i

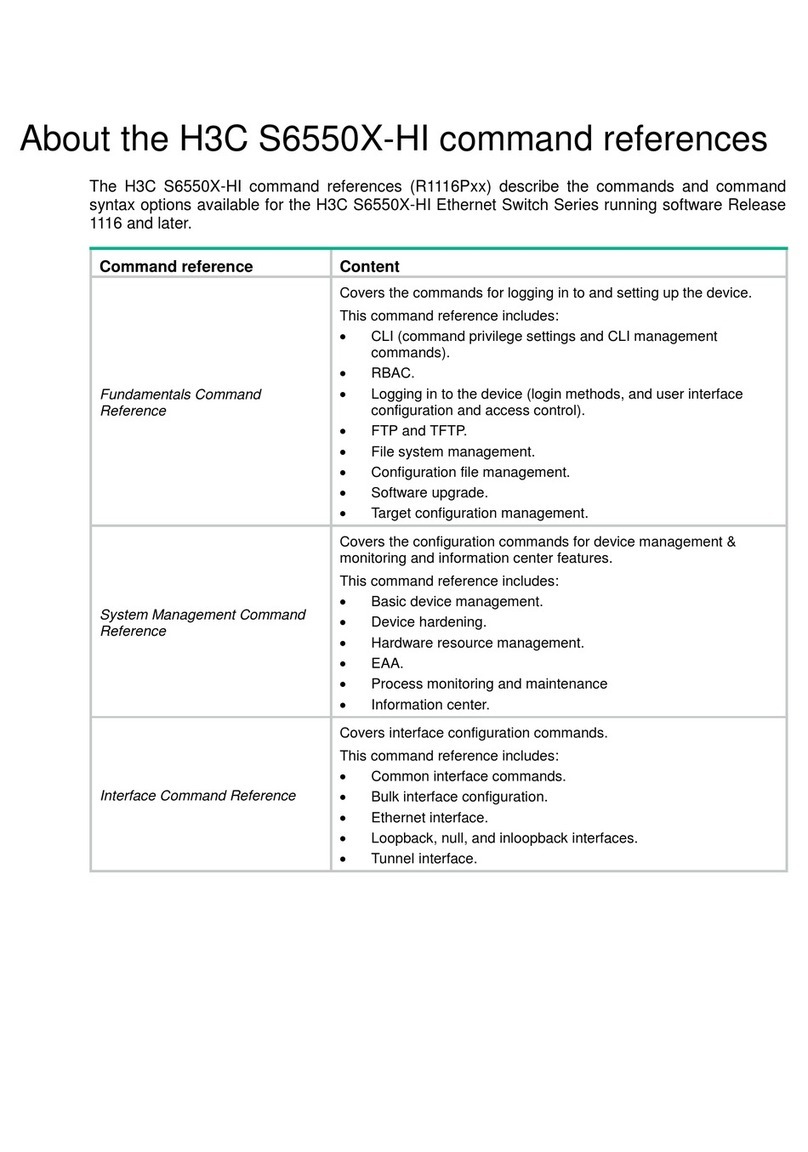

Contents

1 Preparing for installation··········································································1-1

Safety recommendations ································································································································1-1

Examining the installation site·························································································································1-1

Temperature/humidity·····························································································································1-1

Cleanliness··············································································································································1-2

Corrosive gas limit···································································································································1-2

EMI··························································································································································1-3

Laser safety·············································································································································1-3

Installation tools ··············································································································································1-4

Installation accessories···································································································································1-4

2 Installing the switch··················································································2-1

Installing the switch in a 19-inch rack··············································································································2-1

Installation methods································································································································2-2

Rack mounting accessories····················································································································2-2

Rack-mounting by using front and rear mounting brackets·····································································2-4

Rack-mounting by using front mounting brackets and rack mounting rail kit··········································2-6

Mounting the switch on a workbench············································································································2-10

Grounding the switch ····································································································································2-10

Grounding the switch with a grounding strip·························································································2-10

Grounding the switch with a grounding conductor buried in the earth ground······································2-11

Installing/removing a fan tray························································································································2-12

Installing a fan tray································································································································2-13

Removing a fan tray······························································································································2-13

Installing/removing a power module ·············································································································2-14

Installing a power module ·····················································································································2-14

Removing a power module ···················································································································2-15

Connecting the power cord···························································································································2-16

Connecting the power cord for a PSR150-A1 power module ·······························································2-16

Connecting the power cord for a PSR150-D1 power module·······························································2-17

Verifying the installation································································································································2-18

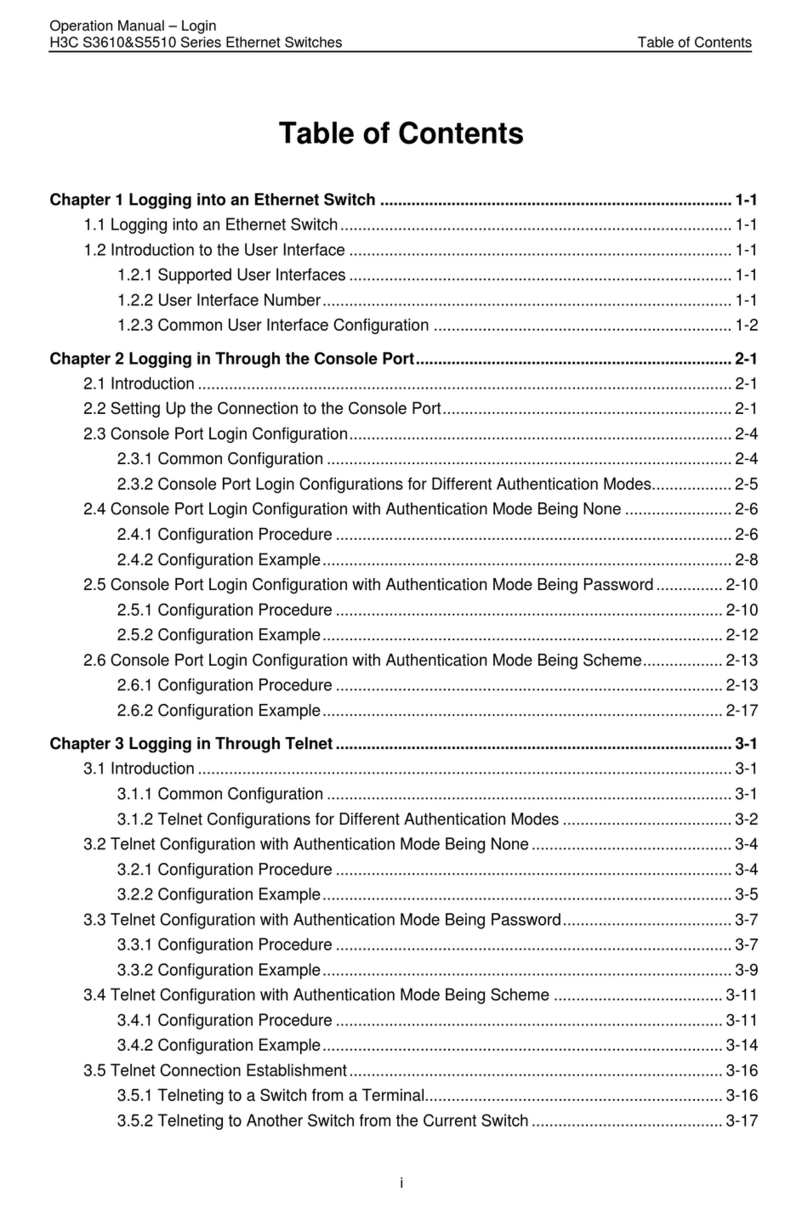

3 Accessing the switch for the first time······················································3-1

Setting up the configuration environment ·······································································································3-1

Connecting a console cable····························································································································3-1

Connecting a DB9-to-RJ45 console cable······························································································3-1

Connecting a USB-to-RJ45 console cable······························································································3-2

Connecting a Mini USB console cable············································································································3-4

Setting terminal parameters····························································································································3-6

Powering on the switch···································································································································3-6

4 Setting up an IRF fabric···········································································4-1

IRF fabric setup flowchart ·······························································································································4-1

Planning IRF fabric setup································································································································4-2

Planning IRF fabric size and the installation site·····················································································4-2

Identifying the master switch and planning IRF member IDs··································································4-2

Planning IRF topology and connections··································································································4-2

Identifying physical IRF ports on the member switches··········································································4-3

Planning the cabling scheme··················································································································4-4

Configuring basic IRF settings························································································································4-5

Connecting the physical IRF ports··················································································································4-5

Verifying the IRF fabric setup··························································································································4-6

5 Maintenance and troubleshooting····························································5-1

Power module failure ······································································································································5-1

Symptom·················································································································································5-1

Solution···················································································································································5-1