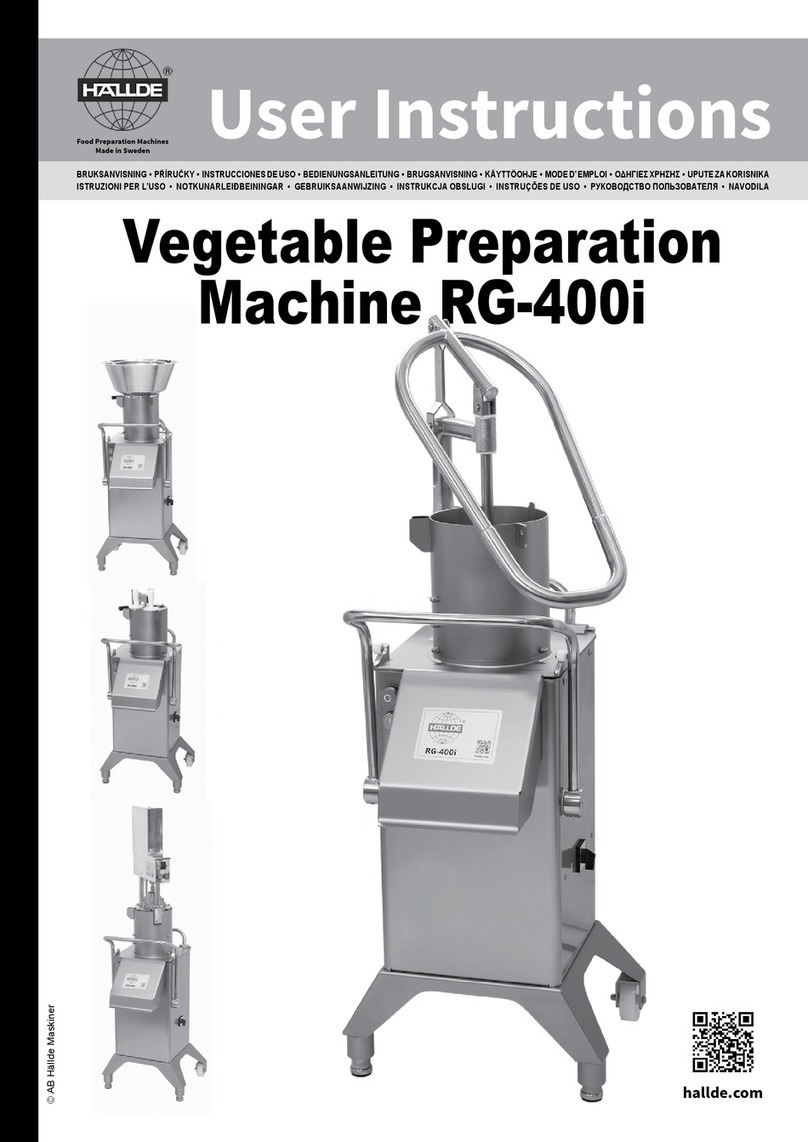

HALLDE • User Instructions

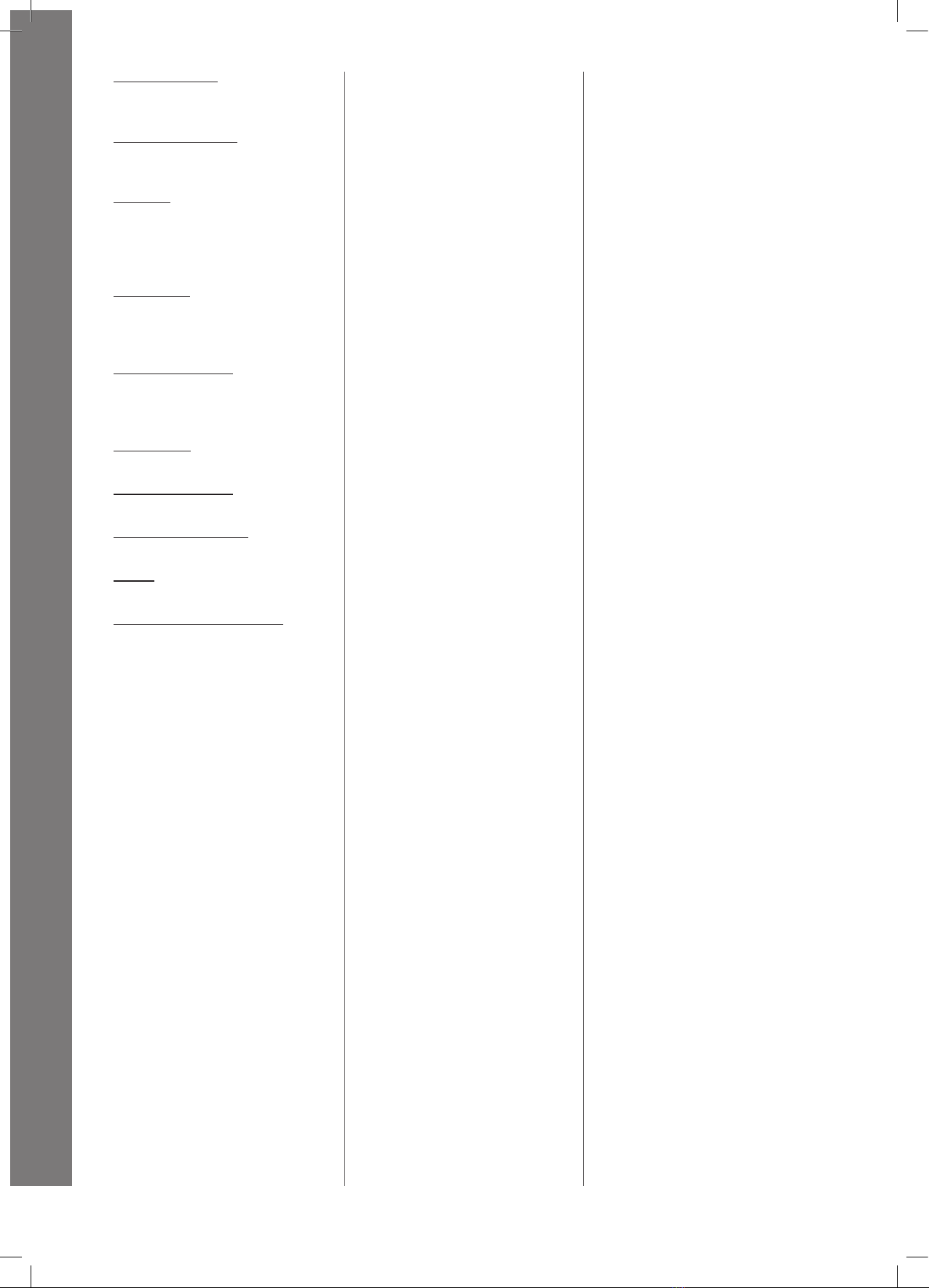

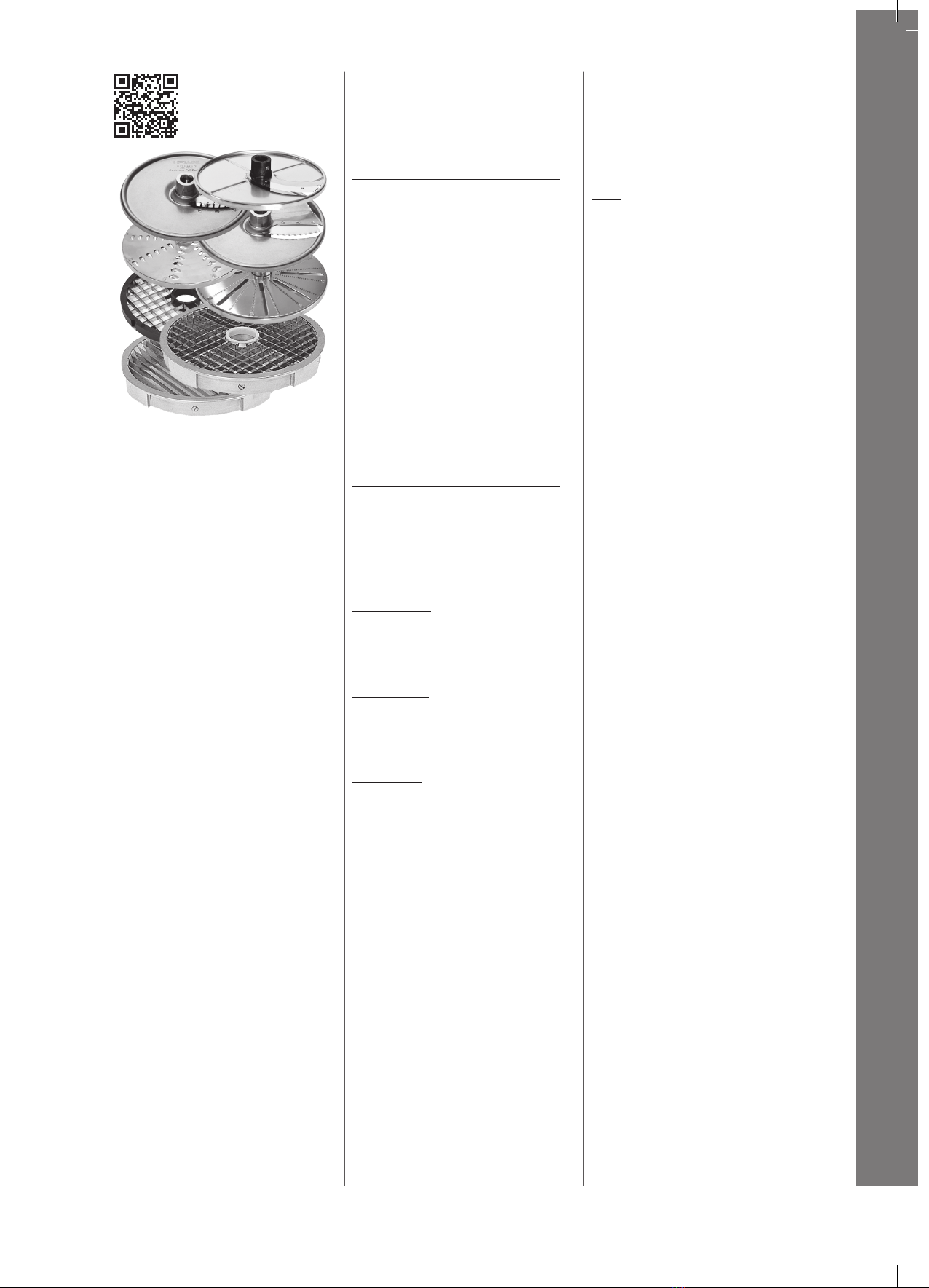

TYPE OF PROCESSING

Slices, dices, grates, shreds, cuts julienne,

crimping slices and potato chips in a variety

of dimensions, depending on the cutting tool

selected. Processes vegetables, fruit, dry

bread, cheese, nuts, mushrooms etc.

USERS

Restaurants, shop kitchens, hospitals, schools,

fast food outlets, catering, pizzerias, ships,

central kitchens, institution kitchens, food

processing industries etc.

CAPACITY

Up to 3 000 portions per day, 15 kg per minute

with the manual feeder and 40 kg per minute

with the feed hopper.

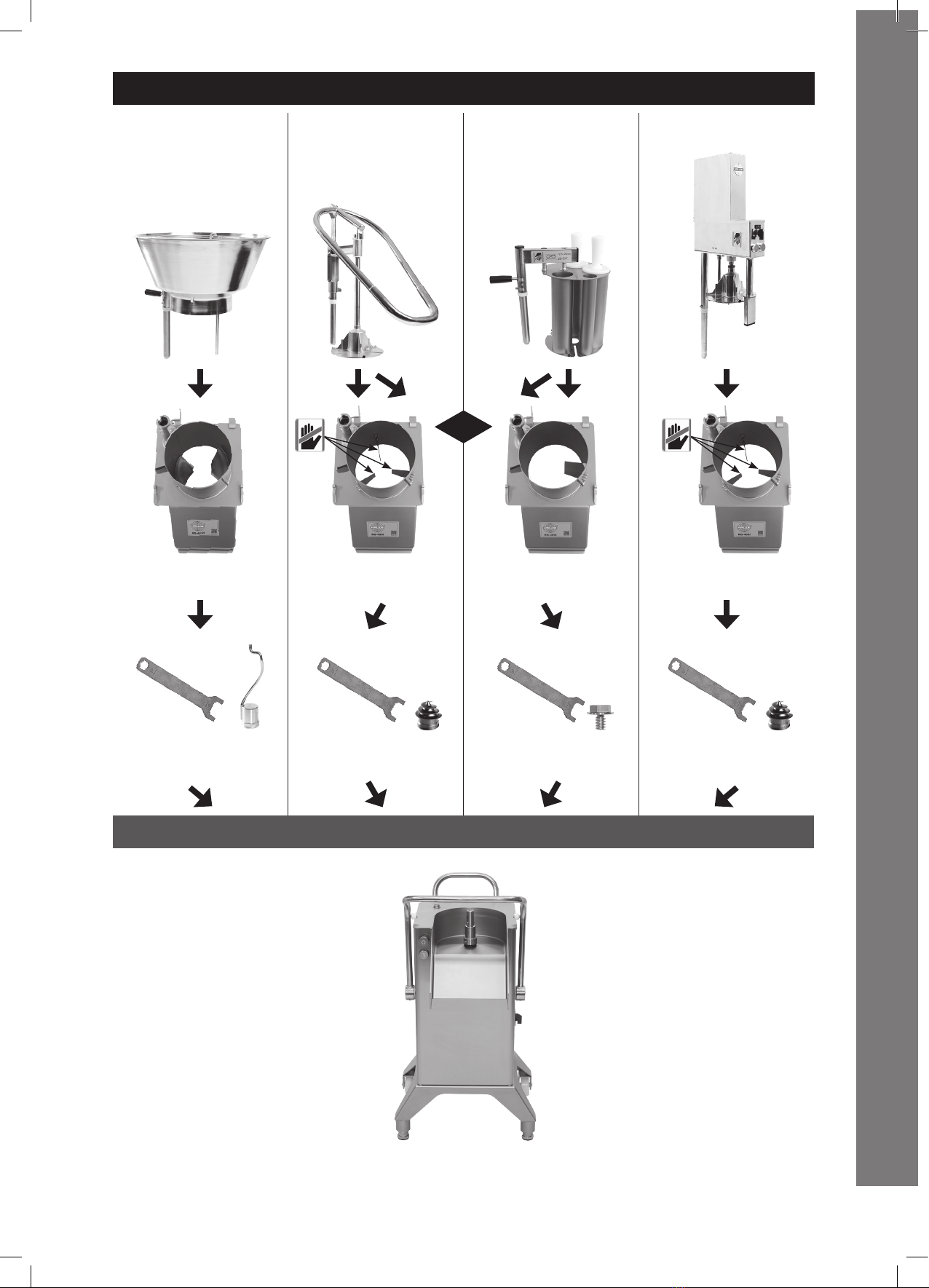

USING THE FEEDERS

MANUAL FEEDER, ERGO LOOP/

PNEUMATIC PUSH FEEDER:

These two feeders can be used for all types of

products, small and large.

Feed Cylinder A with three internal knives x

and divide up the product during preparation

and is optimized for preparation of cabbage.

MANUAL FEEDER, ERGO LOOP

Feed Cylinder B with one internal wall is

optimized for manually orienting of products,

stacking.

THE FEED HOPPER:

Is used for continuous cutting of large quantities

of round products like potatoes, onions etc.

THE 4-TUBE INSERT:

Is used for cutting long products such as

cucumbers into slicers, see picture.

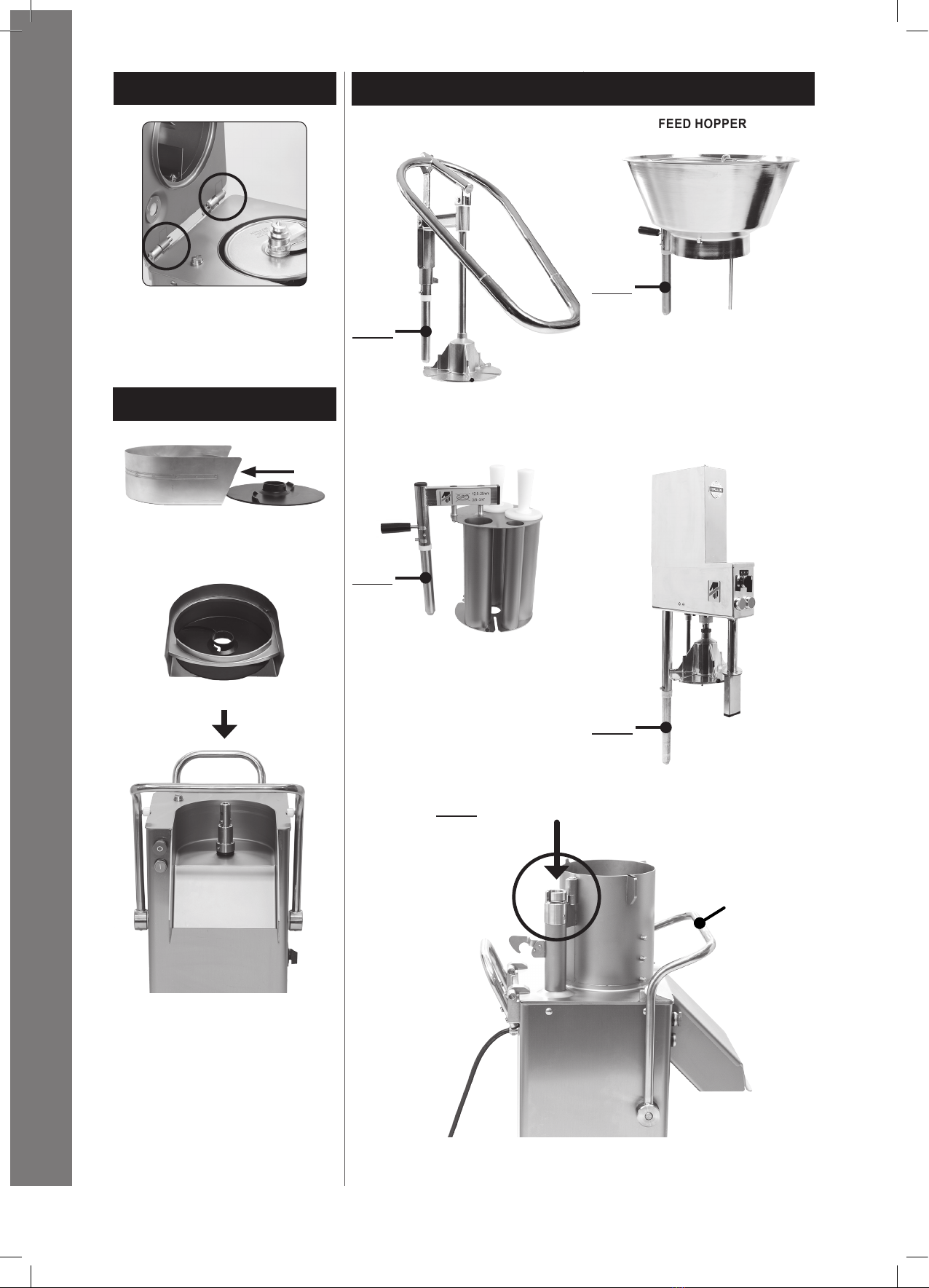

ASSEMBLING AND DISMANTLING

THE FEED CYLINDER

When tting, fold down the locking handle.

Push the feed cylinder onto the hinge pins of

the machine, and lower the feed cylinder.

Raise the locking handle.

When removing, rst remove the feed attach-

ment.

Lower the locking handle.

Remove the feed cylinder from the hinge pins

of the machine.

THE 4-TUBE INSERT

Press the stop button.

When tting, t feed cylinder A or B.

Place the 4-tube insert in the feed cylinder with

the shaft in the feed cylinder tube.

Press down the 4-tube insert and turn the

locking knob anti-clockwise.

When removing, turn the locking knob clock-

wise and remove the 4- tube insert.

THE MANUAL PUSH FEED

ATTACHMENT

Press in the machine stop button.

When tting, t feed cylinder A or B.

Move the lever up all the way.

Fit the manual push feed attachment shaft

into the feed cylinder tube.

Press down the manual push feed attachment

and swing it in anti-clockwise.

When removing, press down the stop pad and

swing out the manual push feed attachment

clockwise and remove it.

THE PNEUMATIC PUSH FEED

ATTACHMENT

Press in the machine stop button.

When tting, t feed cylinder A.

Fit the pneumatic push feed attachment shaft

into the feed cylinder tube.

Press down the pneumatic push feed

attachment and swing it anti-clockwise.

Push the compressor hose snap coupling onto

the pneumatic push feed attachment nipple.

Set the speed controls of the machine and of

the pneumatic push feed attachment to suit

the cutting tool being used as specied in the

instructions under the heading SETTING THE

SPEED CONTROLS.

Start the compressor and adjust its delivery

pressure to 5,5 bar. Handle the compressor

in accordance with the manufacturer’s

instructions.

Check the air pressure on the pressure gauge.

The recommended air pressure is 5 bar but

the actual value needed may vary. If the air

pressure reading on the pressure gauge is

different, pull the control upwards and then turn

it until the pressure gauge reading is 5 bar, and

then press it back down again.

When removing, switch off the compressor

and then disconnect the compressor hose

snap coupling from the pneumatic push feed

attachment nipple.

Press down the stop pad and swing out the

pneumatic push feed attachment clockwise,

and then remove it.

THE FEED CYLINDER FOR FEED

HOPPER

When tting, fold down the locking handle.

Push the feed cylinder onto the hinge pins of

the machine, and lower the feed cylinder.

Raise the locking handle.

When removing, rst remove the feed attach-

ment.

Lower the locking handle.

Remove the feed cylinder from the hinge pins

of the machine.

THE FEED HOPPER

Press in the stop button.

When fitting, fit the feed cylinder with two

internal guides.

Place the feed hopper in the centre of the feed

cylinder, with the shaft in the feed cylinder tube.

Press down the feed hopper and turn the

locking knob anti-clockwise.

When removing, turn the locking knob

clockwise and remove the feed hopper.

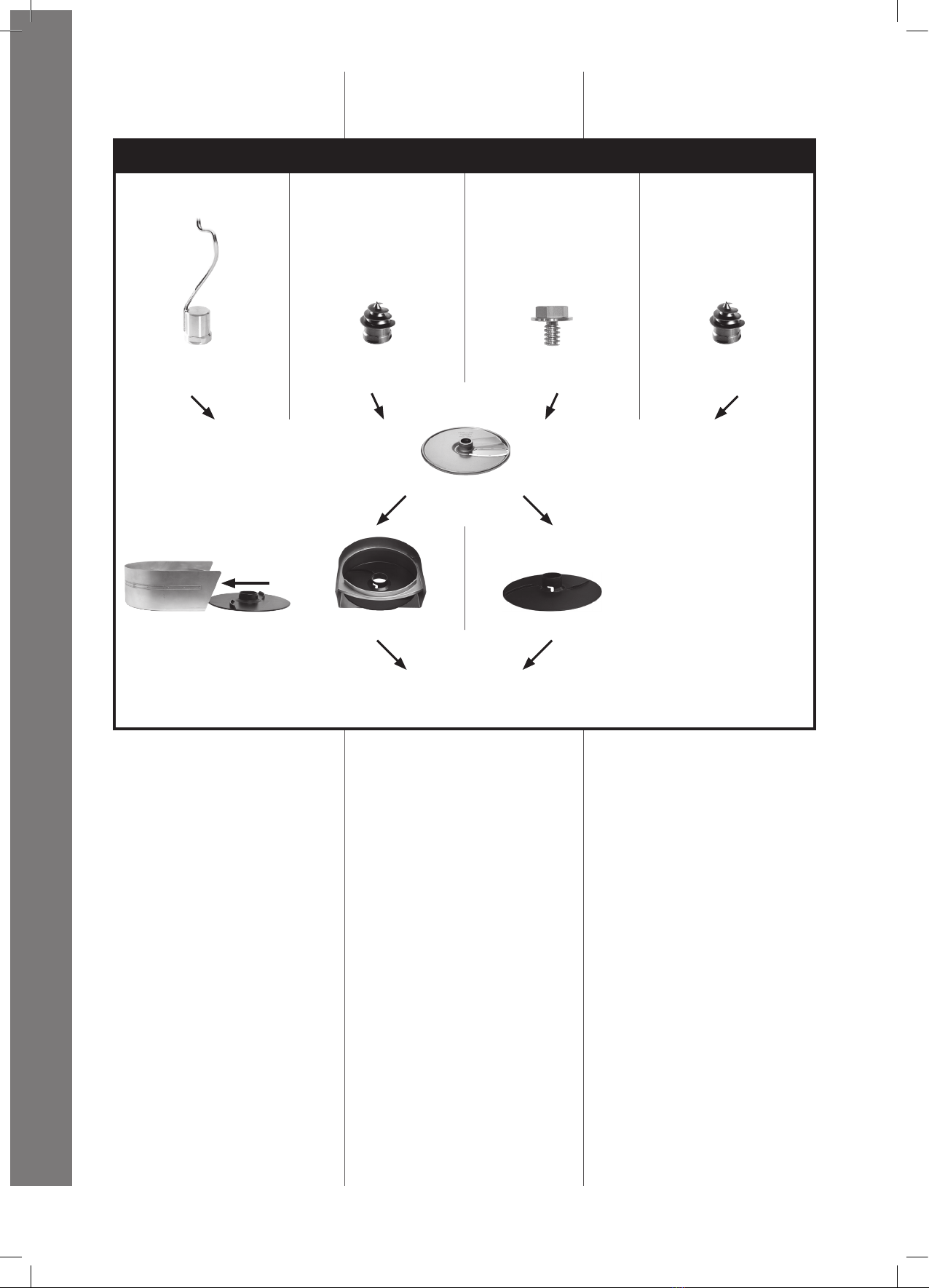

FITTING THE CUTTING TOOLS

AND TRAY

While using the manual or pneumatic feeder,

make sure the pusher plate is in the upper

position and swing it out the feeder to the left.

If the feed hopper or 4-tube insert is being

used, lift the shaft out of its mounting at the

back of the machine.

Lower the locking handle and tilt the feeder

backwards.

If the tray is to be used, the ejector plate is

placed in the bottom of the tray. Ensure that the

machine’s knife housing has been thoroughly

cleaned. The tray, containing the ejector

plate, is then mounted around the shaft of the

machine’s knife housing. Turn/push down the

ejector plate down into its coupling.

Place the chosen cutting tool on the shaft and

rotate the cutting tool so that it drops rmly

into its position.

When using Dicing Grid or French Fry Grid:

place the ejector plate in the bottom of the

tray, which is, in turn, mounted around the

shaft of the machine’s knife housing. Turn

the ejector plate down into its coupling. Then

mount the chosen grid onto the shaft followed

by the slicer, ensuring that both fall properly

into place.

Secure the agitator device when using the

feed hopper, the locking bolt when using the

4-tube insert, or the decoring device when

using the manual or the pneumatic push feed

attachment, by turning them anti-clockwise by

means of the wrench onto the centre shaft of

the cutting tool.

REMOVAL OF THE CUTTING TOOLS

AND TRAY

Unscrew the screw cap, drill sleeve or lock

bolt clockwise using the key and remove the

cutting tool/tools, and the ejector plate together

with the tray.

SETTING THE SPEED CONTROLS

The machine speed control is normally set to

position “2” for all cutting other than dicing,

when the speed control should be in position

“1”.

When cutting with the pneumatic push feed,

set the speed control of the machine and

push feed attachment in accordance with the

following table.

PF = Pneumatic push feed attachment.

M = Machine.

SLICER

0.5–1.5 mm:.........................PF = 1. M = 2.

2–3 mm:...............................PF = 2. M = 2.

4–7 mm:...............................PF = 3. M = 2.

8–14 mm:.............................PF = 3. M = 1.

15–20 mm:...........................PF = 3. M = 1.

HC SLICER

2 mm: ..................................PF = 2. M = 2.

4–6 mm:...............................PF = 3. M = 2.

8–20 mm:............................PF = 3. M = 1.