HY-OPTIMA™ 2700 Series ATEX Operating Manual

90000079 R8Page 3 of 45

Chapter 1: Model Specifications and Certifications

1.1 Description.................................................................................................................... 6

1.2 Models.......................................................................................................................... 6

1.2.1 Model 2710 .............................................................................................................6

1.2.2 Model 2720 .............................................................................................................6

1.2.3 Model 2730 .............................................................................................................7

1.2.4 Model 2740 .............................................................................................................7

1.3 Specifications................................................................................................................ 8

1.3.1 Performance Specifications.....................................................................................8

1.3.2 Operating Specifications .........................................................................................8

1.4 Analyzer Certifications.................................................................................................. 9

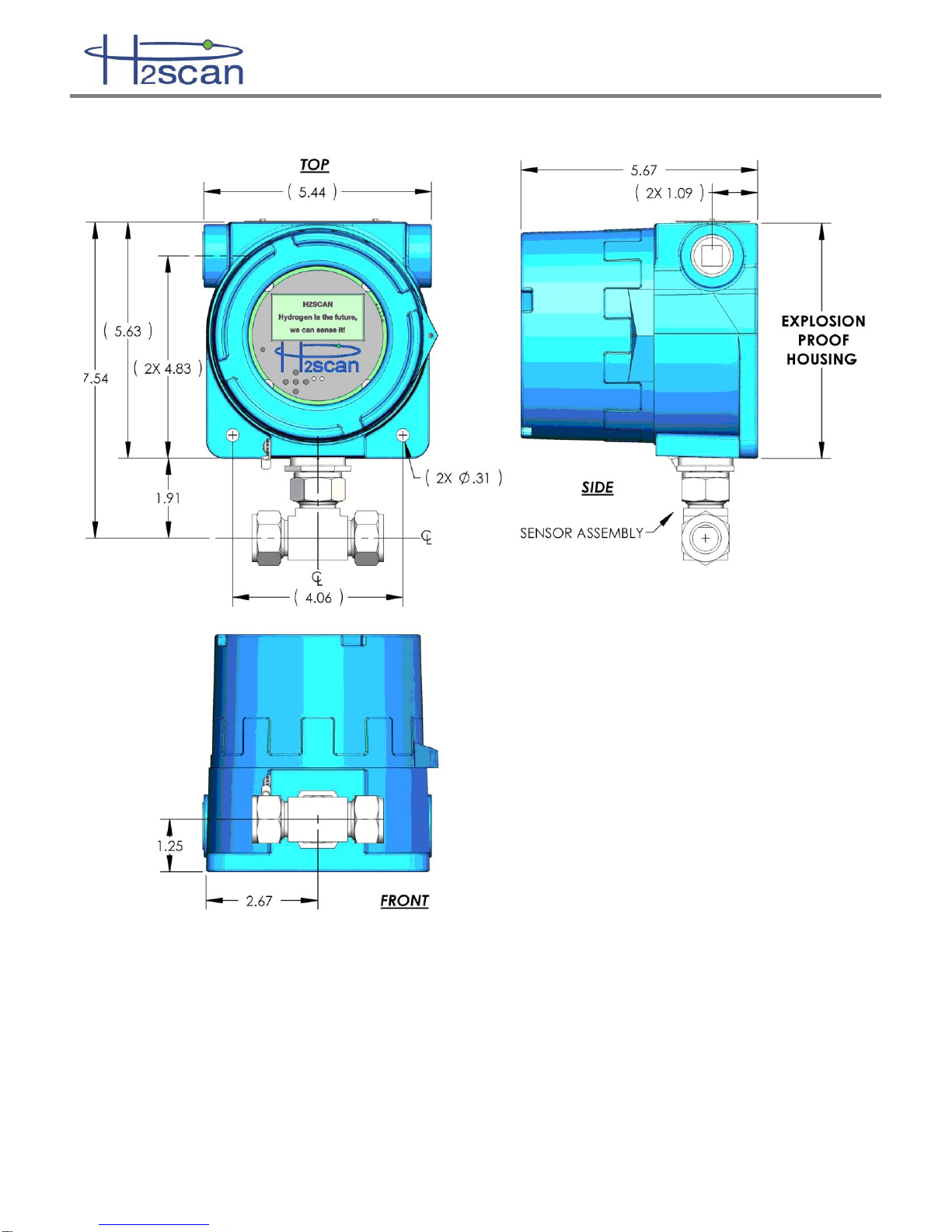

1.5 Dimensions................................................................................................................. 10

Chapter 2: Installation

2.1 Opening the Analyzer ................................................................................................. 11

2.2 Wiring ......................................................................................................................... 13

2.2.1 AC Power Wiring...................................................................................................15

2.2.2 Relay Wiring..........................................................................................................15

2.2.3 Pressure Sensor Wiring (Optional)........................................................................15

2.2.4 4-20mA Interface Wiring........................................................................................16

2.2.5 Serial Interface Wiring...........................................................................................16

2.3 Relays......................................................................................................................... 16

2.4 Analyzer Mounting...................................................................................................... 17

2.5 Startup........................................................................................................................ 18

2.5.1 Models 2710, 2730, 2740......................................................................................18

2.5.2 Model 2720 ...........................................................................................................18

2.6 Shutdown.................................................................................................................... 18

Chapter 3: Operation and Configuration

3.1 Optimum Analyzer Performance................................................................................. 19

3.1.1 Effect of Pressure..................................................................................................19

3.1.2 Calibration Gas Bottle Accuracy............................................................................19

3.2 Pressure Sensor (Optional) ........................................................................................ 19

3.2.1 Pressure Sensor Installation .................................................................................20

3.2.2 Pressure Sensor Configuration .............................................................................20

3.2.3 Pressure Sensor Installation Troubleshooting.......................................................22

3.3 Cleaning ..................................................................................................................... 22

3.4 Analog Output............................................................................................................. 22

3.5 Serial Communication................................................................................................. 23

3.5.1 Serial Commands Summary .................................................................................23

3.5.2 A Command (Relays)............................................................................................24

3.5.3 CI Command (Calibrate Analog Output)................................................................25

3.5.4 D Commands (Display Product Information).........................................................25

3.5.5 G Command (Go, Stream Data)............................................................................25

3.5.6 H Command (Modify H2 Reporting Range)...........................................................26

3.5.7 I Command (Modify Analog Output)......................................................................26

3.5.8 PS Command (Configure Pressure Sensor) .........................................................27

3.5.9 SV Command (User Selectable Averaging) ..........................................................27