10

1

1

1

1

1

2

3

1

2

3

1

1

1

1

1

1

1

1

1

1

2

1

1

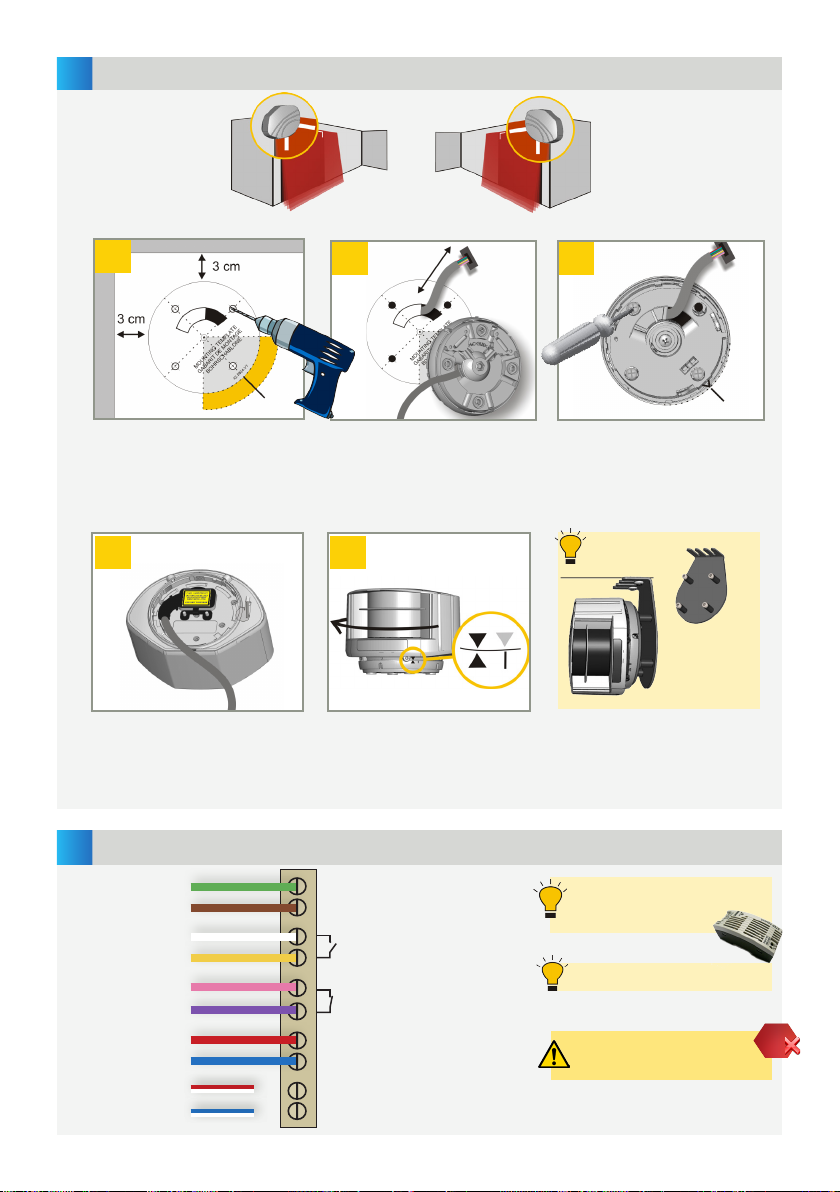

TROUBLESHOOTING

No blue LED

Only the blue LED

is on.

The detection LED

remains green.

The orange LED is

flashing and the

detection LEDs are

red.

The detection LED

remains red.

The orange LED

is on.

The sensor does

not respond to the

remote control.

The sensor does not

unlock.

There is no power.

The test input is not

connected.

The detection field is too

small or deactivated.

Someone or something is

in the detection field.

The field is touching the

floor, the wall or the door,

which leads to detection.

No background (reference

point) is found.

The sensor is masked.

The power supply voltage

is exceeding the acceptable

limits.

The sensor exceeds its

temperature limits.

Internal error

30 minutes after last use

of the remote control, the

sensor locks the access to

the remote control session.

The batteries in the remote

control are not installed

properly or dead.

The remote control is badly

pointed.

A reflective object is in close

proximity to the sensor.

You have to enter an access

code or the wrong code was

entered.

The object size is too small.

The polarity of the power

supply is inverted.

Check cable and conneicton.

Check wiring.

The RED and BLUE cable have to be connected

to the test input or the power supply.

Check the size of the fields.

Launch a teach-in.

Step out of the field and/or remove the any

object(s) from the field.

Activate the 3 red beams and check if the

position of the sensor is correct.

If not, adjust the hex screws.

Verify the field size.

Launch a teach-in.

Check the position of the sensor.

Check the mounting side setting.

If there is no background, set the mounting side

to value 3 to 5.

Launch a new teach-in.

Verify and clean the front screens

with a damp cloth.

Check the power supply voltage.

Verify the outside temperature where the sensor

is installed. Eventually protect the sensor from

sunlight using a cover.

Wait a few seconds.

If the LED remains ON, reset the power supply.

If the LED turns on again, replace the sensor.

Cut and restore power supply.

The remote control session is accessible again

during 30 minutes.

Verify or replace the batteries.

Point the remote control towards the sensor,

but with a slight angle. The RC should not be

pointed in a right angle in front of the sensor.

Avoid highly reflective material in proximity to

the sensor.

Cut and restore power supply.

No code is required to unlock during the first

minute after powering.

Check the polarity of the power supply.

Decrease the min. object size.

All LEDs have been de-

activated by remote control.

Activate the LEDs by remote control.