507787G02 / 31-5000675-1Issue 2336Page 4 of 22

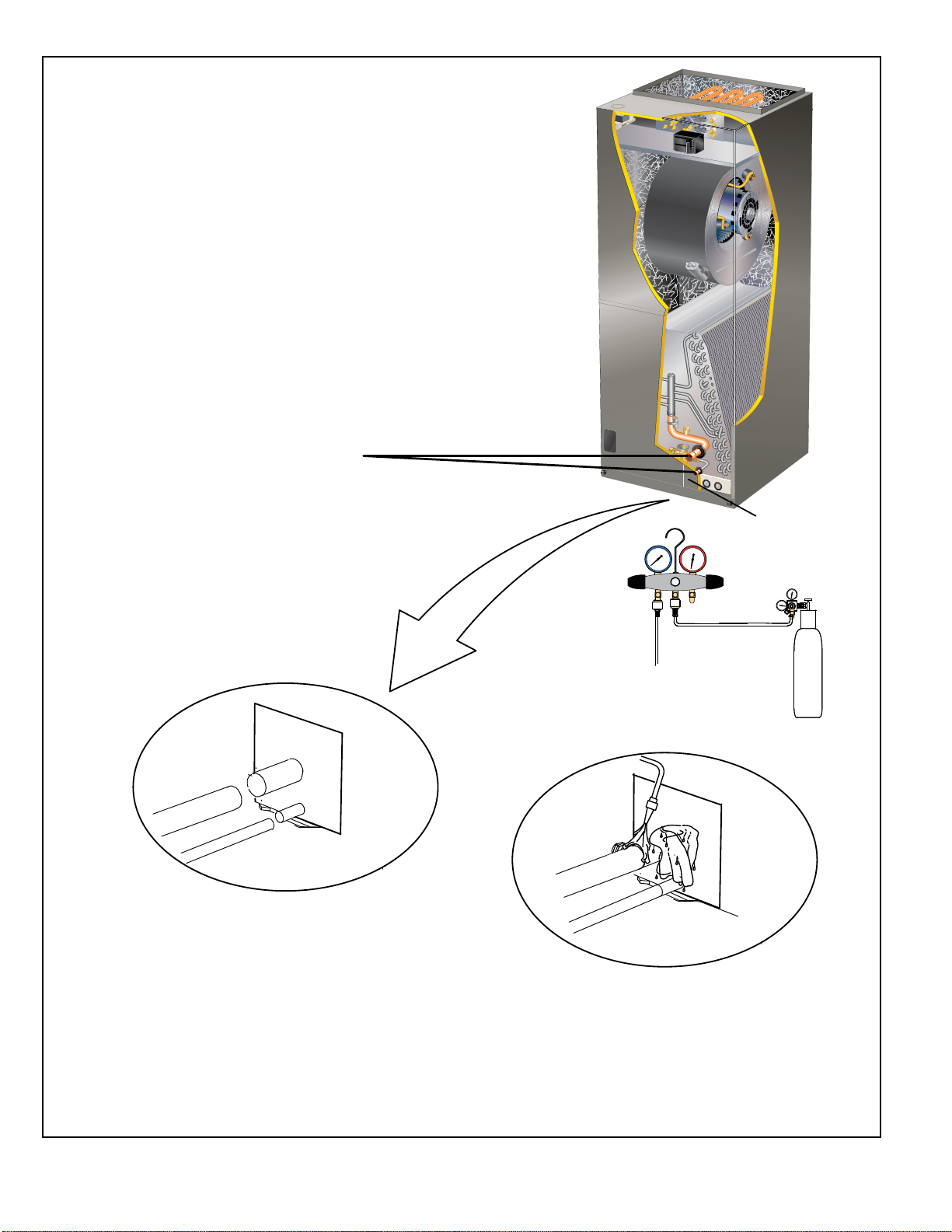

([FHVVLYHFRQGHQVDWLRQPD\RFFXULIWKHXQLWLVLQVWDOOHG

LQDZDUPKXPLGSODFH:KHQWKHXQLWLVLQVWDOOHGLQDQ

XQFRQGLWLRQHG VSDFH DSSO\ VHDODQW DURXQG HOHFWULFDO

ZLUHV UHIULJHUDQW SLSLQJ DQG FRQGHQVDWH OLQHV DW WKH

SRLQWZKHUHWKH\HQWHUWKHFDELQHW

$SSO\ VHDODQW RQ WKH LQVLGH RI WKH FDELQHW DW WKH

SRLQW ZKHUH WKH HOHFWULFDO ZLUHV H[LW WKURXJK WKH

FRQGXLW RSHQLQJ 7KLV ZLOO DOVR NHHS ZDUP DQG PRLVW

XQFRQGLWLRQHGDLURXWRIWKHDLU KDQGOHUFDELQHWZKHUH

LW ZLOO IRUP FRQGHQVDWH RQ WKH FRROHU FRQWURO ER[ DQG

HOHFWULFDOFRQWUROV

IMPORTANT

7KLV XQLW LV DSSURYHG IRU LQVWDOODWLRQ FOHDUDQFH WR

FRPEXVWLEOH PDWHULDO DV VWDWHG RQ WKH XQLW UDWLQJ

SODWH $FFHVVLELOLW\ DQG VHUYLFH FOHDUDQFHV PXVW WDNH

SUHFHGHQFHRYHUFRPEXVWLEOHPDWHULDOFOHDUDQFHV

7KHDLUKDQGOHUPXVWEHLQVWDOOHGVRWKDWIUHHDFFHVVLV

DOORZHGWRWKHFRLO¿OWHUFRPSDUWPHQWDQGEORZHUFRQWURO

FRPSDUWPHQW

IMPORTANT

• 'XULQJ FRROLQJ RSHUDWLRQ H[FHVVLYH VZHDWLQJ PD\

RFFXU LI WKH DLU KDQGOHU LV LQVWDOOHG LQ D ZDUP DQG

KXPLGVSDFH

• ,ILQVWDOOHGLQDQXQFRQGLWLRQHGVSDFHVHDODQWVKRXOG

EH DSSOLHG DURXQG WKH HOHFWULFDO ZLUHV UHIULJHUDQW

WXELQJ DQG FRQGHQVDWH OLQHV ZKHUH WKH\ HQWHU WKH

FDELQHW

• (OHFWULFDOZLUHVVKRXOGEHVHDOHGRQWKHLQVLGHZKHUH

WKH\ H[LW WKH FRQGXLW RSHQLQJ 6HDODQW LV UHTXLUHG WR

SUHYHQWDLUOHDNDJHLQWRDQGFRQGHQVDWHIURPIRUPLQJ

LQVLGHRIWKHDLUKDQGOHUWKHFRQWUROER[DQGRQWKH

HOHFWULFDOFRQWUROV

Use of Air Handler During Construction

8QLWVPD\EHXVHGIRUKHDWLQJKHDWSXPSVRUFRROLQJRI

EXLOGLQJVRUVWUXFWXUHVXQGHUFRQVWUXFWLRQLIWKHIROORZLQJ

FRQGLWLRQVDUHPHWWRHQVXUHSURSHURSHUDWLRQ

DO NOT USE THE UNIT FOR CONSTRUCTION HEAT

UNLESS ALL OF THE FOLLOWING CRITERIA ARE

MET:

• $ URRP WKHUPRVWDW PXVW FRQWURO WKH DLU KDQGOHU 7KH

XVHRI¿[HGMXPSHUVLVQRWDOORZHG

• $LU¿OWHUPXVWEHLQVWDOOHGLQWKHV\VWHPDQGPXVWEH

PDLQWDLQHGGXULQJFRQVWUXFWLRQ

• $LU ¿OWHU PXVW EH UHSODFHG XSRQ FRQVWUXFWLRQ

FRPSOHWLRQ

• 7KHDLUKDQGOHUHYDSRUDWRUFRLOVXSSO\IDQDVVHPEO\

DQGGXFWV\VWHPPXVWEHWKRURXJKO\FOHDQHGIROORZLQJ

¿QDOFRQVWUXFWLRQFOHDQXS

• $OO DLU KDQGOHU RSHUDWLQJ FRQGLWLRQV PXVW EH YHUL¿HG

DFFRUGLQJWRWKHVHLQVWDOODWLRQLQVWUXFWLRQV

(48,30(17 0$< (;3(5,(1&( 35(0$785(

&20321(17)$,/85($6$5(68/72))$,/85(72

)2//2:7+($%29(,167$//$7,21,16758&7,216

)$,/85( 72 )2//2: 7+( $%29( ,167$//$7,21

,16758&7,216 92,'6 7+( 0$18)$&785(5¶6

(48,30(17 /,0,7(' :$55$17< GEA ',6&/$,06

$// /,$%,/,7< ,1 &211(&7,21 :,7+ ,167$//(5¶6

)$,/85( 72 )2//2: 7+( $%29( ,167$//$7,21

,16758&7,216

127:,7+67$1',1*7+()25(*2,1*,167$//(5,6

5(63216,%/()25&21),50,1*7+$77+(86(2)

&216758&7,21+($725&22/,1*,6&216,67(17

:,7+7+(32/,&,(6$1'&2'(62)$//5(*8/$7,1*

(17,7,(6$//68&+32/,&,(6$1'&2'(60867%(

ADHERED TO.

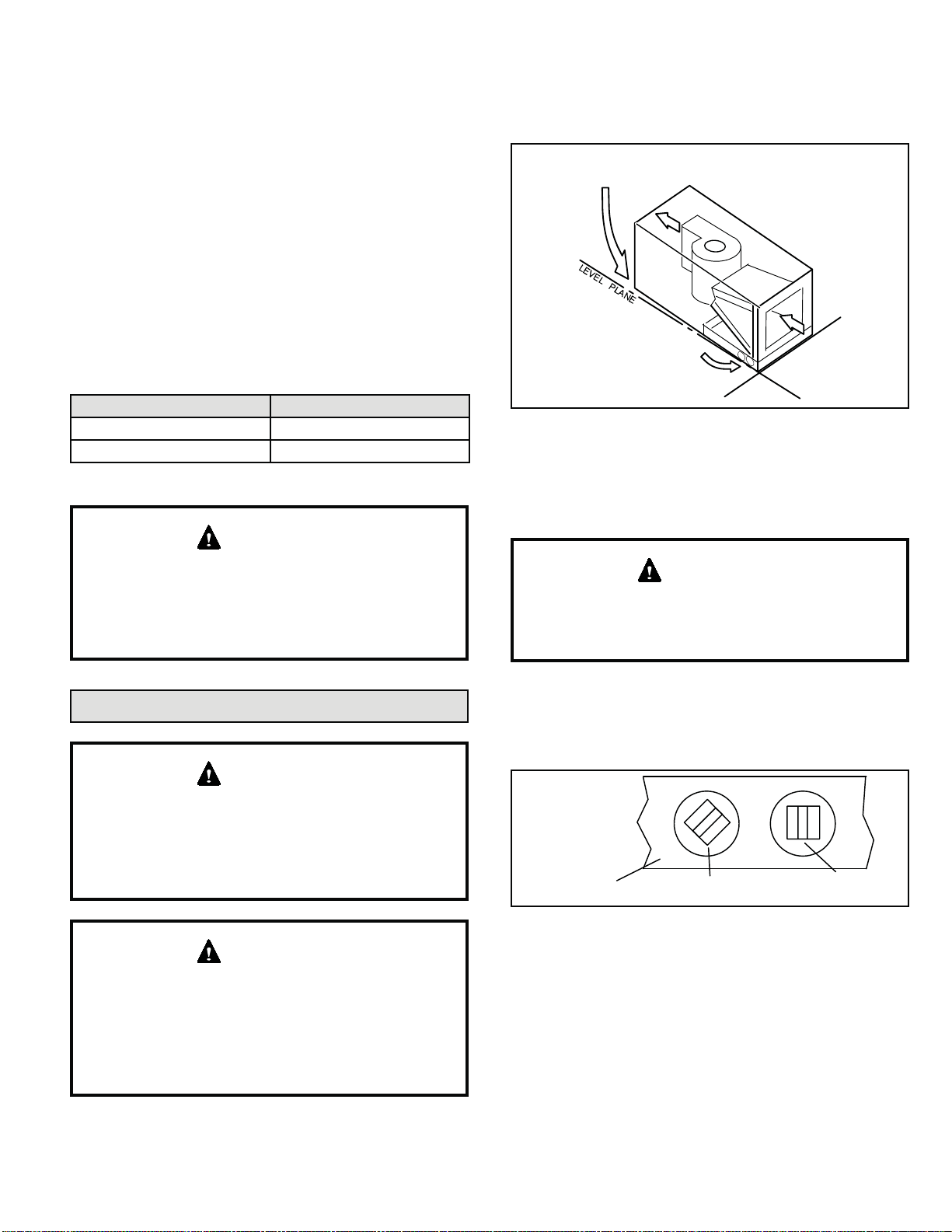

Installation Clearances

Non-Ducted Return Closet Installation

7KH DLU KDQGOHU FDQ EH LQVWDOOHG LQ D FORVHW ZLWK D IDOVH

ERWWRPWRIRUPDUHWXUQDLUSOHQXP,WPD\DOVREHLQVWDOOHG

ZLWKDUHWXUQDLUSOHQXPXQGHUWKHDLUKDQGOHU

/RXYHUVRUUHWXUQDLUJULOOHVDUH¿HOGVXSSOLHG/RFDOFRGHV

PD\OLPLWDSSOLFDWLRQRIV\VWHPVZLWKRXWDGXFWHGUHWXUQWR

single-story buildings.

When a 1$03XQLWLVLQVWDOOHGLQDFORVHWZLWKDORXYHUHG

UHWXUQRSHQLQJWKHPLQLPXPRSHQDUHDIRUWKHORXYHUVZLOO

EH

• VTXDUHLQFKHVIRUDQGPRGHOV

• VTXDUHLQFKHVIRUDQGPRGHOV

• VTXDUHLQFKHVIRUWKUXPRGHOV

,IWKHIUHHDUHDLVQRWNQRZQDVVXPHDIUHHDUHDIRU

ZRRGRUDIUHHDUHDIRUPHWDOORXYHUVRUJULOOHV8VLQJ

WKHORXYHU GLPHQVLRQV DQG WKH RU DVVXPSWLRQ

determine if the open area meets the minimum open area

listed above.

,IDUHWXUQDLUSOHQXPLVXVHGWKHUHWXUQDLUJULOOHVKRXOGEH

LPPHGLDWHO\LQIURQWRIWKHRSHQLQJLQWKHSOHQXPWRDOORZ

IRUWKHIUHHÀRZRIUHWXUQDLU:KHQQRWLQVWDOOHGLQIURQWRI

WKHRSHQLQJWKHUHPXVWEHDGHTXDWHFOHDUDQFHDURXQGWKH

DLUKDQGOHUWRDOORZIRUWKHIUHHÀRZRIUHWXUQDLU

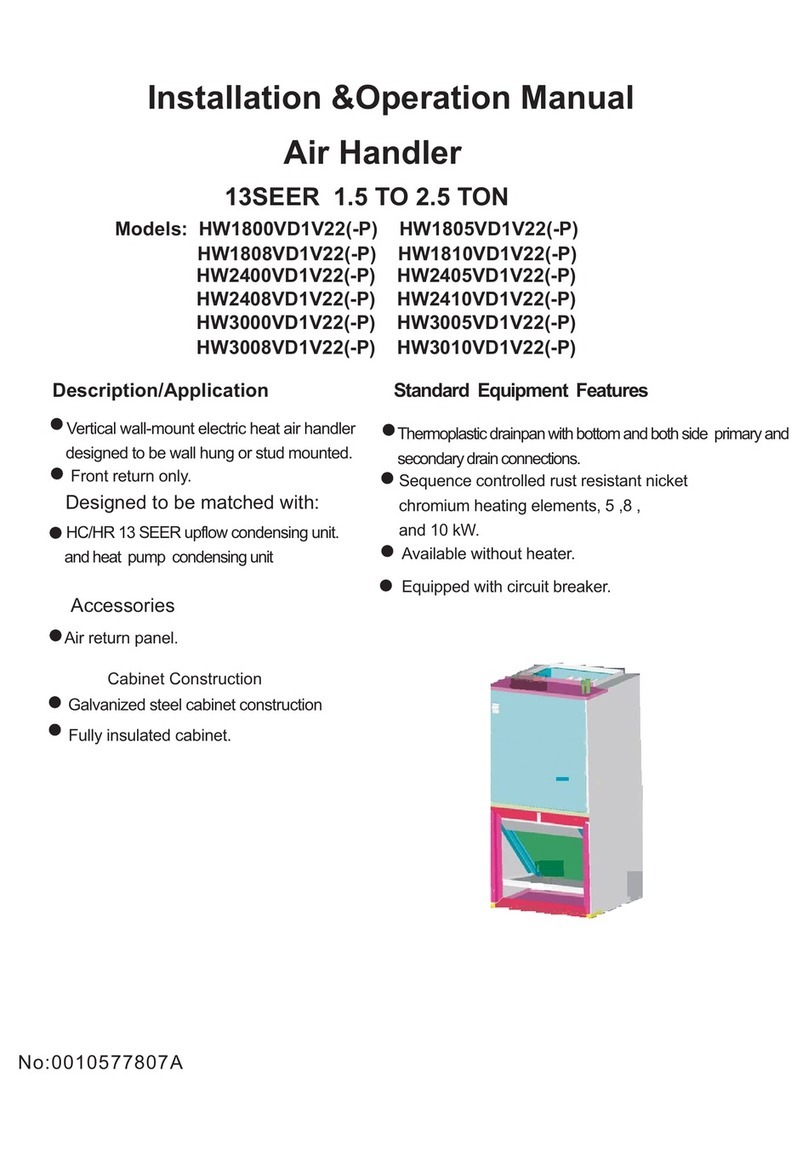

Installation

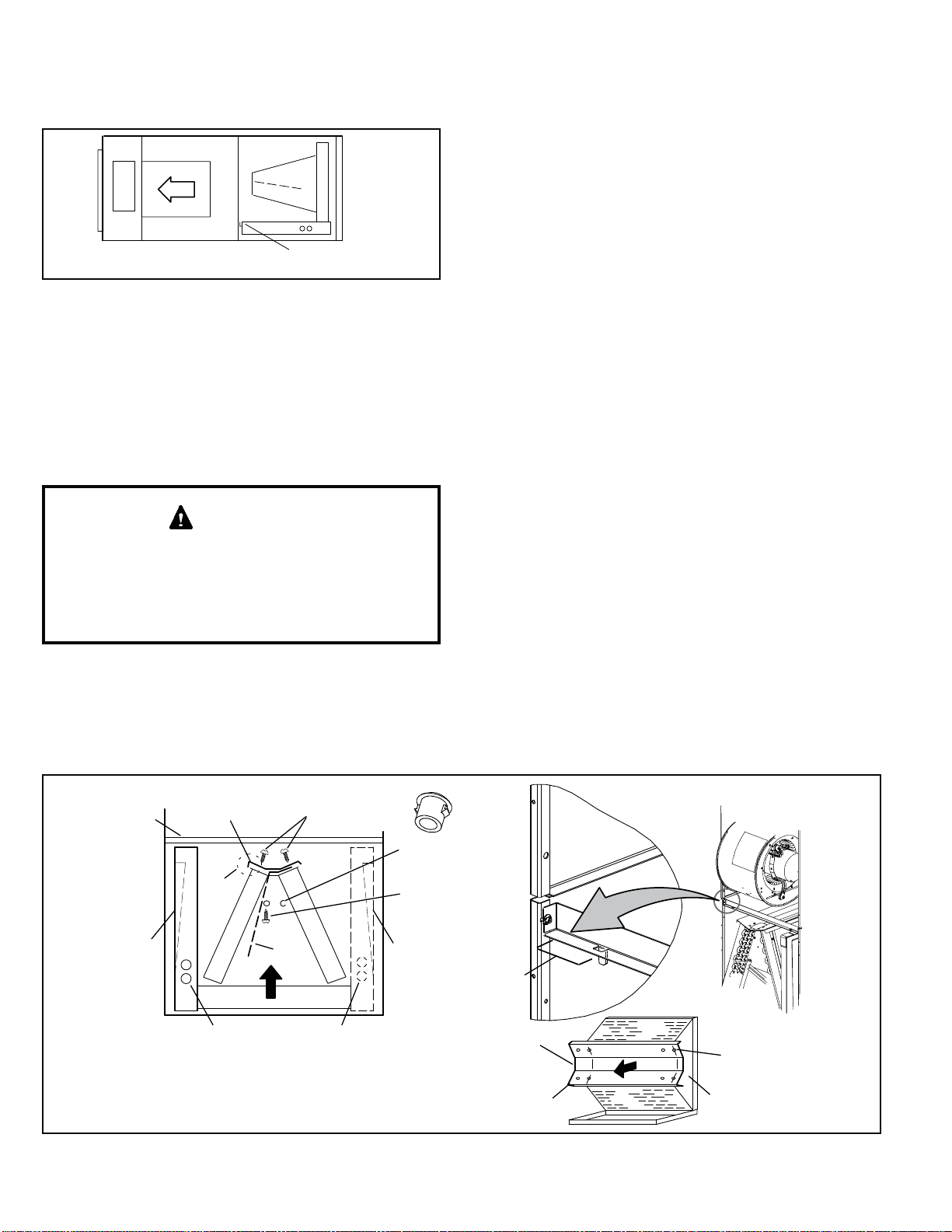

(DFKXQLW FRQVLVWV RIDEORZHU DVVHPEO\UHIULJHUDQW FRLO

DQG FRQWUROV LQ DQ LQVXODWHG JDOYDQL]HG VWHHO IDFWRU\

¿QLVKHG HQFORVXUH .QRFNRXWV DUH SURYLGHG IRU HOHFWULFDO

ZLULQJHQWUDQFH