2

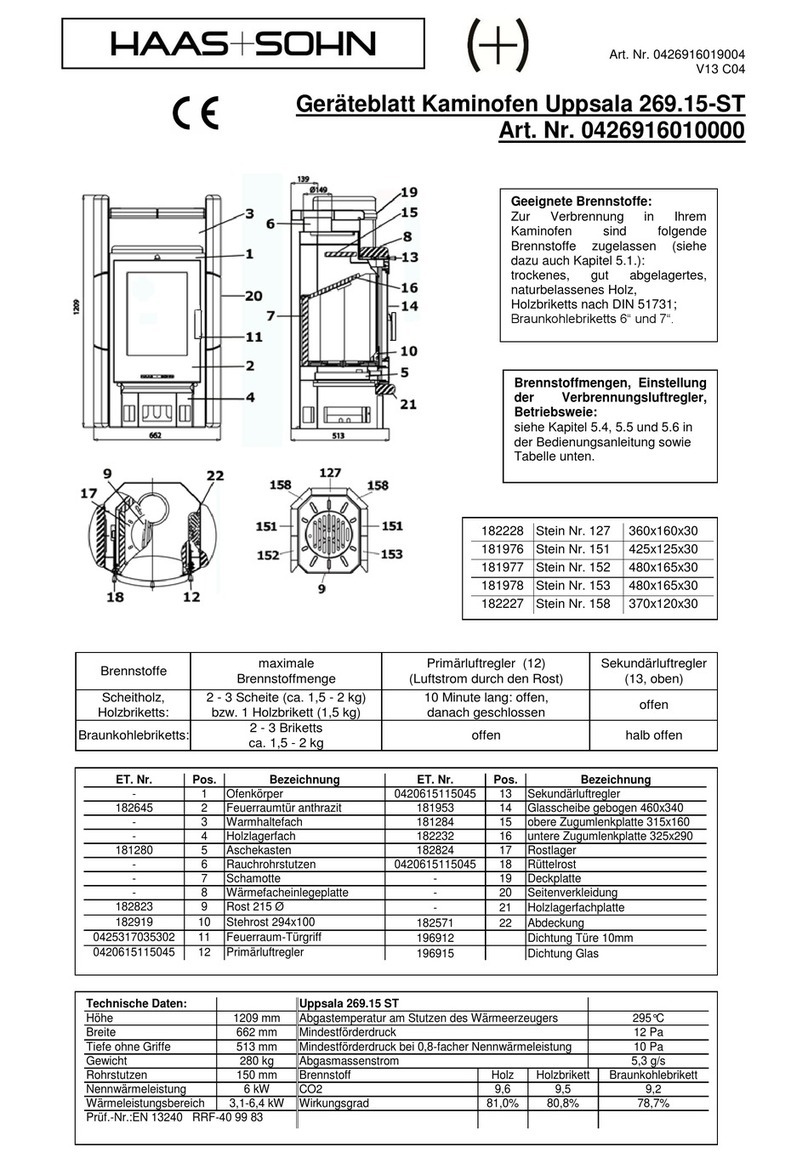

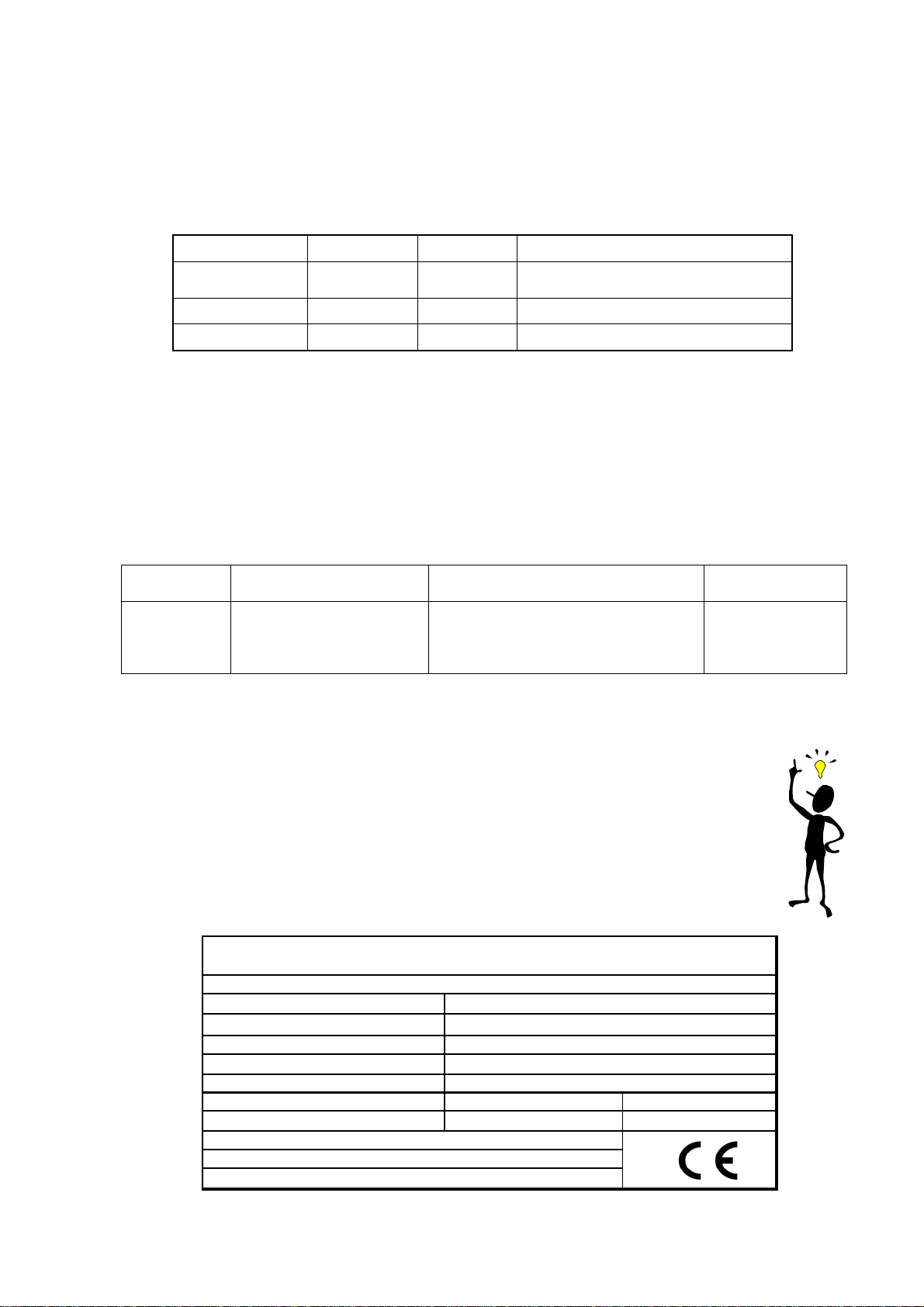

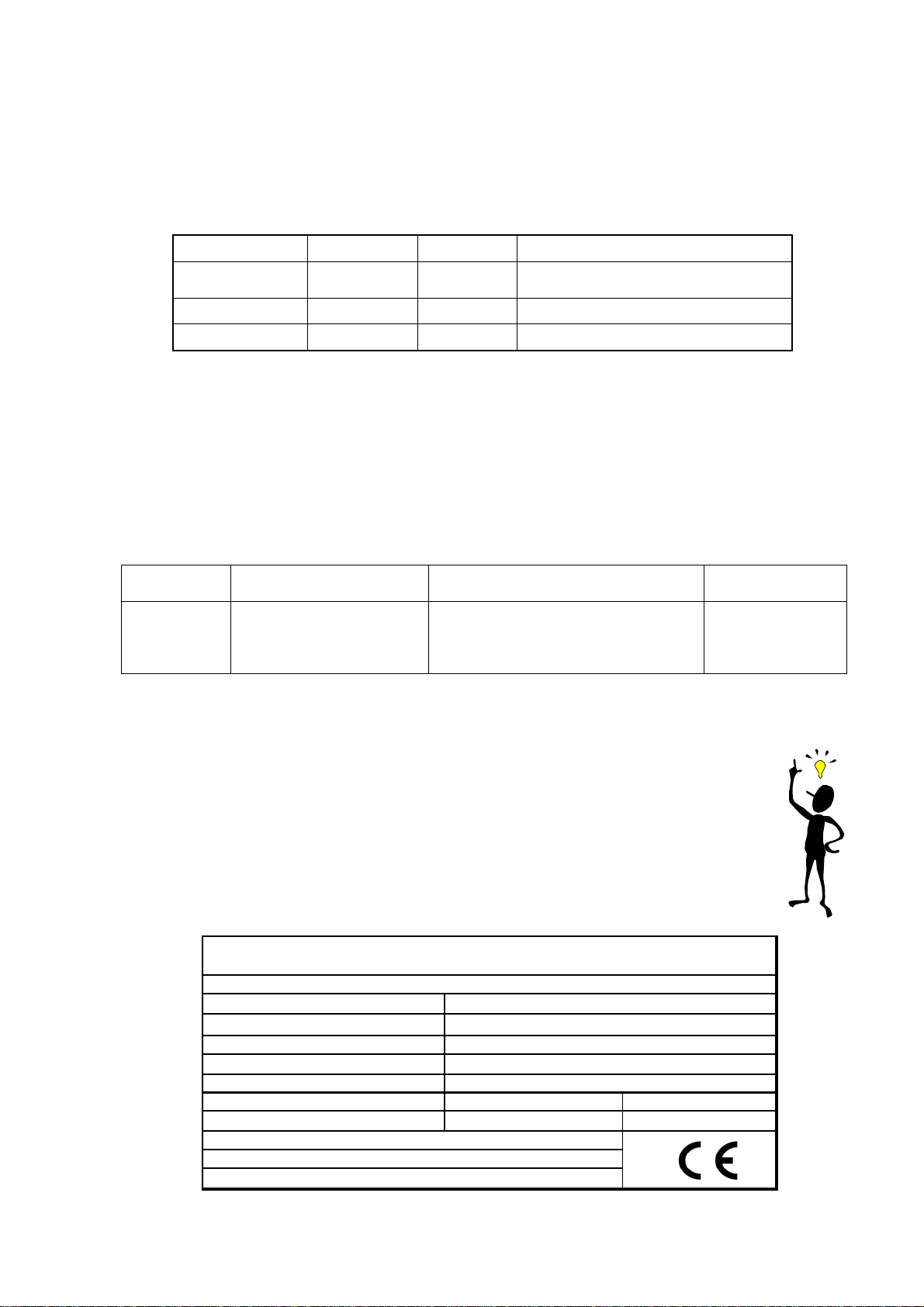

Nennwärmeleistung

Zugelassener Brennstoff:

Staub bez.auf 13% O2:28mg/Nm³ Wirkungsgrad: 81,7% CO:0,08%

Prüf Nr. VKF: 11108 NOx: 93 mg/Nm³ HC: 44 mg/Nm³

Herstellnummer: JI 03 000085

Wärmeleistungsbereich: 4,7 -9,2kW

HAAS + SOHN OFENTECHNIK GMBH

URSTEIN NORD 67 A-5412 PUCH

Kamineinsatz Bauart : EN 13229-W / Zeitbrandfeuerstätte

Typenbezeichnung: Opus 186.18/1-AL

8,0 kW

Holz, Holzbrikett nach -DIN 51731,

Prüfstellenkennziffer: 1625 / Prüf Nr. RRF-29 06 1188

Lesen und befolgen Sie die Bedieungsanleitung!

Mehrfachbelegung des Schornsteins ist zulässig

The system for supplying the air needed for combustion in stove unit type 186.18-AL has three settings: the

primary air is adjusted by means of the air intake control (7). With the handle in position 2 (‘right’) the primary air

I enters through the grate, and the primary air II enters through that area of the combustion chamber which is to

wards the front of the stove. With the handle in position 1 (‘middle’) the primary air I only enters via the grate.

The amount of secondary air is set at an optimum level for the unit to provide the necessary ventilation to keep

the window clean and to provide the necessary air for secondary combustion; it is permanently adjusted for

increased comfort. The pre-heated secondary air flows past the top end of the inspection window (8).

Air intake control Primary air I Primary air II Use:

"right" open open

For use when it is heating up and after

fuel has been added

"middle" shut open In normal operation

"left" shut shut Only for keeping the embers glowing

Connection for providing the air needed for combustion:

In airtight buildings there can be reduction in the oxygen content of the room in which the stove is set up; it must

therefore be ensured that there is adequate ventilation. The stove unit type 186.18-AL therefore offers you the

possibility of drawing in the air needed for combustion from outside. The stove can then be operated without

having to depend on the air within the room. In order to do this the air from outside that is needed for combustion

is supplied by means of a flexible pipe attached to the socket for the pipe (18). It is possible for you to change the

position of the pipe socket to the left, right or rear of the stove unit. The end of the pipe carrying the air must be

located in the open air, or in a well ventilated room situated within the building. Operation of the stove unit in

connection with an air conditioning and ventilation system is permitted. When installing the stove unit in

connection with an automatic air conditioning and ventilation system the end of the pipe supplying the air must not

be located in a room which is connected to this system.

Fuels Amount of fuel Primary air:

air intake control Secondary air

(not adjustable)

Chopped

wood

Wood

briquettes:

2 to 3 pieces of

wood (approx. 2 to 2.5kg)

or 1 wood briquette (2kg)

For approximately 10 minutes: open

(handle to the right),

then operate with the handle in

the middle position

open

The amount of fuel and adjustment of the air intake control:

Lighting, and heating the appliance up: see sections 5.4, 5.5 and 5.6 in the instructions for use of the stove.

Use the gloves provided to protect you against the heat when operating the air intake control.

Before every addition of fuel, the air intake control is to be closed completely (handle setting ‘left’).

Tip for burning wood: Every time the stove is lit leave the appliance in the ‘right’ position until the

fuel is burning well (around 10 minutes). (This time can vary somewhat depending on the amount of

draught and the pressures involved).

When adding fuel shut the air intake as indicated.

Specification plate: