9

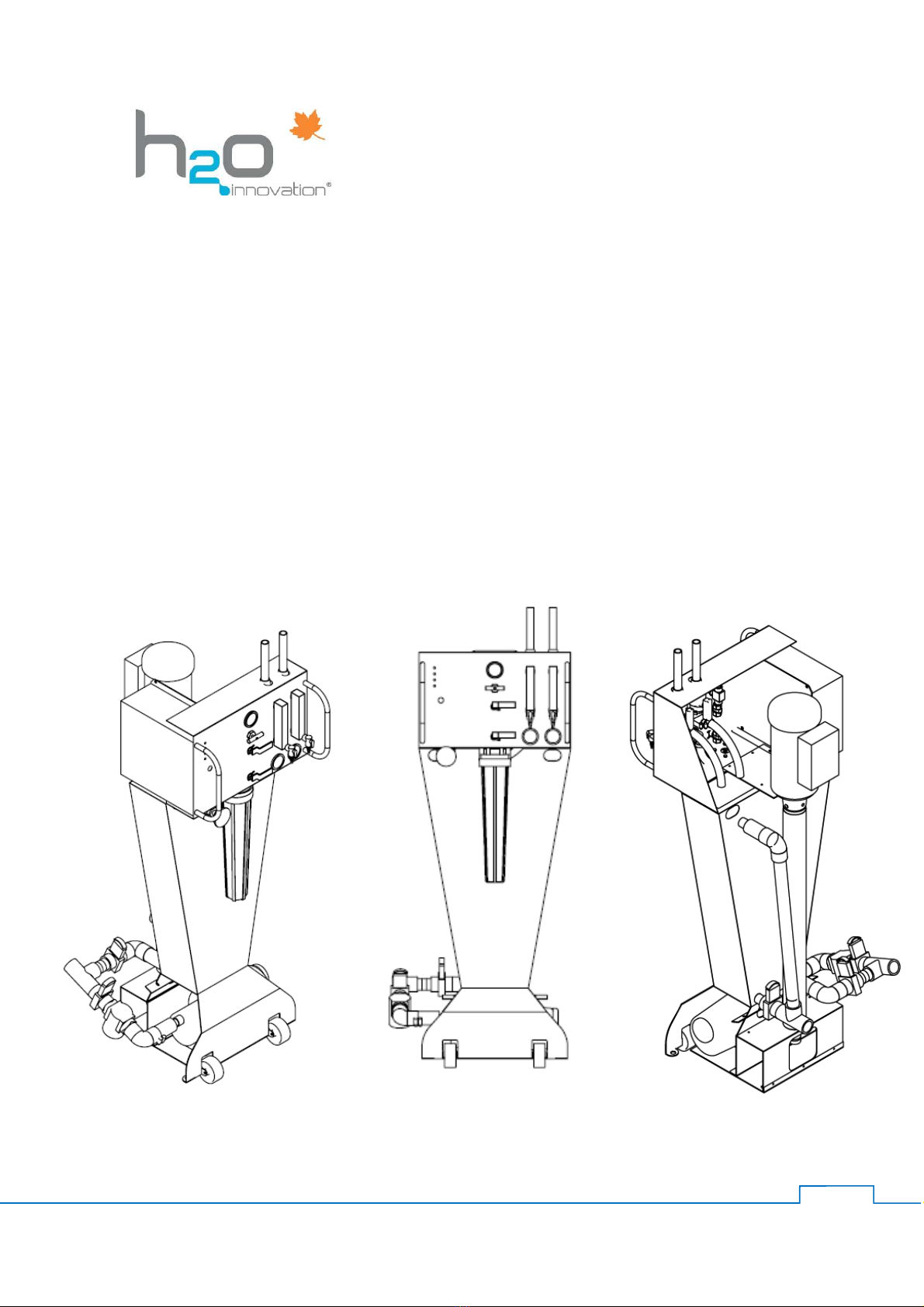

Plumbing installation

The Econox is part of an integrated system of maple sap gathering and concentrating. To

make sure it operates with accuracy and efficiency, it must be correctly linked to all the

other elements of the system. The following explanations will provide you suggestions of

installation. The physical provision of the places can change, but the principles of

suggested connections seem important to us to operate in a sedentary, effective and

reliable way.

Required tanks

There are three tanks, please see page 11 for details

Permeate tank (B-2). To gather pure water (permeate) extracted from maple

sap. This water will be used to wash your Econox separator;

Maple sap tank (B-3). To maintain a sufficient supply of maple sap to feed

your separator

Concentrate tank (B-4). To store concentrated water to supply your

evaporator.

The capacity of the tanks is related to the importance of your maple bush (your number

of taps); to the size and the performance of your evaporator and to the way you want to

manage your equipment (gathering and then concentration before evaporation or

simultaneous operations launched one after the other)

Considering all these possibilities, we will not give here any strict rules. We suggest you

consult your H2O Innovation expert who will guide you according to your personal needs.

However, for best quality maple syrup, most American and Canadian specialists

recommend that maple sap should be concentrated as soon as possible after gathering

and that boiling should begin right after concentration (the sooner the better).

Connecting tanks to system

See the installation chart on page 11. It shows a simple installation that should

adequately suit your personal needs. All tanks must be connected to the drain (sewer)

since each has to be emptied and cleaned regularly. Each tank must be equipped with

an outlet valve (BV-2 to BV-4) connected to a single line leading to the drain.

Permeate and maple sap tanks should be connected to the feed pump. In diagram # 5,

you can see that the same line is used to go towards the feed pump and towards the

drain, using valves BV-6 and BV-1 to proceed to the necessary diversions.

A non-return valve (CR) at the pressure pump's entrance is necessary.

An 840 microns filter installed between the Econox and valve BV-1. To prevent

discharges and for more protection against bacterial contamination, we recommend that

a built-in air gap should be installed between the line and the drain.