4

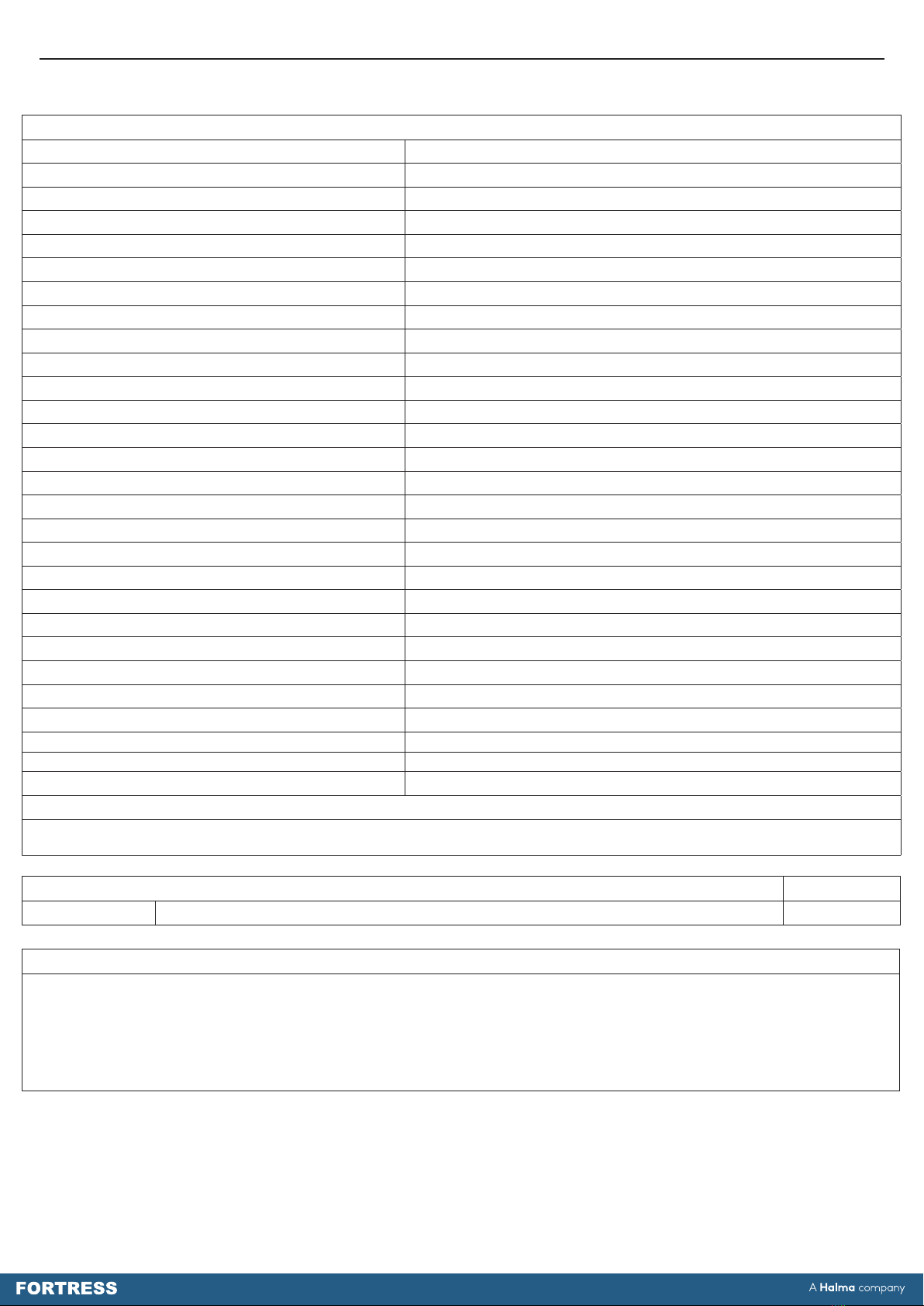

Tools and Fixings Required

Pin Hex Driver Bit (Provided)

1/4” Driver (to suit above)

Ø8.2mm Drill or M5 Drill and Tap

3.5mm Flat Blade Electrical Screwdriver

4 x M8 screws for rear-xing. (Screws must be suitable length for a minimum of 10mm thread engagement with Stop

module. Required screw type and class; A2 70. Required torque setting; 4-6 Nm.)

4 x M5 Cap-Head screws for through-xing. (Screws must be suitable length for a minimum of 6mm thread engagement if

mounting to a threaded panel. Required screw type and class; A2 70. Required torque setting; 2-4 Nm.)

Required Torque Settings:

If removed during mounting, re-orientation or electrical wiring, all supplied xing screws of the complete Guard Interlocking

Device must be retted using the following torque settings;

- M3 Screws – 0.8-1.0 Nm.

- M4 Screws – 2-4 Nm.

- M5 Screws – 2-4 Nm.

- M8 Screws (required for device mounting but not supplied) – 4-6 Nm.

If M4 Lid screws have been removed during electrical wiring and installation, they must be fully retted to a torque setting of

2-4 Nm to guarantee IP protection level.

Mounting

1. Mount the safety switch only in the correctly assembled condition.

2. Locate the safety switch so that inspection and replacement are possible.

3. Using the driver bit provided, loosen the 4 tamperproof lid screws. Remove the lid assembly complete with the

retained screws.

4. Remove the Tongue assembly from the complete Guard Interlocking Device by pulling it out of the head. Mount the safety

unit only in the correctly assembled condition.

5. M o u n t t h e e n c l o s u r e a s s e m b l y t o g e t h e r w i t h h e a d a s s e m b l y t o a a t m e t a l , s t a t i c p a r t o f t h e m a c h i n e . U s e M 5 s c r e w s

through the unit or M8 screws from the rear. The mounting surface should be at.

6. Make sure that the gap around the perimeter of the guard, when closed (Safety Circuits Closed), does not exceed the

limits specied in En294 & En953.

7. A l l x i n g s c r e w s u s e d t o m o u n t t h e c o m p l e t e G u a r d L o c k i n g D e v i c e m u s t b e p e r m a n e n t l y p r e v e n t e d f r o m r e m o v a l , e i t h e r

by vibration or by personnel using standard tools. If mounting xings are visible, they must be secured against

m a n i p u l a t i o n a n d u n - a u t h o r i s e d o r u n - i d e n t i a b l e r e m o v a l . I n t h e s e c a s e s , a m i d d l e s t r e n g t h a d h e s i v e s c r e w l o c k e r i s

required.

8. The installation and operation of the complete Guard Interlocking Device must take into account the requirements of

EN ISO 14119; in particular Section 7 – Design for minimising defeat possibilities.

9. The complete Guard Interlocking Device must not be used as a mechanical stop. Where applicable, precautions must be

made to ensure the door or gate of any guarded area has sucient support and stops to prevent the impact on the

Guard Interlocking Device.

10. If tted in conjunction with an S40 Push IR Escape Release module, the complete Guard Interlocking\Device must be

mounted in the correctly assembled condition so that the Escape Release action is only possible from within the

guarded area (danger zone).

Operating Instructions: Stop - Non Solenoid Switch Body