Safety Notes

Gloves should be worn during installation to prevent

crushing and cutting injuries.

The shower system may only be used for bathing,

hygienic and body cleansing purposes.

Children as well as adults with physical, mental and/

or sensoric impairments must not use this shower

system without proper supervision. Persons under

the influence of alcohol or drugs are prohibited from

using this shower system.

The hot and cold supplies must be of equal pres-

sures.

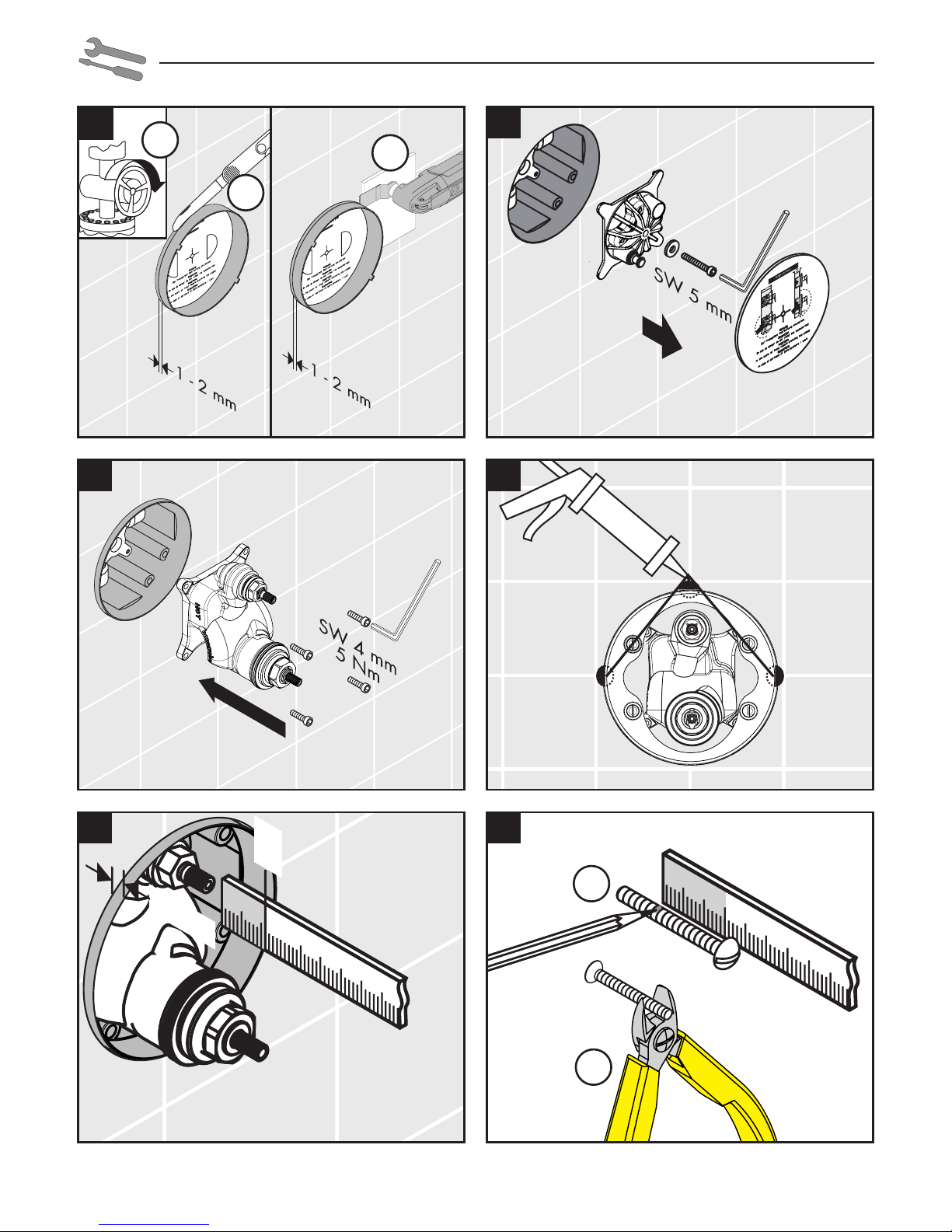

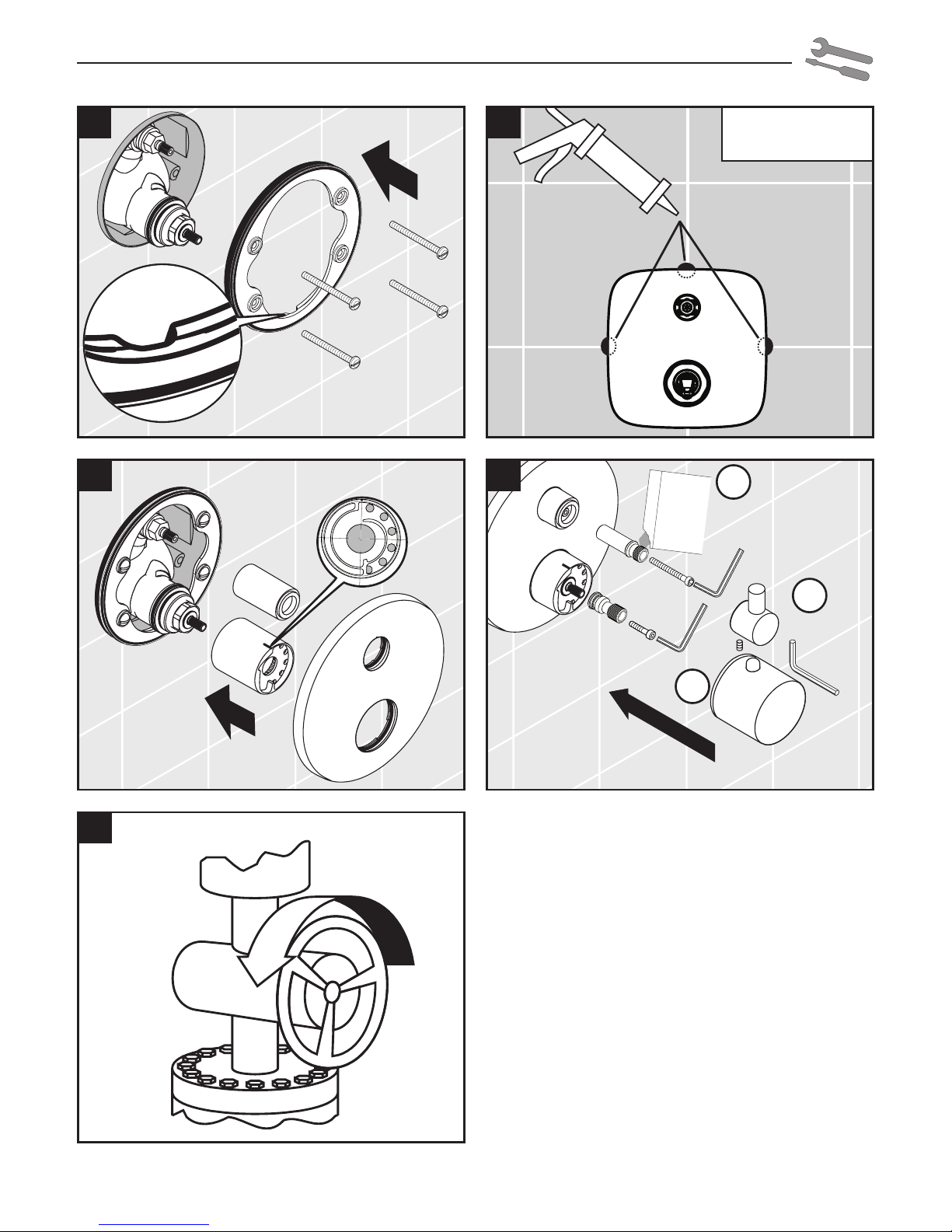

Installation Instructions

• The fitting must be installed, flushed and tested after

the valid norms!

• The plumbing codes applicable in the respective

countries must be oberserved.

• Prior to installation, inspect the product for transport

damages. After it has been installed, no transport or

surface damage will be honoured.

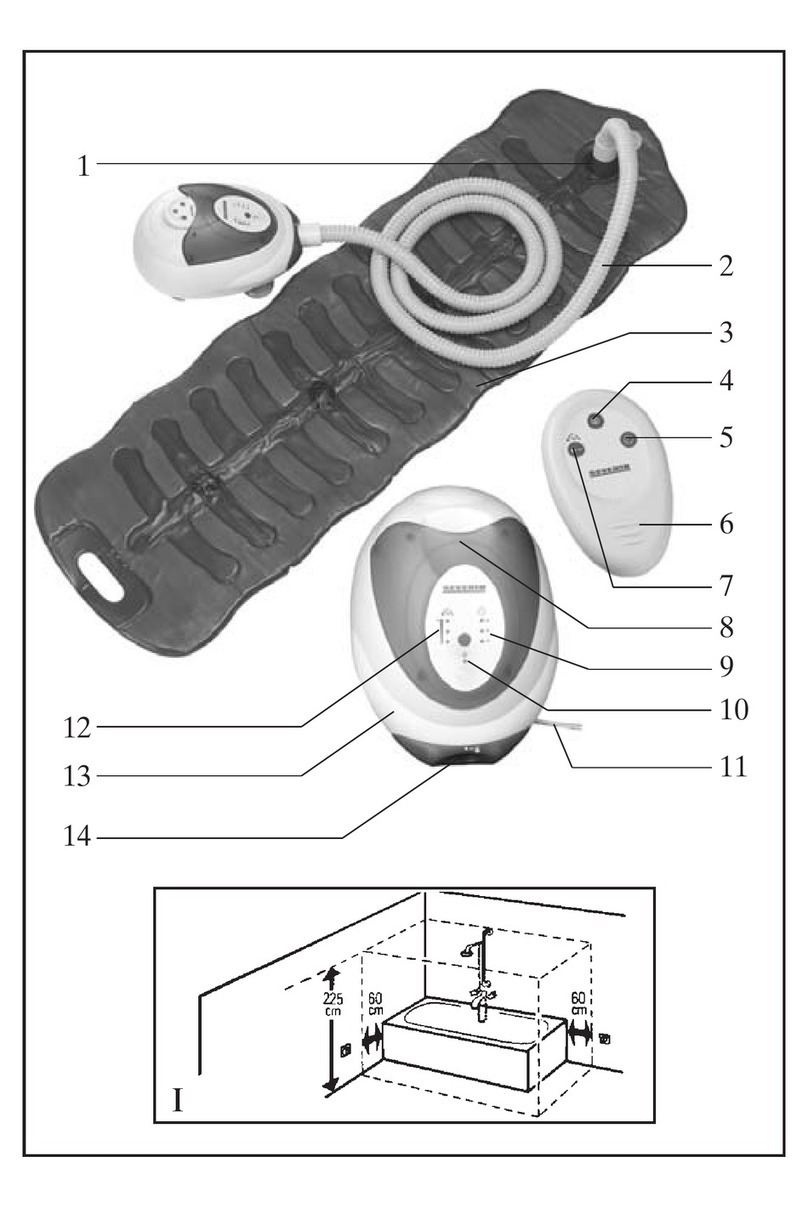

Technical Data

Operating pressure: max. 1 MPa

Recommended operating pressure: 0,1 - 0,5 MPa

Test pressure: 1,6 MPa

(1 MPa = 10 bar = 147 PSI)

Hot water temperature: max. 80°C

Recommended hot water temp.: max. 65°C

Thermal disinfection: max. 70°C / 4 min

Safety against backflow

The product is exclusively designed for drinking water!

English

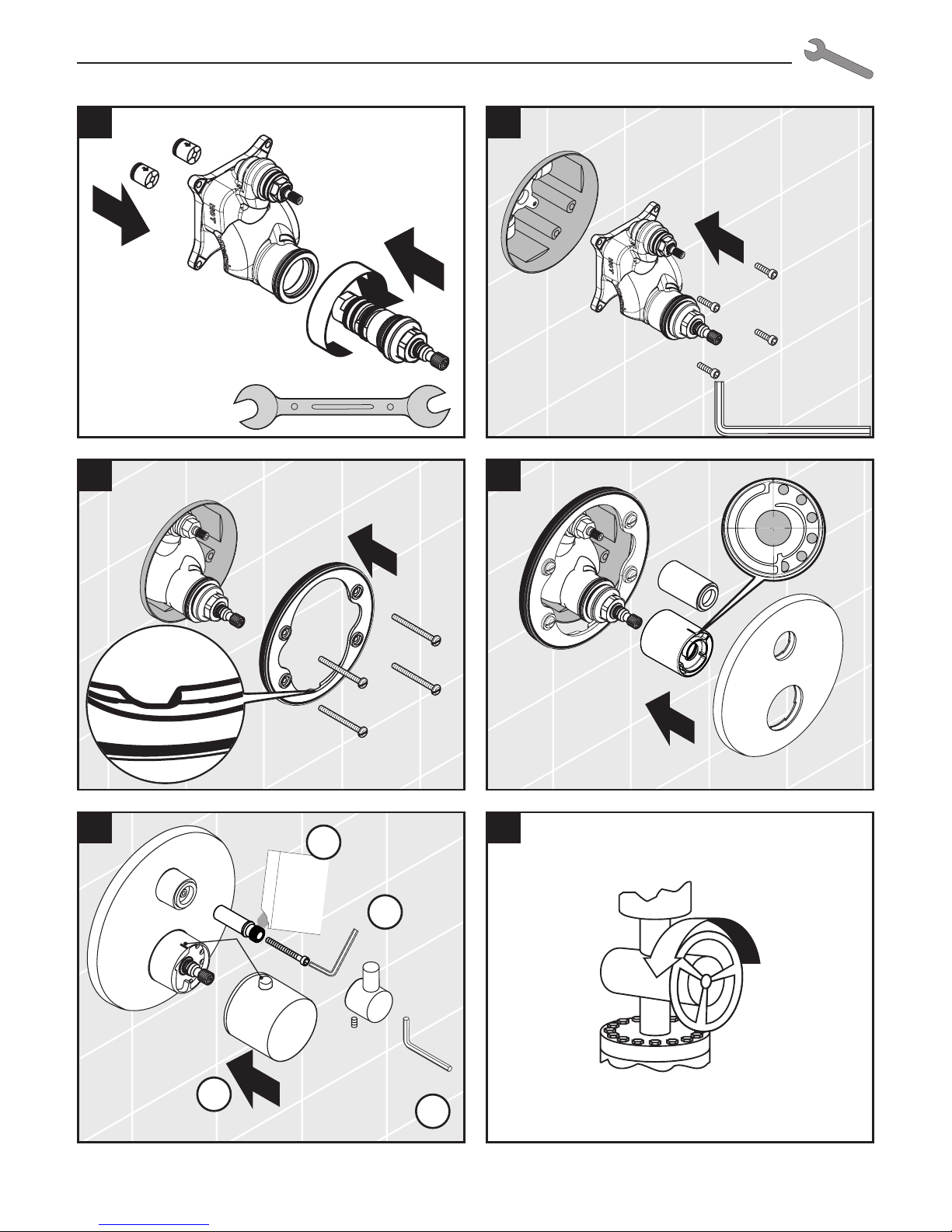

Maintenance (see page 64)

• To guarantee the smooth running of the

thermostat, it is necessary from time to

time to turn the thermostat from total hot

to total cold.

• The mixer is equipped with check valves.

The check valves must be checked

regularly according to DIN EN 1717 in

accordance with national or regional

regulations (at least once a year).

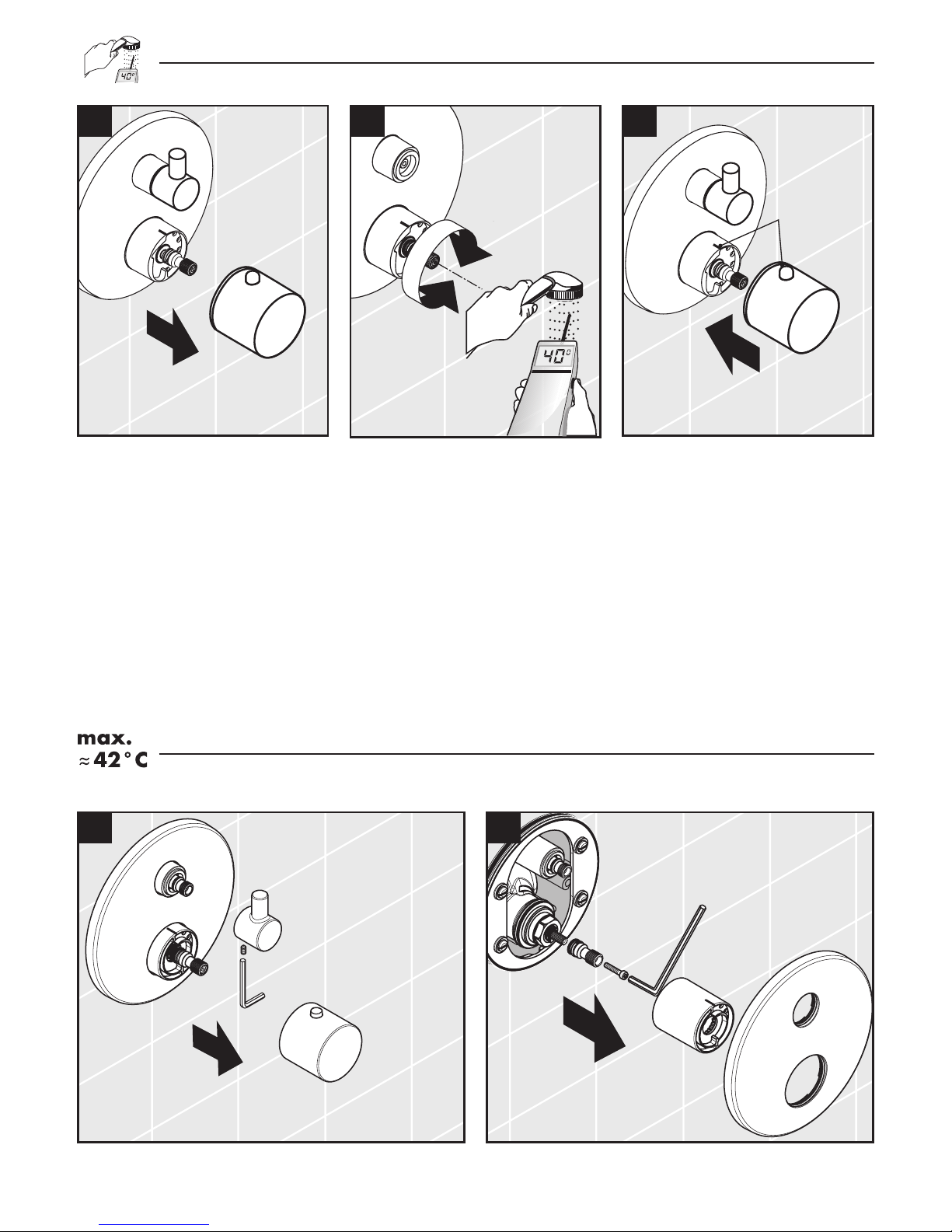

Adjustment (see page 62)

After the installation, the output tempera-

ture of the thermostat must be checked. A

correction is necessary if the temperature

measured at the output differs from the

temperature set on the thermostat.

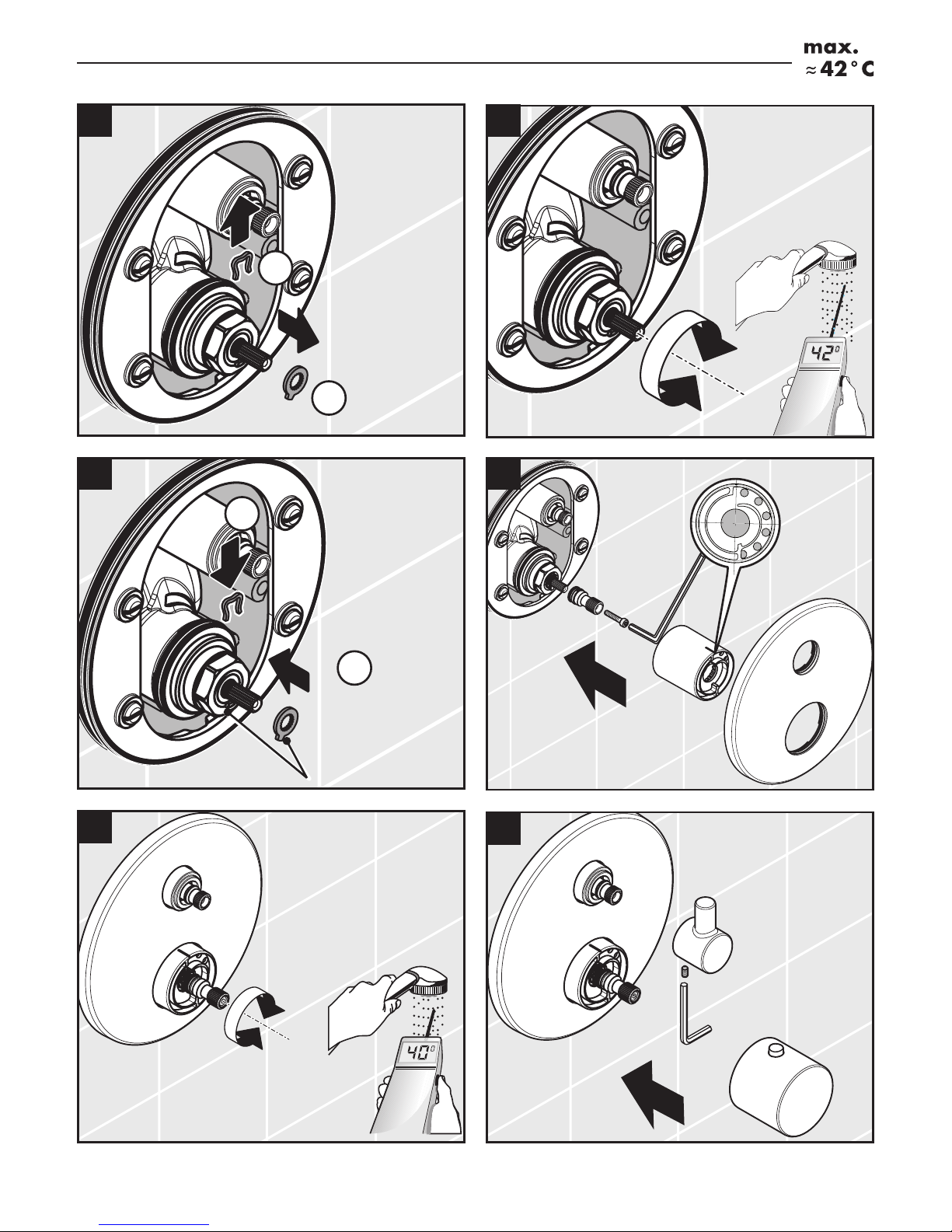

Safety Function (see page 62)

The desired maximum temperature for exam-

ple max. 42º C can be pre-set thanks to the

safety function.

Spare parts (see page 68)

XXX = Colors

000 = chrome plated

400 = white/chrome plated

Do not use silicone containing acetic acid!

Symbol description

Operation (see page 66)

6