Habasit Italiana S.p.A.

Via del Lavoro 50

I-31016 –Cordignano (TV)

Tel.: +39 0438 9113

Fax: +39 0438 912374

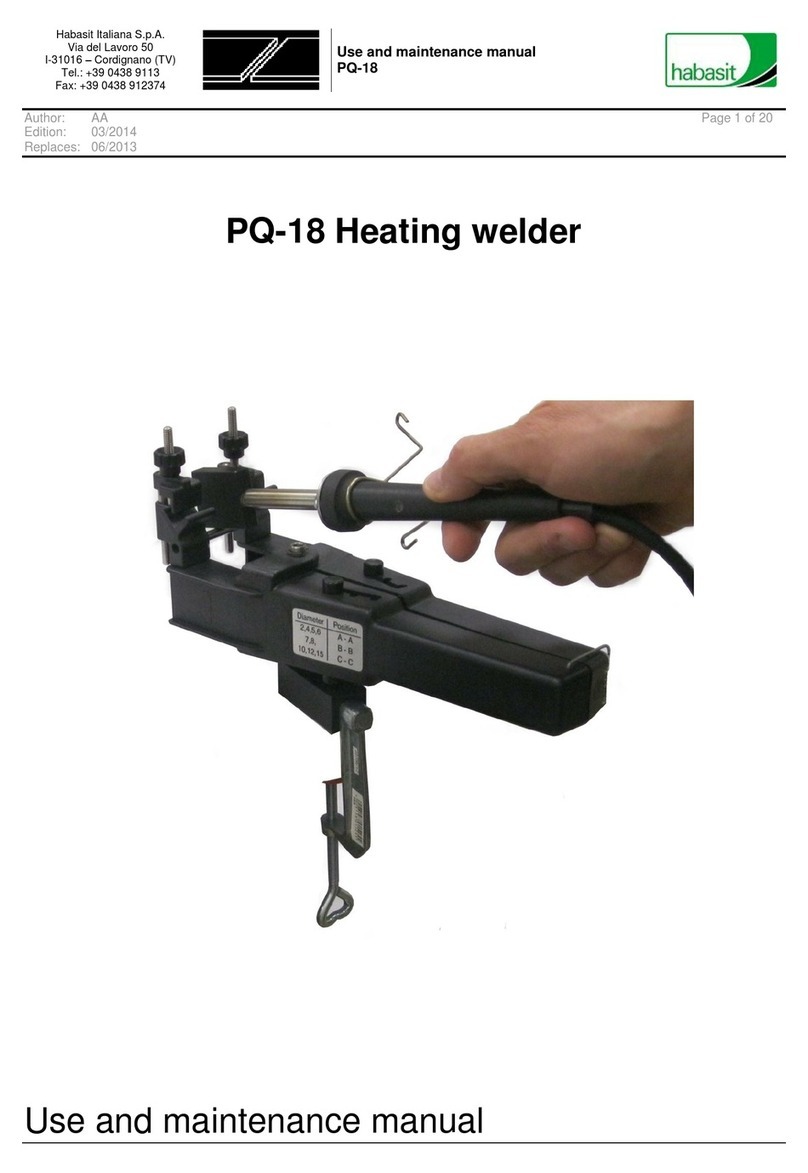

Use and maintenance manual

W-01

Author: FT Page 3 of 15

Edition: 06/2017 R. 0

Replaces:

CONTENTS

SAFETY WARNINGS!.......................................................................................................................................2

0INTRODUCTION.........................................................................................................................................4

1GENERAL INFORMATION........................................................................................................................4

1.1 Application..........................................................................................................................................4

1.2 Important safety terms........................................................................................................................4

1.3 EC declaration of conformity ..............................................................................................................6

1.4 EC plates............................................................................................................................................7

2GENERAL DESCRIPTION.........................................................................................................................7

3TECHNICAL DATA ....................................................................................................................................8

4OPERATING MODE...................................................................................................................................8

5GETTING STARTED ..................................................................................................................................9

6WELDING OF ROUND BELTS................................................................................................................10

7MAINTENANCE........................................................................................................................................10

7.1 Measuring of the plate temperature on the welder W-01/6 or W-01/8.............................................10

7.2 Replacement of the power cord on welder W-01/6 or W-01/8.........................................................11

7.3 Accessory/spare parts orders...........................................................................................................11

7.4 Warranty...........................................................................................................................................11

7.5 Technical consulting.........................................................................................................................11

8DISMANTLING AND SCRAPPING..........................................................................................................12

9SPARE PARTS.........................................................................................................................................13

10 CUSTOMER SERVICE.............................................................................................................................13

11 A1 - PREVENTIVE MAINTENANCE CHECKLIST..................................................................................14

12 A2 - PREVENTIVE MAINTENANCE SUMMARY SHEET.......................................................................15