Document #101-0079 6 11/30/17

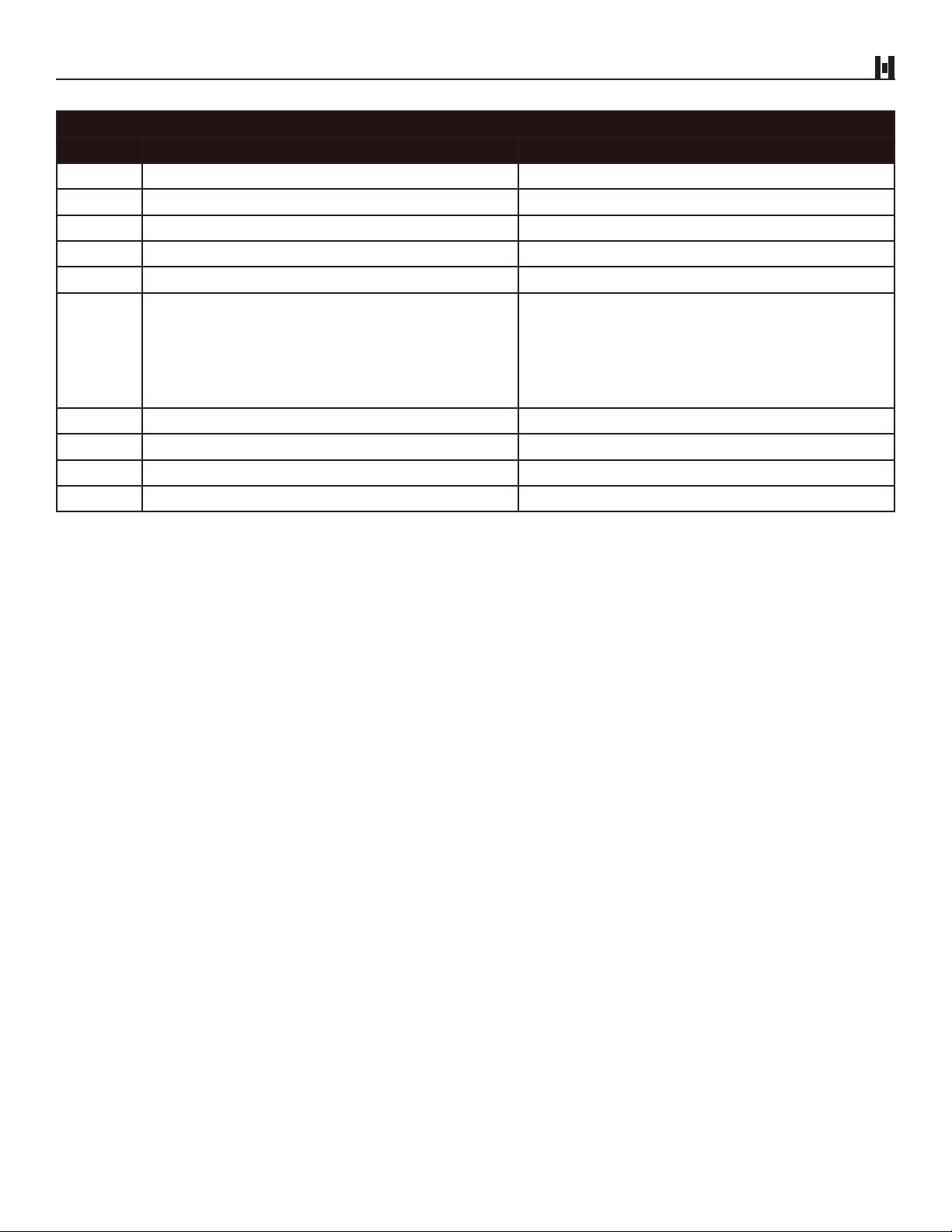

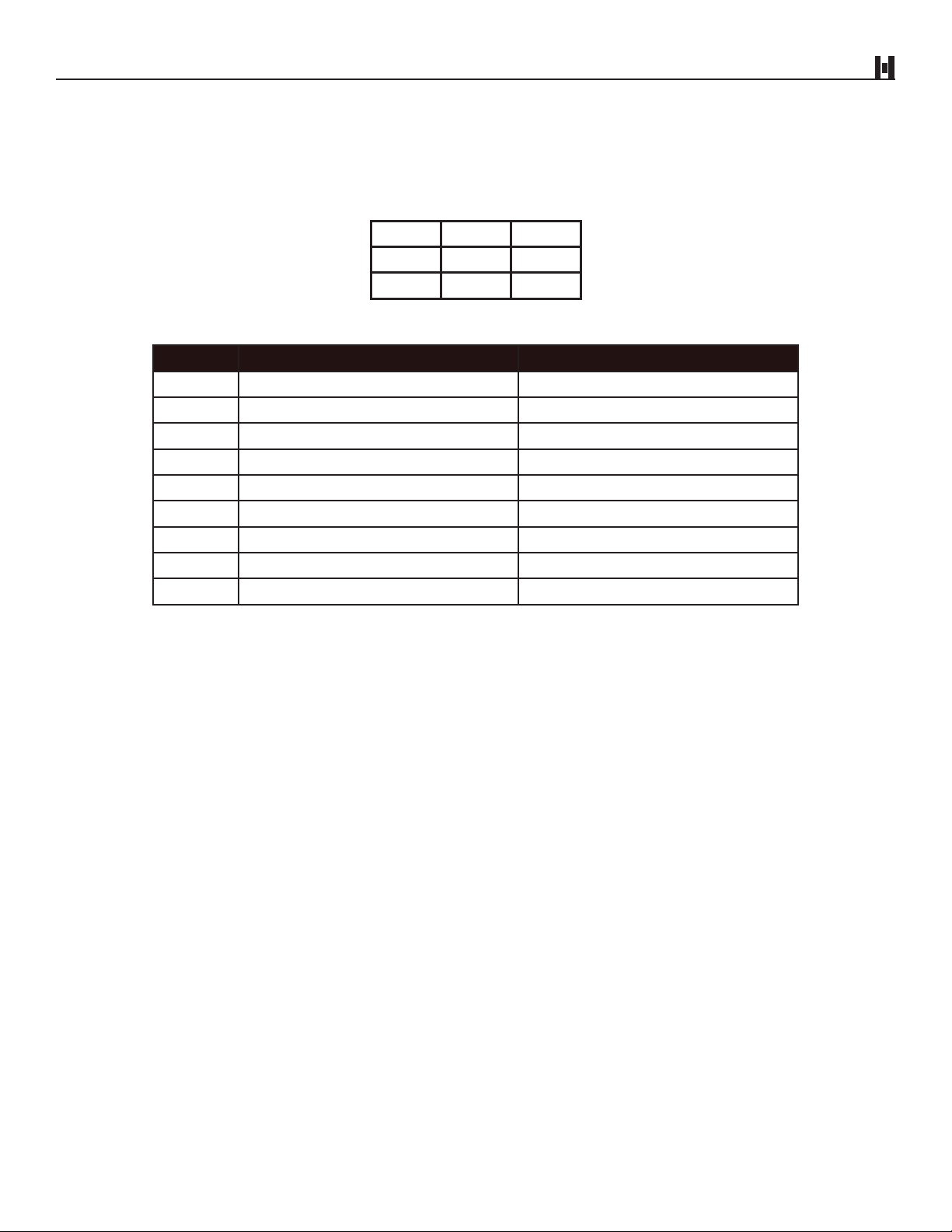

Switch #5: Switch #5 selects which direction the validator will accept an inserted bill. If this switch

is OFF, the validator will accept bills face up in either direction. If this switch is ON, the

validator will only accept bills face up and the end with the black seal inserted first.

Switch #6: Switch #6 selects how the validator signals the dispensing equipment after accepting a

bill. If this switch is OFF, the validator will activate the $1 Relay once for an accepted $1

bill, the $5 Relay once for an accepted $5 bill, the $5 Relay twice for an accepted $10

bill, and the $5 Relay four times for an accepted $20 bill.

If switch #6 is ON, the Validator will activate the $1 Relay once for an accepted $1 bill,

the $1 Relay five times for an accepted $5 bill, the $1 Relay ten times for an accepted

$10 bill, and the $1 relay twenty times for an accepted $20 bill.

SWITCH #6 DOES NOT WORK WITH TUBE TYPE CHANGERS.

Switch #7: Switch #7 selects whether the validator will accept or reject $1 bills. If the switch is in

the OFF position, the validator will accept $1 bills. If the switch is ON, the validator will

reject $1 bills.

Switch #8: Switch #8 selects whether the validator will accept or reject $5 bills. If the switch is in

the OFF position, the validator will accept $5 bills. If the switch is ON, the validator will

reject all $5 bills.

Switch #9: Switch #9 selects whether the Validator will accept or reject $10 bills. If the switch is in

the OFF position, the validator will accept $10 bills. If the switch is ON, the validator will

reject all $10 bills.

Switch #10: Switch #10 selects whether the Validator will accept or reject $20 bills. If the switch is

in the OFF position, the validator will accept $20 bills. If the switch is ON, the validator

will reject all $20 bills.