GW–S Automatic Sprinkler

SSP, SSU, CUP, WUP,HSW, WHEC

Heat & Electrically actuated (by Metron Actuator ®)

Page 1 of 4

GW Sprinkler A/S

Kastanievej 15, Data Sheet No.: GW SH060 1001 B

DK-5620 Glamsbjerg

e-mail: sales.dep@gwsprinkler.com Date: 08.02.2017

web: www.gwsprinkler.com

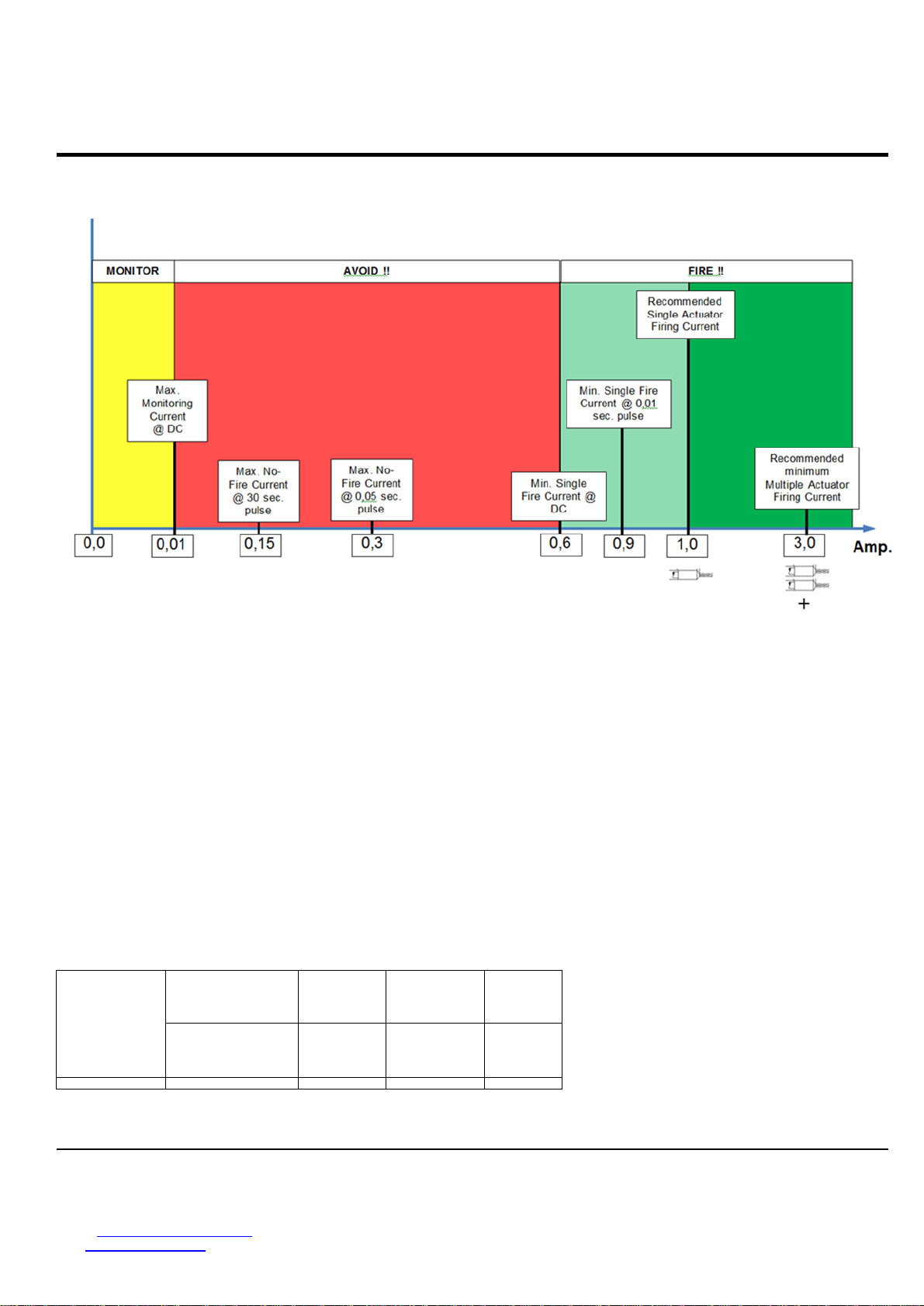

Nominal Energy (Type 1) 6 millijoules

Resistance Range (ohms)

0.9 - 1.6

Max. No-Fire Current D.C. (2)

30 sec Pulse

0.050 sec. Pulse

0.15 amp

0.3 amp

Min. Single Firing Current D.C. (3)

10 ms Pulse 0.6 amp

0.9 amp

Recommended Single Firing Current

1.0 amp

Recommended min. Series Firing Current

3.0 amp

Max. Monitoring *) Current (continuous) 0.01 amp

SSP SSU CUP WUP HSW WHEC

(pendent) (upright) (conventional) (wall U/P) (window) (horizontal ext. cov.)

DESCRIPTION

The GW-S sprinkler series offers high quality, European manufactured, modern compact design, that meet the rigid test

requirements set out by the world leading approval authorities. The unique GW PTFE / double groove seal in

combination with high end heat responsive frangible glass bulbs guarantee durable operation and reliable performance.

All manufacturing and testing processes are performed strictly in compliance with our quality management system,

certified to ISO 9001.The use of precisely CNC-machined hot forged frames eliminates the risk of porosity.

The heat & electrically operated sprinkler is fitted with an electrically operated Metron Actuator that enables instant and

remote actuation of the sprinkler – typically in combination with a detection system and/or a manually operated switch

box.

APPLICATION

GW-S heat & electrically actuated sprinklers are used in fixed fire protection systems. Care must be exercised that RTI,

orifice size, temperature rating, deflector style and sprinkler type is in accordance with the latest published sprinkler

installation standards i.e. EN12845, CEA4001 or NFPA13.

The GW-S heat & electrically actuated sprinklers are ideal for applications where instant and fully controllable actuation

of single or multiple heads is called for – e.g. applications involving protection of explosive components/environments.

OPERATION (Metron Actuator)

The Metron Actuator is a highly reliable, compact single shot device which can push with a power to weight ratio in

excess of 10,000:1. It operates within milliseconds of receiving the appropriate electrical impulse, a rate which is almost

impossible to achieve with a mechanical source of energy. The short reaction times and high power to weight ratios are

achieved by sophisticated pyrotechnique. Within the metal body of each device, rapid expansion of hot combustion

products generates very high pressures which are used to do mechanical work, in this case to drive a piston forward to

shatter the sprinkler glass bulb.

Its ability to rapidly convert small electric signals into high mechanical work output, its compact size, high reliability and

good environmental resistance makes the Metron Actuator ideal for automatic or remote controlled fire protection

applications.

TECHNICAL SPECIFICATION (Metron Actuator)

See ( ) notes on next page.

*) possibility of the actuator circuit remaining intact after firing must be borne in mind.