3

Table of Contents

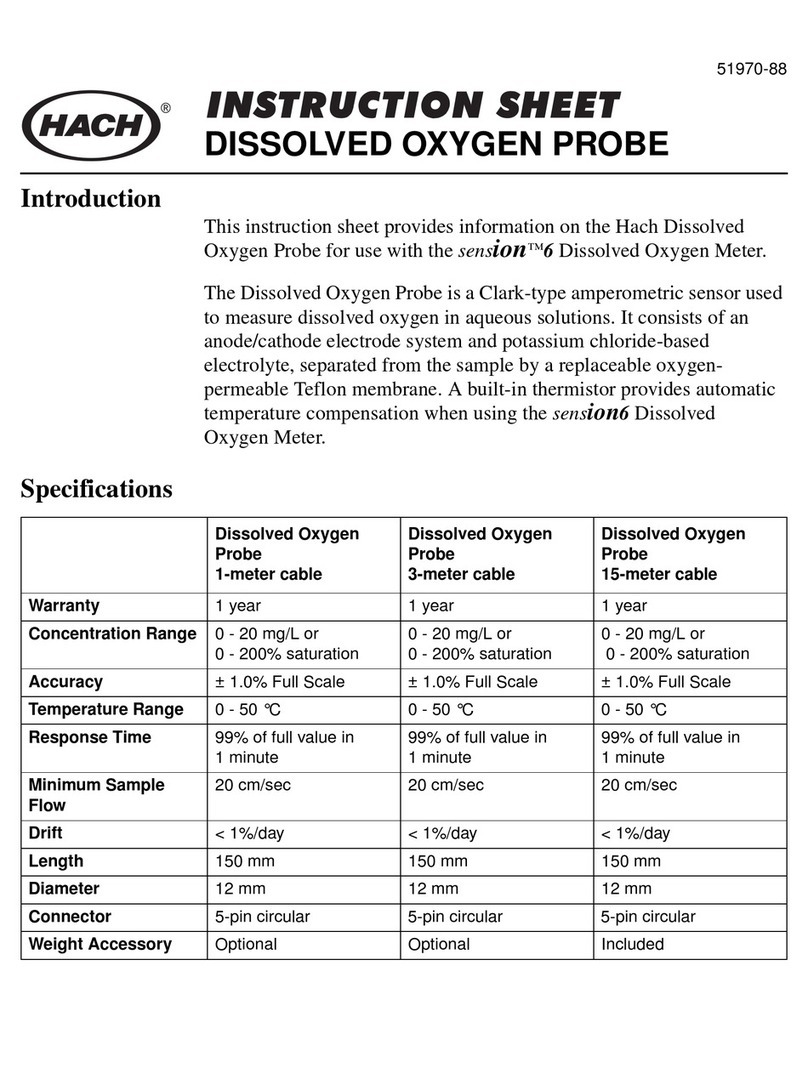

Section 1 Specifications ........................................................................................................................ 5

1.1 Dimensions ................................................................................................................................... 6

Section 2 General Information............................................................................................................... 7

2.1 Safety information......................................................................................................................... 7

2.1.1 Use of hazard information.................................................................................................... 7

2.1.2 Precautionary labels ............................................................................................................ 7

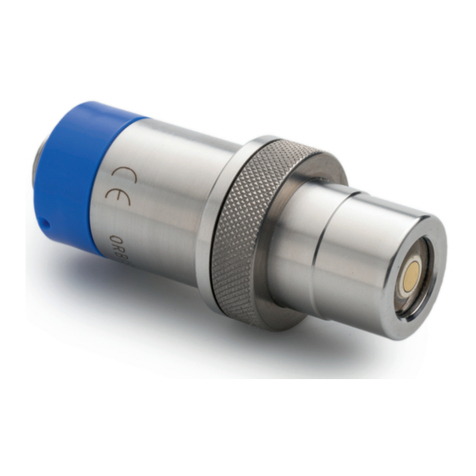

2.2 General sensor information........................................................................................................... 8

2.3 Theory of operation....................................................................................................................... 9

Section 3 Installation ............................................................................................................................ 11

3.1 Unpacking the sensor ................................................................................................................. 11

3.2 Unpacking the sensor cartridge .................................................................................................. 11

3.3 Sensor assembly ........................................................................................................................ 13

3.4 Installation of the cleaning unit (optional).................................................................................... 15

3.5 Installation of the sensor in the sample flow ...............................................................................15

3.6 Connect the sensor to the sc controller (non-hazardous location) with quick-connect fittings.... 17

Section 4 Operation.............................................................................................................................. 19

4.1 Using an sc controller ................................................................................................................. 19

4.2 Sensor setup............................................................................................................................... 19

4.3 Sensor data logging.................................................................................................................... 19

4.4 Sensor diagnostics menu............................................................................................................ 19

4.5 Sensor setup menu..................................................................................................................... 20

4.6 Calibration................................................................................................................................... 22

4.6.1 Sensor code calibration ..................................................................................................... 22

4.6.2 Matrix correction overview ................................................................................................. 23

4.6.3 Matrix correction ................................................................................................................ 24

4.6.3.1 MATX1 correction (one point matrix correction)........................................................ 24

4.6.3.2 MATX1 CL- correction............................................................................................... 24

4.6.3.3 MATX2 correction (2nd point matrix correction)........................................................ 25

4.6.3.4 MATX2 CL- correction............................................................................................... 26

4.6.3.5 Value correction ........................................................................................................27

Section 5 Maintenance ......................................................................................................................... 29

5.1 Maintenance schedule................................................................................................................ 29

5.2 Clean the sensor......................................................................................................................... 29

5.2.1 Polish the chloride electrode.............................................................................................. 29

5.3 Replace the sensor cartridge...................................................................................................... 30

5.4 Storage ....................................................................................................................................... 32

Section 6 Troubleshooting................................................................................................................... 33

6.1 Error codes ................................................................................................................................. 33

6.2 Warning codes............................................................................................................................ 33

6.3 Troubleshooting ......................................................................................................................... 34

6.3.1 Troubleshooting during operation ...................................................................................... 34

6.3.2 Troubleshooting during calibration..................................................................................... 36

Section 7 Spare Parts and Accessories.............................................................................................. 37

7.1 Spare parts ................................................................................................................................. 37

7.2 Accessories................................................................................................................................. 37

7.3 Validation accessories ................................................................................................................ 37

7.4 Corresponding documentation.................................................................................................... 37

Section 8 Contact information............................................................................................................. 39

Section 9 Warranty and liabilityLimited warranty.............................................................................. 41