HANKISON SPXFLOW HF Series User manual

HF Series

Compressed Air Filters

Models HF(grade)-52 through HF(grade)-92 Standard, High Pressure and Corrosion Resistant Models

FORM NO.: 4011208 REVISION: 10/2015 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

Contents

MODEL NUMBER CONFIGURATION ..................... 1

1.0 INSTALLATION ............................................... 2

2.0 OPERATION .................................................. 5

3.0 MAINTENANCE............................................. 6

DIMENSIONS AND WEIGHTS ........................................ 8

WARRANTY ......................................................... 9

General Safety Information

1. Pressurized devices

• Donotexceedmaximumoperatingpressure

indicatedonserialnumbertag.

• Makecertainlterisfullydepressurizedbefore

servicing.

2. Breathing Air

• Airtreatedbythisequipmentmaynotbesuit-

ableforbreathingwithoutfurtherpurication.

RefertoOSHAstandard1910.134forbreathing

airrequirements.

3. Flammable gases

Thematerialsofconstructionusedinthisproduct

arecompatiblephysicallywithammablegases,

however,thereareapplicationlimitationsforthis

productwhenusedwithammablegases.Each

application(otherthanairorinertgas)shouldbe

carefullyreviewedtominimizethechancesof

creatingareorexplosionhazard.

IMPORTANT

Tightencartridgesbeforeuse.Cartridgesmay

haveloosenedduringtransit.Toensureatight

sealbetweenthecartridgeendcap(s)andinlet

manifold,openvesselandturncartridgeclockwise

(asseenfrombottom)untilhandtight.See

Section3.0,Bforinstructionsonenteringvessel.

1

Grade Identification

Filtergradecanbeidentiedbythethirddigitofthemodelnumber.Inaddition,elementswithafoamouter

sleevecanbeidentiedbycolor.

Grade Description Type Outer foam color

11 Mechanical Separator Impaction type separator none

9 Separator/filter Mechanical separator and 3 micron coalescer none

7 General purpose air line filter 1 micron coalescer none

6 Dry Desiccant Afterfilter 1 micron after-filter for desiccant dryers none

5 High efficiency oil removal filter High efficiency (99.99+%) coalescer Red

3 Maximum efficiency oil removal filter Maximum efficiency (99.999+%) coalescer Blue

1 Oil vapor removal filter Activated carbon adsorber Green

Model Number Configuration

HF (1) -(2) -(3) -(4)

1. Filter Grade is indicated in space (1).

2. Housing Number is indicated in space (2).

3. Connection Size is indicated in space (3)

4. If optional corrosion proof stainless steel cores are included, an S

is indicated in space (4). Corrosion resistant stainless steel cores

are standard.

Example: A Grade 5 high efficiency oil removal filter with a capacity of

1250 scfm and 3” NPTM connections would be configured

as: HF 5-56-24-G

(2) Housing (3) Connection Sizes

Number

Capacity

scfm [m3hr] @

100 psig [7 kgf/cm2]

52 625 [1110] 24 - 3” NPTM 80 - DN 80 Flange

54

56

1000 [1700]

1250 [2125] 24 - 3” NPTM 80 - DN 80 Flange

60 1875 [3158] 24 - 3” NPTM 80 - DN 80 Flange

64

68

2500 [4250]

3125 [5310] 4F - 4” ANSI Flange 100 - DN 100 Flange

72 5000 [8490] 6F - 6” ANSI Flange 150 - DN 150 Flange

76

80

6875 [11,670]

8750 [14,850] 6F - 6” ANSI Flange 150 - DN 150 Flange

84 11,875 [20,175] 8F - 8” ANSI Flange 200 - DN 200 Flange

88 16,250 [27,610] 8F - 8” ANSI Flange 200 - DN 200 Flange

92 21,250 [36,100] 10F - 10” ANSI Flange 250 - DN 250 Flange

(4) Features

D= Internal Automatic Drain

Mechanism

G= Differential Pressure Gauge

Indicator

S = Corrosion Proof Stainless

Steel Element

M= Filter Monitor

(1) Filter Grade

11 - Mechanical Separator

9- Separator/Filter

7- Air Line Filter

6- Dry Desiccant Afterfilter

5- High Efficiency Oil Removal Filter

3- Maximum Efficiency Oil Removal Filter

1- Oil Vapor Removal Filter

2

1.0 Installation

A. Where Used/Air Quality After Filtration

Grade Where used

Solid particle

removal (maximum

size in microns)

Liquid removal

efficiency (at

rated conditions)

Maximum inlet

liquid loading

ppm w/w

Remaining

oil content

ppm w/w

11

Separator - downstream of an aftercooler

Point-of-use - where no aftercooler is installed

upstream

— 95% of water 30,000

bulk liquids —

9

Separator - downstream of an aftercooler

Point-of-use - where no aftercooler is installed

upstream or as prefilter to refrigerated dryer

3 99+% of water

25,000

aerosols &

bulk liquids

5

7

Prefilter -

•PreltertoGrade3&Grade5highefciency

coalescing filters

Point-of-use - where aftercooler is installed

upstream

1 100% of water 2, 000

aerosols

1

aerosols

6

Afterfilter - downstream of a pressure-swing

(heatless) desiccant dryer

•DownstreamofanActivatedCarbonor

Desiccant Tower

1No liquid should be

present at inlet

No liquid should be

present at inlet —

5

Prefilter

•Aheadofdesiccantandmembranedryers

Afterfilter

•Downstreamofrefrigerateddryer

•Downstreamofpressure-swing(heatless)

desiccant dryers for finer solid particle removal

•Oilremovalatpoint-of-use

0.01 99.99+% of oil 1, 000

aerosols

0.008

aerosols

3

Prefilter - ahead of desiccant and membrane

dryers (use after Grade 7 to reduce liquid and

solids load, prolong element life and ensure

filtration efficiency)

Afterfilter - downstream of refrigerated dryer

0.01 99.999+% of oil 100

aerosols

0.0008

aerosols

1Afterfilter to Grade 3 & Grade 5 for true oil free

applications 0.01 Removes vapors

only

No liquid should be

present

0.003

vapor

3

B. Piping

1. Beforeinstalling,blowoutpipelinetoremove

scaleandotherforeignmatter.

2. Mounting(Grades11,9,7,5,3)-mountsothat

inletandoutletconnectionsarehorizontal(lter

bowlvertical)toensureproperliquiddrainage.

3. FlowDirection-installsothattheairowisinthe

directionindicatedonlter.

NOTE:Grade6owsfromoutsidetoinsideof

element.Allothergradesowfrominsideto

outside.Observeowarrowsonunit.

4. Isolationvalvesandby-passpiping-Foreaseof

service,isolationandby-passvalvesaredesirable.

Incriticalapplications,twoltersinstalledinparal-

lelmaybenecessarytoavoidinterruptionofair

supply.

C. Drain Provisions (Grades 11, 9, 7, 5, 3)

Thebottomofthepressurevesselisprovidedwith

adrainplugforshippingpurposes.Provisionfor

manualorautomaticdrainingisnecessaryforproper

operation.

Donotattempttoremovedrainplugif

theunitispressurized.

1. ManualDrain-Whendrainingisperformedmanu-

allyonaregular,periodicbasis,asimple(open/

shut)valvemaybeusedtodrainthevessel.When

drainingmanually,thevalveshouldbeopened

slowlytoavoidrapiddepressurizationandpossible

elementdamage.

2. AutomaticDrain-Whereregularmanualdraining

isnotperformed,anautomaticcondensatedrain

shouldbeused.Avarietyofdrainsisavailable

fromthemanufacturer.

SNAP-TRAP®TRIP-L-TRAP®

1" DRAIN PORT

FILTER

HOUSING

MANUAL

OVERRIDE

22

MIN

SEC

1

7

15

145

POWER

ON

ELECTRIC DRAIN

4

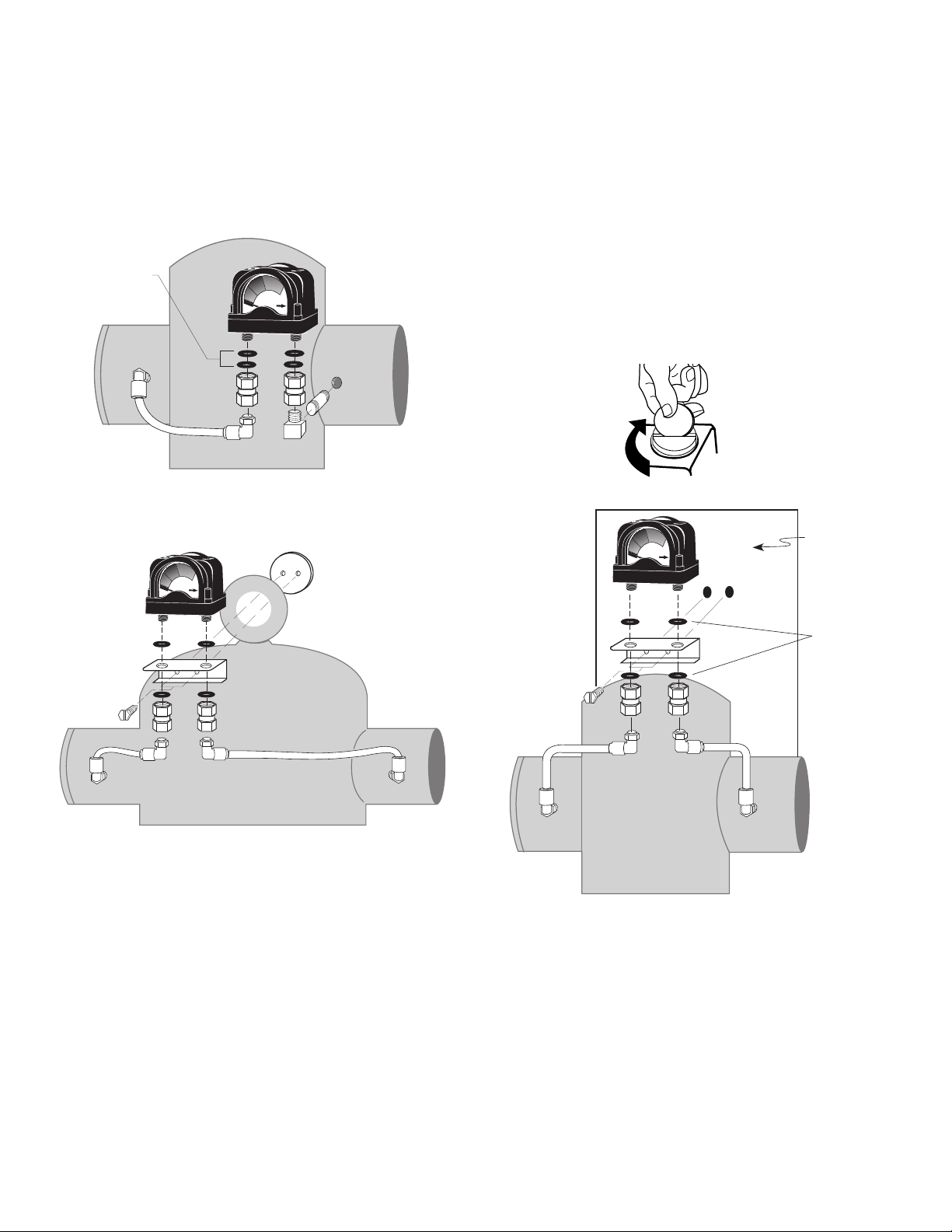

NOTES:

1) Makecertaino-ringsareinplaceonthebottom

ofthegaugebody.

2) Connectthelowpressuretransmissionbolt(bolt

nexttoREDbandongauge)tothegaugeportat

thelteroutlet(down-streamsideoflter).

3) Connectthehighpressuretransmissionbolt(bolt

nexttoGREENbandongauge)tothegaugeport

atthelterinlet(upstreamsideoflter).

4) Torqueboltsto25+/-5inchoz.Aathead

screwdriverwitha3/8”(1cm)minimumblade

widthcanbeusedtoassemble/disassemblethe

gauge.Smallbladewidthswilldamagethebolt

heads.DO NOT OVER TIGHTEN

WALL

INLET OUTLET

O-RINGS

All Models - Wall Mounted

D. Differential Pressure Gauge (DPG) -

Grades 9, 7, 6, 5, 3

Onstandardunits,agaugeandinstallationkitare

shippedseparatelypackagedforeldinstallation.

Refertodiagramforproperinstallation.Gauge

maybeinstalledonlterhousingoronanearby

wallusingthewallmountingbracketsupplied.

INLET OUTLET

O-RINGS

Model 52 - Equipment Mounted

Model 54 and Larger - Equipment Mounted

5

2.0 Operation

Donotoperatelteratpressuresinex-

cessofMaximumWorkingPressureindicatedonSerial

NumberTag.

NOTE:MaximumOperatingTemperature-150°F,

66°C.Liquidltrationabove120°F,49°Cisnotrecom-

mendedsincethereistypicallyoilpresentinavapor

statewhichpassesthroughthelterandcondenses

downstream.

NOTE:Grade1-Ifoperatedabove100°F,38°C,a

Grade1ltermayexperiencelessthan1000hoursof

lifebecauseofgreateroilvaporcontent.

A. Operational Checkpoints

Grades 11,9,7,6,5,3

1. Grades9,7,6,5,3-Checkpressuredropacrossthe

lter

a. Pressuredifferentialinexcessof6psi(0.42kgf/

cm2)-pressureindicatorinredarea-indicates

thattheltersleeveorelementshouldbe

replaced.

NOTE:Elementshouldbechangedannuallyorwhen

indicatorchangestored,whicheveroccursrst.

NOTE:Pressuredropshouldneverexceed15psi

(1.0kgf/cm2).

NOTE:Grades9,7,5,3-Pressuredropmaytemporar-

ilyincreasewhenowisresumedafterowstoppage.

Pressuredropshouldreturntonormalwithinone

hour.

b. Checkforsuddenreductioninpressuredrop.

Thismightindicate:

(1) Possibleleakacrosselemento-ringseal

(2) Leakthroughtheelementduetophysical

damage

2. Checkow,pressure,andtemperaturetomake

certainlterisbeingoperatedwithindesign

conditions.

3. Grades11,9,7,5,3-Checktoseethatlteris

installedleveltoinsureproperdrainage.

4. Grades11,9,7,5,3-Checkthatmanualdrainsare

drainedperiodicallyorthatautomaticdrainsare

functioning.

Grade 1

1. Checkforanoilysmellbyopeningthemanual

valve.Ifanoilysmellexists,thefollowingshould

bechecked:

a. Filterelementadsorptioncapacityexhausted

b. Leakacrosselemento-ringseal

c. Leakthroughelementduetophysicaldamage

d. Presenceofliquidsbecauseoflackoforfailure

ofprelters

e. Flow,pressureandtemperaturesoutsidede-

signconditions

f. Presenceofgaseousimpuritieswhichcannot

beadsorbedbyactivatedcarbon

Methane,carbonmonoxide,carbondi-

oxideandvariousinorganicgasescannotberemoved

byaGrade1lter.

C. Flow Capacity

Maximumairowforthevariousltersat100psig

(7kgf/cm2)isindicatedinTable1.Todetermine

maximumairowsatinletpressuresotherthan100

psig(7kgf/cm2),multiplyowfromTable1byairow

correctionfactorfromTable2thatcorrespondstothe

minimumoperatingpressureattheinletofthelter.

NOTE:Filtersshouldnotbeselectedbypipesize.

Selectusingowrateandoperatingpressureonly.

Table 1 - Maximum Flow @100 psig [

7 kgf/cm

2

]

Housing scfm [m3/hr]

52 625 [1110]

54 1000 [1700]

56 1250 [2125]

60 1875 [3158]

64 2500 [4250]

68 3125 [5310]

72 5000 [8490]

76 6875 [11,670]

80 8750 [14,850]

84 11,875 [20,175]

88 16,250 [27,610]

92 21,250 [36,100]

Table 2 - Air Flow Correction Factor

Maximum

Inlet

Pressure

psig 20 30 40 60 80 100 125 150 175 200

kgf/cm21.4 2.1 2.8 4.2 5.6 7.0 8.8 10.6 12.3 14.1

Correction Factor 0.30 0.39 0.48 0.65 0.82 1.00 1.22 1.43 1.65 1.87

Maximum

Inlet

Pressure

psig 250 300 350 400 450 500 550 600 650 700

kgf/cm217.6 21.1 24.6 28.1 31.6 35.2 38.7 42.2 45.7 49.2

Correction Factor 2.31 2.74 3.18 3.62 4.05 4.49 4.92 5.36 5.80 6.23

6

3.0 Maintenance

A. When to Replace Filter Element

NOTE:Grades7,6,5,3,1-completeelementisre-

placed;Grade9-unlessseparatorcoreisdamaged

outersleeveonlyisreplaced.

1. Grades6(drydesiccantafterlter)

Initialdrop:1psi(0.07kgf/cm2).Pressuredrop

increasesaselementloadswithsolidparticles.Re-

placewhenpressuredropreaches10psi(0.7kgf/

cm2)(indicatorinredarea)orannually,whichever

occursrst.

2. Grade11(mechanicalseparator)

Elementshouldnotrequirereplacementunless

physicallydamaged.Ifsludgeaccumulates,ele-

mentcanberemovedandcleanedwithsoapand

water.

3. Grades9,7,5,3(coalescinglters)

a. Initial(dry)pressuredrop:1psi(0.07kgf/cm2)

to2psi(0.14kgf/cm2)

b. Operatingpressuredrop:Aslterbecomesliq-

uidloaded(wetted),pressuredropwillincrease

to2to6psi(0.14to0.42kgf/cm2).Further

pressuredropoccursaselementloadswith

solidparticles.

FORMAXIMUMFILTRATIONEFFICIENCY,REPLACE

ELEMENTWHENPRESSUREDROPREACHES6PSI(0.42

KGF/CM2)(INDICATORINREDAREA)ORANNUALLY,

WHICHEVER OCCURS FIRST.

NOTE:Pressuredropmaytemporarilyincreasewhen

owisresumedafterowstoppage.Pressuredrop

shouldreturntonormalwithinonehour.

NOTE:Grades5and3-Duringnormaloperation

bottomoffoamsleevewillhaveabandofoil.

Spottingabovethebandindicatesthatliquidsare

accumulatingfasterthantheycanbedrainedandthat

preltrationisrequired.

4. Grade1(activatedcarbonlters)

a. Adsorptioncapacity-1000hoursatrated

capacity.Elementlifeisexhaustedwhenodor

canbedetecteddownstreamofthelter.

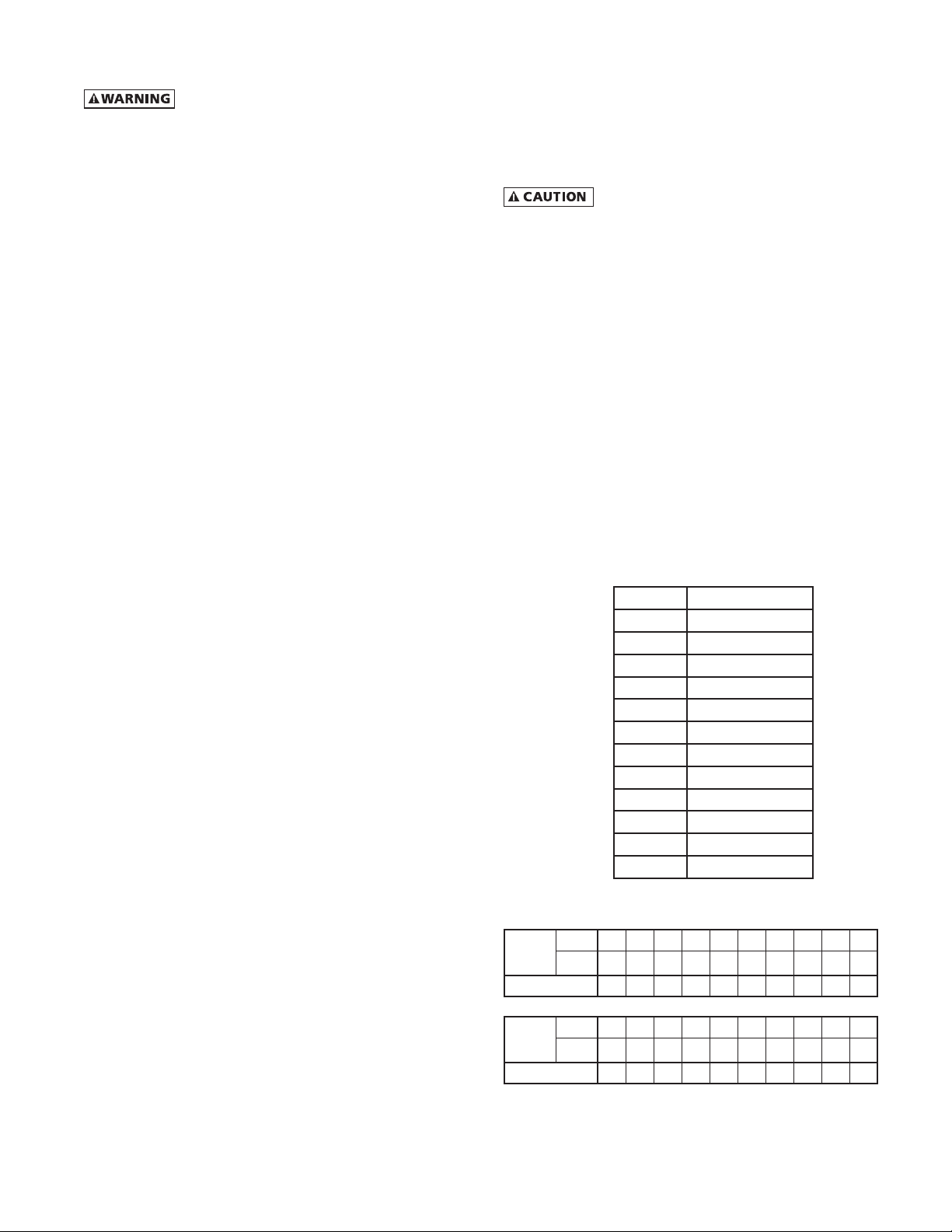

SEAL PLATE

VESSEL

YOKE

NUT

GASKET

TILT THE SEAL PLATE

AND GASKET TO FIT IN OPENING

HAND HOLE

Handhole

O-RING

PLASTIC

SEAL RING

RETAINER

LOWER

BOTTOM

OF SHELL

Model 52

B. Procedure for Element Replacement

THIS FILTER IS A PRESSURE CONTAINING

DEVICE. DEPRESSURIZE BEFORE SERVICING.

1. By-passtheltertopermit

servicing.

2. Depressurizethelteras-

semblyslowlybyopening

blowdownvalve.

3. Openpressurevessel

3A.Model52-Removeange

bolts.Lowerbottom

shell,o-ring,andsealring

retainer.

3B.Modelswithhandhole

a. Removenutandyoke

b. Liftsealplateandturnsothatsealplateand

sealplategasketcanberemoved.

3C.Modelswithangedbottom

a. Loosenbottomblindangebolts.

b. Removeallbutonebolt.

c. Swingangetooneside.

Bottom Flange

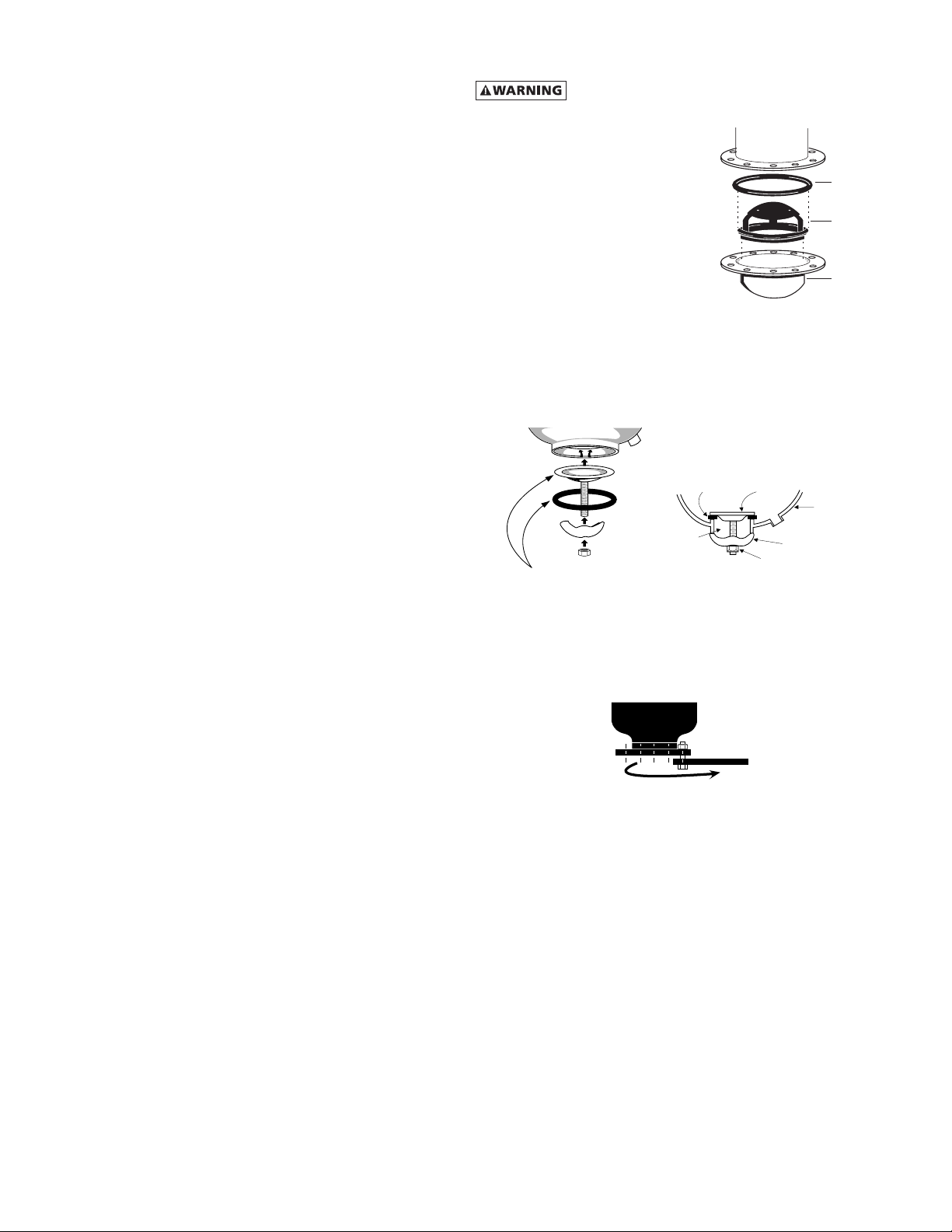

4. Startinginthecenter,unscrewthelterelements

andremovethelterelementsandelemento-

rings.

7

5. Grades7,6,5,3,1-Discardoldelementsando-

rings.

5A.Grade9

a. Removenylonnutand

bottomcap

b. Slidedisposablelter

sleevedownoversepa-

ratorcore.

c. Ifnecessary,cleansepa-

ratorcorewithsoapand

water.

d. Slidenewltersleeve

overseparatorcoreand

replacebottomcapand

nylonnut.

6. Cleanfaceofinletmanifold

withamilddetergentus-

ingalong-handledbrush

orcleanragattachedtoa

rod.Manifoldfacemustbe

freeofalldirtandgrease

toinsurepropero-ringseal

betweennewlterelement

topcapandinletmanifold.

7. Installnewo-ringsinthe

o-ringgroovesineachlter

elementtopcap.

8. Startingfromtheoutside(lterelementclosest

tothevesselwall),screwnewlterelementsinto

inletmanifoldconnections.Aconeinthemani-

foldwillguidetheelementboltintothefemale

threads.

NOTE:Grades5,3and1-Donothandleelementsby

outsidefoamcover.Handlebyplasticpackagingand

bottomendcaponly.

NOTE:Itisonlynecessarytongertightenthelter

elementtoinsureaseal.DO NOT WRENCH TIGHTEN

9. Closevessel

9A.Model52-Reassemblebottomshell,o-ringand

seal-ringretainertohousing.Makesureseal-ring

retainerprovidesabackupfortheo-ringasshown

indrawing.

9B.Modelswithhandhole

a. Reinsertsealplateandsealplategasketinto

vesselandpositiononlipasshownindrawing.

NOTE:Donotreusegasketifgasketistornorgasket

surfaceisdamaged.

b. Reinstallyokeandnut.

c. Tightennutmakingsurethatgasketisproperly

positionedundersealplate.

CONE

INLET

MANIFOLD

O-RING

SEPARATOR

CORE

REPLACEMENT

SLEEVE

BOTTOM

CAP

NUT

CONE

INLET

MANIFOLD

O-RING

CARTRIDGE

Grade 9 -

Sleeve Replacement

All Grades -

Element Replacement

9C.Modelswithangedbottom

a. Swingblindbottomangeintoposition.

b. Reboltafterinspectingangegaskettoensure

itsintegrity.

10. Pressurizeunitslowlybyslowlyopeninginlet

valve,thenopeningoutletvalve,andnallyclos-

ingby-passvalve.

8

Standard and CR

HF (Grade)-

52-24 52-24-D

(2)

54-24 56-24 60-24 64-4F 68-4F 72-6F 76-6F 80-6F 84-8F 88-8F 92-10F

Connection 3” NPT 3” NPT 3” NPT 3” NPT 3” NPT 4” ANSI Flg. 4” ANSI Flg. 6” ANSI Flg. 6” ANSI Flg. 6” ANSI Flg. 8”ANSI Flg. 8”ANSI Flg. 10”ANSI Flg.

Maximum Working Pressure 300 psig 300 psig 225 psig 225 psig 225 psig 225 psig 225 psig 225 psig 225 psig 225 psig 225 psig 225 psig 225 psig

HF (Grade)-

52-80 52-80-D

(2)

54-80 56-80 60-80 64-100 68-100 72-150 76-150 80-150 84-200 88-200 92-250

Connection

DN 80 Flg. DN 80 Flg. DN 80 Flg. DN 80 Flg. DN 80 Flg. DN 100 Flg. DN 100 Flg. DN 150 Flg. DN 150 Flg. DN 150 Flg. DN 200 Flg. DN 200 Flg. DN 250 Flg.

Maximum Working Pressure 21.0 kgf/cm

2

21.0 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

15.8 kgf/cm

2

High Pressure

HF (Grade)-

52-24-34 52-24-34-D 52-24-48 54-24-31 56-24-31 60-24-45 64-4F-30 68-4F-30 72-6F-24 76-6F-22 80-6F-22 84-8F-18

Connection 3” NPT 3” NPT 3” NPT 3” NPT 3” NPT 3” NPT 4” ANSI Flg. 4” ANSI Flg. 6” ANSI Flg. 6” ANSI Flg. 6” ANSI Flg. 8”ANSI Flg.

Maximum Working Pressure 500 psig 500 psig 700 psig 450 psig 450 psig 650 psig 440 psig 440 psig 360 psig 330 psig 330 psig 260 psig

HF (Grade)-

52-80-34 52-80-34-D 52-80-48 54-80-31 56-80-31 60-80-45 64-100-30 68-100-30 72-150-24 76-150-22 80-150-22 84-200-18

Connection

DN 80 Flg. DN 80 Flg. DN 80 Flg. DN 80 Flg. DN 80 Flg. DN 80 Flg. DN 100 Flg. DN 100 Flg. DN 150 Flg. DN 150 Flg. DN 150 Flg. DN 200 Flg.

Maximum Working Pressure 35.0 kgf/cm

2

35.0 kgf/cm

2

49.0 kgf/cm

2

31.5 kgf/cm

2

31.5 kgf/cm

2

45.0 kgf/cm

2

30.8 kgf/cm

2

30.8 kgf/cm

2

25.2 kgf/cm

2

23.1 kgf/cm

2

23.1 kgf/cm

2

18.2 kgf/cm

2

No. of Elements E(Grade)-PV or PVS 1 1 1 2 (1) 2 3 4 5 8 11 14 19 26

34

Models HP HP HP HP HP HP HP HP

CF (Grade)-

52-24(5)

52-24-D(2)

52-80(5)

52-80-D(2)

52-24-34

52-24-34-D(2)

52-80-34

52-80-34-D(2)

52-24-48

52-80-48

54-24-31

54-80-31

56-24-31

56-80-31

54-24

54-80

56-24(5)

56-80(5)

60-24(5)

60-89(5)

60-24-45

60-80-45

64-4F(5)

64-100(5)

68-4F(5)

68-100(5)

64-4F-30

64-100-30

68-4F-30

68-100-30

72-6F

72-150

72-6F-24

72-150-24

76-6F

76-150

80-6F

80-150

76-6F-22

76-150-22

80-6F-22

80-150-22

84-8F

84-200

84-8F-18

84-200-18

88-8F

88-200

92-10F

92-250

Dimensions in (mm)

“A” w/thread

10.25 (260) 10.25 (260) 10.25 (260) 20.00 (508) 16.00 (406) 16.25 (413) 16.25 (413) — — — — — — — — — —

“A” w/flange

10.63 (270) 11.63 (295) 11.00 (279) 21.38 (543) 16.38 (416) 16.63 (423) 17.63 (448) 20.00 (508) 20.00 (508) 24.00 (610) 24.00 (610) 28.00 (711) 28.00 (711) 33.00 (838) 33.00 (838) 39.00 (991) 45.88 (1165)

“B”

40.88 (1038) 42.38 (1076) 40.44 (1027) 50.44 (1281) 48.00 (1219) 49.00 (1245) 55.50 (1410) 52.25 (1327) 55.50 (1410) 54.63 (1387) 55.88 (1419) 62.56 (1589) 63.88 (1622) 69.13 (1589) 66.25 (1683) 67.94 (1726) 70.94 (1802)

“C”

4.88 (124) 4.88 (124) 8.31 (211) 10.81 (275) 9.69 (246) 9.69 (246) 11.69 (297) 11.63 (295) 12.69 (322) 13.44 (341) 14.69 (373) 16.88 (429) 18.19 (462) 19.63 (498) 19.69 (500) 19.56 (497) 21.56 (548)

“D”

32.25 (819) 32.25 (819) 29.5 (749) 39.63 (1006) 38.31 (973) 39.31 (99) 40.50 (1029) 40.63 (1032) 40.56 (1030) 41.19 (1046) 39.44 (1002) 45.69 (1160) 43.44 (1103) 49.50 (1257) 44.31 (1126) 48.38 (1229) 49.38 (1254)

Weight lb (kg)

w/thread

36 (16) 39 (17) 128 (58) 270 (123) 90 (41) 118 (54) 294 (133) — — — — — — — — — —

w/flange

52 (23) 65 (29) 154 (70) 296 (135) 106 (48) 134 (61) 320 (145) (3) (3) 271 (123) 524 (238) (4) (4) 709 (322) 980 (445) 918 (416) 1412 (640)

Drain Connection

1/2” 1/4” 3/4” 1” 1” 1” 1” 1” 1” 1” 1” 1” 1” 1” 1” 1” 1”

Vessel Type

I I II III IV IV III IV V IV V IV V IV V IV IV

NOTE: Dimensions and Weights are for reference only. Request certified drawings for construction purposes.

(1)

E(Grade)-54

(2) D signifies internal auto drain.

Add 1.5 in. (38mm) to dim. B and 3 lb (1.4 kg) to weight.

(3) 64-4F and 64-100: 178 (81);

68-4F and 68-100: 180 (82);

64-4F-30 and 64-100-30: 408 (183);

68-4F-30 and 68-100-30: 405 (184)

(4) 76-6F and 76-150: 518 (235);

80-6F and 80-150: 525 (238);

76-6F-22 and 76-150-22: 693 (314);

80-6F-22 and 80-150-22: 700 (318)

(5) Includes Corrosion Resistant (CR) Models

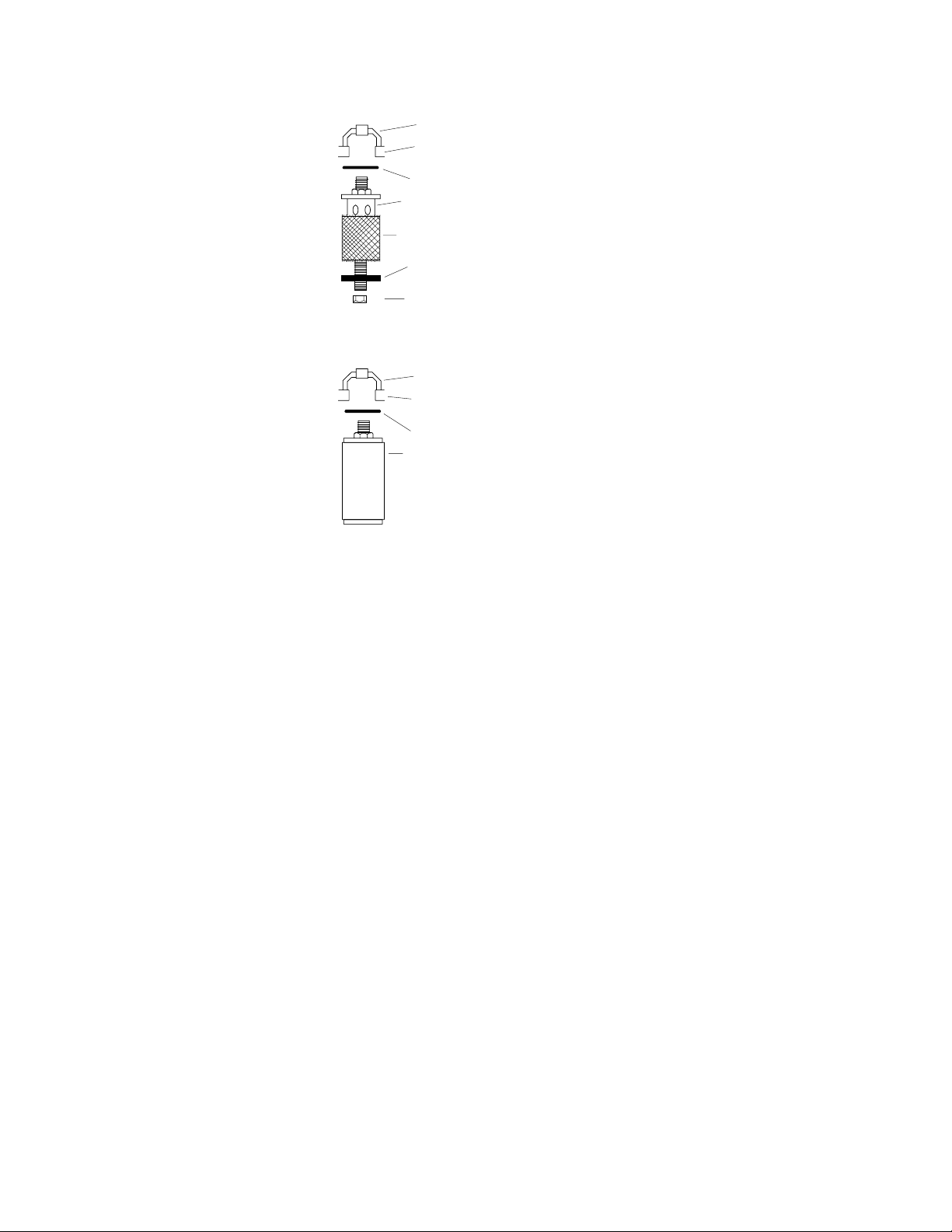

Dimensions and Weights

SERVICE CLEARANCE

24" (610mm)

DRAIN

D

B

C

A

TYPE II

SERVICE CLEARANCE

24" (610mm)

DRAIN

D

B

C

A

TYPE V

SERVICE CLEARANCE

24" (610mm)

DRAIN

D

B

C

A

TYPE IV

A w/Flg.

A

Optional

Internal

Auto Drain

SERVICE CLEARANCE

24" (610mm)

DB

C

A w/Flg.

A

DRAIN

SERVICE CLEARANCE

24" (610mm)

D

B

C

A w/Flg.

A w/Flg.

A w/Flg.

TYPE I TYPE III

9

SERVICE DEPARTMENT: (724) 746-1100

WARRANTY

Themanufacturerwarrantstheproductmanufacturedbyit,whenproperlyinstalled,operated,applied,andmain-

tainedinaccordancewithproceduresandrecommendationsoutlinedinmanufacturer’sinstructionmanuals,tobe

freefromdefectsinmaterialandworkmanshipforaperiodofone(1)yearfromdateshipmenttothebuyerbythe

manufacturerormanufacturer’sauthorizeddistributorprovidedsuchdefectisdiscoveredandbroughttothemanu-

facturer’sattentionwithintheaforesaidwarrantyperiod.

Themanufacturerwillrepairorreplaceanyproductorpartdeterminedtobedefectivebythemanufacturerwithin

thewarrantyperiod,providedsuchdefectoccurredinnormalserviceandnotasaresultofmisuse,abuse,neglect

oraccident.Normalmaintenanceitemsrequiringroutinereplacementarenotwarranted.Thewarrantycoversparts

andlaborforthewarrantyperiod.Repairorreplacementshallbemadeatthefactoryortheinstallationsite,atthe

soleoptionofthemanufacturer.Anyserviceperformedontheproductbyanyoneotherthanthemanufacturer

mustrstbeauthorizedbythemanufacturer.

Unauthorizedservicevoidsthewarrantyandanyresultingchargeorsubsequentclaimwillnotbepaid.

Productsrepairedorreplacedunderwarrantyshallbewarrantedfortheunexpiredportionofthewarrantyapplying

totheoriginalproduct.

Theforegoingistheexclusiveremedyofanybuyerofthemanufacturer’sproduct.Themaximumdamagesliabilityof

themanufactureristheoriginalpurchasepriceoftheproductorpart.

THEFOREGOINGWARRANTYISEXCLUSIVEANDINLIEUOFALLOTHERWARRANTIES,WHETHERWRITTEN,ORAL,ORSTATU-

TORY,ANDISEXPRESSEDINLIEUOFTHEIMPLIEDWARRANTYOFMERCHANTABILITYANDTHEIMPLIEDWARRANTYOF

FITNESS FOR A PARTICULAR PURPOSE. THE MANUFACTURER SHALL NOT BE LIABLE FOR LOSS OR DAMAGE BY REASON OF

STRICTLIABILITYINTORTORITSNEGLIGENCEINWHATEVERMANNERINCLUDINGDESIGN,MANUFACTUREORINSPECTION

OFTHEEQUIPMENTORITSFAILURETODISCOVER,REPORT,REPAIR,ORMODIFYLATENTDEFECTSINHERENTTHEREIN.

THEMANUFACTURER,HISREPRESENTATIVEORDISTRIBUTORSHALLNOTBELIABLEFORLOSSOFUSEOFTHEPRODUCTOR

OTHERINCIDENTALORCONSEQUENTIALCOSTS,EXPENSES,ORDAMAGESINCURREDBYTHEBUYER,WHETHERARISING

FROMBREACHOFWARRANTY,NEGLIGENCEORSTRICTLIABILITYINTORT.

Themanufacturerdoesnotwarrantanyproduct,part,material,component,oraccessorymanufacturedbyothers

andsoldorsuppliedinconnectionwiththesaleofmanufacturer’sproducts.

AUTHORIZATION FROM THE SERVICE DEPARTMENT IS NECESSARY BEFORE MATERIAL

IS RETURNED TO THE FACTORY OR IN-WARRANTY REPAIRS ARE MADE.

HF SERIES

Compressed Air Filters

Models HF(grade)-52 through HF(grade)-92

Standard, High Pressure and Corrosion

Resistant Models

SPX FLOW, INC.

4647 S.W. 40th Avenue

Ocala, Florida 34474-5788 U.S.A.

P: (724) 745-1555

F: (724) 745-6040

E: hankison.americas@spxflow.com

www.spxflow.com/hankison

Improvements and research are continuous at SPX FLOW Inc.

Specifications may change without notice.

ISSUED 10/2015 Form No.: 4011208 Revision: E

COPYRIGHT ©2015 SPX FLOW Inc.

This manual suits for next models

2

Table of contents

Popular Air Cleaner manuals by other brands

Pure n Natural Systems

Pure n Natural Systems FM22 H.E.P.A. user manual

Honeywell

Honeywell HPA-051 Series manual

ElectrIQ

ElectrIQ STORM80E user manual

Deltech

Deltech PBA-12 instruction manual

Mitsubishi Electric

Mitsubishi Electric Plasma Quad Connect MAC-100FT-E OPERATION INSTRUCTIONS AND INSTALLATION MANUAL

Sharp

Sharp FZ-80SEF Operation manual