HY-OPTIMA™ 1700 Series Operating Manual

90000011 R16Page 3 of 41

Chapter 1: Model Specifications and Certifications

1.1 Description.................................................................................................................... 6

1.2 Models.......................................................................................................................... 6

1.2.1 Model 1720 .............................................................................................................6

1.2.2 Model 1730 .............................................................................................................7

1.2.3 Model 1740 .............................................................................................................7

1.3 Specifications................................................................................................................ 8

1.3.1 Performance Specifications.....................................................................................8

1.3.2 Operating Specifications .........................................................................................8

1.4 Analyzer ATEX Rating.................................................................................................. 9

1.5 Dimensions................................................................................................................. 10

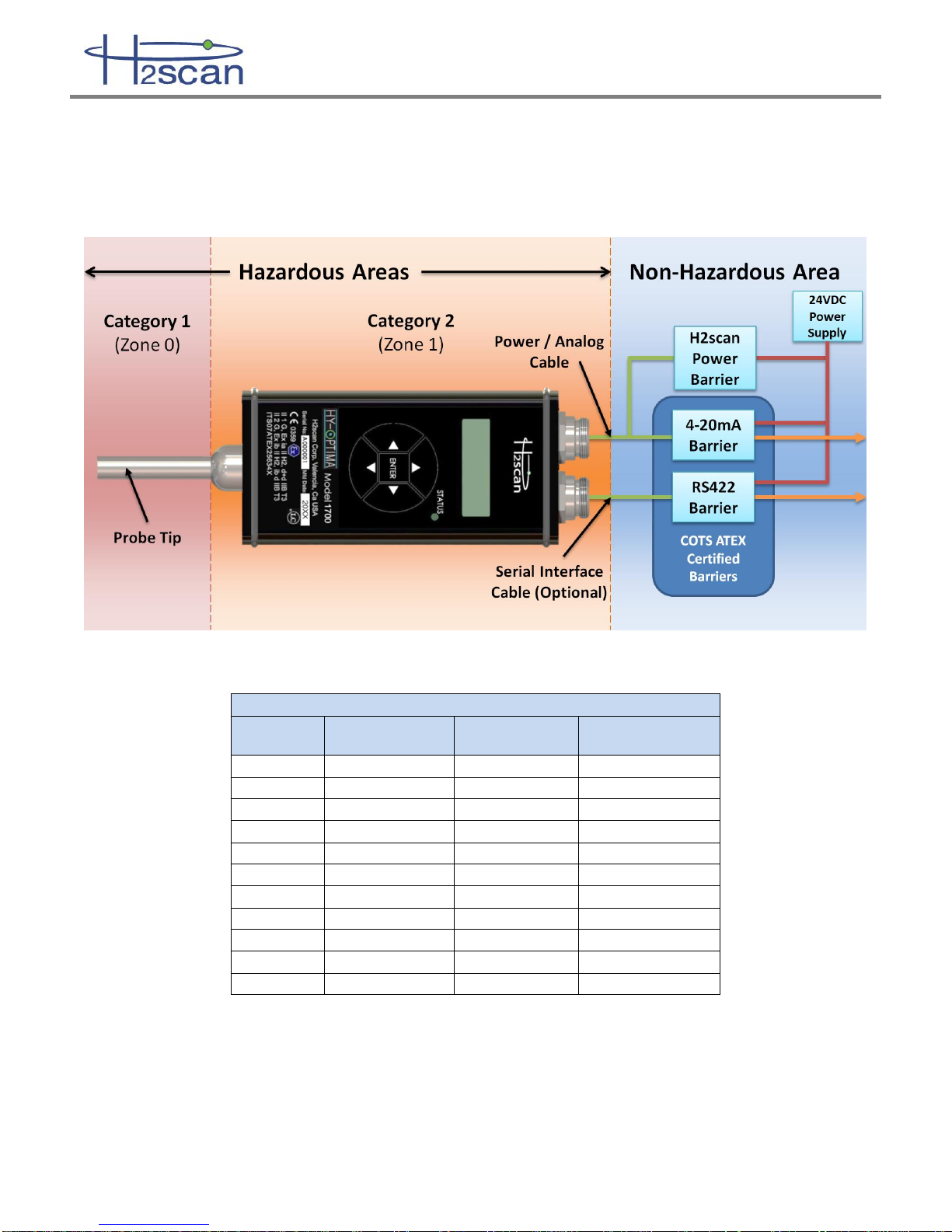

Chapter 2: Installation

2.1 Associated Equipment................................................................................................ 11

2.2 Analyzer Mounting...................................................................................................... 11

2.3 Power and Analog Connector..................................................................................... 12

2.4 Serial Connector......................................................................................................... 12

2.5 Startup........................................................................................................................ 13

2.5.1 Models 1710, 1730, 1740......................................................................................13

2.5.2 Model 1720 ...........................................................................................................13

2.6 Shutdown.................................................................................................................... 13

Chapter 3: Operation and Configuration

3.1 Optimum Analyzer Performance................................................................................. 14

3.1.1 Effect of Pressure..................................................................................................14

3.1.2 Calibration Gas Bottle Accuracy............................................................................14

3.2 Analog Output............................................................................................................. 14

3.2.1 Calibrate the Analog Output..................................................................................15

3.3 Serial Communication................................................................................................. 15

3.3.1 Serial Command Summary ...................................................................................15

3.3.2 A Command (LED Set Points)...............................................................................16

3.3.3 D Commands (Display Product Information).........................................................16

3.3.4 G Command (Go, Stream Data)............................................................................17

3.3.5 H Command (Modify H2 Reporting Range)...........................................................17

3.3.6 I Command (Modify Analog Output)......................................................................17

3.3.7 X Command (Clear Field Cal) ...............................................................................18

3.3.8 F Command (Field Cal).........................................................................................18

3.4 Display........................................................................................................................ 18

3.4.1 Keypad..................................................................................................................18

3.4.2 Configuration Menu...............................................................................................19

3.4.3 Display Menus.......................................................................................................20

Chapter 4: Field Calibration

4.1 Calibration Interval...................................................................................................... 25

4.2 Calibration Gases....................................................................................................... 25

4.2.1 Background Gases................................................................................................25

4.3 Calibration Procedure................................................................................................. 26

4.3.1 Procedure Using the Keypad.................................................................................26