Hélicoptères Guimbal Maintenance Manual

CABRI G2 TABLE OF CONTENT

Issue 03 Approved under DOA.EASA.21J.211 c

Table of content

SECTION A

GENERAL..................................................................................................A-I

A-1

I

NTRODUCTION

............................................................................................................. A-1

Manual revisions................................................................................................................ A-1

Abbreviations ..................................................................................................................... A-4

Maintenance authorization ................................................................................................. A-5

Overhaul authorization....................................................................................................... A-5

A-2

C

ABRI

G2 D

ESCRIPTION

................................................................................................ A-6

Night-VFR optional equipment ........................................................................................... A-6

External dimensions........................................................................................................... A-7

A-3

H

ELICOPTER BASIC SERVICING

....................................................................................... A-9

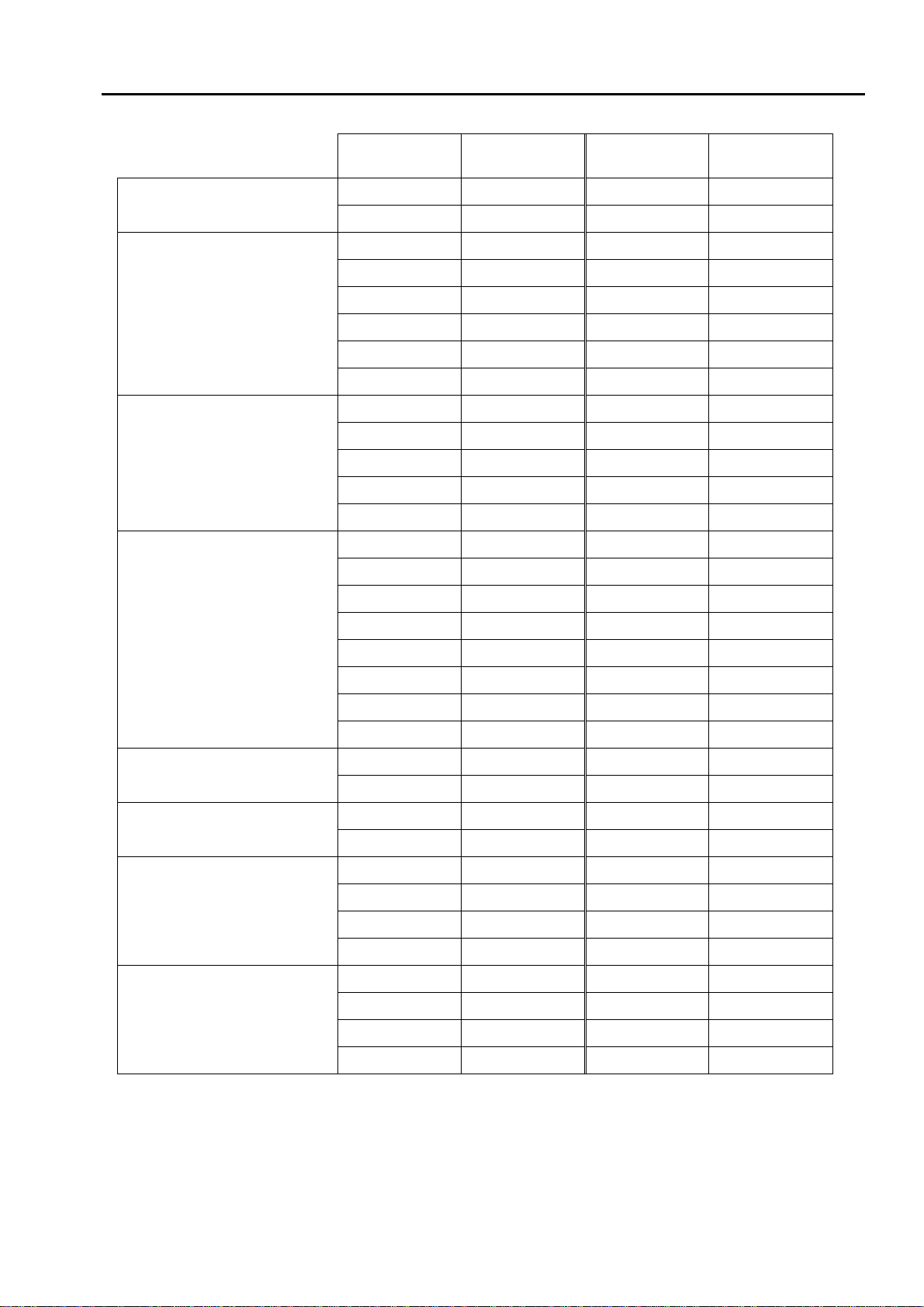

SECTION B

MAINTENANCE INSPECTIONS................................................................B-I

B-1

I

NTRODUCTION

............................................................................................................. B-1

B-2

F

IRST

25-

HOUR INSPECTION

.......................................................................................... B-2

B-3

50-

HOUR INSPECTION

.................................................................................................... B-3

B-4

100-

HOUR

/ 12-

MONTH INSPECTION

............................................................................... B-4

B-5

500-

HOUR

/ 60-

MONTH INSPECTION

............................................................................... B-5

B-6

S

PECIAL INSPECTIONS

................................................................................................... B-6

B-61 Tail skid strike............................................................................................................ B-6

B-62 Tail rotor damage....................................................................................................... B-6

B-63 Main rotor strike......................................................................................................... B-6

B-64 Rotor / engine overspeed........................................................................................... B-6

B-65 Hard landing.............................................................................................................. B-6

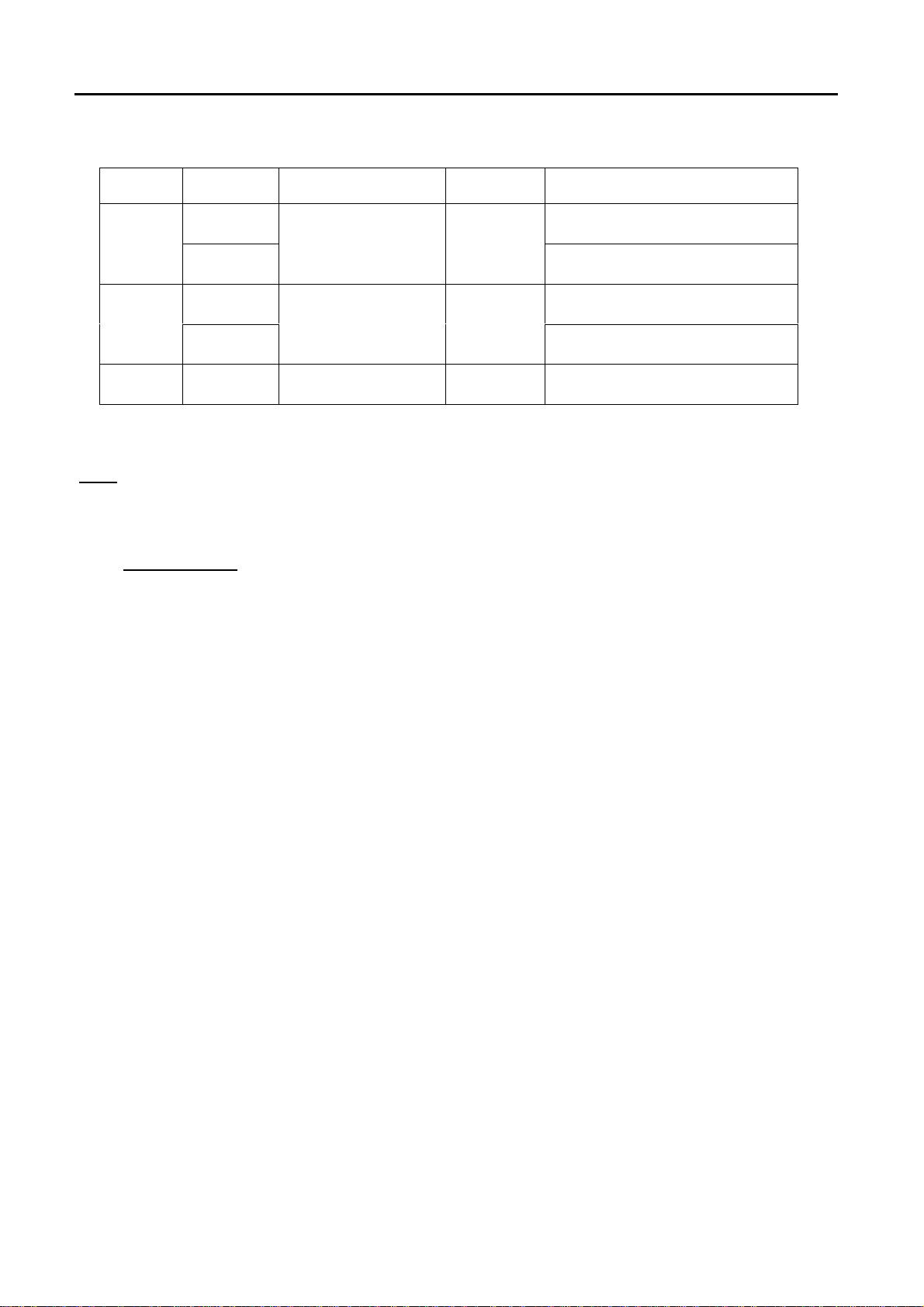

SECTION C

AIRWORTHINESS LIMITATIONS .............................................................C-I

C-1

G

ENERAL

.....................................................................................................................C-1

C-2

L

IMITATIONS

.................................................................................................................C-1

Fatigue life-limited components..........................................................................................C-1

Structural inspection intervals (On-condition limitation) ......................................................C-1

Tail structure paint..............................................................................................................C-2

SECTION D

OTHER LIMITATIONS...............................................................................D-I

D-1

T

IME

-

IN

-

SERVICE RECORDS

...........................................................................................D-1

D-2

M

ANUFACTURER TIME LIMITS

.........................................................................................D-2

D-3

O

VERHAUL REQUIREMENTS

...........................................................................................D-3

D-4

I

NCIDENTS AND ACCIDENT REPORTS

...............................................................................D-4

SECTION E

MAINTENANCE INSTRUCTIONS...........................................................D-4-I

E-1

M

AIN ROTOR

............................................................................................................... E-1-

I

Introduction.....................................................................................................................E-1-1

Description......................................................................................................................E-1-1

E-2

M

AIN TRANSMISSION

................................................................................................... E-2-

I

DESCRIPTION................................................................................................................E-2-1

E-3

T

AIL ROTOR AND TRANSMISSION

.................................................................................. E-3-

I

DESCRIPTION................................................................................................................E-3-1

DESCRIPTION................................................................................................................E-3-1

DESCRIPTION................................................................................................................E-3-4

E-4

F

LIGHT CONTROLS

...................................................................................................... E-4-

I

DESCRIPTION................................................................................................................E-4-1

E-5

E

NGINE INSTALLATION

................................................................................................. E-5-

I

INTRODUCTION.............................................................................................................E-5-1