6. To protect the wires from shorts, smooth the

edges of the 5/8" wire routing hole. If desired, a user-

supplied grommet can be installed in the 5/8" wire routing

hole.

7. Align the holes in the mounting gasket with

the appropriate holes in the base and apply the mounting

gasket to the base of the light . Route the light’s wires

through the gasket’s wire routing hole and through the

mounting surface.

8. Apply a silicone sealing compound around the

wires and grommet (if installed) where they pass through

the mounting surface to prevent leakage.

9. See figure 3. Secure the base to the mounting

surface with the three #10 thread-forming screws and flat

washers.

10. Replace the dome.

11. Route the light’s gray eight-conductor cable to

the control unit. Insert the gray cable’s connector into the

receptacle on the bottom of the control unit.

12. Connect the light’s black wire to a known good

vehicle ground.

13. Connect the light’s red wire to one side of a

user-supplied fuseholder. Connect the other side of the

fuseholder to the positive (+) terminal of the vehicle’s

battery. Install a six (6) ampere fuse in the fuseholder.

B. Pipe Mount Models.

1. Route the light’s wires through the pipe that

will be used for mounting the light.

2. Screw the flange mount light onto the pipe.

Position the light with the dome release button toward the

rear.

3. Route the light’s gray eight-conductor cable to

the control unit. Insert the gray cable’s connector into the

receptacle on the bottom of the control unit.

4. Connect the light’s black wire to a known good

vehicle ground.

5. Connect the light’s red wire to one side of a

user-supplied fuseholder. Connect the other side of the

fuseholder to the positive (+) terminal of the vehicle’s

battery. Install a six (6) ampere fuse in the fuseholder.

C. Magnetic Mount Models.

Magnetic mounting provides a secure, temporary

mounting method for most installations. However, it is not

intended for use on the exterior of a moving vehicle.

WARNING

Because vehicle roof construction and driving condi-

tions vary, Federal does not recommend driving a

vehicle with a magnetically mounted warning light

installed. The light could fly off the vehicle causing

injury or damage. Repair of damage incurred because

of ignoring this warning shall be the sole responsi-

bility of the user.

Holding power of magnetic mounting systems is

dependent upon surface finish, surface flatness, and

thickness of the steel mounting surface. Therefore,

to promote proper magnetic mounting:

• Mounting surface and magnets must be kept

clean, dry, and free of foreign particles that

prevent good surface contact.

• Ensure that mounting surface is flat.

• Magnet mounting system should not be used

on vehicles with vinyl tops.

• To prevent sliding of light assembly on mount-

ing surface, quick acceleration and hard stops

should be avoided.

• If the light is to be held directly to the roof by

the magnet, ensure that the power cable is not

under the magnet.

1. Place the light assembly on a level steel

surface. Ensure that the light is placed to promote maxi-

mum coverage and range of the light’s warning signal.

2. Insert the plug on the end of the power cord

into the cigar lighter socket.

NOTE

When using the vehicle’s cigar lighter socket as the

light’s power source, Federal recommends replacing

the original lighter circuit fuse with an eight-ampere

fuse. After the original fuse has been replaced, de-

vices requiring more than eight amperes will cause

failure of the lighter circuit fuse and therefore should

not be plugged into the cigar lighter socket.

If direct connection to the power source (not utilizing

the cigar lighter plug) is desired, a user-supplied in-

line fuseholder and eight-ampere fuse must be

installed in the power cord’s ribbed (positive) lead.

3. Route the light’s gray eight-conductor cable to

the control unit. Insert the gray cable’s connector into the

receptacle on the bottom of the control unit.

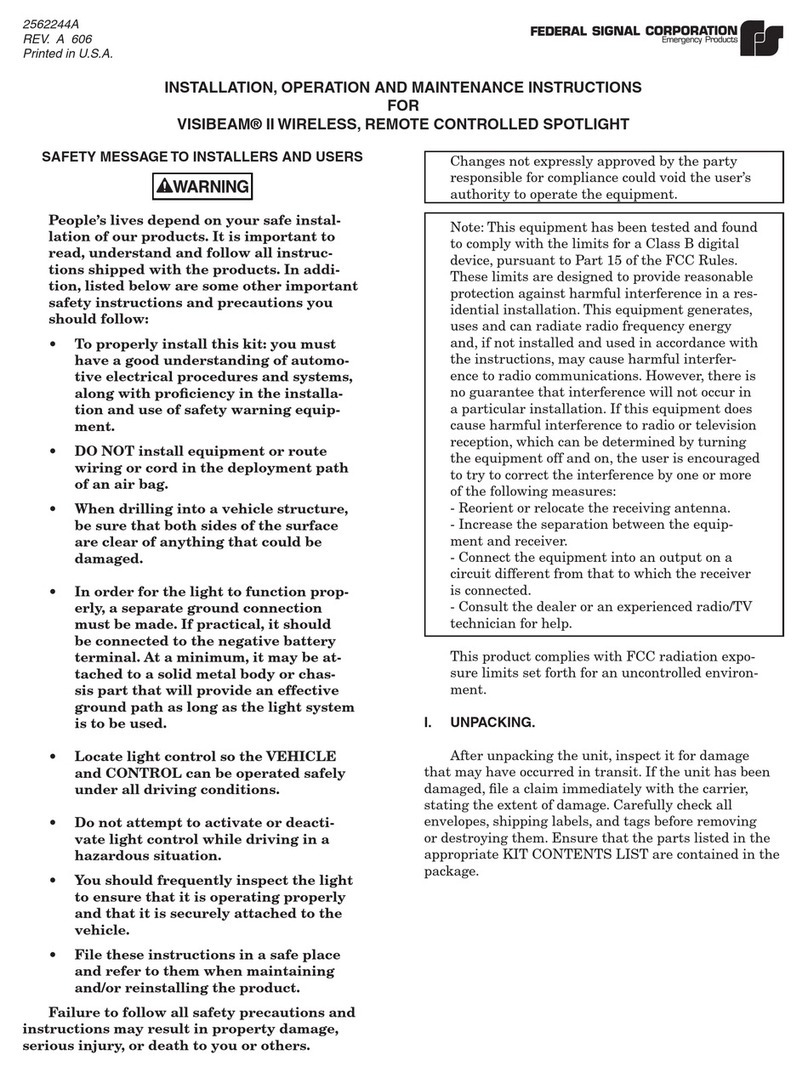

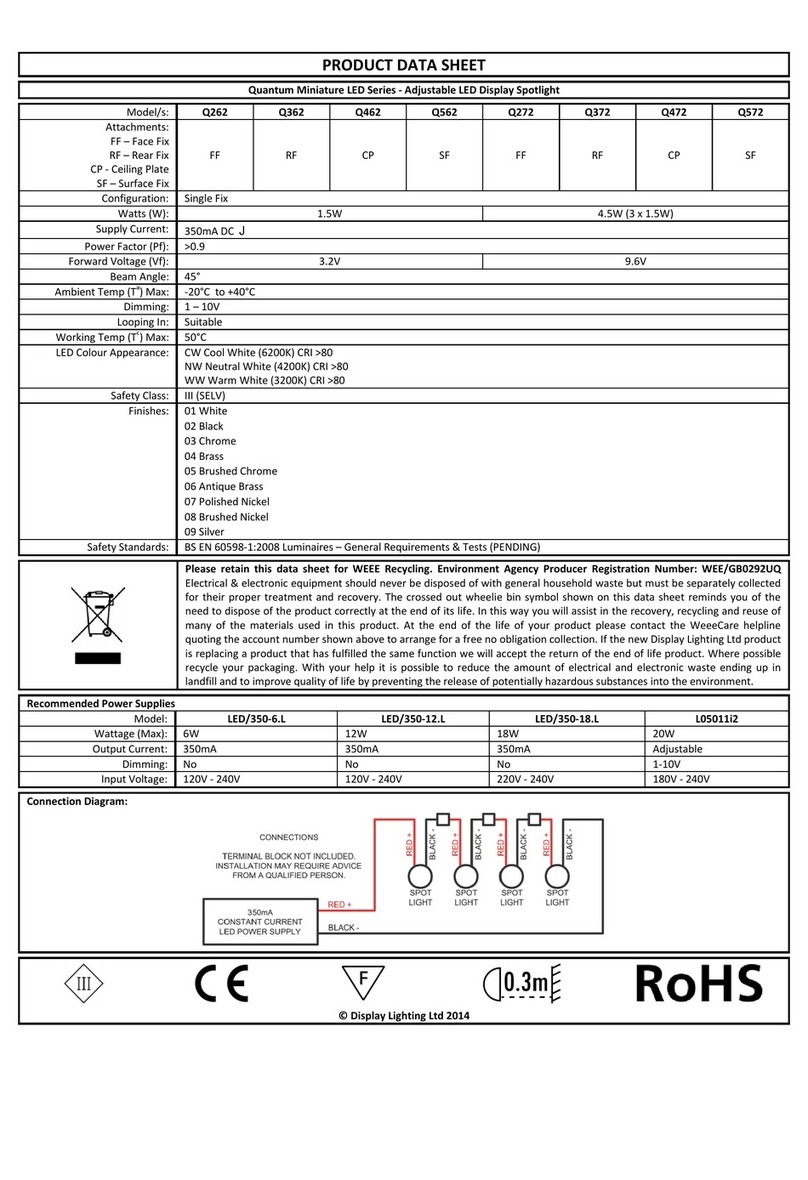

Figure 3.

-3-

DOME

BASE MOUNTING

SURFACE

MOUNTING

GASKET

RED TO FUSE AND POS.(+)

#10 FLAT WASHERS (3) #10-32 x 3/4" SCREWS (3)

290A2669-05B

BLK TO GND (-)GRA, 8 CONDUCTOR TO CONTROL