ............................................................................................................................ 14

AIR PRESSURE GAUGE............................................................................................................................. 14

SPRAY VALVE (Ball Valve)........................................................................................................................ 15

FORMULATION FILTER AND ORIFICE ......................................................................................................15

FORMULATION TANK .............................................................................................................................. 15

ATOMIZATION NOZZLE ........................................................................................................................... 16

INSTALLATION ............................................................................................................................................. 17

COLD FOG GENERATOR (ULV SPRAYER) CONTENTS ............................................................................... 17

FACTORY FLUID LEVELS........................................................................................................................... 17

VEHICLE INSTALLATION...........................................................................................................................17

ENGINE STARTING & STOPPING.............................................................................................................. 18

Engine Symbols ....................................................................................................................................... 19

Recoil Start (Pull Start) ........................................................................................................................ 19

MAINTENANCE............................................................................................................................................20