To avoid damage to the cover, it is absolutely essential to comply with the following instructions.

Hailo accepts no liability or warranty for damage caused by improper handling. The lid must sit

correctly in and be firmly screwed to the frame while the outer concrete surround is being created!

Otherwise there is a risk that the frame will move when the reinforcement is installed or when it is

set into the concrete. The correct and secure positioning of the lid may then no longer be

guaranteed. The lid must remain closed until the concrete has hardened! Only then is the cover

opened and the gas spring fitted.

1. The recess required in your structure is calculated as follows: External dimensions of the cover + min.

80 / 120mm all round for the concrete.

2. Remove the parts supplied from the cover, e.g. the gas spring, and any keys and closure parts. Lift

the shaft cover with suitable lifting tackle or equipment, such as a forklift, crane or digger, and insert it

into the recess provided.

3. Level the cover using a spirit level and place it at the required height. Any difference in height can

be compensated by putting shims under the frame. Make sure that the frame is lying straight. Make

sure the installation height takes account of additional road or footpath surfaces.

4. Once the cover is finally fixed, seal the gap all the way round between frame and structure (with a

wooden frame, sealing cord ...).

5. Make sure that the lid of the shaft cover is tightly closed while it is being concreted in. This prevents

the frame from getting out of shape. To safeguard against lifting and movement when concreting, the

cover can be secured using ballast.

6. The cover can now be finished off with a seal. We recommend compressing the concrete with

internal compactors. Allow for the setting times specified for the concrete.

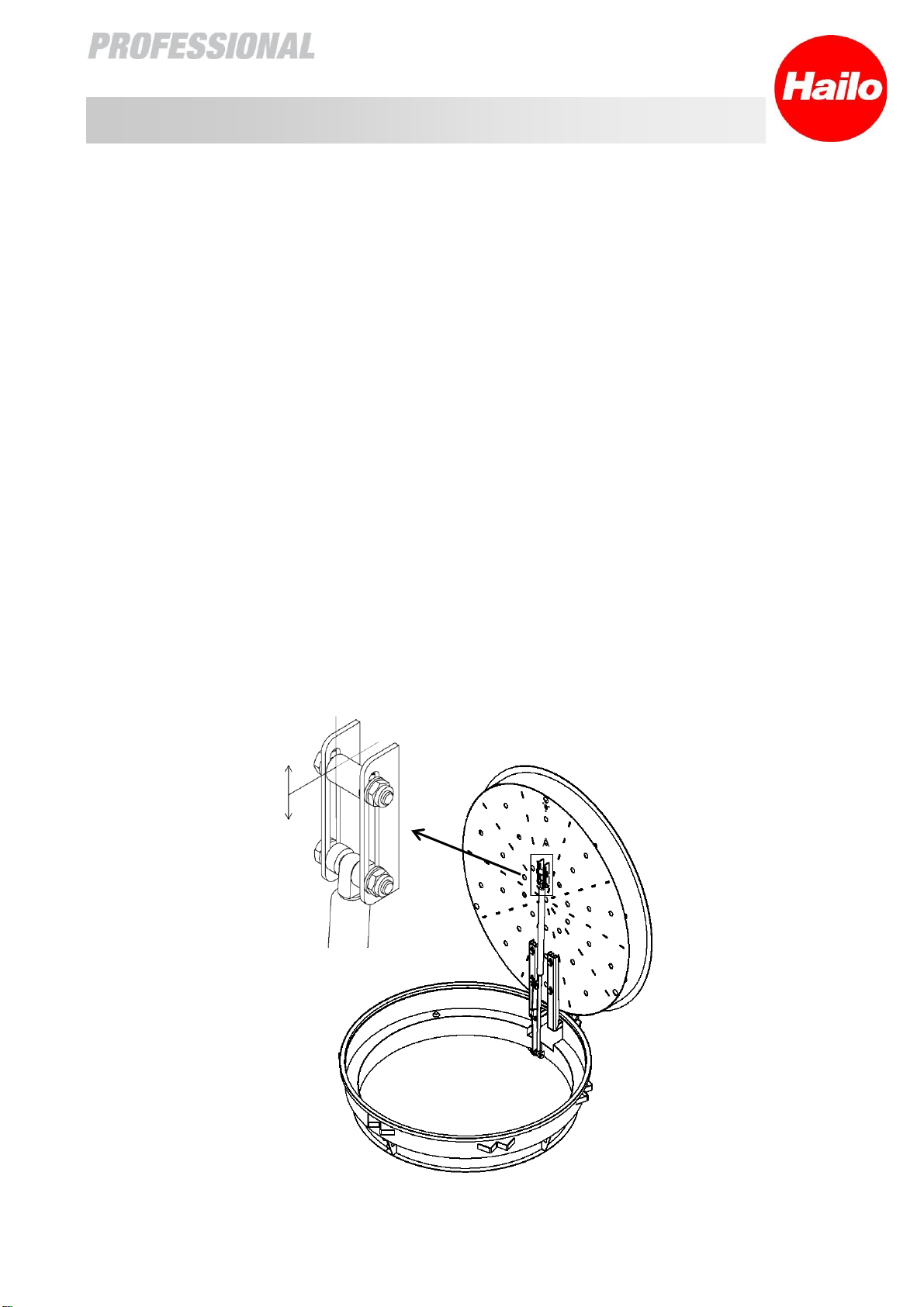

7. Once the concrete has hardened, the gas spring can be installed. The piston rod is always screwed

to the frame and the cylinder to the lid. The necessary means of attachment are pre-fitted.

8. Once all work has been completed, it is important to remove any concrete residue and dirt from the

frame and the lid. This ensures that your Hailo shaft cover will have a long and trouble-free service life.