Hansa Sailing Liberty Quick start guide

1

Liberty

Rigging Guide

Manufactured by

Hansa Sailing Systems Pty Ltd

ABN 56 079 318 031

Head Office: 4/4 Cumberland Avenue

SOUTH NOWRA NSW 2541 AUSTRALIA

Postal: PO Box 5048 NOWRA DC NSW 2541

Telephone: +61 2 4403 0595

Facsimile: +61 2 4403 0598

Email: admin@hansasailing.com

Website: www.hansasailing.com

2

Index

Introduction ……………………………………………………………………………………………………….3

Description of Craft: The Liberty

Specification ……………………………………………………………………………………………………...5

General ……………………………………………………………………………………………………………6

Maintenance & Repairs ………………………………………………………………………………………….7

Safety Recommendations …………………………………………………………………………….………...8

PART ONE

Special Features of the Liberty ……………………………………………………………………………..….9

PART TWO

How to Rig a Liberty

Stepping the Mast, fitting the boom ………………………………………………………………………….12

Stepping the Foremast …………………………………………………………………………………………14

Setting up Main and Jib Sheets ……………………………………………………………………………….15

Reefing the Main ………………………………………………………………………………………………..16

Reefing and Furling the Jib …………………………………………………………………………………….17

Steering …………………………………………………………………………………………………………..18

Launching ………………………………………………………………………………………………………..19

PART THREE

Liberty Servo Assist System—Overview ……………………………………………………………………..19

Control Box ………………………………………………………………………………………………………20

The Batteries …………………………………………………………………………………………………….21

The Helm Winch ………………………………………………………………………………………………...21

The Mainsheet Winch …………………………………………………………………………………………..22

The Jibsheet Winch ……………………………………………………………………………………………..22

Controllers ………………………………………………………………………………………………………..23

Maintenance and Troubleshooting …………………………………………………………………………….24

Adjusting the steering …………………………………………………………………………………………...25

Changing between manual and servo assist systems ………………………………………………………25

3

Introduction

This manual has been compiled to help you to operate your craft with safety and pleasure. It contains de-

tails of the craft, the equipment supplied or fitted, its systems, and information on its operation and mainte-

nance. Please read it carefully, and familiarise yourself with the craft before using it.

If this is your first sailing craft, or you are changing to a type of craft you are not familiar with, for your own

comfort and safety, please ensure that you obtain handling and operating experience before assuming

command of the craft. Your Hansa Sailing Distributor, National Sailing Federation or Yacht Club will be

pleased to advise you of nearby sailing schools or instructors.

Personal Floatation Devices (PFD’s)

There are many types and variety of buoyancy aids available, manufactured to different sets of standards.

The PFD is a personal item of safety equipment, designed specifically to assist in preserving a person’s

life when in the water. Most PFD’s provide sufficient buoyancy to help you float with your head above the

water.

All sailors and volunteers should wear a PFD at all times whilst on, or near water.

Care

PFD’s are subject to normal wear and tear. Each one should be checked regularly and if in doubt about its

serviceability it should be replaced. If they become wet from salt water they should be hosed down with

fresh water and allowed to dry.

PFD’s and Children

A properly designed PFD of the correct size will keep a child’s mouth and nose clear of the water. A child

should be taught how to put on a device and should be allowed to try it out in the water. It is important

that the child feels comfortable and knows what the PFD is for and how it functions.

4

Safety Precautions

If sailed with care, this boat is unlikely to capsize in normal use, provided that the sail area is adjusted to

suit the prevailing conditions and the main sheet is not belayed. Whilst Hansa sailing craft have inherent

design features ensuring maximum stability thereby reducing the chance of capsize, it should be remem-

bered that these are small keelboats and under certain weather, water and sailing conditions sensible pre-

cautions should be taken:

• Always reef the sails according to the weather conditions.

• Always have a manned safety boat in the sailing area.

• Always cancel sailing activities if inclement weather conditions dictate.

• Always lock centreboard in position with long centreboard locking pin provided.

Man Overboard

In the event of man overboard, use the centreboard handle as a handhold. Board over the port or star-

board sides.

Towing

The strong point for towing is the main mast. Pass the tow line through the guide ring at the bow and at-

tach to the mast with a bowline.

The safety of the sailors should come first under all circumstances

5

Description of Craft: The Liberty

Specifications

Length 3.6 mtrs.

Beam 1.35 mtrs.

Draft 1mtr.

Hull Weight 72 kg

Load Maximum number of people: 1

Maximum weight of people 120 kg.

Maximum weight of additional load 30 kg.

Centreboard Weight 72 kg

Sail Plan Mainsail and free standing, self-tacking Jib.

Sail Area Mainsail 4.5 sq. mtrs (unbattened and reefable to .5 sq. mtr).

Jib 1.75 sq. mtrs (full roller reefing).

Masts Main (unstayed 5.6 mtr. Incorporating reefing drum in foot).

Jib (unstayed 3.5 mtr. Incorporating reefing drum in foot).

Hull Positive buoyancy.

Heavily rockered for easy manoeuvrability.

Strong construction with solid bonded hull/deck joins. Seating design keeps

helm weight low, plus weighted centre board makes the boat uncapsizable.

Seating Fibreglass adjustable seat.

Controls Steered by manual joystick.

Mainsail is reefed and un-reefed by a single hauling line. Jib is reefed and un

-reefed by a single hauling line.

Mainsail and Jib controlled by manual mainsheets.

Electric Controls Servo-assist electric controls can be fitted to the Liberty.

6

General

The boat has an engraved plate fitted on the starboard side of forward cockpit, showing the manufacturer,

boat design category, maximum person capacity, maximum additional load and the CE Mark.

The parameters shown on this plate should not be exceeded.

Steering is by a manual joystick located between the helm’s legs, moving it to the left to go left and to the

right to go right.

The sail area can be reduced or increased whilst under way using a reef furling system operated by haul-

ing on a single continuous line. (For further information on reefing see: “How to Rig a Liberty, later in this

guide).

Parts of a Liberty:

Main Mast

Fore Mast

Boom

Centreboard

Rudders x 2

Rubber Box x 2

Rudder Box Pin x 2

Installed reefing system

Mainsail

Foresail (Jib)

Bobbin

Mainsheet

Outhaul

Traveller

Painter

Jib Sheet with clew sheave

Jib strut downhaul

Jib Strut and Claw

Boom vang

Items with Servo Assist – As above, plus:

Main sheet winch

Jib sheet winch

Helm winch

Control box

Rubber bungs

Batteries x 2,

Battery Y Connector,

Battery Charger (if 240V),

Controller

Controller holder

7

Maintenance

It is recommended that the boat is covered when not in use to prevent UV and other weather damage. A

specially designed cover is available from Hansa Sailing Systems for this purpose.

If sails are to be left furled on the mast when the boat is not in use it is recommended that these are cov-

ered using a protective sail sock to prevent UV and other weather damage. These are available Hansa

Sailing Systems.

Do not let water remain in the boat when not in use. This can accelerate the deterioration of running rig-

ging, finishes and electrics where applicable.

Winter Storage: Remove electrics, remove and fold sails and fully cover the boat.

Repairs

Contact Hansa Sailing Systems or the nearest Hansa Sailing Distributor for advice and replacement parts.

Fibreglass repairs should be done professionally.

8

Safety Recommendations

Hansa Sailing craft are designed with a hull form and other features which combine to give considerable

stability. There is a simple set of rules which should be followed to maintain the boats’ excellent safety

record and prevent any accidents. The stability of Hansa Sailing craft rely upon the following:

Centreboards

It is most important that the centreboard be locked in the fully down position when sailing. The hole locat-

ed one-third down the centreboard is to enable the short pin to be inserted laterally and facilitate move-

ment of the boat with the centreboard inserted.

The Liberty centreboard weighs 72kg and therefore must not be lifted manually. Always use a

hoist to place the centreboard into position.

Under no circumstances should the boat be sailed with the centreboard fixed in the raised position.

There is a long pin provided to lock the centreboard fully lowered so that even in a “knock down” it re-

mains in place.

Seating

Because the placement of sailors’ weight affects stability it is important that people remain seated low in

the boat. If a sailor needs support from strapping, use only quick release Velcro ™ straps to secure a

sailor in place.

Reefing

Being a displacement type hull, the use of full sail area in strong winds does not mean more speed, but

does make the boat more difficult to manage. In fresher breezes it is recommended to reef to suit the

stronger gusts.

Towing

If a Liberty needs to be towed on the water by a safety boat, it is safer and easier to tie the boat close

alongside and remove the rudder blade so that it cannot be steered in the wrong direction.

Transferring

A stable floating pontoon system enables safe, centreboard-down transfer of sailors to and from the Liber-

ty. This avoids off the beach centreboard handling and transferring problems. A portable floating pon-

toon system is available from Hansa Sailing

9

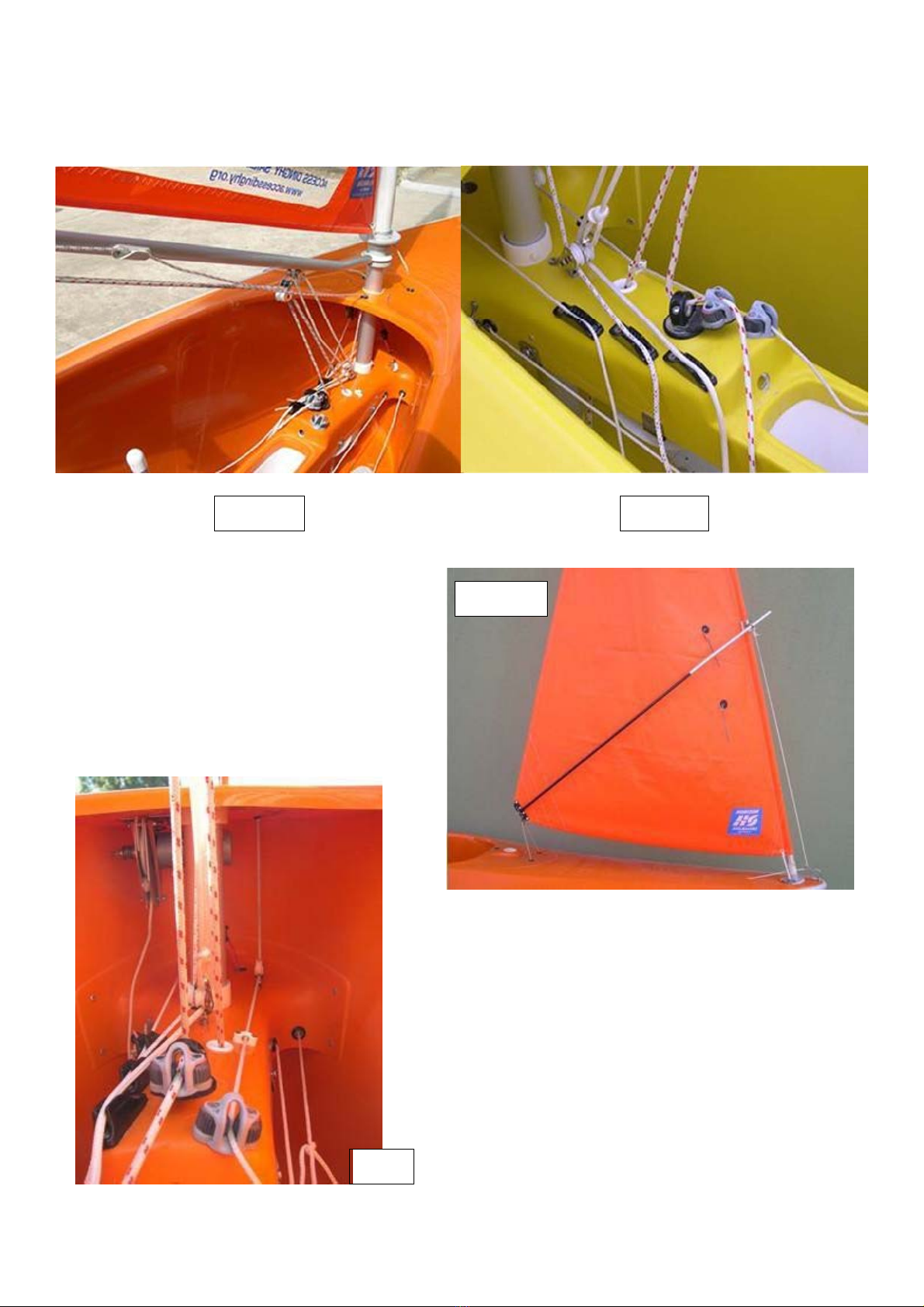

Fig. 2

Fig. 3

The Liberty has 2 rudders which give directional control at

even extreme angles of heel

There is the option of fitting

a boom with a 3 part manu-

al mainsheet, rigged as per

the 303W, (fig 2 )

or a 2 part double ended

mainsheet (fig 3), one end

going to a servo assist

sheet winch and the other

through a conventional

swivel/deadeye/ camcleat

for manual operation, (fig

4)

Both these ends pass

through a double block at-

tached to the boom about

400mm back from the

mast. (see fig 4.

A boom vang is fitted which prevents

the boom skying when running in fresh

to strong winds. (see fig 4)

Liberty Special Features

Fig 1

10

The mainsail outhaul primarily cleats at the boom, (fig 5) but passes thru a deckeye just behind the main

mast, down to the console and turns through the boom vang/ outhaul double becket block and back to the

central of the 3 clamcleats on the port side of the console. (fig 6)

The jib is self-tacking with a diagonal strut be-

tween the clew and a claw at the mast which

holds the jib flat and prevents twisting as the

sheet is eased. (fig 7)

The jib sheet is 2 part which gives the option of one end going

to a servo assist winch and the other down to the camcleat on

the starboard side of the console for manual operation. (fig 8

shows the jib sheet winch behind mast, jib sheet and

camcleat).

Fig. 5 Fig. 6

Fig. 7

Fig. 8

11

The Liberty has a solid seat designed to take cushions and padding to suit individual needs. The adjusta-

ble backrests are available in short and long versions. Thoracic supports, headrests and various types of

seat belts are available. (as below)

(If photos are in B&W the yellow cross-over shoulder straps will be hard to see.)

12

Rigging the Liberty

1. Stepping the Mast, Fitting the Boom

With the sail rolled and tied up, bobbin in place tied

to the tack of the sail (fig 9), carefully step the main-

mast making sure the foot is firmly in the step.

Take the boom, free its outhaul and sheet, pull the

outhaul block and traveling ring as far forward as it

will go, then shackle the traveling ring onto the low-

est hole of the clew board, and shackle the outhaul

to the central hole of the clew board. (fig 10)

Unroll the mainsail (about 5 turns) until the rowlock

at the front end of the boom can be pushed onto the

bobbin.

Then pull the sail out tight with the outhaul. Cleat

the outhaul on the boom. (see fig 5—page 10)

Run the outhaul through the deck eye in the cowling just aft of the main mast, down through the deadeye

on the console just aft of the mast, then back to the black clam cleat on the console port side. Pull on the

outhaul, but cleat it at the white clam cleat on the starboard side of the boom. (see fig 4—page 9)

Pass the boom vang through its block on the boom and back through its block on the console just aft of

the mast and cleat it at the furthest aft of the 3 black clamcleats on the port side of the console. Do not

over-tension the boom vang, it is there to prevent the boom skying when running downwind in fresh to

strong winds, not to flatten the mainsail when going to windward. (see fig 4– page 9).

If the boat is to be sailed manually, and has a 3 part sheet fitted to the boom, use the following procedure.

Unravel the sheet, clear any twists and shackle its block onto the traveller and rig (as per fig 2—page 9).

Pass the live end of the sheet through the deadeye and camcleat on the console and tie a figure of eight

knot in its end.

Fig. 10

Fig. 9

13

If the boat is to be sailed servo assist and has the sheet on its winch and a bare boom, unravel the main-

sheet which comes up through the console from the sheet winch then: (as per figs. 3 & 4—page 9)

pass its end through the right side of the double block on the boom,

then through the plastic guide-ring half way along the boom,

then through the first of the blocks towards the end of the boom,

then down and through the block on the traveller,

then back up and through the block at the end of the boom,

then again through the plastic guide-ring, and then through the right side of the double block,

and then down through the fairlead

and cam cleat on the centre of the

console.

Tie a stopper knot in its end. If there was not

enough rope for this operation set up the servo

assist electrics and feed out sufficient rope.

(see Setting Up the Main & Jib Sheets on page

15) Rotate the mast to fully unroll the sail, haul

in on the outhaul and cleat it, pull the starboard

reefing line till its knot is as far as it will go on

the port side, then tighten the reefing drum

clamp. (The reefing drum clamp is under the

console and as per fig 11).

If full sail is not needed at this time release the

outhaul and pull the port side reefing line till its

knot stops at the starboard side, cleat the

reefing line on the port side aft of the console,

then haul on and cleat the outhaul. (fig 12,

reefing lines)

Fig. 11

Fig. 12

14

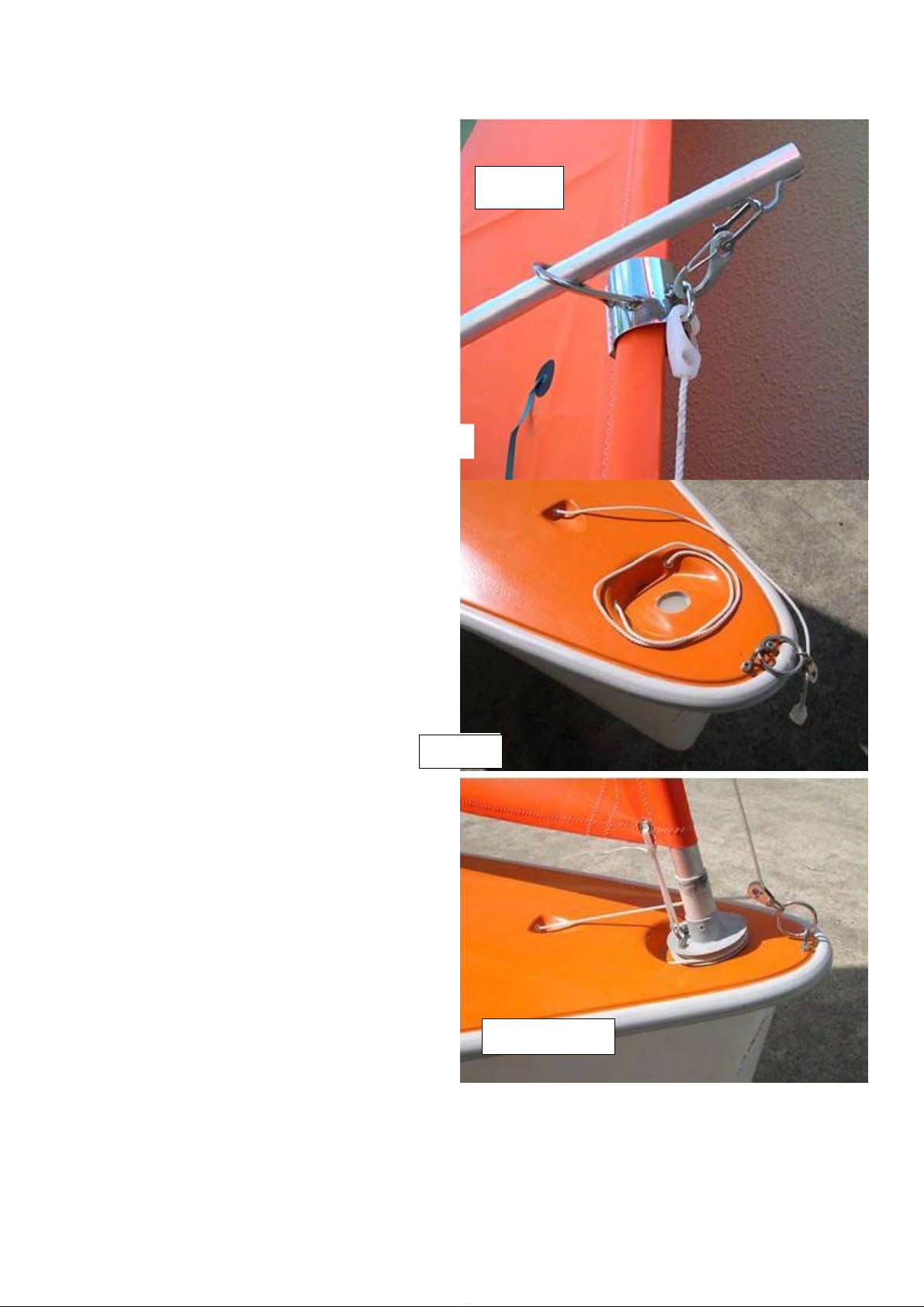

2. Stepping the Foremast

Before stepping the mast, unroll the sail, fit the claw

and strut, then attach the strut to the claw with the

stainless steel spring hook.

(as per fig. 7– page 10; fig. 9—page 12 & fig. 13)

At the bow pull the port side jib reefing line till its

knot is at its stop hard up on the port side of the

console in the cockpit. (see fig 12– page 13, reefing

lines)

Unhook the jib reefing line tension shock cord hook

(located on back bulk- head behind the seat) and

set up the reefing line in a loop to complete a full

turn around the foremast reefing drum. (fig 14, view

of loop)

Step the mast, fit the reefing line and re-tension the

shockcord. (fig 15)

Presuming the jib sheet block is shackled to the bot-

tom hole of the clewboard, feed the sheet through

the block and down through the deckeye to the turn-

ing block, then thru the deadeye and the cam cleat,

then tie a stopper knot in its end. (see fig. 8—page

10 & fig. 9—page 12).

Fig. 15

Fig 13

Fig 14

15

At the bow is the jib strut downhaul, free it and attach its plastic hook to the lug on the front of the claw. (fig

13—page 14).

Pull in on the downhaul (located on the left side of the console) and cleat it on the most forward of the

black clamcleats. (fig 6 on page 10)

Check the manual operation of the jib sheet located at the cam cleat on the right side of the console.

(*) To furl the jib, remove the strut, unhook the downhaul, slide

the claw to the base of the mast then pull the port jib reefing

line to completely roll up the sail. (fig 16)

(If fig. 16 is in B&W it may be hard to see the orange

sails rolled around the mast.)

It is OK to roll 1 to 3 turns on the foremast to reef for strong

winds, but for furling do as per (*) above.

3. Setting up Main and Jib sheets

If sheet winches are fitted and the boat is to be sailed manual-

ly, it will be necessary to run all but about half a metre of sheet out of the winches to leave all the sheet

available for manual operation. Read carefully below and PART THREE (p19) for an understanding of the

Servo Assist System.

Presuming the boat is servo assist equipped it will

be necessary to set up the main and jib sheet winch-

es to work in sync. Commence by installing the bat-

teries and connecting the joystick. (fig 17 showing

battery with Y connector going forward around front

of the centreboard case to second battery).

See fig 18 on page 16 for a typical joystick control-

ler. Plug the joystick into the 9 way yellow connector

on the lead below the helm winch drum behind the

seat starboard side. (fig 24 on page 19)

On the joystick box is a push button switch (Main

Only Switch or MO Switch) which disconnects the jib

sheet winch to allow the main sheet to be fine tuned

independently. A red light is on when the MO Switch is activated. Press the button again to operate both

winches together. This function can be used to set up the sheets so both main and jib are correctly set for

windward work.

Fig 16.

Fig. 17

16

Both main and jib sheets are double ended, one end going to a servo assist winch, the other to a cleat for

manual operation. When sailing servo assist both sheets should be cleated with about half a metre free

outside the cleat. There should be a stopper knot in the end of the sheet outside the camcleats. (see fig

4—page 9, figs. 5 & 6 —page 10)

Presuming the servo assist gear is installed cor-

rectly with battery and joystick attached, wind in on

both sheets (pull joystick back) until either main or

jib is in hard enough to simulate being hard on the

wind. Be careful not to over sheet either sail. (fig

17– page 15, battery with “Y” connector & fig 18

typical joystick).

For this exercise the mainsail is correctly set when the sheet is in hard and the main- mast begins to bend

aft, while the jib should be around 15 degrees off the centerline. That is the clew should be about 200mm

outboard from the mainmast.

If the jib sheets in hard first, press the MO switch to disengage the jib sheet winch and use the joystick to

further adjust the main sheet.

If the main sheets in first, either:

un-plug the main sheet winch (the white plug is under the console on the starboard side of the cen-

terboard case) and then using the joystick wind in more on the jibsheet, or

press the MO switch to disengage the jib sheet winch and use the joystick to let out the main sheet

only, then re-engage both winches and haul in both sheets, repeat until the jib is correctly set. It is

very easy to over sheet the jib so beware.

If you wish to sail the boat manually and adjust the sheets by hand, reverse the process and wind the rope

out of the winches leaving a tail of about half a meter outside the winches. This will leave the full length of

the sheets available for manual operation.

Reefing the Mainsail (reducing sail area)

Pull on the port reefing line to reduce sail area

Pull the Starboard line to increase sail area.

Fig. 18

17

Never pull and “push” on both at once.

Use the white “clamcleats” on the left (port) side of the console to cleat the reefing line or the sail will un-

roll. (fig 23 on page 18)

You can put one complete turn of sail around the mast without adjusting the outhaul.

To reef further the outhaul needs to be released to allow the sail to travel forward along the boom.

Conversely, when un-reefing, you need to pull on the outhaul.

Always re-cleat the outhaul after adjusting. Cleat the outhaul at the white clamcleat on the boom.

The idea is not to flatten the sail along the boom as it should have enough slack to form a gentle curve.

(fig. 19 & fig. 20)

Reefing and Furling the Jib

Un-cleat the jib sheet and downhaul before attempting to reef.

Use the port reefing line to reef, the starboard to unreef.

Remember to cleat the reefing line after reefing (use the clamcleat on the console port side) or the sail will

unroll.

Adjust the downhaul to suit.

To furl the jib, remove the strut, unhook the downhaul, slide the claw to the base of the mast then pull the

port jib reefing line to completely roll up the sail.

When de-rigging, leave the sheet block shackled to the clew, untie the figure of eight knot in the sheet end

and un-reeve the sheet.

Fig. 19

Fig. 20

18

The Steering

Ensure the steering lines pass under the joystick correctly. A ca-

ble tie can be fitted through the lower hole to prevent a derail.

(fig 21)

Fit the rudders making sure the rope traveller is above the tillers.

Remove the spring clips and pass the clevis pins up

through the holes at the end of the tillers. Re-insert

the spring clips. (fig 22)

Fit the alloy joystick extension. (fig 23). If there is a problem of

sailors accidentally removing this joystick extension a spring

clip can be fitted. Contact Hansa Sailing for details.

Also in fig. 23 are the two white camcleats on the aft port side

of the console used to cleat the mainsail and jib reefing lines.

Fig. 21

Fig. 22

Fig. 23

19

If the boat is to be steered manually, wind out (anticlockwise)

the helm winch drum to release the clutch. (fig 21)

If the boat is to be steered servo assist the clutch needs to be

engaged. Push the manual joystick hard over to either port or

starboard and do the same with the helm winch by connecting

battery and servo joystick and push it over to either port or star-

board as done with the manual joystick. This should align the

clutch. Then wind in (clockwise) the star knob to engage the

clutch. (see fig 24)

To align the steering see Part 3, SERVO ASSIST SYSTEM-

Adjusting the steering lines, page 25.

Launching

Pass the bow line (called a painter) through the guide ring at the bow and fasten it around the mast using

a bowline (a knot which is always easy to untie)

Use a hoist to lower the keel in place. Keels are best carried on shore in a Keel Caddy or a common hand

truck.

DO NOT ALLOW ANYONE TO SAIL WITHOUT THE CENTREBOARD FULLY DOWN OR THEY MAY

CAPSIZE.

USE THE LONG ALLOY PIN TO LOCK THE CENTREBOARD DOWN.

NEVER USE SEAT BELTS OR HARNESSES UNLESS THE CENTREBOARD IS LOCKED DOWN.

PART THREE : LIBERTY SERVO ASSIST SYSTEM

OVERVIEW

Hansa boats are extremely easy to sail servo assist and a severely disabled sailor can be very competitive

against anyone. Unfortunately, however efficient servo assist equipment may be, sheet and helm winches

will always be mechanical and without feel, and slower than an able bodied person working sheets and

joystick manually. But without doubt, its better to be sailing without feel than not sailing at all.

Servo Assist equipment is fitted only to our single seaters for three reasons.

Sailors who require servo assist generally have limited mobility which prohibits them moving body

weight to windward to counteract heeling. The boat will therefore heel more and single seaters with

their wide side decks stay dry, even at extreme angles of heel.

Sailors with limited mobility are more secure in the narrow single seater cockpit

As winches are less responsive than manual control, the boat is likely to occasion- ally be heeled

more in wind gusts, so the single seater is dryer.

Fig. 24

20

The Liberty system comprises a control box with wiring harness (fig 25), helm winch (fig 28—page 21),

mainsheet winch (fig 29—page 22), jib sheet winch (fig 30—page 22), controller (figs 31– 36—pages 23

and 24) batteries (fig 26—page 21) and battery charger (fig 27—page 21).

Control Box. (fig 25)

The control box, part number RC5, is hanging on a

saddle inside the starboard cockpit inspection port.

It has;

3 leads running forward, they are: (1) jib sheet

winch - long lead with red plug. (2) main sheet

winch - mid length lead with white plug. (3) battery -

short lead with blue plug. These leads run forward

and out into the cockpit via a 2 hole and a 1 hole

rubber bungs,

then forward through the back of the console to the

battery, the main sheet winch, and the jib sheet

winch.

2 leads running aft, (1) the larger of the 2 passing through the aft bulkhead, via a 32mm single hole rubber

bung, its yellow 9 pin plug connecting to the joy- stick. (2) The smaller of the 2 aft leads plugs into the

helm winch lead (black plugs) which should always be hanging on a hook just aft of the starboard side in-

spection port.

These plugs, except the yellow 9 way joystick plugs, should be sprayed with corrosion guard, particularly

the blue battery plug which is the one most likely to get wet.

Those left connected, ie, the male and female red jib sheet winch plugs and the white mainsheet winch

plugs can be taped together and the mainsheet winch plugs pushed up under the console and held there

with the small piece of foam.

The black helm winch plugs can also be taped together and should be sup- ported on the plastic hook in-

side the starboard inspection port.

The blue battery lead plug, when disconnected from the battery, should be plugged into the dummy fe-

male plug attached to the console close the battery compartment. Never let these plugs lie in water. Spray

them with corrosion guard regularly.

Fig. 25

Other manuals for Liberty

1

Table of contents

Other Hansa Sailing Boat manuals