CONTENTS

............................................................................................................................ 4

1. WARNINGS AND RECOMMENDATIONS...........................................................................5

1.1. Transport and storage ................................................................................................................................... 5

.............................................. 5

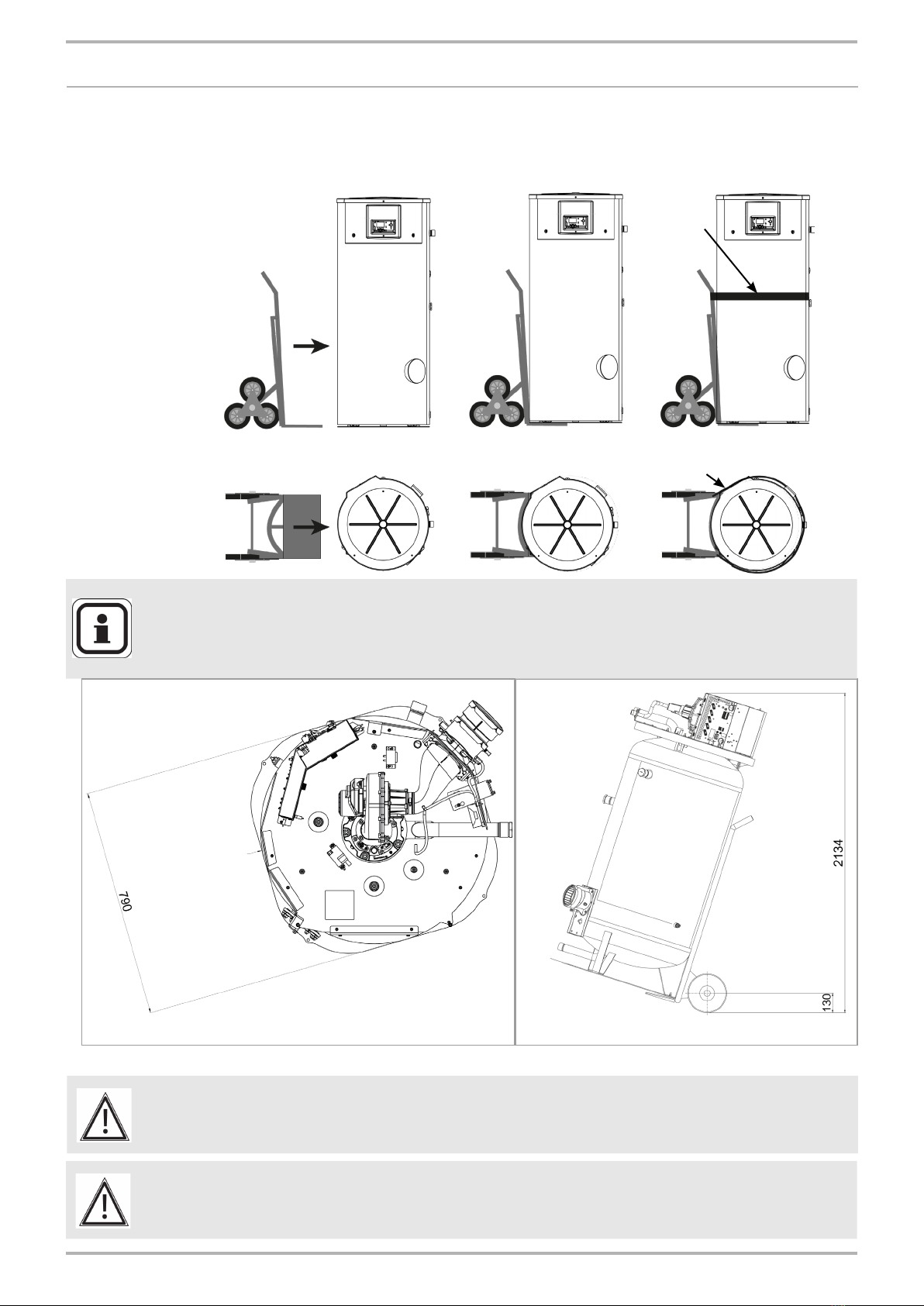

1.3. Handling ........................................................................................................................................................ 6

......................................................................................................................................... 7

1.5. Water composition......................................................................................................................................... 8

2. APPROVALS .........................................................................................................................8

.......................................................................................................... 8

2.2. Gas category............................................................................................................................................... 11

2.3. Gas supply pressures ................................................................................................................................. 11

3. TECHNICAL SPECIFICATIONS ........................................................................................12

................................................................................................................................................. 12

3.2. Boiler components ...................................................................................................................................... 14

3.3. Combustion at 15°C and 1013 mbar........................................................................................................... 16

3.4. Operating conditions ................................................................................................................................... 22

3.5. Electrical connection ................................................................................................................................... 22

4. INSTALLATION ...................................................................................................................23

4.1. Ventilation.................................................................................................................................................... 23

4.2. Unvented installation................................................................................................................................... 23

4.3. Vented installation ....................................................................................................................................... 25

4.4. Removing the cover panel .......................................................................................................................... 26

................................................................................................................ 26

4.6. Flue installation connection......................................................................................................................... 27

4.7. Hydraulic connection................................................................................................................................... 31

4.8. Gas change G20-G31 ................................................................................................................................. 32

4.9. Gas connection ........................................................................................................................................... 37

4.10.Electrical connection / Wiring diagram....................................................................................................... 37

5. START-UP ............................................................................................................................42

5.1. Filling the boiler ........................................................................................................................................... 42

................................................................................................................................................... 42

6. CHECKS AFTER COMMISSIONING.................................................................................42

6.1. Condensate removal ................................................................................................................................... 42

6.2. Gas supply .................................................................................................................................................. 42

7. MAINTENANCE OPERATIONS.........................................................................................43

................................................................................................ 44

7.2. Checking the ignition and ionisation electrodes .......................................................................................... 44

13.01.2023 Page 3 / 104

DORCHESTER DR-SG - Installation, Operation and Maintenance