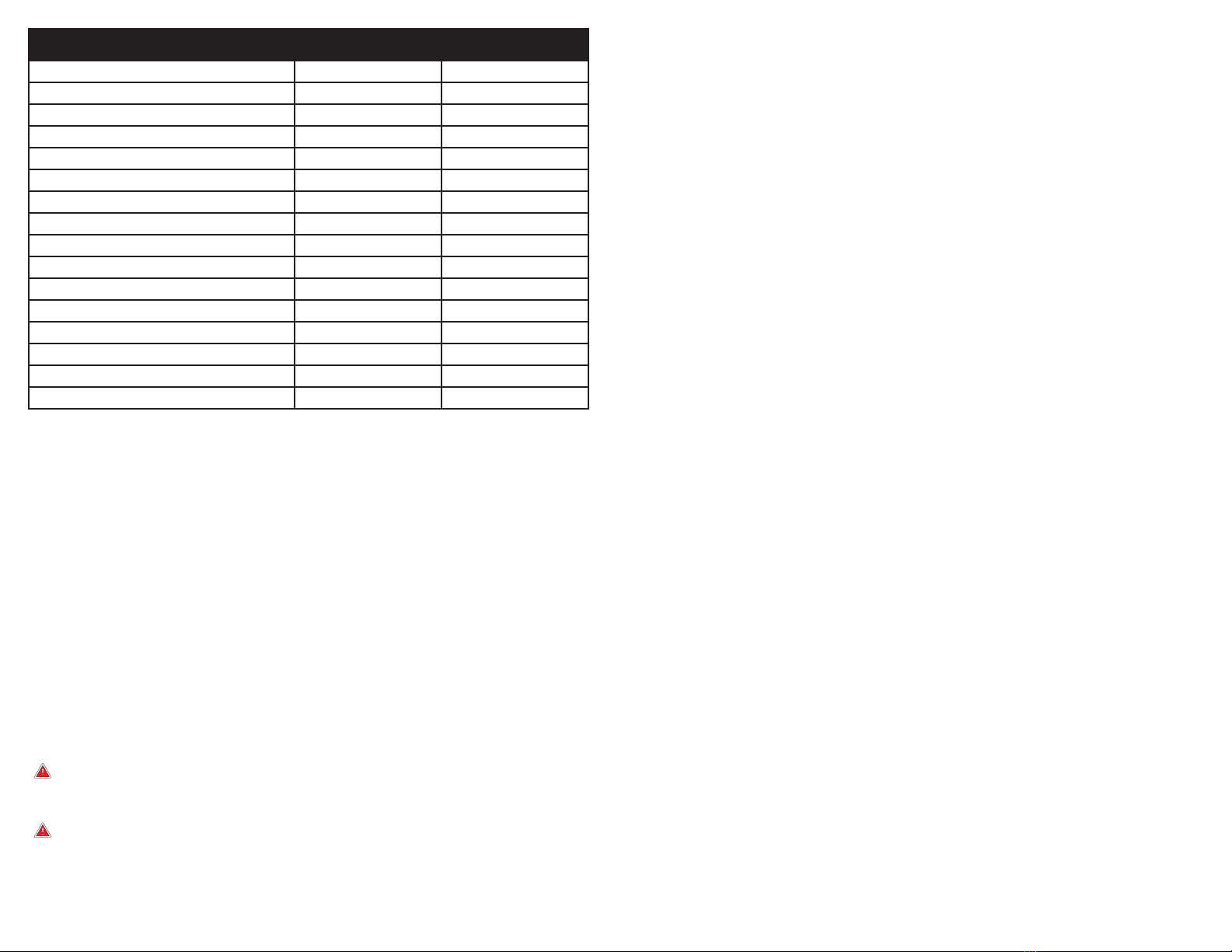

3-STAGE RO SYSTEM – MODEL HAGUE REVERSE OSMOSIS

U.S. Metric

Membrane Production135 gpd 132 lpd

195% minimum 95% minimum

213.32 gpd 50.4 lpd

2

1000 ppm 1000 ppm

10 gpg 2.64 gpL

3.0 ppm 3.0 ppm

23.2 gallons 12.11 liters

317.91% 17.91%

Recovery429.43% 29.43%

SPECIFICATIONS – QUALIFIED SYSTEM PERFORMANCE

1.

Membrane that has been rinsed for 24 hours. The production rate of a new Membrane can

decrease by 10% per year or more, depending upon the scaling and fouling tendencies of the

2.

3.

typical daily usage.

4.

system that is available to the user as reverse osmosis treated water when the system is

operated without a storage tank or when the storage tank is bypassed.

NON-POTABLE WATER SOURCES:

ARSENIC REDUCTION:

Arsenic (abbreviated As) is found naturally in some well water. Arsenic in water has no color,

well, you can have the water tested. The local health department or the state environmental

lab to determine what type and how much of each type of arsenic is in the water. Check with the

labs in your area to see if they can provide this type of service.

Reverse osmosis (RO) water treatment systems do not fully remove trivalent arsenic from water.

rapidly convert trivalent arsenic to pentavalent arsenic. Other water treatment chemicals such

as ozone and potassium permanganate will also change trivalent arsenic to pentavalent arsenic.

A combined chlorine residual (also called chloramine) may not convert all the trivalent arsenic.

combined chlorine is used in the water system.

arsenic to pentavalent arsenic. The system was tested in a lab. Under testing conditions, the

Have the treated water tested for arsenic to check whether the system is working properly.

NITRATE/NITRITE TEST KIT:

test kit. Product water should be monitored periodically according to the instructions provided

with the test kit.

INSTALLATIONS IN THE COMMONWEALTH OF MASSACHUSETTS:

of Massachusetts must be followed in these cases.