PENDENT & UPRIGHT SPRINKLERS , STD. COVERAGE

MODEL F892 DESIGNER

STANDARD RESPONSE, K=16.8 , 3/4"NPT **

GENERAL DESCRIPTION

The 16.8 K-Factor Model F892 De-

signer, Standard Response, Standard

Coverage, Pendent and Upright Sprin-

klers (Ref. Figure A) are automatic

sprinklers of the frangible bulb type.

They are “standard response - spray

sprinklers” which produce a hemi-

spherical water distribution pattern be-

low the deflector.

The F892 Sprinklers are intended for

use in fire sprinkler systems designed

in accordance with the standard instal-

lation rules recognized by the applica-

ble Listing or Approval agency (e.g.,

UL Listing is based on the require-

ments of the National Fire Protection

Association). Also, when acceptable

to the Authority Having Jurisdiction,

they may be used with a “Reduced

Design Area” as indicated in Table A.

The 16.8 K-Factor F892 Sprinklers

were subjected to full scale, high-piled

storage, fire tests to qualify their use in

lieu of 8.0 or 11.2 K-Factor standard

spray sprinklers for the protection of

high-piled storage.

Higher flow rates can be achieved at

much lower pressures with the 16.8

K-Factor F892 Sprinklers — making

their use highly advantageous in high

density applications, such as the pro-

tection of high-piled storage.

The 16.8 K-Factor F892 Sprinkler also

has the advantage of having a UL and

C-UL specific application listing, which

in some cases can subsequently re-

duce the design area and the overall

water demand of the sprinkler system.

Refer to Table A for details.

Applications for the 16.8 K-Factor

Model F892 Pendent and Upright

Sprinklers are expanding beyond the

current listings/approvals. For infor-

mation regarding research fire tests

which may be acceptable to an Author-

ity Having Jurisdiction, please contact

the Technical Services Department.

APPROVALS AND STANDARDS

Laboratory listings and approvals for

the 16.8 K-Factor, Model F892 De-

signer, Standard Response, Standard

Coverage, Pendent and Upright Sprin-

klers are given in Table A.

WARNING

The 16.8 K-Factor, Model F892 Pen-

dent and Upright Sprinklers de-

scribed herein must be installed and

maintained in compliance with this

document, as well as with the appli-

cable standards of the National Fire

Protection Association, in addition to

the standards of any other authorities

having jurisdiction. Failure to do so

may impair the integrity of these de-

vices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. The installing contractor or

manufacturer should be contacted

relative to any questions.

Printed in U.S.A. 3-01 TD595J

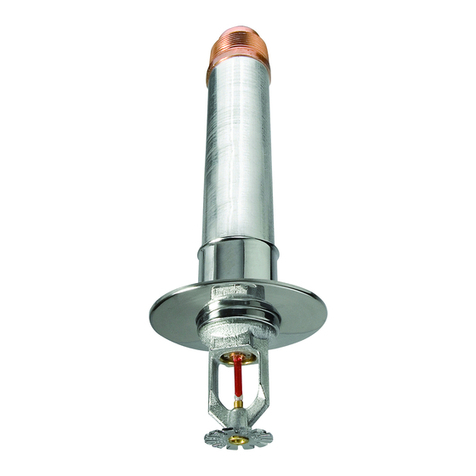

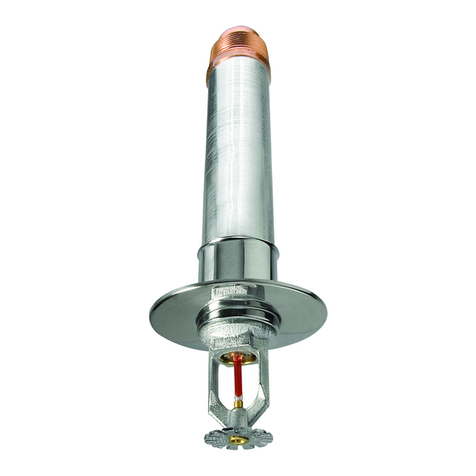

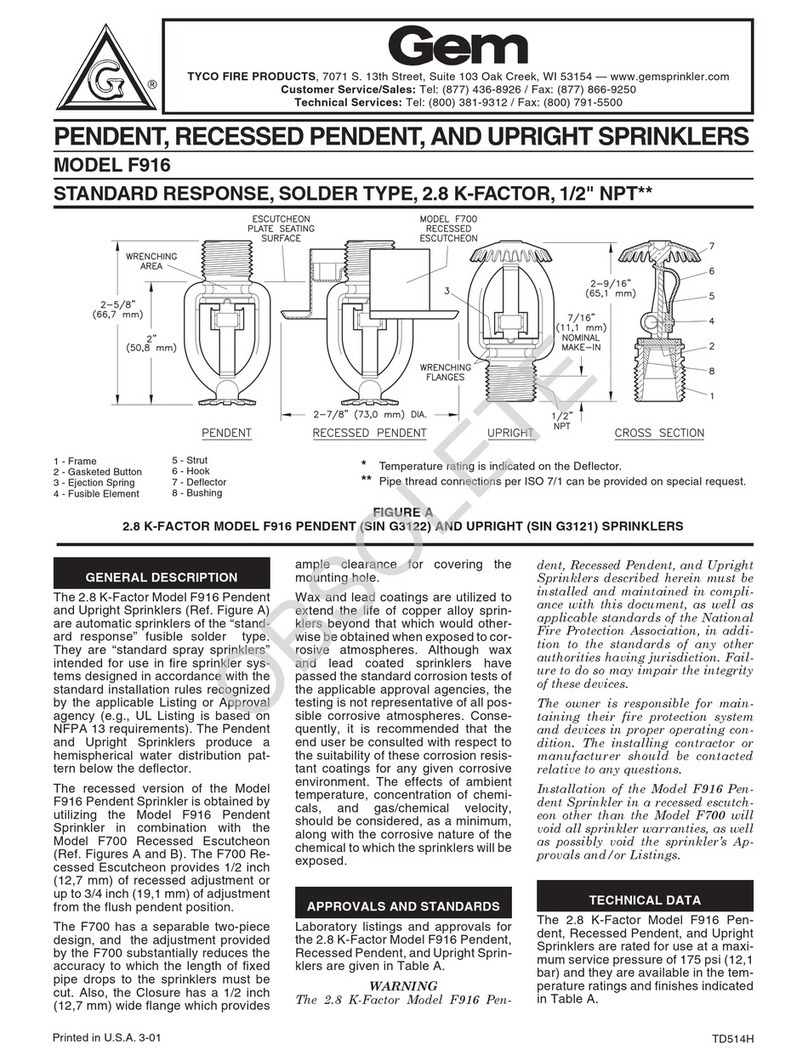

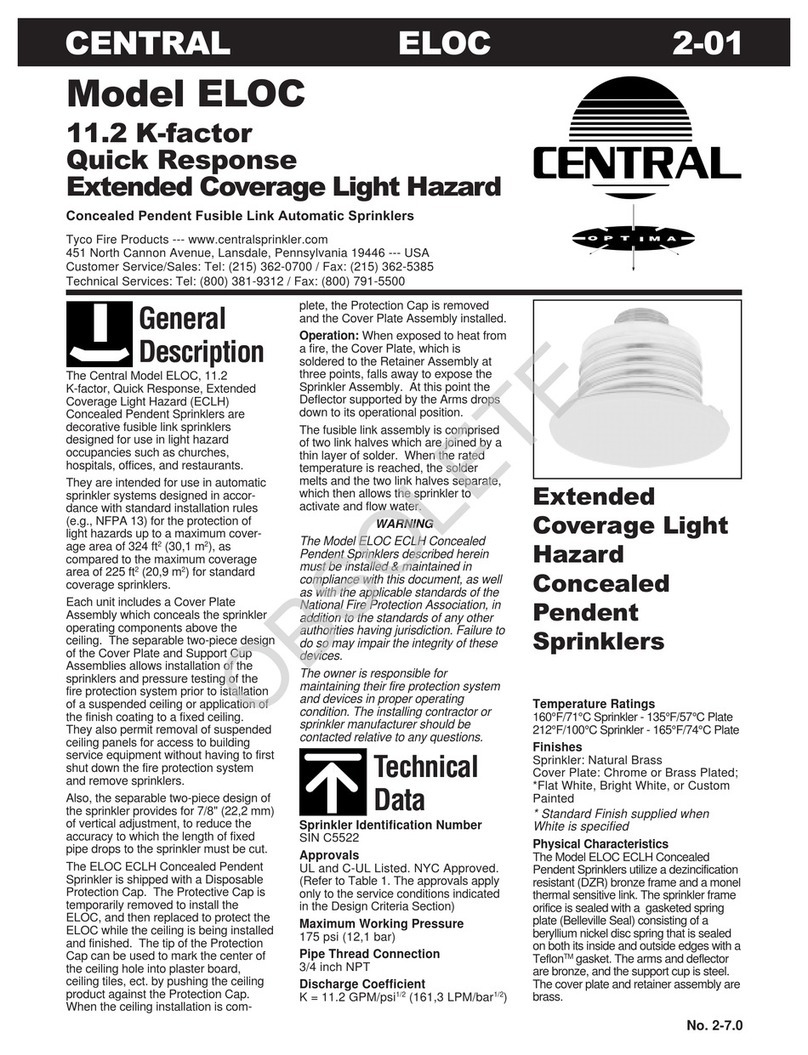

FIGURE A

16.8 K-FACTOR MODEL F892 PENDENT (SIN G1889) AND UPRIGHT (SIN G1888) SPRINKLERS

1-Frame

2 - Button

3 - Gasketed

Spring Plate

4 - Bulb

5 - Deflector

6 - Compression

Screw

*Temperature rating is indicated on deflector.

** Pipe thread connections per ISO 7/1 can be provided on special request.

TYCO FIRE PRODUCTS, 7071 S. 13th Street, Suite 103 Oak Creek, WI 53154 — www.gemsprinkler.com

Customer Service/Sales: Tel: (877) 436-8926 / Fax: (877) 866-9250

Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500