7

Troubleshooting

Under normal use, your Guest Beamer spotlight will provide you with many years of

reliable service. If your unit should become damaged by a severe impact, we recommend

that you return the unit to our factory for reconditioning.

If an operational problem occurs:

1. Confirm that all fuses are intact. If a fuse has blown, do not replace the fuse until

the cause of the problem has been located and corrected. NEVER replace a blown fuse

with a higher value fuse.

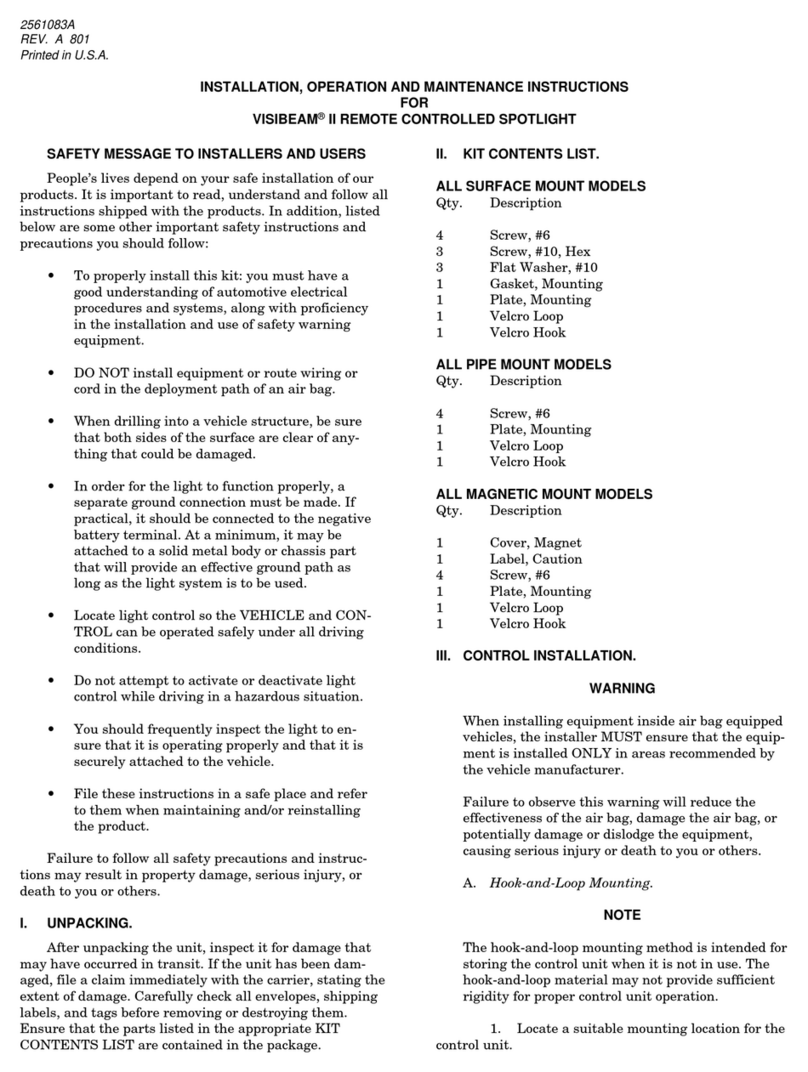

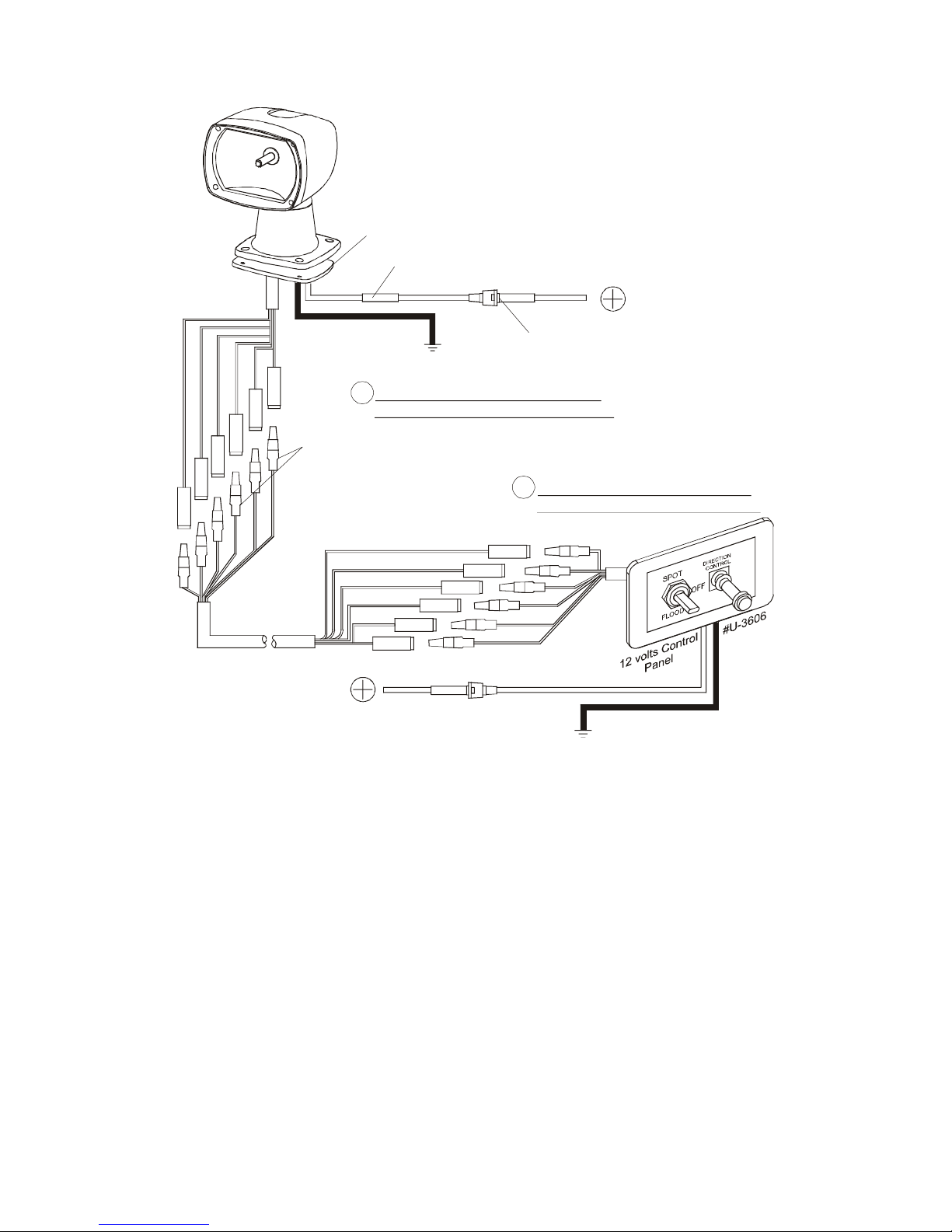

2. Confirm that all wiring connections are accurate and that the spotlight is connected

to a 12 volt DC power source capable of supplying 10 amps even when other

accessories are operating. (See diagrams on pages 4 and 5.)

Check wiring connections, for loose or corroded connections.

MOST PROBLEMS ARE CAUSED BY POOR WIRING CONNECTIONS.

4. If the spotlight does not move or light, remove the 4 bolts that fasten the spotlight

onto the mounting surface and gently lift the light until you can see inside its base.

Avoid cutting any wires. Inspect the visible wiring for loose or broken connections. If

there are signs of water damage, return the spotlight and control to the Guest Service

Department with information about how the spotlight was installed. If there are no

signs of damage, re-install the spotlight and then replace the control pad.

5. If the spotlight moves properly but does not light, examine the halogen bulb.

Replace it if it appears discolored or broken. If the bulb appears normal, test for a

faulty relay by listening at the base of the light while someone activates the bulb from

the control panel. If no "click" is audible, or if a "chattering" sound is heard, return

the spotlight to the Guest Service Department for relay replacement. NOTE: An

inadequate power source may cause similar symptoms.

6. If the spotlight does not move in one direction only (i.e.: up, but not down or left,

but not right), and the connections are good, replace the control panel.

7. If the spotlight will not move left or right but operates normally otherwise, listen at

the base of the light while someone else moves the joystick to the left and right. If the

lower motor makes no sound when it is activated, replace the lower motor.

If your light has a problem that is not described above, return the unit to the Guest Service

Department for a free examination. Be sure to include a brief description of the problem,

proof of purchase (if requesting warranty service), and your daytime telephone and/or fax

number.