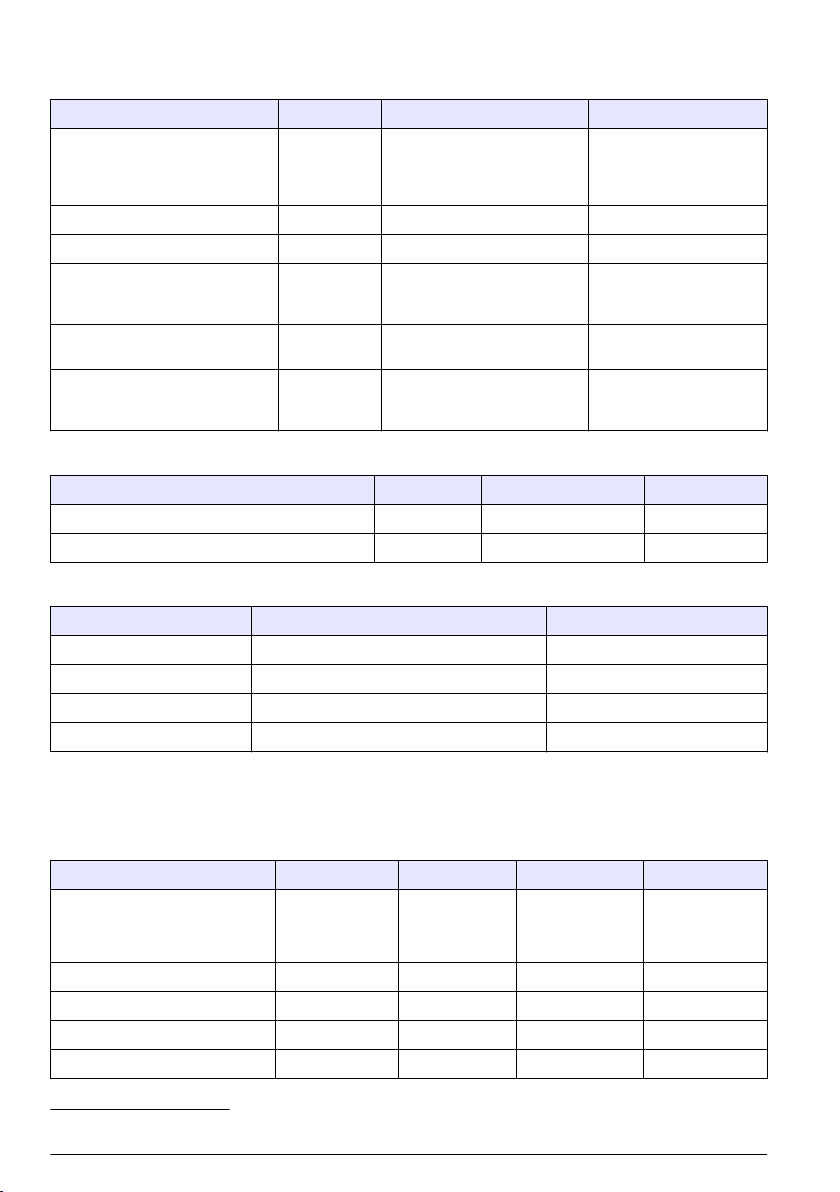

Table of Contents

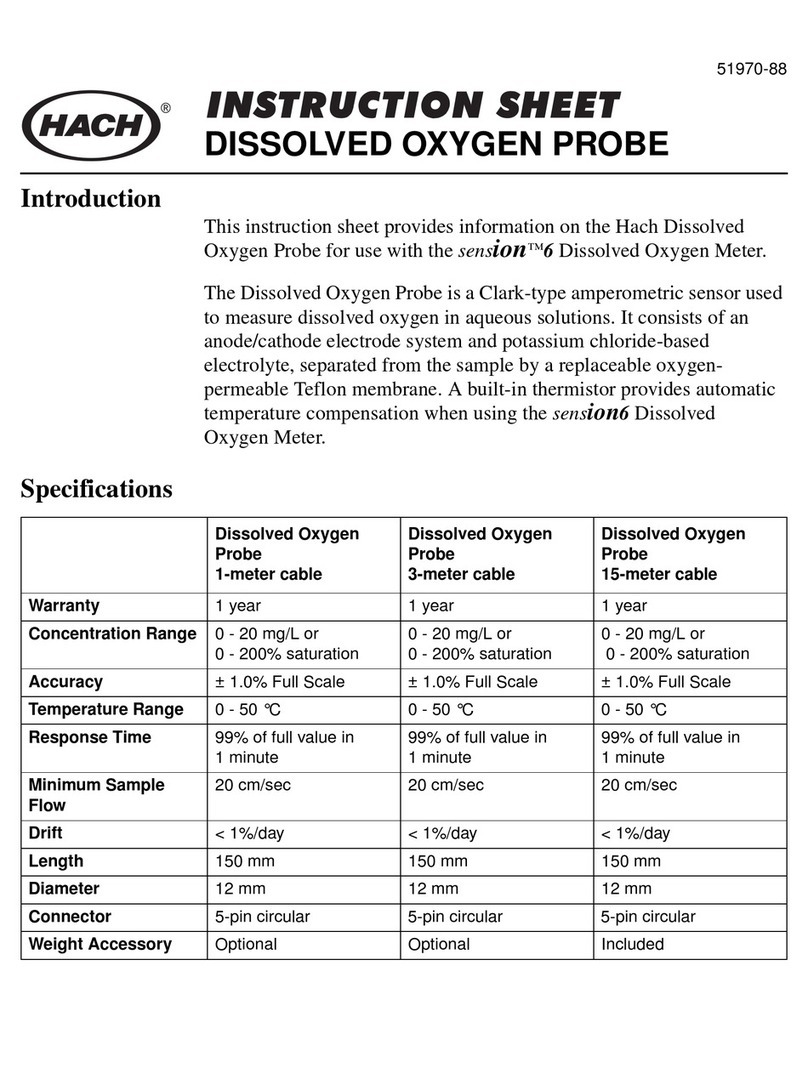

Section 1 Specifications........................................................................................ 3

1.1 Sensor specifications............................................................................................ 3

1.2 Sensor configurations........................................................................................... 4

1.3 Sensor membrane specifications.......................................................................... 4

1.3.1 Oxygen sensors (Table 1).......................................................................... 4

1.3.2 Oxygen sensors (Table 2).......................................................................... 5

Section 2 General information............................................................................ 6

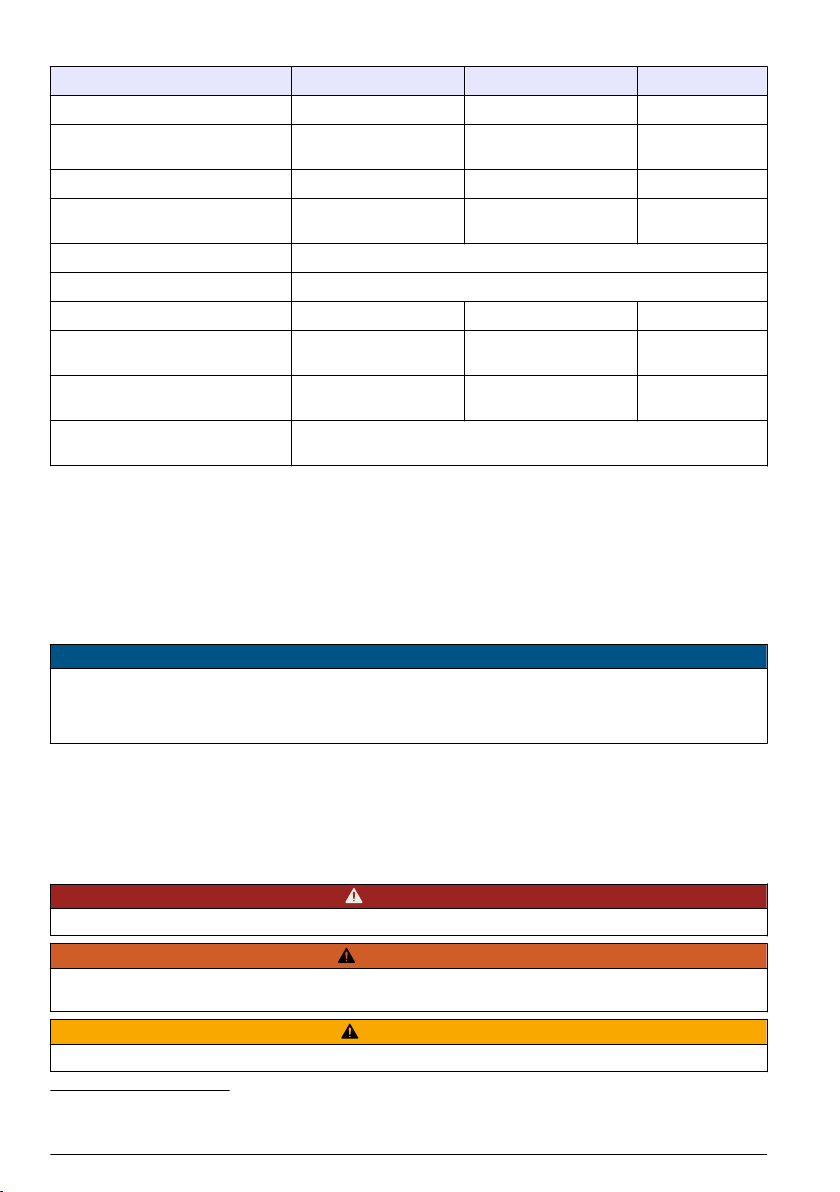

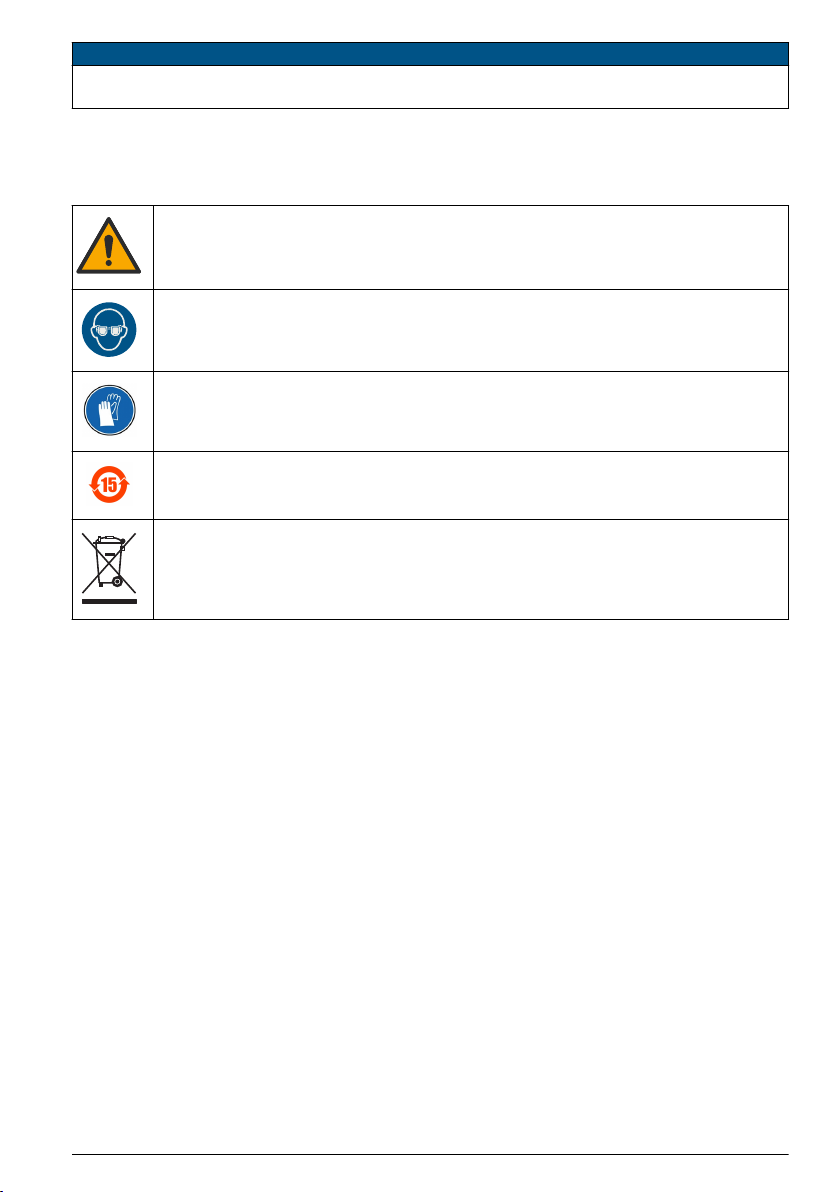

2.1 Safety information................................................................................................. 6

2.1.1 Use of hazard information.......................................................................... 6

2.1.2 Precautionary labels................................................................................... 7

2.2 Product overview.................................................................................................. 7

2.2.1 Operating principle..................................................................................... 7

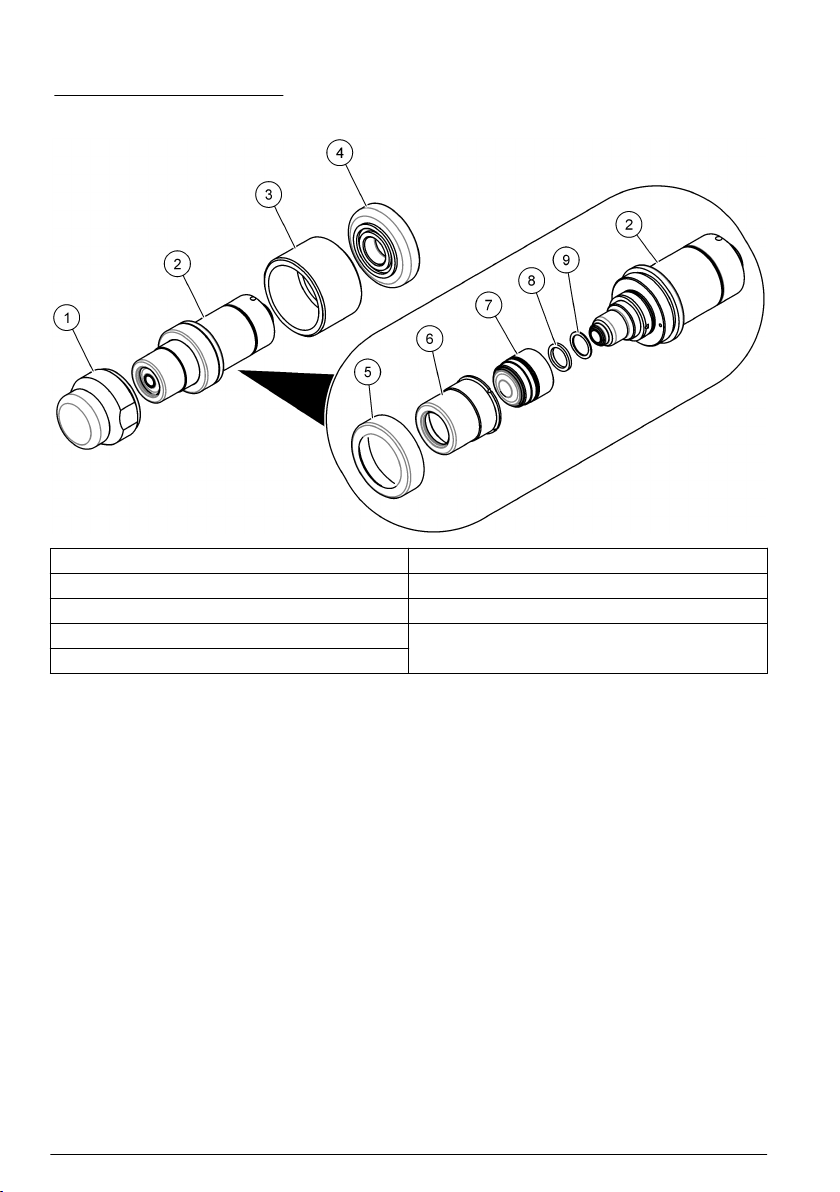

2.2.2 Sensor components.................................................................................... 8

2.3 Product components............................................................................................. 8

2.3.1 Electrochemical sensor.............................................................................. 9

2.3.2 Protection caps........................................................................................... 9

2.3.3 Sensor recharge kit.................................................................................... 9

Section 3 Installation............................................................................................. 10

3.1 Sensor preparation............................................................................................. 10

3.2 Sensor installation.............................................................................................. 13

3.2.1 Sensor positioning information................................................................. 13

3.2.2 Sensor insertion........................................................................................ 14

3.2.3 Sensor removal........................................................................................ 14

3.3 Accessories installation...................................................................................... 15

3.3.1 External pressure sensor.......................................................................... 15

3.3.2 Weld-on stainless steel socket................................................................. 15

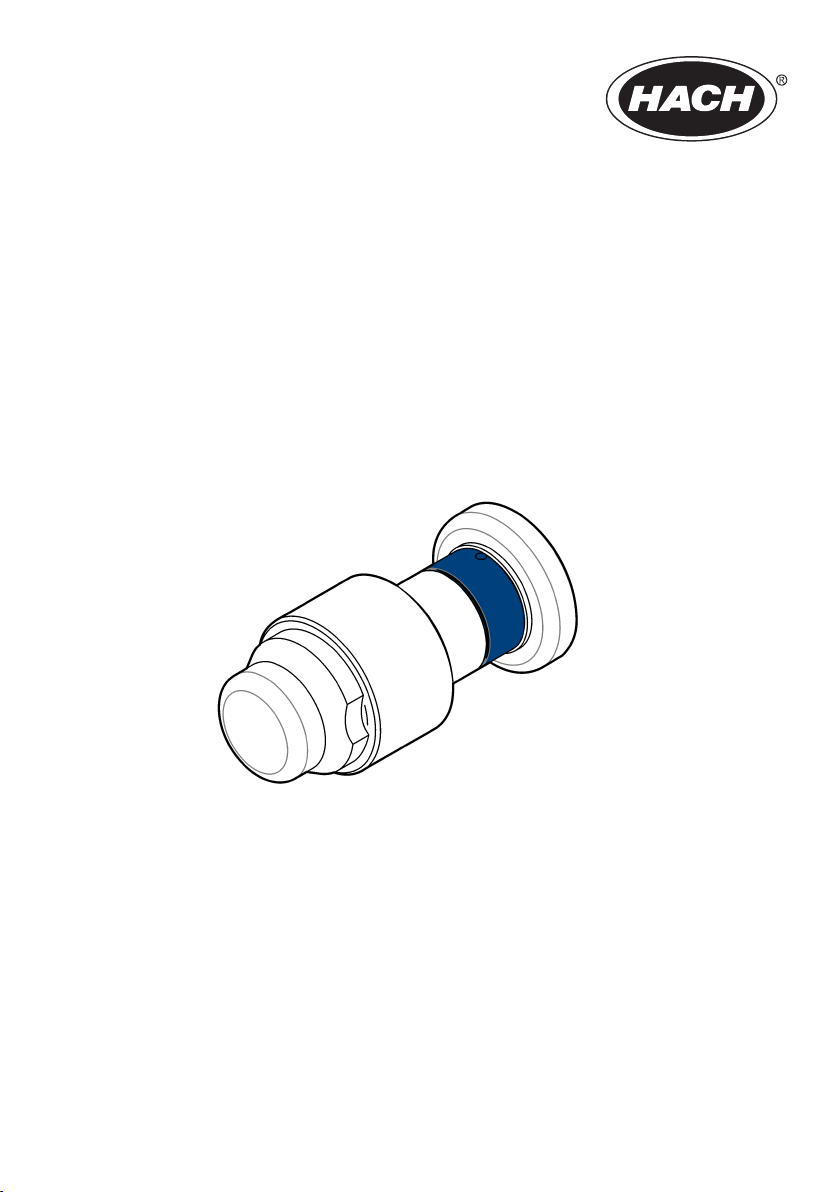

3.3.3 The 32003 insertion/extraction valve........................................................ 16

3.3.4 The 33095 sensor housing....................................................................... 17

3.3.5 Tuchenhagen Varivent® in-line access unit.............................................. 17

3.3.6 ORBISPHERE flow chambers.................................................................. 18

3.3.7 Multi-parameter flow chamber.................................................................. 19

Section 4 Maintenance......................................................................................... 20

4.1 Maintenance schedule........................................................................................ 21

4.2 Prerequisites for sensor maintenance................................................................ 21

4.3 Membrane replacement and sensor head cleaning............................................ 22

Section 5 Troubleshooting................................................................................. 28

5.1 Oxygen sensor.................................................................................................... 28

Section 6 Replacement parts and accessories......................................... 29

1