SAFETY

A fireguard conforming to BS 8423:2010 should be

used in the presence of children, the old or infirm.

Please note, this appliance should be used with

the fire door closed at all times except when

fuelling, de-ashing or initial lighting.

Do not use aerosol sprays or any other

flammable materials near the appliance

under fire.

Fire cement is caustic, hand and eye

protection should always be worn,

prolonged contact with the skin should be

avoided.

Arada Ltd will not be responsible for any

consequential or incidental loss or

injury however caused.

Before continuing any further with the

installation of this appliance please read the

following guide to manual handling.

Always obtain assistance when lifting the

appliance.

When lifting always keep your back straight,

bend your legs not your back.

Avoid twisting at the waist. It is better to

reposition your feet.

Avoid upper body/top heavy lifting. Do not lean

forwards or sideways when handling the fire.

Always grip with the palms of your hands.

Do not use your fingertips for support, use

gloves for a better grip.

Always keep the stove close to the body as this

will minimise the cantilever action.

CO ALARM

Building regulations require that whenever a new

or replacement fixed solid fuel or wood / biomass

appliance is installed in a dwelling a Carbon

Monoxide Alarm must be fitted in the same room

as the appliance. Further guidance on the

installation of the CO Alarm is available in

BS EN 50292:2002 and from the alarm

manufacturers instruction.

Provision of an alarm must not be considered

a substitute for either installing the appliance

correctly or ensuring regular servicing and

maintenance of the appliance and chimney

system.

THE PRINCILE OF THE STOVE

Your HSB Boiler Stove is built to the highest

standard of craftsmanship using the best materials

and most modern equipment available. It is a highly

efficient and sophisticated piece of machinery and

when properly installed and operated it should

provide a lifetime of heating satisfaction.

Safety is the most important consideration when

installing your fire. If not properly installed and

operated a house fire may result. Installation must

comply with the Building regulations and conform to

all safety standards.

Arada produce a variety of appliances ranging from

the traditional to the modern in style and appearance,

all bristling with ‘High Tech’ features.

The fire door is fitted with a special high temperature

ceramic glass panel through which the fire can be

viewed.

An internal throat plate produces turbulence to

encourage secondary combustion and direct the flue

gas around the whole upper firebox before allowing it

to escape up the chimney.

Arada stoves are also fitted with an ‘air wash’ so

called because it provides a curtain of high speed

preheated air behind the glass to help keep it clean

and provide secondary air /over draught.

The air inlets on the stove give a wide range of

primary / secondary air, under draught / over draught

combinations. The optimum setting will only be

established by experience in firing the appliance,

and will depend on the type of fuel, the position of

the appliance in the house, conditions of chimney

etc..

Asbestos

This stove contains no asbestos.

If there is a possibility of disturbing any asbestos in

the course of installation then please seek specialist

guidance and use appropriate protective equipment.

Electrical Connections

The installation of any electrical services during the

installation of this boiler and associated heating

system must be carried out by a registered

competent electrician and in accordance with the

requirements of the latest issue of BS 7671.

The design, installation and commissioning of any

water based heating system should be in accordance

with the following standards:-

BSEN12828:2003; BSEN12831:2003

BSEN14336:2004

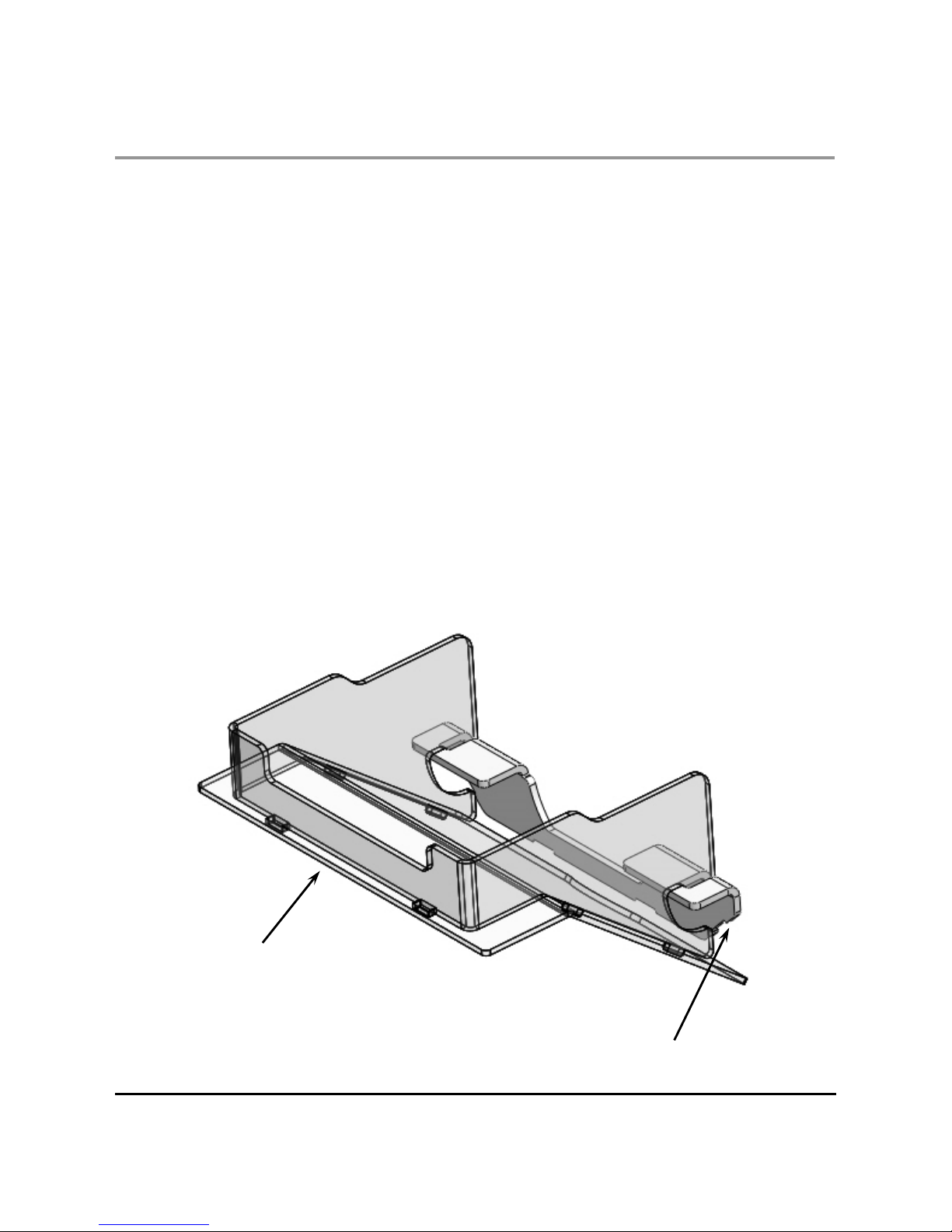

HSB Boiler Stove

INTRODUCTION

5