Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

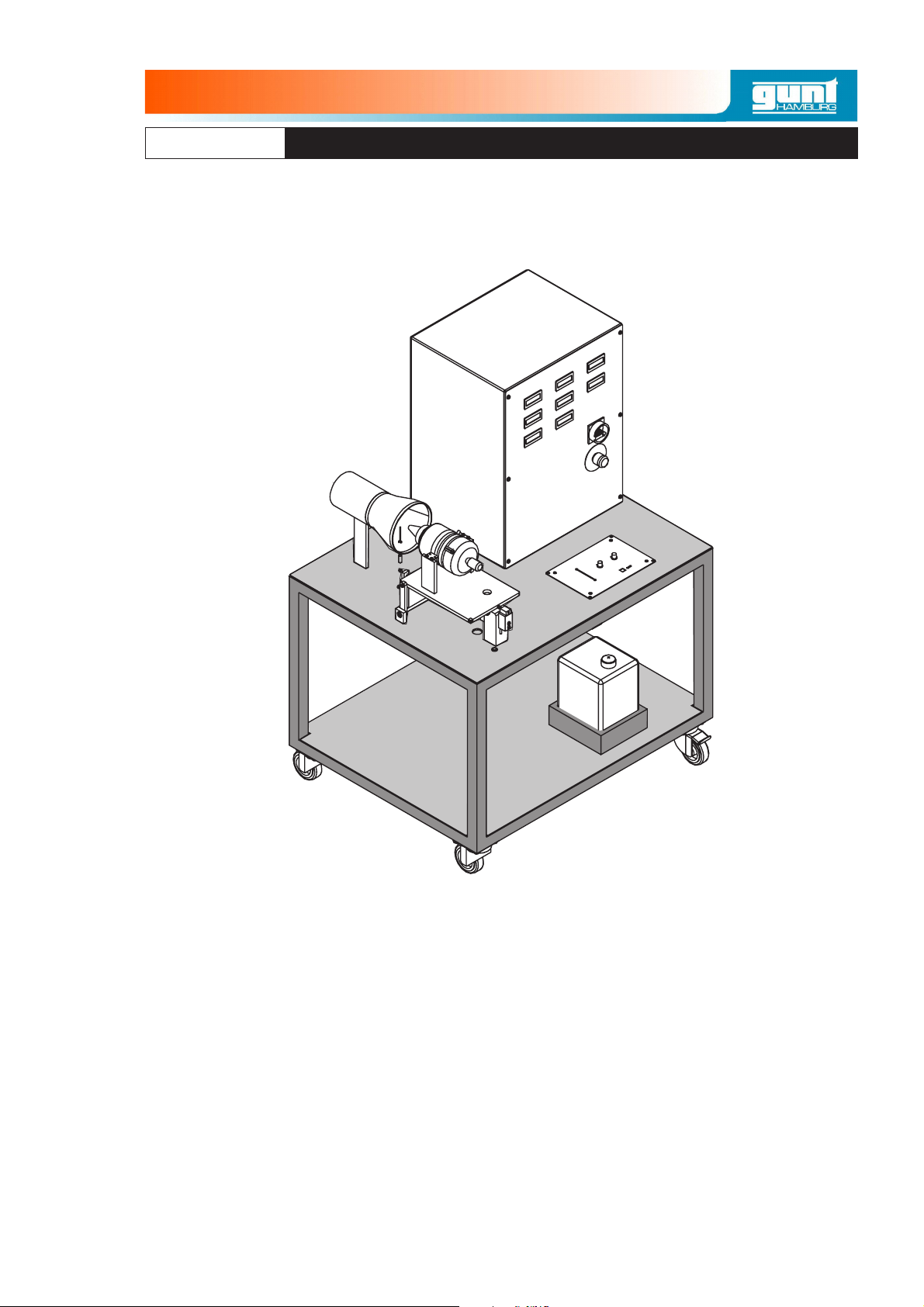

2 System description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

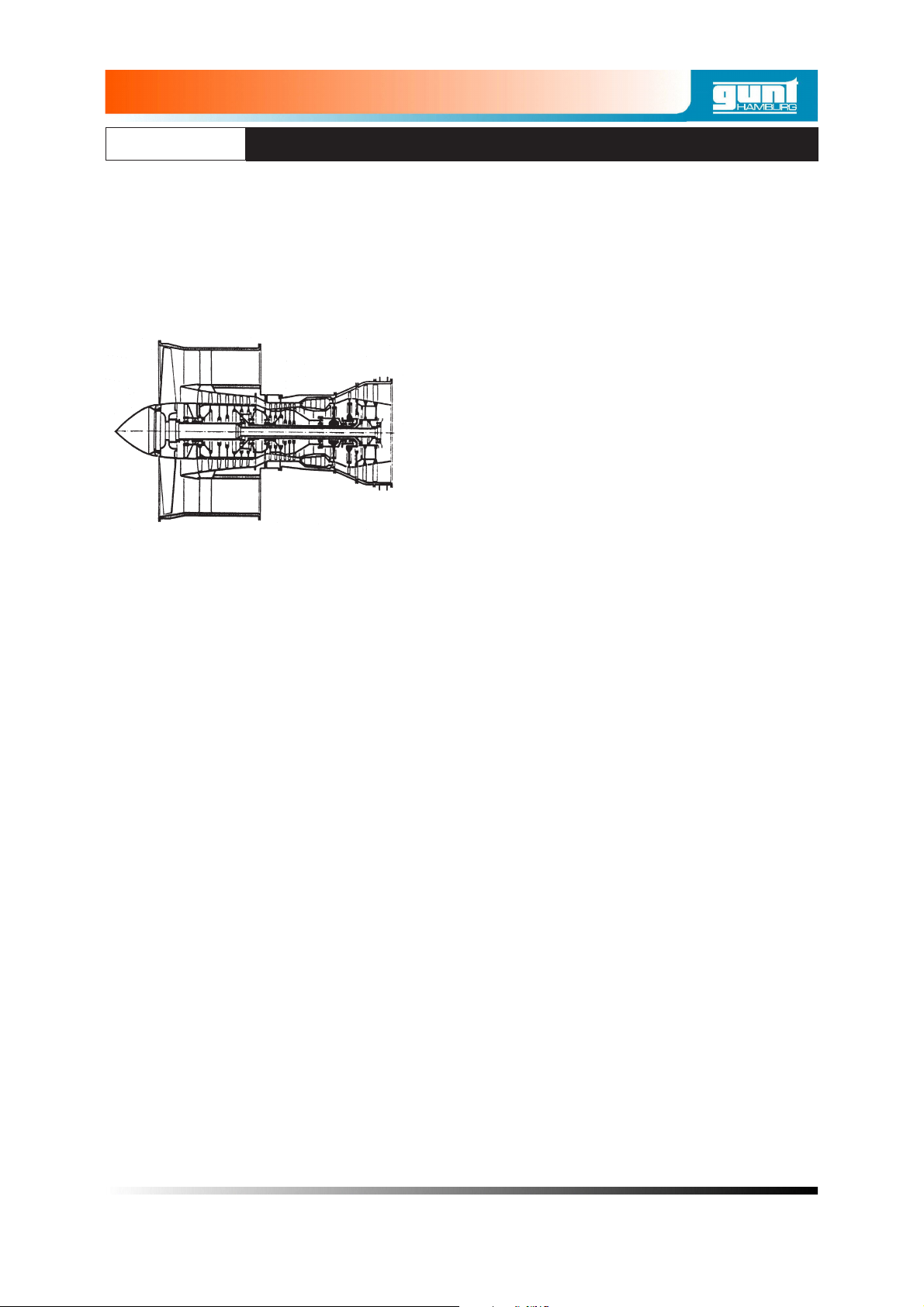

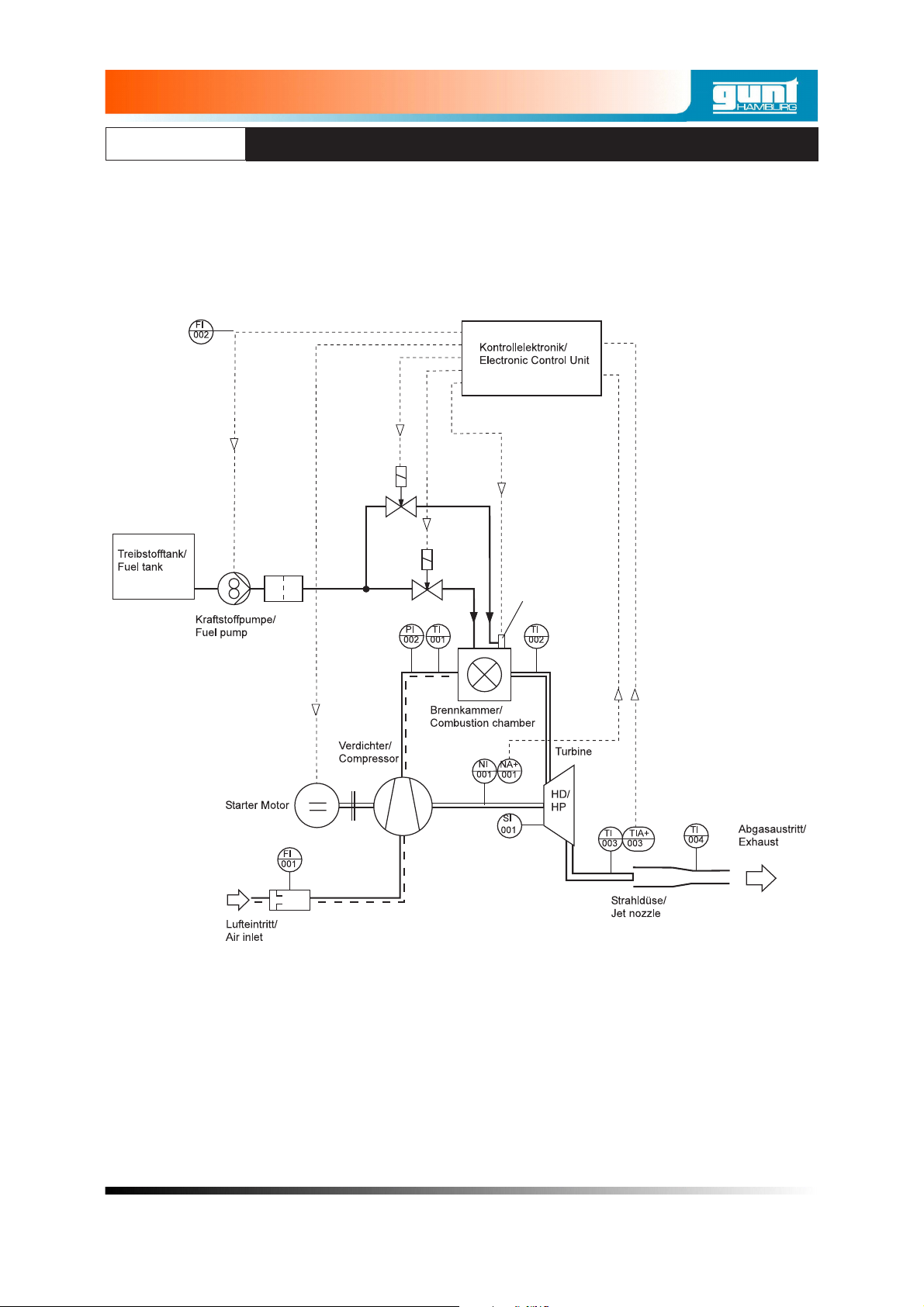

2.1 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.1 Jet turbine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.2 Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.3 Starter and ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Layout of the experimental module . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Setting up and maintaining the gas turbine . . . . . . . . . . . . . . . . . . . 12

2.4.1 Checking the gas turbine . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4.2 Setting up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Operation of the gas turbine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5.1 Preparations for starting . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5.2 Starting up the gas turbine . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5.3 Operation of the gas turbine . . . . . . . . . . . . . . . . . . . . . . . . 19

2.5.4 Shutting down the gas turbine . . . . . . . . . . . . . . . . . . . . . . 20

2.6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.6.1 Glow plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.6.2 Inspecting the turbine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.7 Faults and fault rectification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.8 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3 Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.1 Hazards for life and limb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.2 Special safety rules for handling kerosene . . . . . . . . . . . . . . . . . . . 33

3.3 Hazards for unit and function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

ii

ET 796

GAS TURBINE AS JET ENGINE

11/2007