2

Chapter 1: General Infromation...................................... 2

1-1. General Guidelines ........................................................................... 3

1-2. Caution and Warning symbols........................................................... 3

1-3. Function indication symbols............................................................... 3

Chapter 2: Product Features............................................ 4

2-1. Features........................................................................................... 4

2-2. Specification .................................................................................... 5

Chapter 3: SAFETY PRECAUTIONS............................. 6

3-1. Safety................................................................................................. 6

3-2. Warning and Cautions ....................................................................... 6

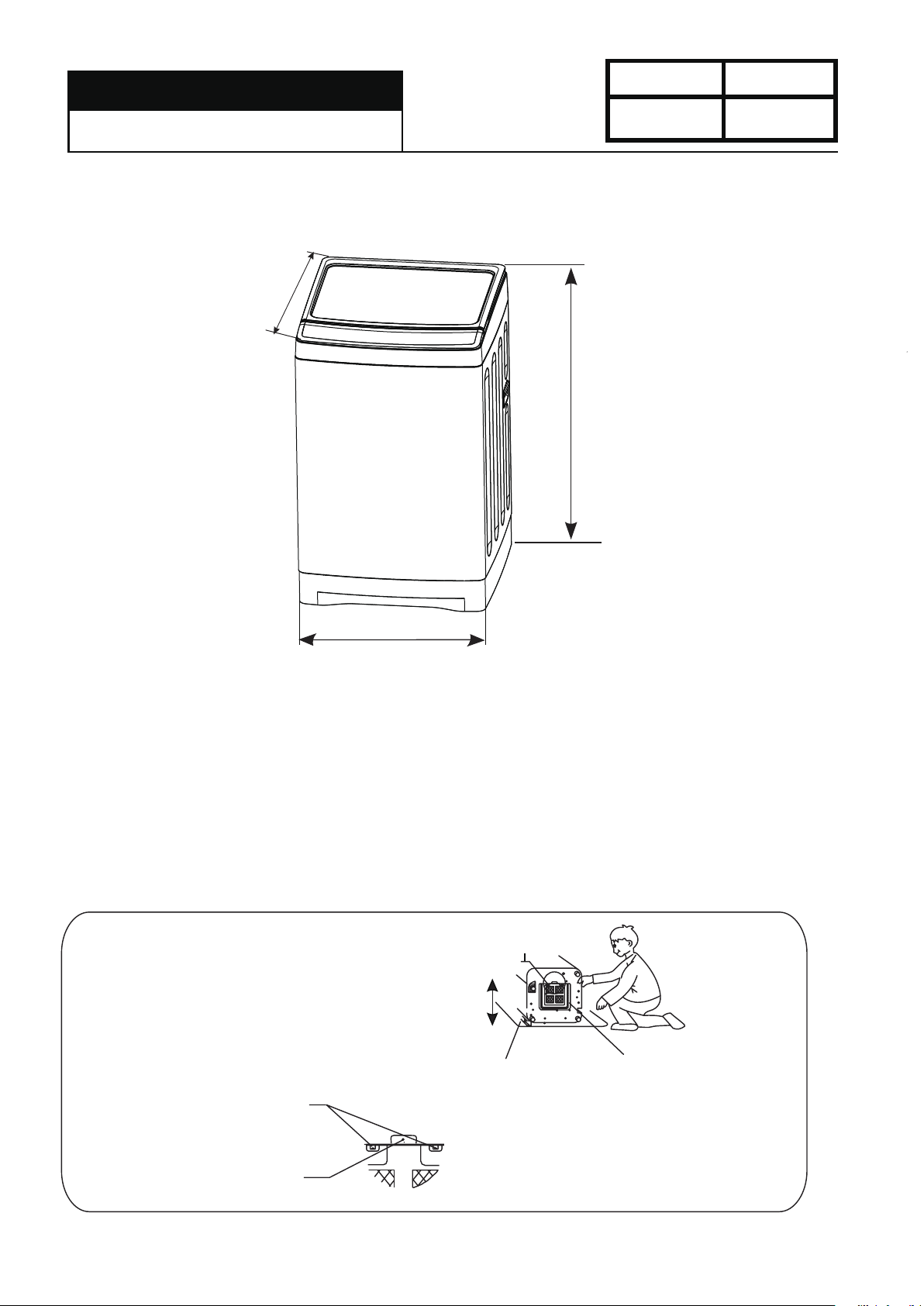

3-3. Net Dimensions ................................................................................. 8

Chapter 4: Installation and Accessory Parts................... 8

4-1. Key points in installation..................................................................... 8

4-2. Install the bottom plate ...................................................................... 8

4-3. Adjustment of the installation position................................................ 9

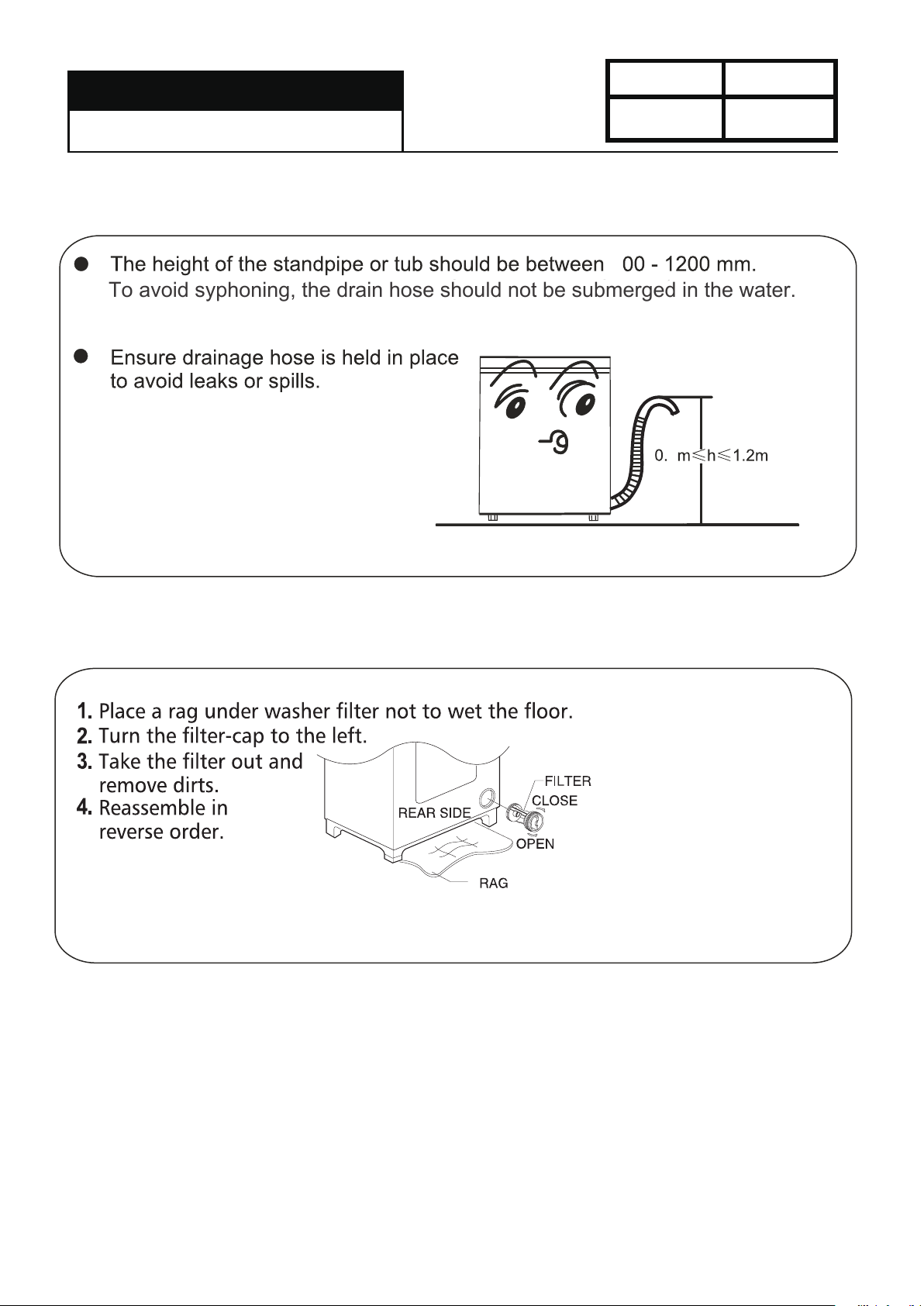

4-4. Install drainage hose

..................................

9

4-5. Placement of Drainage Hose .

...............................................

10

4-7. Usage of operation buttons ...........................................................

4-8. Key points in disassembly............................................................... 13

4-8-1 Points of attention in maintance...............................................................13

4-8-3 Points of attention in assembly................................................................14

Chapter 5: PARTS AND FUNCTIONS.......................... 15

Chapter 6: MAINTENANCE SERVICE

AND TROUBLE SHOOTING ........................ 16

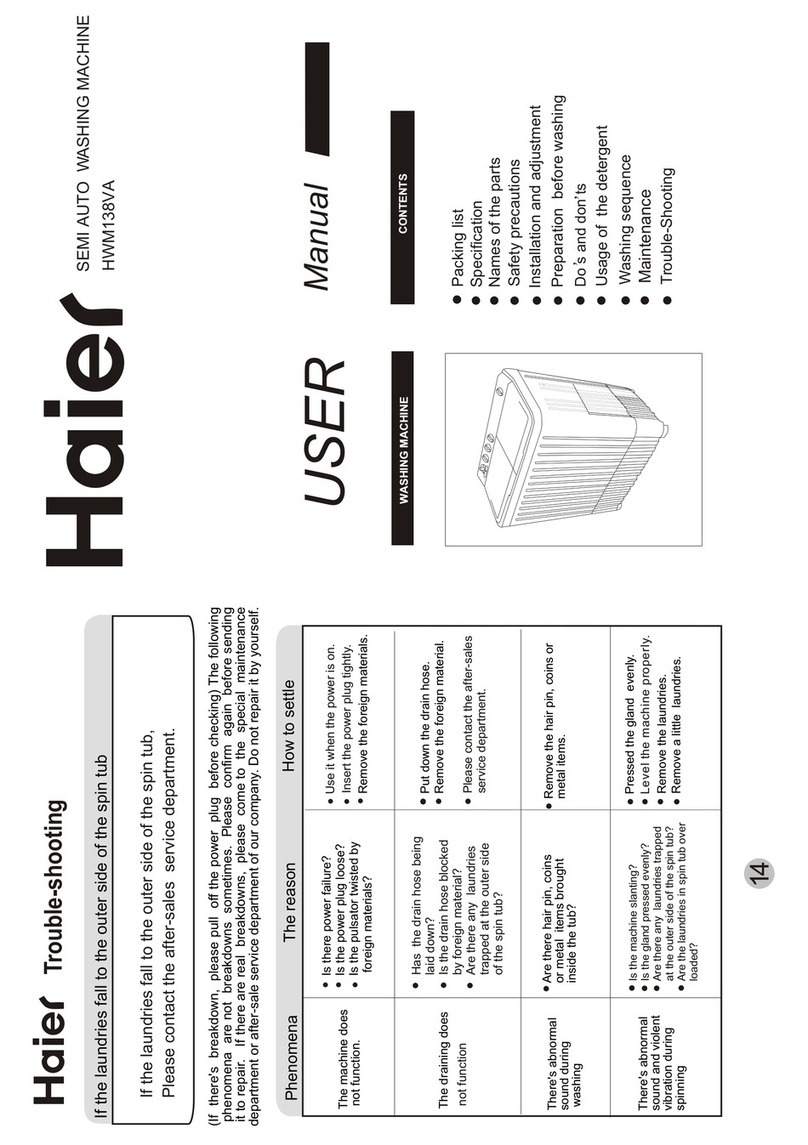

6-1. Trouble alarm and solve method...................................................... 16

6-2. Trouble-shooting charts................................................................... 17

6-2-1 No action (The indicator is off) .........................................................................17

6-2-2 No water filling........................................... ........................................................18

6-2-3 No rotation in washing (or rotate to one direction only) ....................................18

6-2-4 No draining........................................................................................................19

6-2-5 Keep filling water...............................................................................................19

6-2-6 No spinning .......................................................................................................20

6-2-7 Too much spinnin noise.....................................................................................20

6-2-8 Too much noise in washing...............................................................................21

6-2-9 The tub rotate to one direction(in washing)......................................................21

6-2-10 Brake time out.................................................................................................22

Chapter 7: WIRING DIAGRAM................................................ 23

11

Service Manual

Model No:

Issue

Rev.

Service Manual

LMA4120WPAB0、LMA4120WBAB0

LCA4120WPAB0

4-6. Install and clean the pump filter....................................................... 11

4-8-2 Test program ...............................................................13

................................