3.

Application

The most common applications for Model F1-300 EC Pen-

dent and Recessed EC Pendent Sprinklers will be in fire pro-

tection systems for high rise buildings or where the pressure

entering the sprinkler system is in excess of 175 psi (12 bar).

The use of these sprinklers will provide an opportunity to re-

duce or eliminate the need for pressure reducing valves.

The F1-300 sprinkler is an extended coverage, standard

response sprinkler that is cULus Listed for Light Hazard ap-

plications. For sprinklers systems required to comply with

the 1996 and later editions of NFPA 13, the F1-300 sprinkler

is permitted to be used only for modifications or additions

to existing systems equipped with standard response sprin-

klers, or as a replacement for individual standard response

sprinklers in existing systems.

Installation

Model F1-300 EC sprinklers are standard response sprin-

klers intended for installation as specified in NFPA 13. They

must be installed with the Model D or W2 Sprinkler Wrench

specifically designed by Reliable for use with these sprin-

klers.

The Model F1- 300 EC Recessed Sprinklers are to be in-

stalled with a maximum recess of ¾” (19mm). The Model

F1 escutcheon illustrated is the only recessed escutcheon

to be used with Model F1-300 EC Pendent Sprinklers. The

use of any other recessed escutcheon will void all approvals

and negate all warranties. When installing Model F1-300 EC

Recessed Pendent sprinklers, use the Model GFR1 Sprin-

kler Wrench. Any other type of wrench may damage these

sprinklers.

Glass bulb sprinklers have orange bulb protectors to

minimize bulb damage during shipping, handling and in-

stallation. REMOVE THIS PROTECTION AT THE TIME THE

SPRINKLER SYSTEM IS PLACED IN SERVICE FOR FIRE

PROTECTION. Removal of the protectors before this time

may leave the bulb vulnerable to damage. RASCO wrench-

es are designed to install sprinklers when covers are in

place. REMOVE PROTECTORS BY UNDOING THE CLASP

BY HAND. DO NOT USE TOOLS TO REMOVE THE PRO-

TECTORS.

Maintenance

The Models F1-300 EC Pendent and Recessed EC Pen-

dent Sprinklers should be inspected and the sprinkler sys-

tem maintained in accordance with NFPA 25. Do not clean

sprinklers with soap and water, ammonia or any other clean-

ing fluid. Remove any sprinkler that has been painted (other

than factory applied) or damaged in any way. A stock of

spare sprinklers should be maintained to allow quick re-

placement of damaged or non-operated sprinklers. Prior to

installation, sprinklers should be maintained in the original

cartons and packaging until used to minimize the potential

for damage to sprinklers that would cause improper opera-

tion or non-operation.

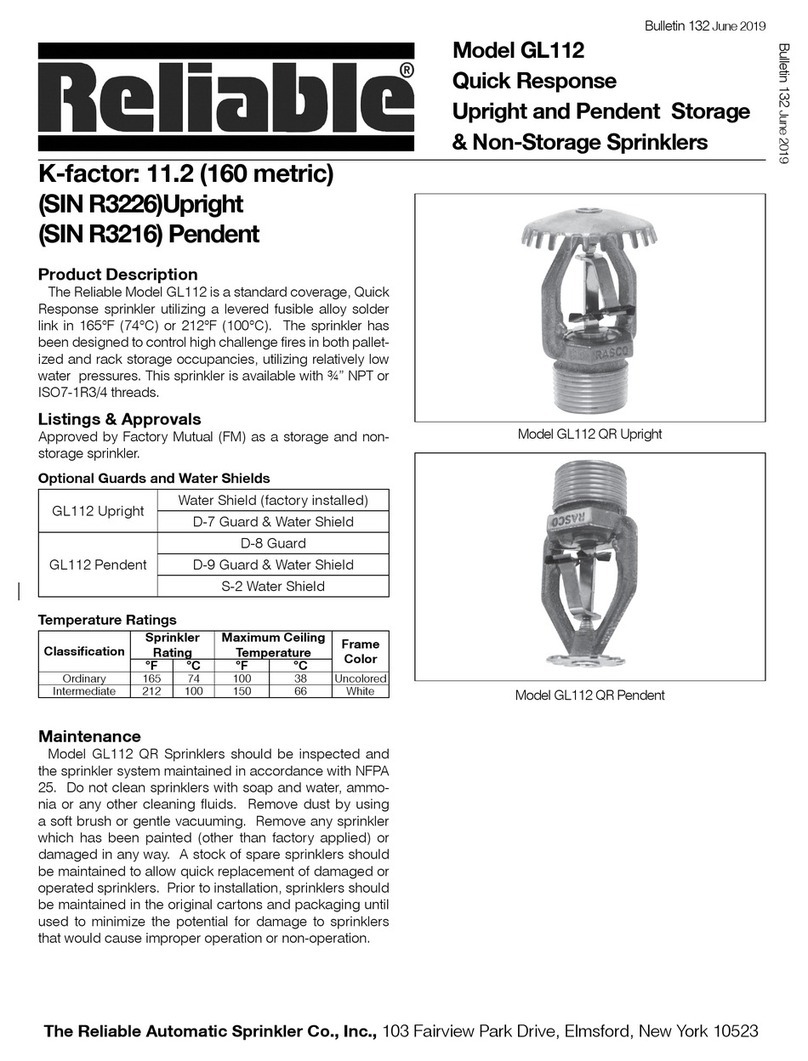

Temperature Ratings

Classication

Sprinkler

Temperature

Maximum

Ambient

Temperature

Bulb

Color

°F °C °F °C

Ordinary 135 57 100 38 Orange

Ordinary 155 68 100 38 Red

Finishes(1)

Standard Finishes:

Sprinkler Escutcheon

Bronze

Chrome Plated

White Polyester Coated (2)

Brass

Chrome Plated

White Painted

Special Application Finishes:

Sprinkler Escutcheon

Bright Brass

Black Plated (2)

Black Paint (2)

Off White

Satin Chrome

Lead Plated (3)

Wax Coated (3)

Wax Over Lead (3)

Bright Brass

Black Plated

Black Paint

Off White

Satin Chrome

Lead Plated

Wax Coated

Wax Over Lead

(1) Other colors are available on special order. Consult factory

for details

(2) UL and ULC Listed.

(3) 155°F (68°C) Rating Only.

Ordering Information

Specify:

1. Sprinkler Model

2. Sprinkler Type

3. Orifice Size

4. Deflector Type

5. Temperature Rating

6. Sprinkler Finish

7. Escutcheon Finish (where applicable)

Note: When Model F1-300 EC Recessed Pendent sprinklers are or-

dered, the sprinklers and escutcheons are packaged sepa-

rately.