H&H SF-828 User manual

www.hh.com.hk

t = 852.24813068

f = 852.24813727

Room 1117, 11/F, Asia Trade Centre, 79 Lei Muk Road, Kwai Chung, N.T., Hong Kong.

SF-828 Multifunctional bonding Machine

Operation Manual

is powered by

H&H Asia Group Limited

SF-828 operation manual

issue 1 17.08.22 P. 1 of 12

Introduction

Thank you for choosing SF-828 multifunctional bonding machine by H&H.

The SF-828 multifunctional bonding machine is a new product developed of different

characteristics of fabric, can be sticking strip, overlap, folding and wrapping and other

processes.

In order to fully understand how to use this machine properly, and avoid damage to

both the machine and operating personnel, please read this manual carefully and keep it

safe for future reference.

SF-828 operation manual

issue 1 17.08.22 P. 2 of 12

Specifications

Model

SF-828

Voltage

220 V, single phase

Frequency

50/60 Hz

Power Consumption

2680W

Compressed Air

>0.4Mpa

Working width

6~20(mm)

Overall Dimensions

1220mm (L) x 700mm (W) x 1450mm (H)

Overall Weight

130 kg

Note: due to continuous improvement, specifications are subjected to change without prior

notification.

SF-828 operation manual

issue 1 17.08.22 P. 3 of 12

Features

Multi-function selection job: sticking strip, overlap, hemming and wrappingfunction

Up and down four heating devices to ensure a more solid fit

Touch screen center control, easy to operate

Freely pressure regulation, speed independent control, suitable for different fabric

operations.

Temperature automatic control, according to different fabrics with different

adhesive tape to adjust the use

Automatic feeding device, according to different tension control adhesive tape

tightness

Suitable for a variety of fabric bonding use

SF-828 operation manual

issue 1 17.08.22 P. 4 of 12

Preparation for Installation

Installation must be carried out by authorized personnel. Follow the steps below:

1. Position the machine on a flat surface and allow at least 50cm clearance on both

sides as well as the back side, this is essential for the hot air ventilation and also

to allow enough room for maintenance personnel to carry out necessary service

and maintenance

2. Adjust the foot stand so that the machine is level and stable.

3. Loosen all packing cable ties and materials in order to free up all machine

movements.

4. Connect the power plug to a suitable outlet with at least 10A capacity. Make sure

grounded and reliable.

5. Locate the air hose supplied with the machine. Connect one end to the inlet of the

compressed air water filter at the back side of the machine; connect the other end

to a compressed air supply such as air compressor or central air supply. Make

sure the compressed air supply has at least 0.4Mpa (4 bar) of pressure.

6. Install the tensioner at the top of the machine and align the tape spool at right

angle to the working table of machine. (see diagram below)

7. Turn on the power,later it will show the languages page.(shown in Figure 1)

SF-828 operation manual

issue 1 17.08.22 P. 5 of 12

Fig.1

8. Select the language,then it will turn to the main page.(shown in Figure 2)

Fig.2

9. The control center internal parameter setting is the factory value parameter

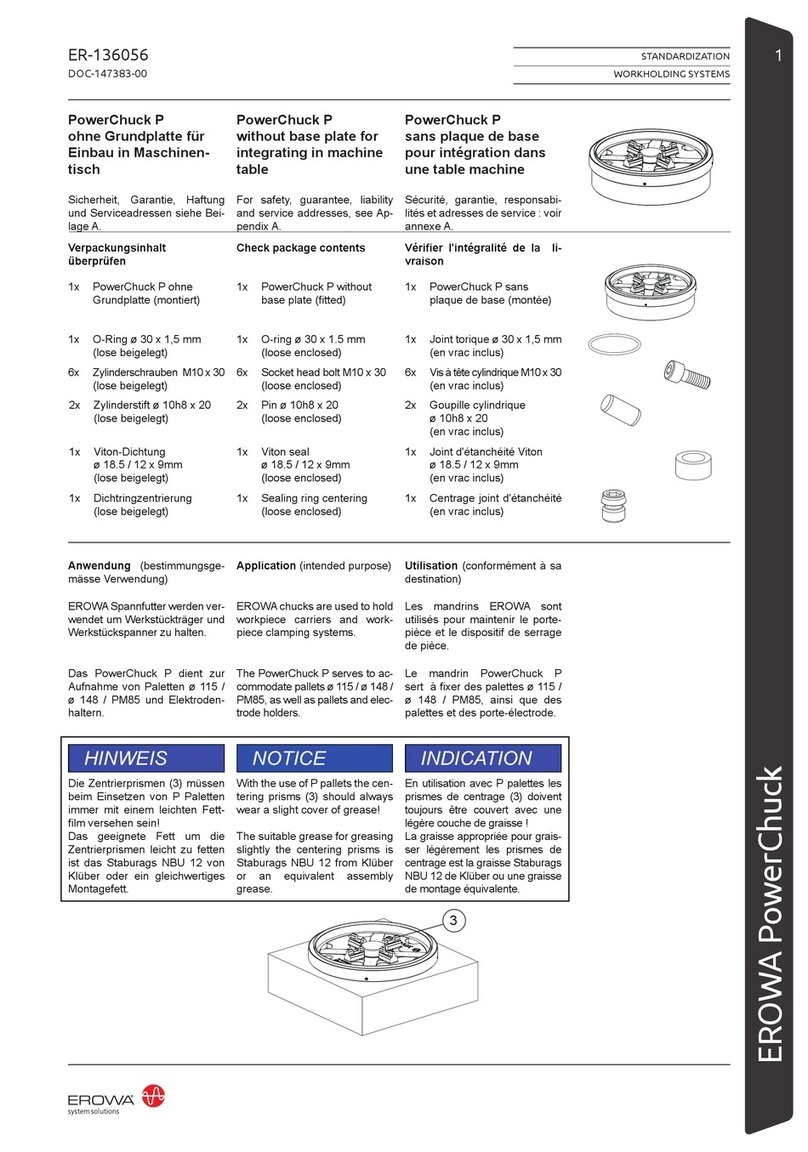

(shown in Figure 3)

Turn to

parameter page

SF-828 operation manual

issue 1 17.08.22 P. 6 of 12

Fig. 3

Note: "parameter setting" factory password is "888888", "advanced setting" factory password is

"88888899";

"advanced settings" parameter for the manufacturers to adjust the machine set the parameters,

not free to change, otherwise it will affect the machine running performance.

Turn to

advanced page

SF-828 operation manual

issue 1 17.08.22 P. 7 of 12

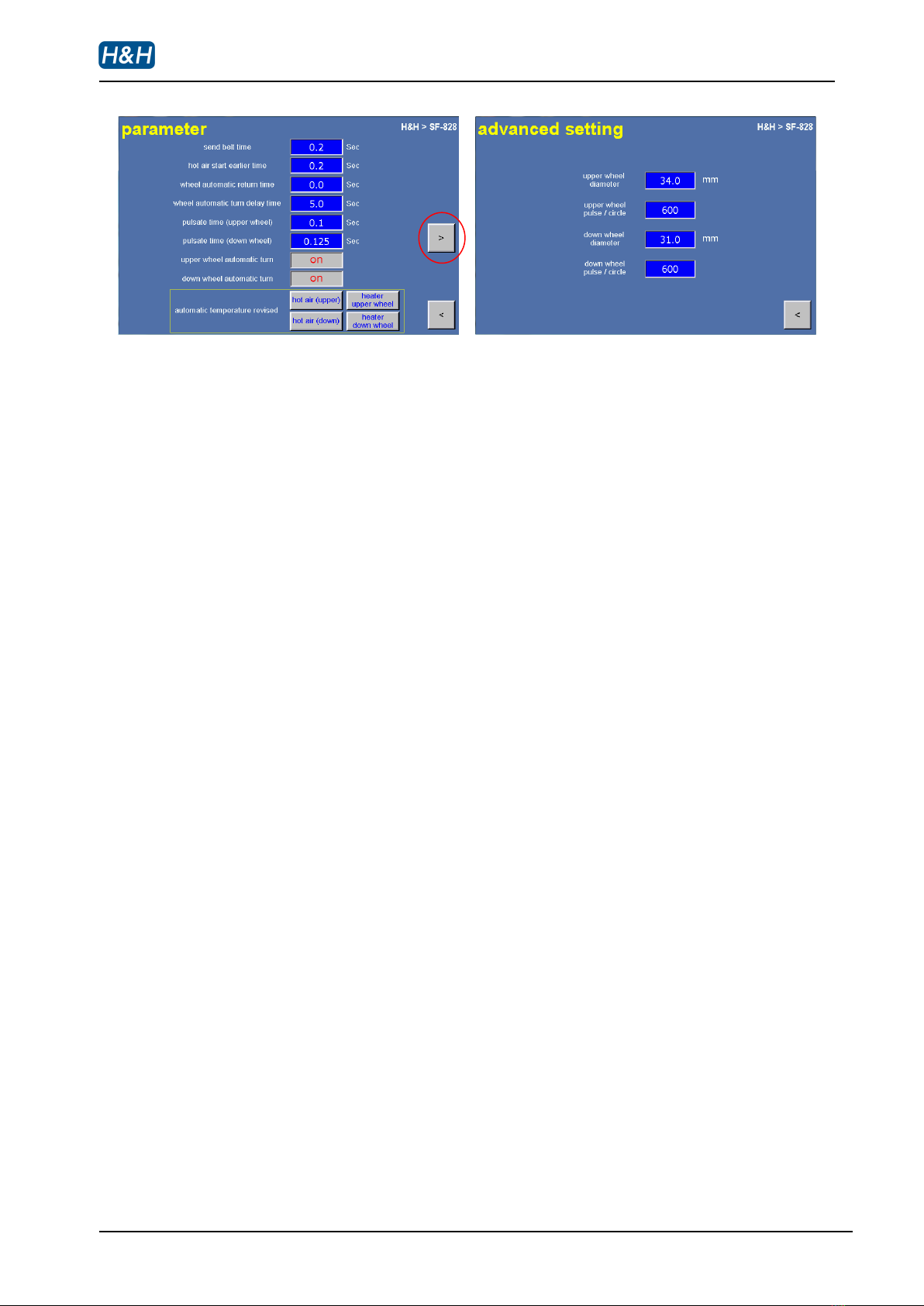

Boot test

Check the upper and lower wheel pressure

Adjust the top of the cylinder adjustable screw and lock cover

Press the foot switch of upper and lower mold at the same time

Gradually adjust the distance between the cutter wheel and the lower mold to change

the pressure until you can completely cut the current work piece. (as shown in Figure 4);

A: the role of adjustable cylinder screw: adjust the distance between the upper wheel

and the lower mold, to changing the working pressure;

B: the role of the lock cover: when the knife wheel and the lower mold spacing is

better, tighten the fixed cylinder screw.

Fig. 4

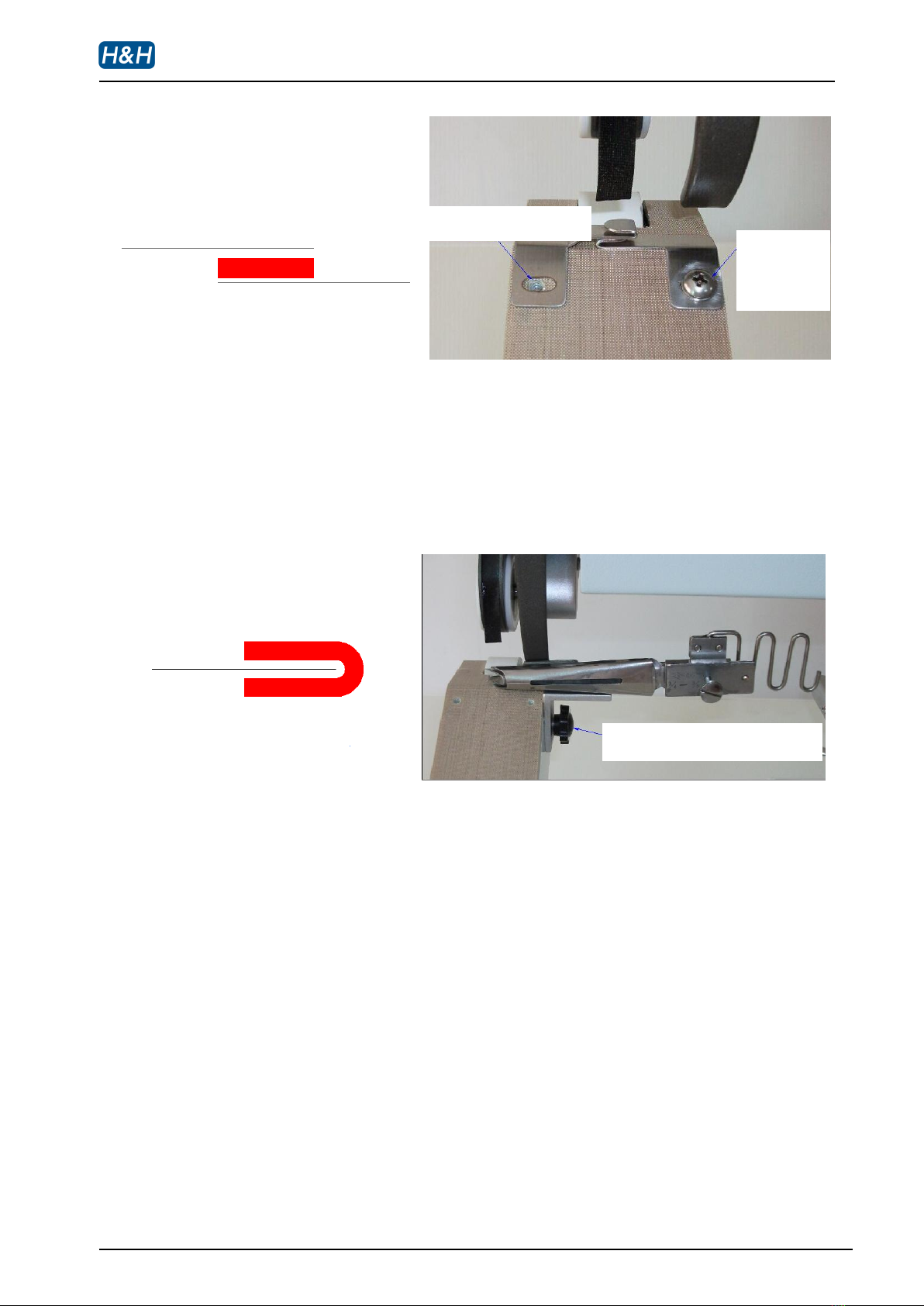

The choice and installation of the jet nozzle

1) The choice of jet nozzle: The machine is equipped with two jet nozzle,

according to different functions to choose a different jet nozzle, sticking strip

function is a separate nozzle, overlap, wrapping and hemming is a separate

nozzle.

adjustable screw

lock cover

SF-828 operation manual

issue 1 17.08.22 P. 8 of 12

Fig.5

2) The installation of jet nozzle: Close the hot air adjust (upper) when installing

the jet nozzle, that is tightened clockwise. “hot air indication”displayed as

0Mpa, After fitted with jet nozzle, In the upper wheel press down, the control

center "upper hot air" in the "open" situation, press start stop pedal switch,

the nozzle comes out automatically, the mouthpiece automatically protrudes

you can move nozzle to find the desired location,after confirm the position,

tighten the screws (as shown in Figure 6)

Fig.6

Function-sticking strip

sticking strip

Function

Folding

Overlap

Wrapping

Fixed screw

SF-828 operation manual

issue 1 17.08.22 P. 9 of 12

Note: the nearest distance between the gas nozzle and the heat conducting slot is about 1mm, which is

the best distance (as shown in Figure 7).

Nozzle Nozzle

Upper

wheel

Upper

wheel

Fig.7

The use and installation of each function parts

1) sticking strip function: After the adhesive tape is installed, you can

use it directly. It should be noted that when the machine is doing

the sticking process, the temperature of the “upper wheel heating”

of the control center shall be lower than 25% of the adhesive strip

temperature, and at the same time, the “lower hot air” temperature

switch shall be switched off. Example: strip the actual temperature

is 120 centigrade. The down wheel heating temperature should be

about 90 degrees Celsius (as shown in Figure 8).

SF-828 operation manual

issue 1 17.08.22 P. 10 of 12

Fig.8

2) folding function:This function is used for cuffs and so on,Arc、

straight and curved edges. adjust the position between it and the

lower wheel before installing the folding brink frame,and tighten

the retaining screws(as shown in Figure 9).

Fig.9

3) overlap function: This can be applied to overlap between two

pieces of workpieces. Install the overlap device according to the

picture, when you install, you can move the baffle,the width

required to reach the overlapping cloth(as shown in Figure 10).

Folding function

Folding width adjust

Sticking strip function

Fixed screw

SF-828 operation manual

issue 1 17.08.22 P. 11 of 12

Fig.10

4) wrapping function: This function is suitable for all kinds of cloth

single-fold wrapping operation. adjust the position between it and

the lower wheel before installing the pack brink frame,and tighten

the retaining screws(as shown in Figure 11).

Fig.11

Note:In the use of folding, overlapping, wrapping function,The reading of the "hot air indication

(lower)" table of the control panel must be less than the "hot air indication (upper)" reading, which can

be achieved by adjusting the "hot air adjustment (upper)" and "hot air adjustment (bottom)"

Belt inspection

1) As shown figure 12, tightening tension can be adjusted by

adjusting the tension regulator (1) and tension adjuster (2) angle to

achieve.

Wrapping function

Pack brink frame fixed screw

Overlap width adjust

Overdrive

fixing

screws

Overlap function

SF-828 operation manual

issue 1 17.08.22 P. 12 of 12

Fig.12

2) By adjusting the left and right movement of the biased device, the

central distance between the adhesive tape and the cutting piece

can be changed(as shown figure 13).

Fig.13

biased device

Tension regulator (1)

Tension regulator (2)

SF-828 operation manual

issue 1 17.08.22 P. 13 of 12

The role of the foot pedal(as shown Figure 14)

1. Up / Down: The upper wheel is down or up. Press down one

time and press again;

2. Start / stop: The action of the upper and lower wheels and the

blowing start and stop. Press and hold, release is stopped;

3. Up and down: in the work to be a small turn when the rapid

micro-beating up and down, making the turn more smooth

4. Folding: in the heel began to fix the pieces, the end of the arc

and through the thick bone position is the telescopic effect. Press

once to stretch, press again to shrink.

Fig.14

Folding

Start/Stop

Up and down

Down/Up

SF-828 operation manual

issue 1 17.08.22 P. 14 of 12

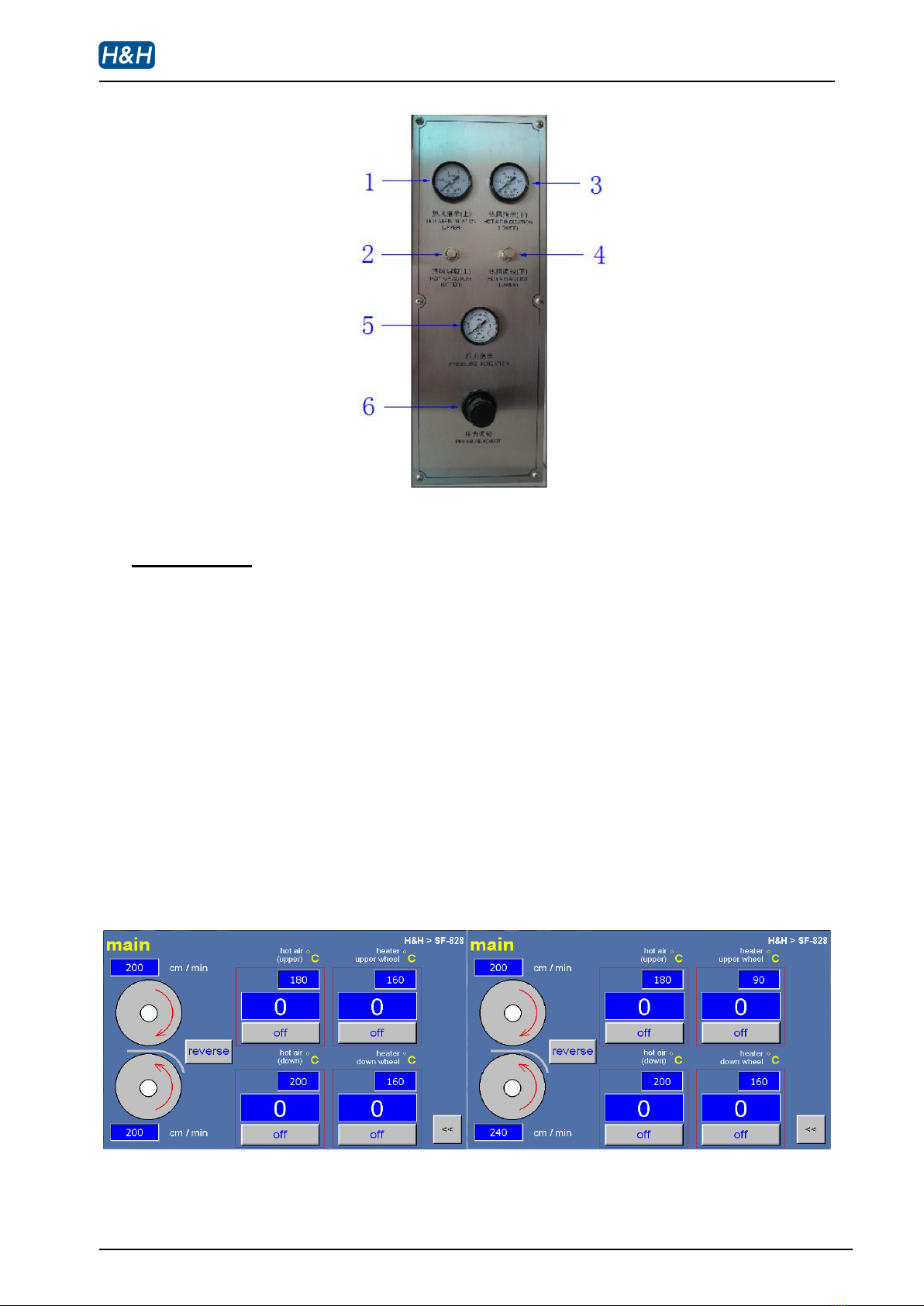

Control panel instructions (as shown in Figure 15)

1) Hot air indication (upper):Upper blowing air volume display. At the

same temperature setting, the greater the air flow, the higher the

actual temperature;

2) Hot air adjust (upper): Adjust the air volume of the upper blow.

Clockwise rotation of the air flow becomes smaller, counterclockwise

rotation of the air flow becomes larger;

3) Hot air indication (lower):Lower blowing air volume display. At the

same temperature setting, the greater the air flow, the higher the

actual temperature;

4) Hot air adjust (lower):Adjust the air volume of the lower blow.

Clockwise rotation of the air flow becomes smaller, counterclockwise

rotation of the air flow becomes larger.

5) Pressure indication:The pressure between the upper and lower

wheels is indicated.

6) Pressure adjust:When the distance between the upper and lower

wheels is fixed.The upper and lower wheels pressure between the

calibration.

SF-828 operation manual

issue 1 17.08.22 P. 15 of 12

Fig.15

Boot steps

Adjust the temperature, pressure, speed, hot air volume required for

the workpiece. In general, the speed ratio of the upper and lower

wheels is 1: 1.2(as shown in figure16-1).When the hemming,

overlapping, wrapping, the upper and lower wheel speed should be

consistent (as shown in Figure 16-2).

Foot press down the foot switch, the upper wheel press down.

Foot press the foot switch, the upper wheel up.

Note: Stop working for a long time, the upper wheel should remain

suspended

Fig.16-1 Fig.16-2

SF-828 operation manual

issue 1 17.08.22 P. 16 of 12

Maintain

Preventative

In order to keep the machine in top running condition, regular maintenance is

important for trouble free operation. This will minimize possible down time and to prolong

machine life.

Check the tightness of the upper and lower wheel timing belt every 3

months, adjust the internal timing belt tension wheel can change the

tightness of the belt;

Always clean the upper and lower wheels and machine;

Pay attention to the heating time, such as heating time becomes long,

you need to check the heater is normal.

SF-828 operation manual

issue 1 17.08.22 P. 17 of 12

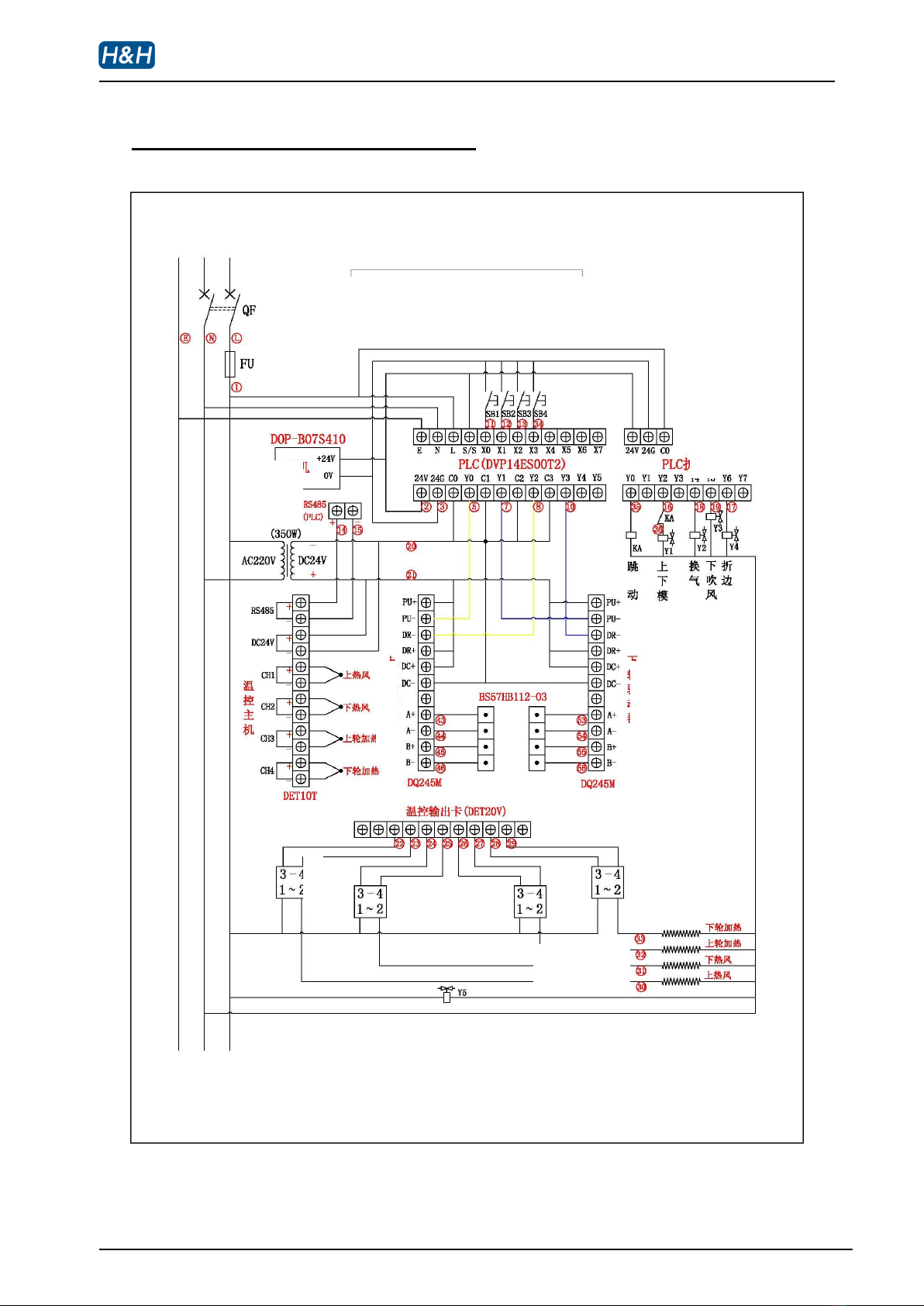

Appendix Wiring Scheme

SF-828 Electrical control

Table of contents