Hans Turck BL20-ECO User manual

Your Global Automation Partner

BL20-E-GW-CO

ECO Gateway for

CANopen

Instructions for Use

2 Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | mor[email protected] | www.turck.com

1

2020/09

Table of Contents

1 About These Instructions

1.1 Target groups 5

1.2 Documentation concept 5

1.3 Explanation of symbols used 6

1.3.1 Additional documents 6

1.4 Feedback about these instructions 6

2 Notes on the Product

2.1 Product identification 7

2.2 Scope of delivery 7

2.3 Legal requirements 7

2.4 Manufacturer and service 7

3 For Your Safety

3.1 Intended use 9

3.2 General safety instructions 9

4 Short Description of CANopen

4.1 CANopen 11

4.2 Communication 11

4.2.1 Network Management Messages 11

4.2.2 Service Data Objects (SDOs) 12

4.2.3 Process Data Objects (PDOs) 12

4.3 BL20 and CANopen 14

4.3.1 EDS-file – electronic data sheet 14

5 Eco Gateway for CANopen

5.1 Introduction 15

5.1.1 Function 15

5.2 Technical data 16

5.2.1 General technical data of a station 17

5.2.2 Technical data for the push-in tension clamp terminals 20

5.3 Connection options at the gateway 21

5.3.1 Power supply 21

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | [email protected] | www.turck.com

2

5.3.2 Fieldbus connection via push-in tension clamp terminals 22

5.3.3 Connection through an I/O-ASSISTANT cable 22

5.4 Setting the node ID 24

5.5 Setting the bit rate 25

5.5.1 Autobaud function 25

5.6 Activation of the terminating resistor 26

5.7 Storing of the BL20 station configuration 26

5.8 Status indicators/diagnostic messages 27

5.8.1 27

6

7

7.1

Diagnostic messages via LEDs

BL20 - Communication in CANopen

Guidelines for Station Planning

Random module arrangement 31

7.1.1 Complete planning 31

7.1.2 Maximum system extension 32

7.2 Power supply 34

7.2.1 Power supply to the gateway 34

7.2.2 Module bus refreshing 34

7.2.3 Creating potential groups 34

7.2.4 C-rail (cross connection) 35

7.2.5 Direct wiring of relay modules 37

7.3 Protecting the service interface on the gateway 37

7.4 Plugging and pulling electronics modules 38

7.5 Extending an existing station 38

7.6 Firmware download 38

8 Guidelines for Electrical Installation

8.1 General notes 39

8.1.1 General 39

8.1.2 Cable routing 39

8.1.3 Lightning protection 40

8.1.4 Transmission cable 40

8.2 Potential relationships 41

8.2.1 General 41

8.2.2 Potential-free installation 41

8.3 Electromagnetic compatibility (EMC) 42

8.3.1 Ensuring electromagnetic compatibility 42

3

2020/09

8.3.2 Grounding of inactive metal components 42

8.3.3 PE connection 42

8.3.4 Earth-free operation 42

8.3.5 Protection against high frequency interference signals 43

8.3.6 Mounting rails 43

8.3.7 EMC compliant cabinet installation 44

8.4 Shielding of cables 45

8.4.1 Potential compensation 46

8.4.2 Switching inductive loads 47

8.4.3 Protection against Electrostatic Discharge (ESD) 47

9 BL20-Approvals for Zone 2/Division 2

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | [email protected] | www.turck.com

4

5

2020/09

1 About These Instructions

These operating instructions describe the structure, functions and the use of the product and will

help you to operate the product as intended. Read these instructions carefully before using the

product. This is to avoid possible damage to persons, property or the device. Retain the instructions

for future use during the service life of the product. If the product is passed on, pass on these instruc-

tions as well.

1.1 Target groups

These instructions are aimed a qualified personal and must be carefully read by anyone mounting,

commissioning, operating, maintaining, dismantling or disposing of the device.

1.2 Documentation concept

This manual contains all information about the CANopen-Gateway of the product line BL20-ECO

(BL20-E-GW-CO).

The following chapter contain a short BL20-description, a description of the used field bus system,

exact information about function and structure of the field bus specific CANopen-gateway as well

as all bus specific information concerning the connection to automation devices, the maximum sys-

tem extension etc.

The bus-independent I/O-modules of the BL20-system as well as all bus independent information

as mounting, labeling etc. are described in a separate manual.

BL20 I/O-modules (Turck-documentation no.: German D300716; English D300717)

In addition to that, the mentioned manual contains a short description of the I/O-ASSISTANT, the

project planning and configuration software tool for Turck I/O-systems.

About These Instructions

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | [email protected] | www.turck.com

6

1.3 Explanation of symbols used

The following symbols are used in these instructions:

†CALL TO ACTION

This symbol identifies steps that the user has to perform.

RESULTS OF ACTION

This symbol identifies relevant results of steps

1.3.1 Additional documents

The following additional documents are available online at www.turck.com

Data sheet

Declaration of Conformity

1.4 Feedback about these instructions

We make every effort to ensure that these instructions are as informative and as clear as possible. If

you have any suggestions for improving the design or if some information is missing in the docu-

ment, please send your suggestions to [email protected].

DANGER

DANGER indicates a dangerous situation with high risk of death or severe injury if not

avoided.

WARNING

WARNING indicates a dangerous situation with medium risk of death or severe injury if not

avoided.

CAUTION

CAUTION indicates a dangerous situation of medium risk which may result in minor or

moderate injury if not avoided.

NOTICE

NOTICE indicates a situation which may lead to property damage if not avoided.

NOTE

NOTE indicates tips, recommendations and useful information on specific actions and

facts. The notes simplify your work and help you to avoid additional work.

7

2020/09

2 Notes on the Product

2.1 Product identification

These instructions apply to the BL20 gateway BL20-E-GW-CO.

2.2 Scope of delivery

BL20-E-GW-CO

2 end brackets

2.3 Legal requirements

The device falls under the following EU directives:

2014/30/EU (electromagnetic compatibility)

2011/65/EU (RoHS Directive)

2.4 Manufacturer and service

Hans Turck GmbH & Co. KG

Witzlebenstraße 7

45472 Muelheim an der Ruhr

Germany

Turck supports you with your projects, from initial analysis to the commissioning of your applica-

tion. The Turck product database contains software tools for programming, configuration or com-

missioning, data sheets and CAD files in numerous export formats. You can access the product data-

base at the following address:www.turck.de/produkte

Should you have any further questions, please contact the sales and service team in Germany under

the following telephone numbers:

Sales: +49 208 4952-380

Technology: +49 208 4952-390

Internet: www.turck.de

Outside Germany, please contact your local Turck representative.

Notes on the Product

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | [email protected] | www.turck.com

8

9

2020/09

3 For Your Safety

The product is designed according to state-of-the-art technology. However, residual risks still exist.

Observe the following warnings and safety notices to prevent damage to persons and property.

Turck accepts no liability for damage caused by failure to observe these warning and safety notices.

3.1 Intended use

The devices are only intended for use in industrial applications.

The BL20 gateway BL20-E-GW-CO is part of the BL20 system. It forms the interface to a CANopen

network and forwards the data collected from the field by the BL20 I/O modules within the BL20 sta-

tion to the higher-level CANopen master.

The devices may only be used as described in these instructions. Any other usage shall be consid-

ered improper and Turck shall not be held liable for any resulting damage.

3.2 General safety instructions

The device may only be assembled, installed, operated and maintained by professionally trained

personnel.

The device may only be used in accordance with applicable national and international regula-

tions, standards and laws.

The device only meets the EMC requirements for industrial areas and is not suitable for use in res-

idential areas.

For Your Safety

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | [email protected] | www.turck.com

10

11

2020/09

4 Short Description of CANopen

4.1 CANopen

The following description of CANopen is an excerpt from the homepage of CiA (CAN in Automa-

tion), the international users’ and manufacturers’ organization for CAN.

CANopen is an open, non-proprietary network protocol. It consists of a profile family, based on a

communication profile and several device profiles.i The CANopen communication profile is stan-

dardized as CiA DS-301 (Application Layer and Communication Profile).

The CANopen device profile for I/O-modules has been published as CiA DS-401 (Device Profile for

I/O-Modules).

CANopen is based on the following standards:

ISO 11 898 (Physical and Data Link Layer) Layers 1 and 2 of the ISO/OSI communication model

CiA DS-301 (Application Layer and Communication Profile) CANopen communication profile

CiA DS-302 (Framework for Programmable CANopen Devices) CANopen Network Management

NMT

CiA DS-401 (Device Profile for I/O-modules)

CiA DS-406 (Device Profile for Encoders) CANopen device profile for counter modules

CiA DS-102 (CAN Physical Layer for Industrial Applications) General application in the field sector

(connectors and bit rates) on the basis of ISO 11898

4.2 Communication

The lower layers of CANopen are defined according to the ISO-OSI model in the ISO 11898 standard.

Communication between the individual nodes is made by transmitting "Telegrams".

4 different types of telegram message are defined for CANopen:

Network management messages

Service data objects SDO

Process data objects PDO

Predefined messages

4.2.1 Network Management Messages

Network management messages are used in the network to control the nodes and their operating

states. This type of message makes it possible, for instance, to configure the data transmission

mechanism of a node.

The Network Management objects include Boot-up message, Heartbeat protocol and NMT mes-

sage.

Boot-up message, Heartbeat and Node Guarding are implemented as single CAN frames with 1-

byte data field.

The NMT message is mapped to a single CAN frame with a data length of 2 byte. The CAN-Identifier

is 0. The first byte contains the command specifier and the second contains the Node-ID of the

device that must perform the command (in the case of Node-ID 0 all nodes have to perform the

command). The NMT message transmitted by the NMT master forces the nodes to transit to another

NMT state. CANopen defines the following status: "Initialization", "Pre-Operational", "Operational"

Short Description of CANopen

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | [email protected] | www.turck.com

12

and "Stopped". After a "power-on", each CANopen devices is in the status "Initialization" and auto-

matically changes to the Pre-Operational status. In this state the transmission of SDOs is allowed. If

the NMT master has set one or more nodes into the state Operational, they are allowed to transmit

and to receive PDOs. In the state Stopped no communication is allowed except that of NMT objects.

The state Initialization is divided into 3 sub-states. in order to enable a complete or partial reset of a

node. In the sub-state Reset Application the parameters of the manufacturer-specific profile area

and the standardized device profile area are set to their power-on values. In the sub-state Reset

Communication the parameters of the communication profile area are set to their power-on values.

The third sub-state is initializing, which a node enters automatically after power-on. Power-on val-

ues are the last stored parameters.

The Heartbeat protocol and Node Guarding are for error control purposes and signals the pres-

ence of a node and its state. The Heartbeat message is a periodic message of the node to one or sev-

eral other nodes. It indicates that the sending node is still working properly.

A device sends the Boot-up message to indicate to the NMT master that it has reached the state

pre-operational. This occurs whenever the device initially boots-up but also after a power-out

during operation. The Boot-up message has the same identifier as the Heartbeat object, however,

its data content is zero.

4.2.2 Service Data Objects (SDOs)

A Service Data Object (SDO) reads from entries or writes to entries of the Object Dictionary.

The SDO transport protocol allows transmitting objects of any size. The first byte of the first segment

contains the necessary flow control information including a toggle bit to overcome the problem of

doubly received CAN frames. The next three bytes of the first segment contain index and sub-index

of the Object Dictionary entry to be read or written. The last four bytes of the first segment are avail-

able for user data. The second and the following segments (using the very same CAN identifier) con-

tain the control byte and up to seven bytes of user data. The receiver confirms each segment or a

block of segments, so that a peer-to-peer communication (client/server) takes place.

4.2.3 Process Data Objects (PDOs)

Process Data Objects (PDOs) are mapped to a single CAN frame using up to 8 bytes of the data field

to transmit application objects. Each PDO has a unique identifier and is transmitted by only one

node, but it can be received by more than one (producer/consumer communication). PDO trans-

missions may be driven by an internal event, by an internal timer, by remote requests and by the

Sync message received:

13

2020/09

PDO transmissions

„Event-“ or „timer-driven“:

An event (specified in the device profile) triggers message transmission. An elapsed timer addi-

tionally triggers the periodically transmitting of PDO-messages, even if no event has occurred.

Remotely requested:

Another device may initiate the transmission of an asynchronous PDO by sending a remote trans-

mission request (remote frame).

Synchronous transmission:

In order to initiate simultaneous sampling of input values of all nodes, a periodically transmitted

Sync message is required. Synchronous transmission of PDOs takes place in cyclic and acyclic

transmission mode. Cyclic transmission means that the node waits for the Sync message, after

which it sends its measured values. Acyclically transmitted synchronous PDOs are triggered by a

defined application-specific event. The device transmits it's input values. Further transmission is

only done if a further Sync messages occurs.

Special Function Objects

CANopen also defines three specific protocols for synchronization, emergency indication, and time-

stamp transmission.

Synchronization object (Sync)

The Sync Object is broadcast periodically by the Sync Producer. The Sync Object is broadcast

periodically by the Sync Producer. The time period between Sync messages is defined by the

Communication Cycle Period, which may be reset by a configuration tool to the application

devices during the boot-up process. There can be a time jitter in transmission by the Sync Pro-

ducer due to some other objects with higher prior identifiers or by one frame being transmitted

just before the Sync message. The Sync message is mapped to a single CAN frame with the iden-

tifier 128 by default. The Sync message is mapped to a single CAN frame with the identifier 128

by default.

Emergency object (Emcy)

The Emergency message is triggered by the occurrence of a device internal error situation and

are transmitted from an Emergency producer on the concerned application device. This makes

them suitable for interrupt type error alerts. An Emergency message is transmitted only once per

‘error event’. As long as no new errors occurs on a device, no further Emergency message can be

transmitted. Zero or more Emergency consumers may receive these. The reaction of the Emer-

gency consumer is application-specific. CANopen defines several Emergency Error Codes to be

transmitted in the Emergency message, which is a single CAN frame with 8 data byte.

Time stamp object (Time)

By means of Time-Stamp, a common time frame reference is provided to application devices. It

contains a value of the type Time-of-Day. This object transmission follows the producer/con-

sumer push model.

Short Description of CANopen

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | [email protected] | www.turck.com

14

4.3 BL20 and CANopen

BL20 supports the following CANopen-functions:

SDO transfer, any length of information

Emergency object

Sync frame evaluation

Event-driven PDOs

Synchronous PDOs (clock-synchronous)

Remote-requested PDO/polling

4.3.1 EDS-file – electronic data sheet

CANopen nodes are embedded in the CANopen structure by the help of a standardized EDS file

(Electronic Data Sheet).

The EDS file lists all necessary Objects with their corresponding Sub-indices and the matching

entries.

The latest version of a particular EDS file can be downloaded directly from the Turck homepage

www.turck.com.

15

2020/09

5 Eco Gateway for CANopen

5.1 Introduction

This chapter contains a description of BL20-E-CO-gateways for the standardized fieldbus CANopen.

The chapter is divided up as follows: a description of functions, general and specific technical data,

a description of addressing and status displays.

5.1.1 Function

The BL20 gateways enable BL20 modules to operate on CANopen. The gateway is the connection

between the BL20 modules and a CANopen host system. It regulates the process data between the

I/O level and the fieldbus and generates diagnostic data for the higher-level host system.

Information is made available to the software tool I/O-ASSISTANT via the service interface.

Eco Gateway for CANopen

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | [email protected] | www.turck.com

16

5.2 Technical data

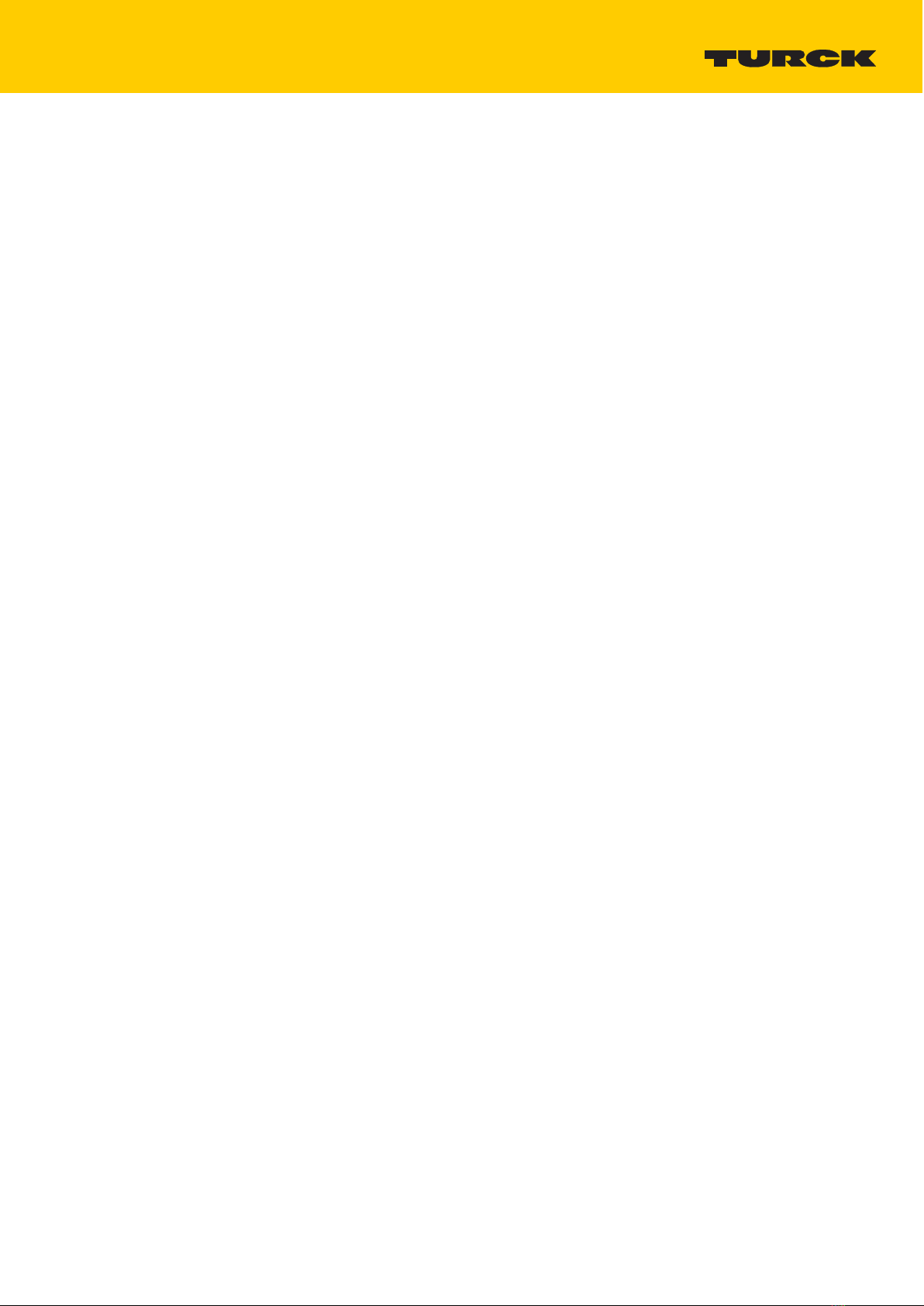

AType designation

BLEDs for BL20 module bus

CService interface

DDIP switch for the Node-ID

EDIP-switch for the bit rate

FDIP-switch for terminating resistor

GLEDs for CANopen

HPush-In for field supply

IPush-In terminals for system supply

JCANopen, Push-In terminals

Fig. 1: Gateway BL20-E-GW-CO

Unlock end-bracket before dismounting

Pull barrier for configuration and service

!

UL

GNDL

USYS

GNDSYS

C N_H

C N_L

C N_H

C N_L

C NGND

C NGND

GW

IOs

BL20-E-GW-CO

SERVICE

10

DDRESS

20

21

22

23

24

25

RT

ERR

Bus

off on

BR

20

21

22

A

C

B

F

D

G

H

I

J

E

17

2020/09

Structure of a BL20-ECO gateway

5.2.1 General technical data of a station

Fig. 2: Structure of a BL20-E-GW-CO

WARNING

Defective power supply unit

Danger to life due to dangerous voltages on touchable parts

†Only use SELV or PELV power supplies in accordance with EN ISO 13849-2, which allow

a maximum of max. 60 VDC or 25 VAC in the event of a fault.

Technical Data

Supply voltage/auxiliary voltage

Usys (nominal value)

provision for other modules

24 V DC

Isys (at max. system extension) Approx. 0.5 A

Permissible range According to EN 61 131-2

(18…30 V DC)

Max. field current IL8 A

Residual ripple According to EN 61 131-2

Isolation voltage (UL to USYS) 500 Veff

Voltage anomalies According to EN 61 131-2

IMB (supply of module bus nodes) 700 mA

Connection technology Push-in tension clamps,

LSF from Weidmueller

Physical interfaces

Fieldbus

Protocol CANopen

Transmission rate 20 kbps…1 Mbps

Isolation voltage (field bus to Usys and UL) 500 Veff

Fieldbus connection technology Push-in tension clamps

LSF from Weidmueller

Field bus

(external)

Service

interface

External

RAM

External

ROM-Flash

Module bus

(internal)

Controller

– internal

RAM

–WDG

–

RTC

Eco Gateway for CANopen

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | [email protected] | www.turck.com

18

Address setting Via DIP-switches (address 1…63)

Service interface

Connection technology RS232 via PS2/mini DIN female connector

Ambient conditions

Ambient temperature

–tAmbient 0 …+55 °C

For vertical installation, the gateway can be positioned

both at the top and bottom. Sufficient ventilation and

heat dissipation must be ensured.

–tStore - 25…+85 °C

Relative humidity according to

EN 61131-2/EN 50178

5 … 95 % (indoor), Level RH-2, no condensation (stor-

age at 45 °C, no function test)

Climatic tests According to IEC 61131-2

Vibration resistance

10…57 Hz, constant amplitude 0.075 mm/

0.003 inch, 1g

Yes

57…150 Hz, constant acceleration 1 g Yes

Mode of vibration Frequency sweeps with a change in speed of

1 Octave/min

Period of oscillation 20 frequency sweeps per axis of coordinate

Shock resistant according to IEC 68-2-27 18 shocks, sinusoidal half-wave 15 g peak value/11 ms,

in each case in ± direction per space coordinate

Resistance to repetitive shock according to IEC 68-

2-29

1000 shocks, sinusoidal half-wave 25 g peak value/

6 ms, in each case in ± direction per space coordinate

Drop and topple

Height of fall (weight < 10 kg) 1.0 m

Height of fall (weight 10…40 kg) 0.5 m

Test runs 7

Device with packaging, electrically tested printed-circuit board.

Electromagnetic compatibility (EMC) according to EN 50 50082-2 (Industry)

Static electricity according to EN 61 000-4-2

–Discharge through air (direct) 8 kV

–Relay discharge (indirect) 4 kV

Electromagnetic HF fields according to

EN 61000-4-3 and ENV 50 204

10 V/m

Conducted interferences induced by HF fields

according to EN 61000-4-6

10 V

Technical Data

This manual suits for next models

1

Table of contents

Popular Gateway manuals by other brands

ZyXEL Communications

ZyXEL Communications ZyXEL Prestige 304 quick start guide

Dell

Dell PowerConnect J-SRX240 Hardware guide

3Com

3Com 3CRWE51196 - OfficeConnect Wireless Cable/DSL... installation guide

Beijer Electronics

Beijer Electronics BoX2 extreme installation manual

Harman

Harman NXB-KNX instruction manual

Hitachi

Hitachi CHL-MBS-02 Installation and operation manual