P29 Instruction Manual

2

Table of Contents:

1 Purpose of instruction manual...............................................................................................4

2 Safety precautions.................................................................................................................5

2.1 Safety concept.................................................................................................................5

2.2 Appropriate use................................................................................................................5

2.3 Shipping, assembly, electrical connections and startup...................................................5

2.4 Troubleshooting, maintenance, repairs, disposal.............................................................5

2.5 Symbols ...........................................................................................................................6

3 Start-up, maintenance, shipping............................................................................................7

3.1 Start-up............................................................................................................................7

3.2 Maintenance, repair.........................................................................................................8

3.3 Shipping...........................................................................................................................8

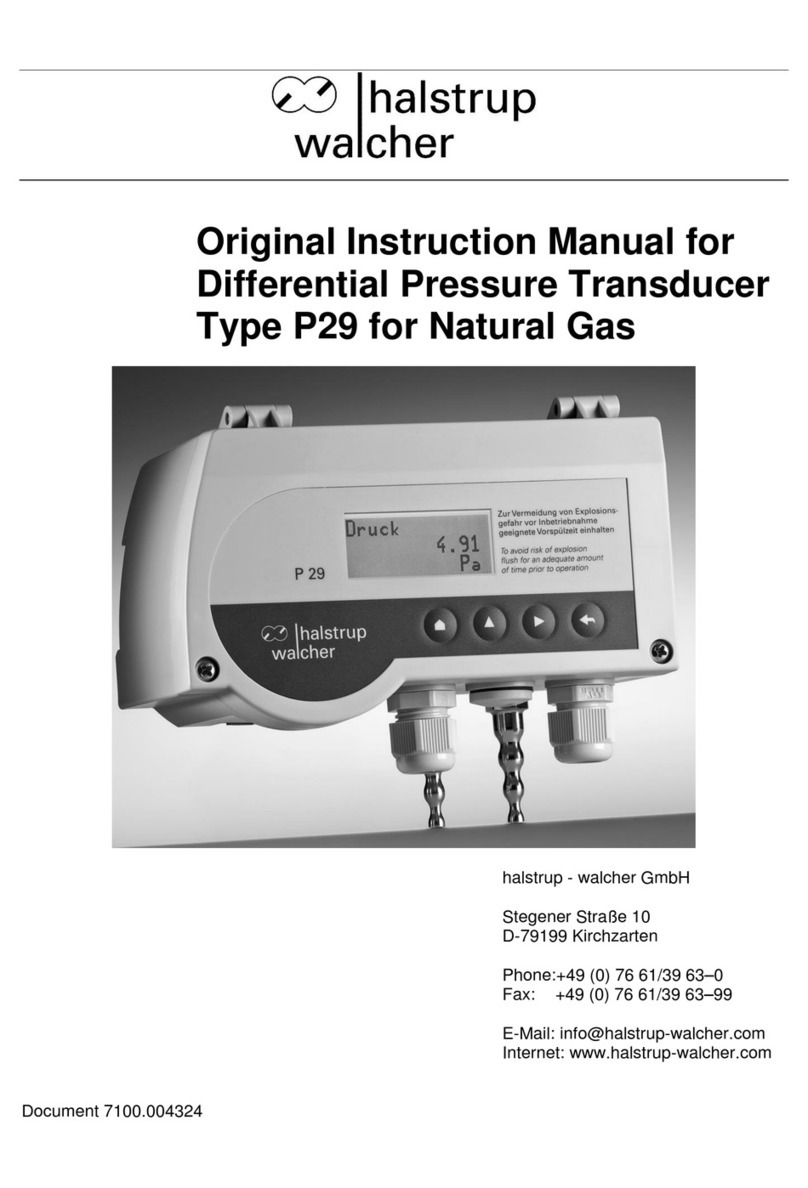

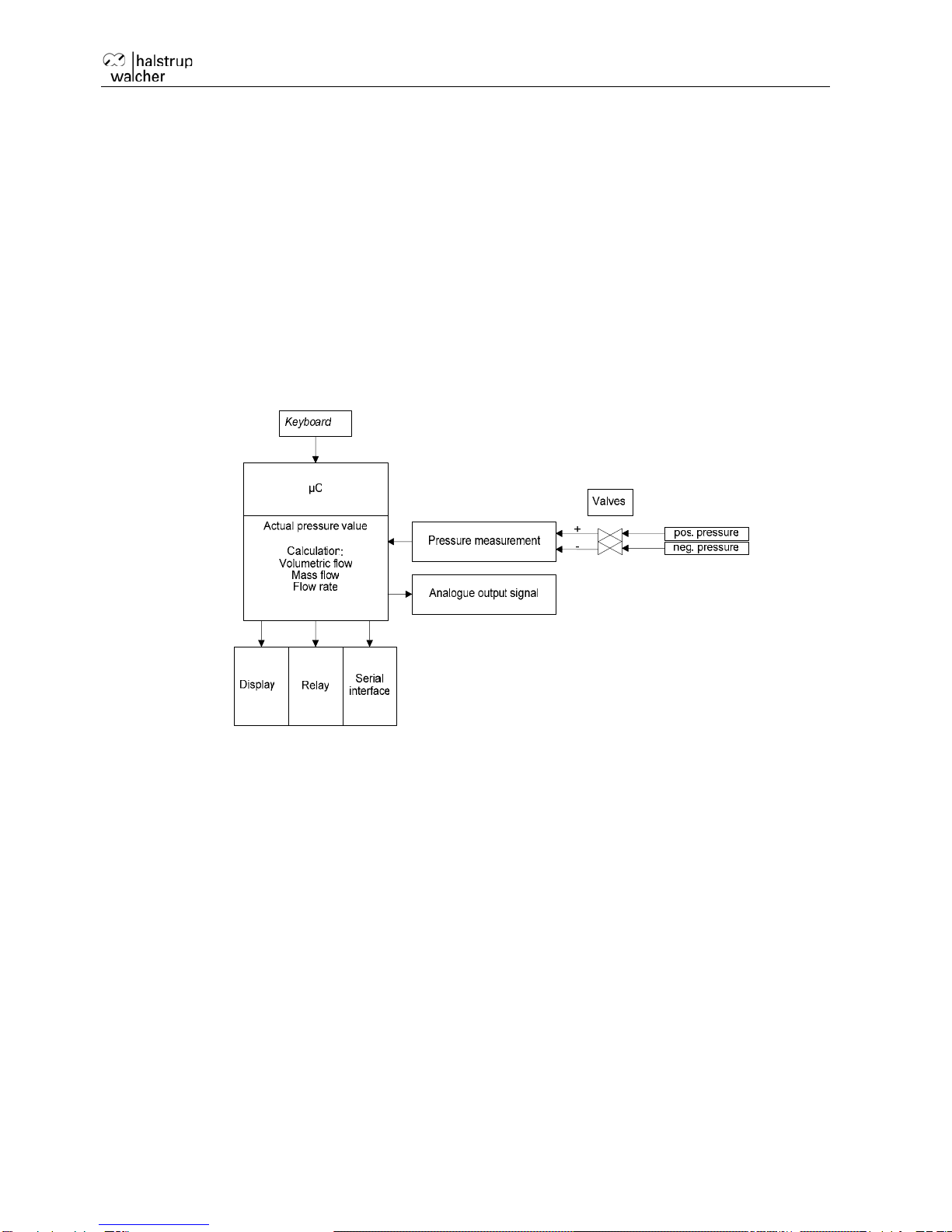

4 Instrument description...........................................................................................................9

4.1 Features...........................................................................................................................9

4.2 User interfaces...............................................................................................................10

4.3 Internal ports and keys...................................................................................................10

4.4 Front view ......................................................................................................................12

5 Zero-point calibration cycle .................................................................................................12

6 Overpressure protection......................................................................................................13

7 Display (optional).................................................................................................................13

8 Menu (optional) ...................................................................................................................13

8.1 Display...........................................................................................................................13

8.2 Scaling...........................................................................................................................14

8.2.1 Pressure ...................................................................................................................14

8.2.1.1 Top.................................................................................................................14

8.2.1.2 Bottom ...........................................................................................................14

8.2.1.3 Unit ................................................................................................................14

8.2.2 Volumetric flow .........................................................................................................14

8.2.2.1 Value..............................................................................................................15

8.2.2.2 Unit ................................................................................................................15

8.2.3 Mass flow..................................................................................................................15

8.2.3.1 Value..............................................................................................................15

8.2.3.2 Unit ................................................................................................................15

8.2.4 Flow rate...................................................................................................................15

8.2.4.1 Value..............................................................................................................15

8.2.4.2 Unit ................................................................................................................15

8.3 Warning..........................................................................................................................16