Hanshen FKR350 User manual

OPERATION

MANUAL

SCR Control CO2Shielding Arc

Welding Machine

FKR/350/500

ATTENTION:

For safety guarantee, only the person with operating

certificate or expert skills can collocate, check,

maintain, fix and repair the welder.

For safety guarantee, please completely read and

understand the details in this manual before using.

Keep the manual in convenient place for easy reading.

1

Comparing with other welding machines, CO2/MAG arc welding machine has the

following features:

◆Higher working efficiency : CO2arc has strong penetration ability, deeper

welding pool, higher melt efficiency. So, welding speed is faster and productivity is

1-3 times higher than stick welding

◆Lower welding cost : CO2gas can be easy and cheaply obtained from any

chemical or brewage factory, just 40~50℅cost of other welding machines

◆Wider application area: It can be used at any position. The thinnest limit

is 1mm and thickness almost no limit(multi-layer welding). Once thin sheet welding,

the speed is faster and distortion is less.

◆Stronger anti-rust ability, lower hydrogen percentage ,better anti-crack

ability.

Do not◆need slag-cleaning after welding, arc is easy control and observation.

Mechanization and automatization are easy realized.

At present, CO2gas welding machine is mainly used for dark metal welding, such as

low carbon steel alloy , low alloy steel and so on, it also can be used for stainless

steel welding with mixed gas or cored wire.

2

CATALOGUE

NOTICE

1,Characteristic........................................................................................4

2,Safety attention ....................................................................................4

3,Installation place and power facility ....................................................6

4,Machine structure and accessories .............. .....................................6

machine st◆ructure and assembly drawing.................................6

5,Components name and function...........................................................7

◆Welding power (operation panel) ..............................................8

◆Remote controller.......................................................................9

CONNECT

Connection and Grounding …………………………………………… 10

Power source and distribution box◆……………………………..11

Power source and workpiece end◆、output cable ………………12

Power source and wire◆-feeder facility、welding torch ………...12

◆Gas cylinder and adjustor………………………………………13

OPERATION

1、Confirmation and preparation before operation ………………… …14

◆Confirmation for safeguard appliance 's usage and preparation

………………………………………………………………..14

Safegar◆d appliance ……………………………………………..14

Inspection a◆fter connection …………………………………..14

Preparation◆before welding …………………………………….15

Switch operating and gas flow's adjusting◆………………………15

Wirei◆nstallation…………………………………………………16

Finger push◆for wire control …………………………………….17

2、Manual operation for welding (base function )…………….. 18

Crater welding◆(self-locating ·crater action) ………………….18

No crater welding◆(acting simultaneously with torch ).………….19

FUNCTION

1、Patulous functions …………………………………………………..20

Connection of Lengthening◆cable …………………………………21

◆welding functions extension……………………………………….22

Socket connection for wire◆-feeder facility ………………………..22

Socket connection for gas adjustor◆………………………………..22

2、Peripheral equipment ……………………………………………….23

T◆orch ………………………………………………………………23

Wire◆-feeder machine ………………………………………………24

Gas flow◆-meter …………………………………………………..24

3

TECH DATA

1、Rated Specification/Standard accessories/ Outline dimension ……...26

2、Instance for welding conditions ……………………………………..28

3、About duty cycle …………………………………………………….29

4、Words and expressions ………………………………………………30

Meani◆ngs of crater (Yes )crater (No )……………………..30

What's slow feeder speed with lift arc ……………………◆………31

What's◆flashback time ……………………………………………31

What's FTT◆ Control …………………………………………..31

OVERHAUL

1、Daily check …………………………………………………………..32

Welding◆power source ……………………………………………...33

Weld◆ing torch …… ………………………………………………...34

wire◆-feeder machine ………………………………………………...35

◆cable …………………………………………………………………35

2、Regular check ………………………………………………………...36

clean dust in power source ………………………………………◆….37

ch◆eck power source and concerned facility ………………………....38

◆cable …………………………………………………………………38

check and repair wearing parts ………………………◆……………...39

TROUBLE SHOOT

1、primary check for abnormity ………………………………………… 40

2、indicating light and solution for abnormity ………………………… ..40

3、other problem and abnormity treatment ………………………………40

investigation of problem and abnormity ……………………◆………41

check flow chart A◇、B……………………………………………41

check flow chart C◇、D……………………………………………42

disposal method after judging r◆eason ……………………………..43

fus◇e broken ……………………………………………………...43

printed board problem ……………………………………………◇.43

other parts' problem except fuse and PCB …………◇……………..43

other reasons ………………………………◇……………………...44

4、after service ………………………………………………………….. .44

P. S :outline for torch and wire-feeder usage and maintenance ………45

CIRCUIT DIAGRAM

1、circuit diagram ……………………………………………………….. 46

4

NOTICE

1、CHAEACTERS

Performance exceeding common SCR welding machine

No◆-remote control cable,enhance maneuverability,decrease cable broken

problem.

New design and tri◆-protection treatments,dust、water、smog protections,improve

performance and suitable to any worksite and environment.

Separately adjust for current and voltage /simple centralize conversion f◆unction,

whatever skilled or non skilled operator can use easily.

2、SAFETY ATTENTION

Following rules must be abided by to ensure operation safety

CAUTION! AVOID SERIOUS BODY INJURED ACCIDENT HAPPENING

precaution for grounding◆

should be let qualified electric person to connect grounding cable as per concerned

law and regulations

Usage of protection cloth◆、protection appliance

should use protection appliance in order to avoid burning eye and skin

precaution for ventilation◆

To avoid harm air poisoning and choking accident happening(CO2 and welding smog

is harmful to health),ventilation and effective breath protection appliance must be

prepared so as to meet local requirement of law and regulation .

CAUTION! AVOID WELDING MACHINE DAMAGE AND FIRE ARISING

preven◆t welding machine damage or fire arising from over-heat

keep the machine 20cm away from wall ,or keep 50cm away from tinder

prevent welding machine damage or fire arising from sparking◆

must guard against sparking on tinder (splash,flash ),or go inside via inspiration gob

or opening

prevent welding machine impaction and damage arising from falling◆

when setting welding machine on scaffold,should be screwed firmly,enough not to

falling down(and not let gas cylinder fall down )

should read operation manu◆al

The operation manual includes welding machine ,wire-feeder, gas regulator and so on,

please operate carefully base on reading manual

5

3、INSTALL ENVIRONMENT AND POWER FACILITY

Power 3 PHASE AC(380V) 50Hz

Model FKR350 FKR500

Adopted power 20KVA 40KVA

Capacity Engine generator 18.1 KVA

2 times up

31.9KVA

2 times up

Fuse size 30A 50A

Input

protection Circuit breaker

(leakage protection) 30A 50A

Power inlet 8 mm2up 12 mm2up

Power outlet 38 mm2up 60 mm2up

Cable section

dimension Earth lead 14 mm2up 14 mm2up

If working environment is damp,or on iron plate or shelf,please install earth leakage

circuit breaker.

Attention

To avoid parts damage、unstable arc,even machine damage,please abide following

rules and operate machine properly:

●power voltage undulation: voltage tolerance is ±10%

●when using the engine generator: two times up rated input capacity with

compensating coils

(FKR200:7.6KVA,FKR350:18KVA,FKR500:32KVA,FKR630:47KVA)

●Input cable: install suitable automatic switch or circuit breaker.(leakage

protection device)according to rated capacity

6

●please use different circuit breaker(or leakage protecting device)for

welding machine、generator and transformer.

●please use appointed wire-feeder with our welding machine

4、MACHINE STRUCTURE AND ACCESSORIES

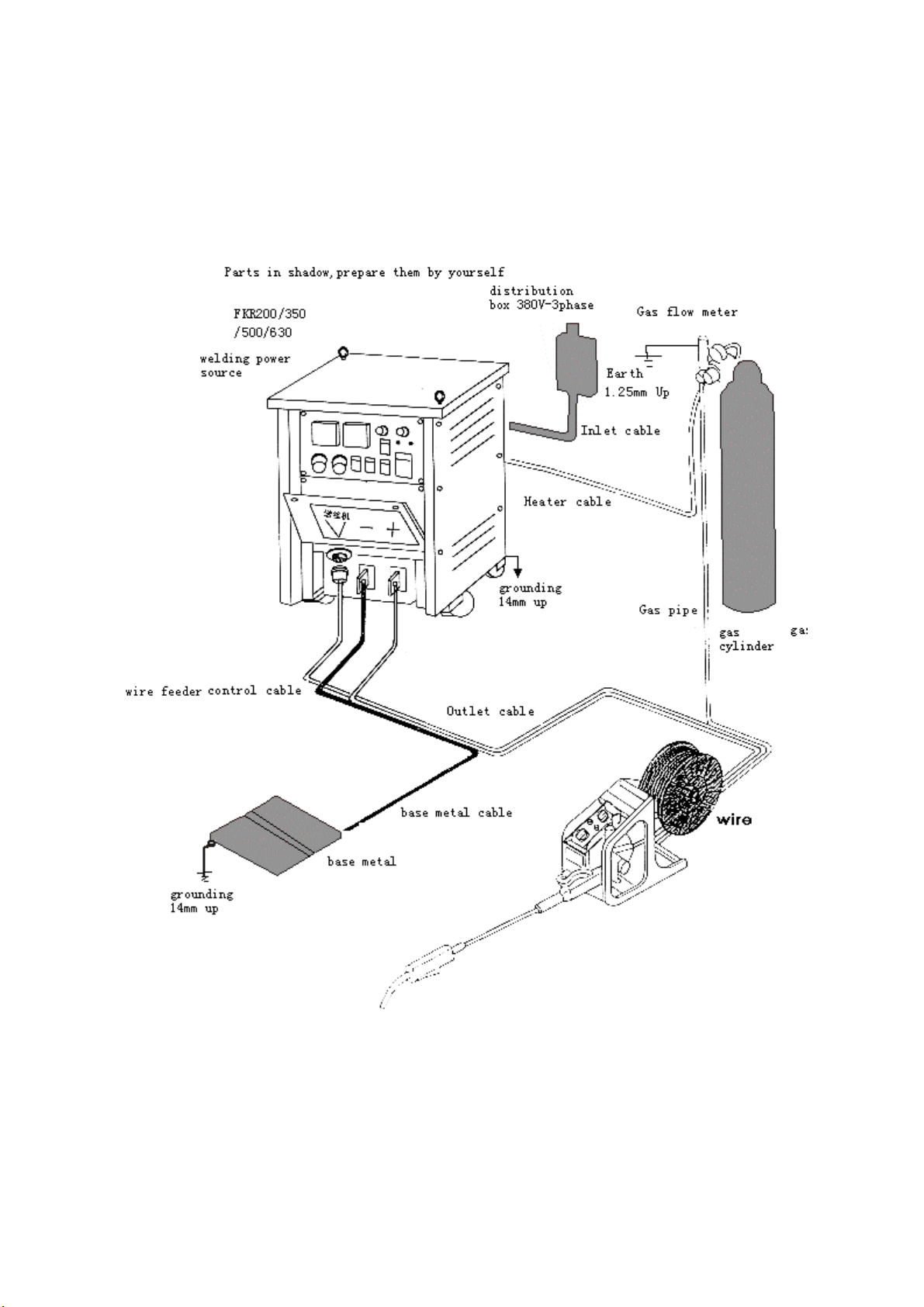

●machine structure and assembly drawing

7

5、PARTS NAME AND FUNCTION

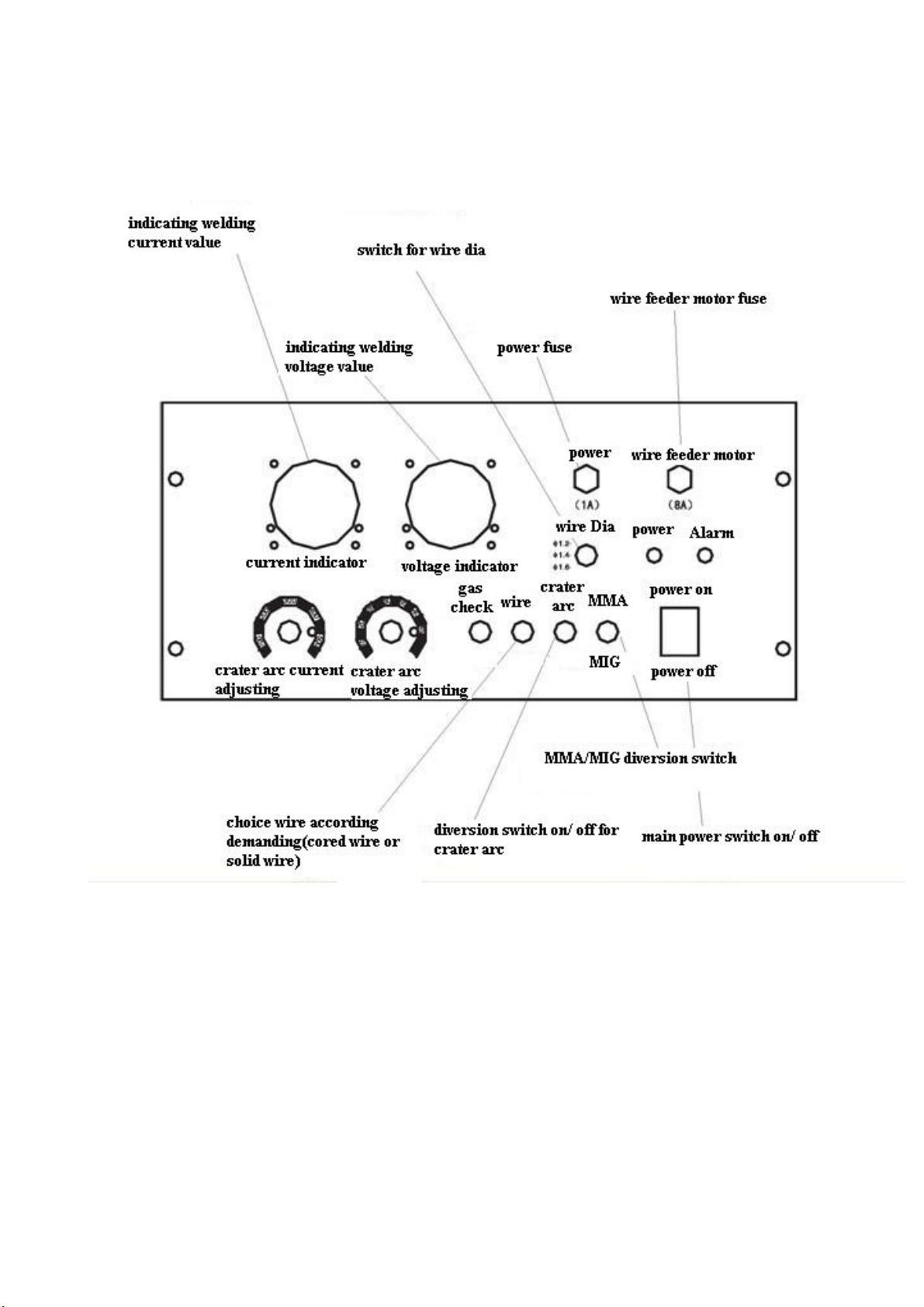

●welding power (operation front panel)

8

Welding power

9

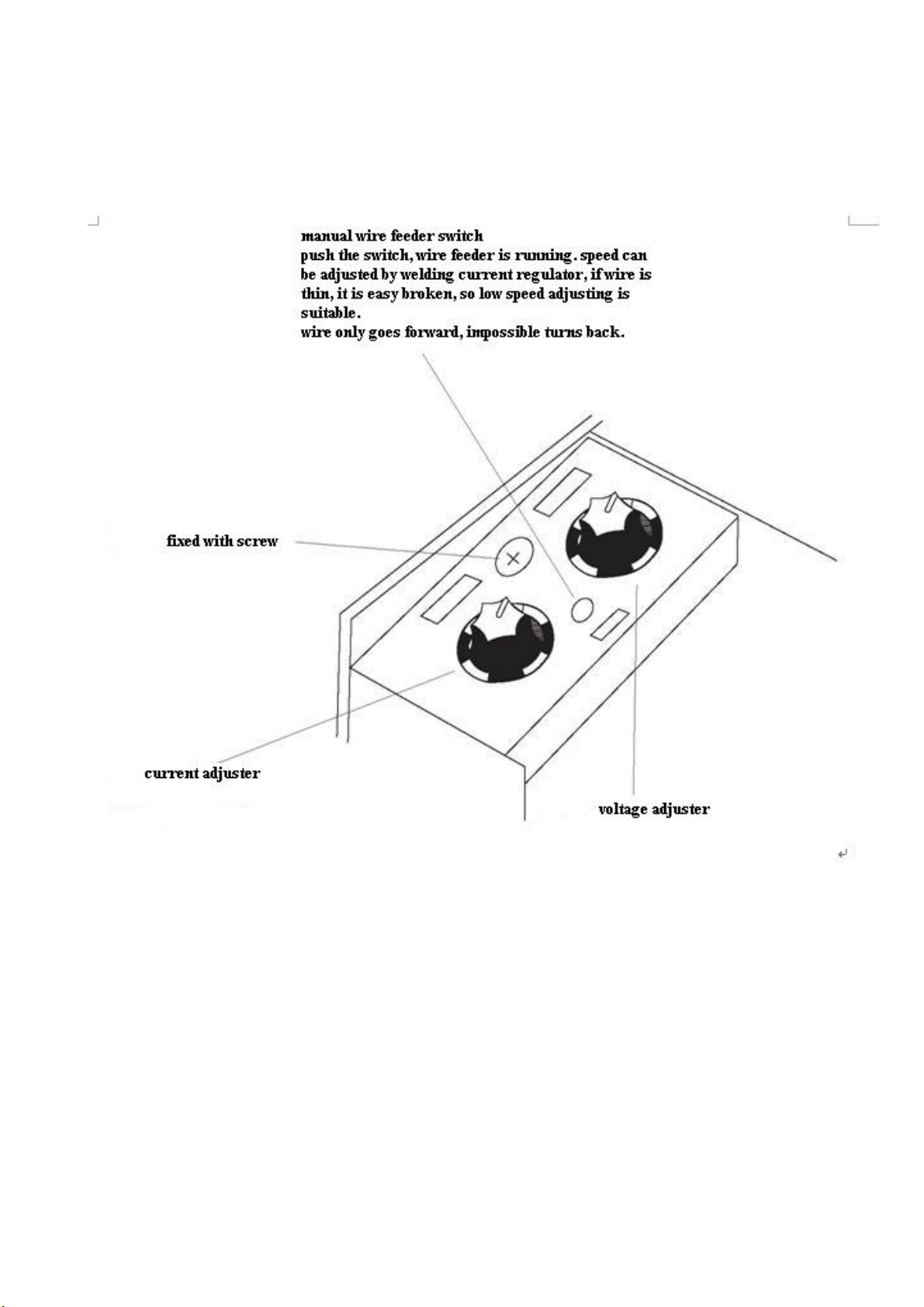

●remote controller

10

CONNECT

Connection and Grounding

Safety warning

Avoiding accidents happen such as electric shock,burning etc, follow rule should be

abided by:

●Connecting power cable should be under”power off”, and absolutely safety

condition.

●Don’t touch any parts with damp hands.

Attention

Avoiding fire, burn machine or unstable arc occurred by cable over-heated:

●cable should be more than demaned specification

●don’t hang any things on cable or touch welding parts

11

●please tightly connect cables’ joints.

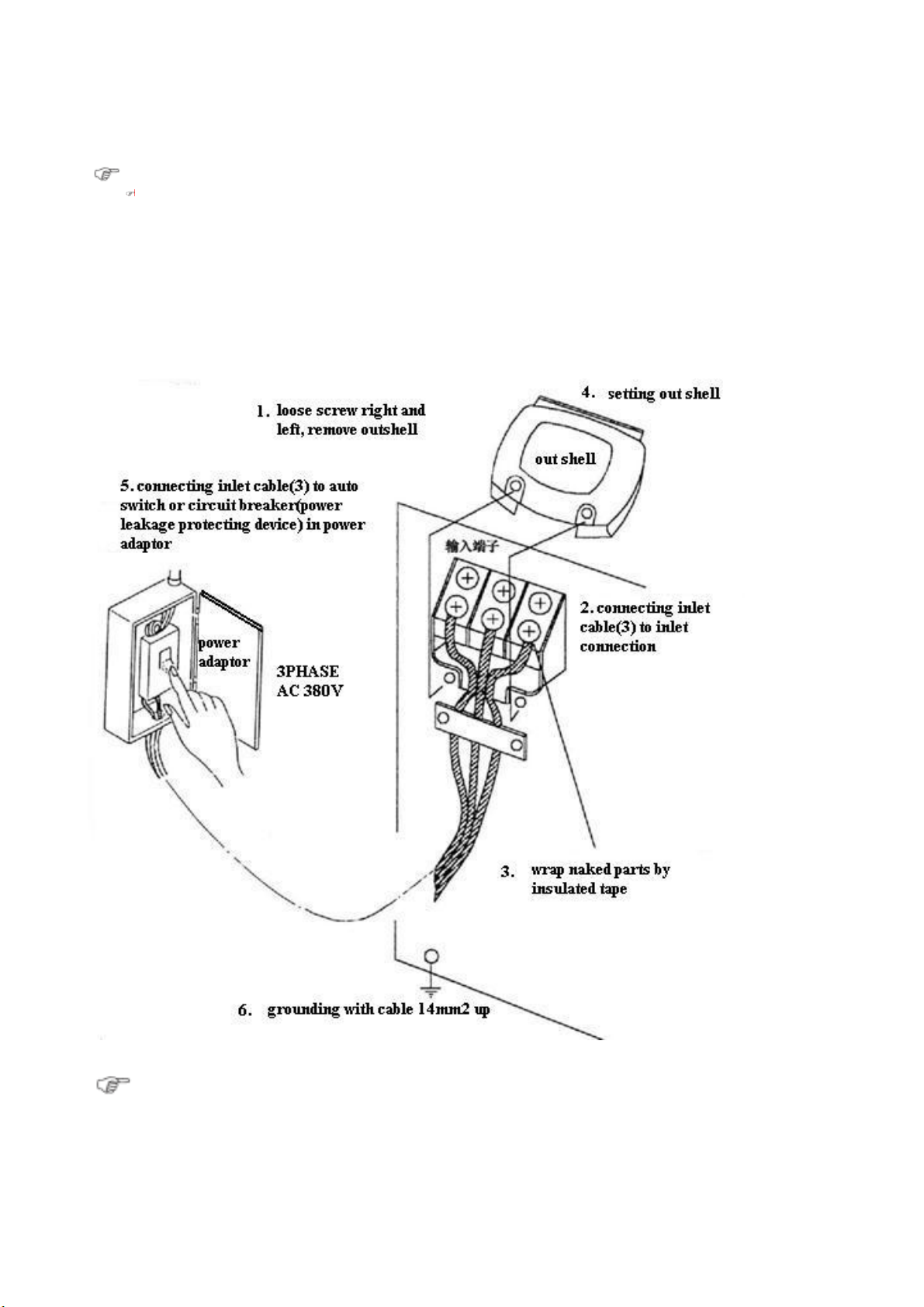

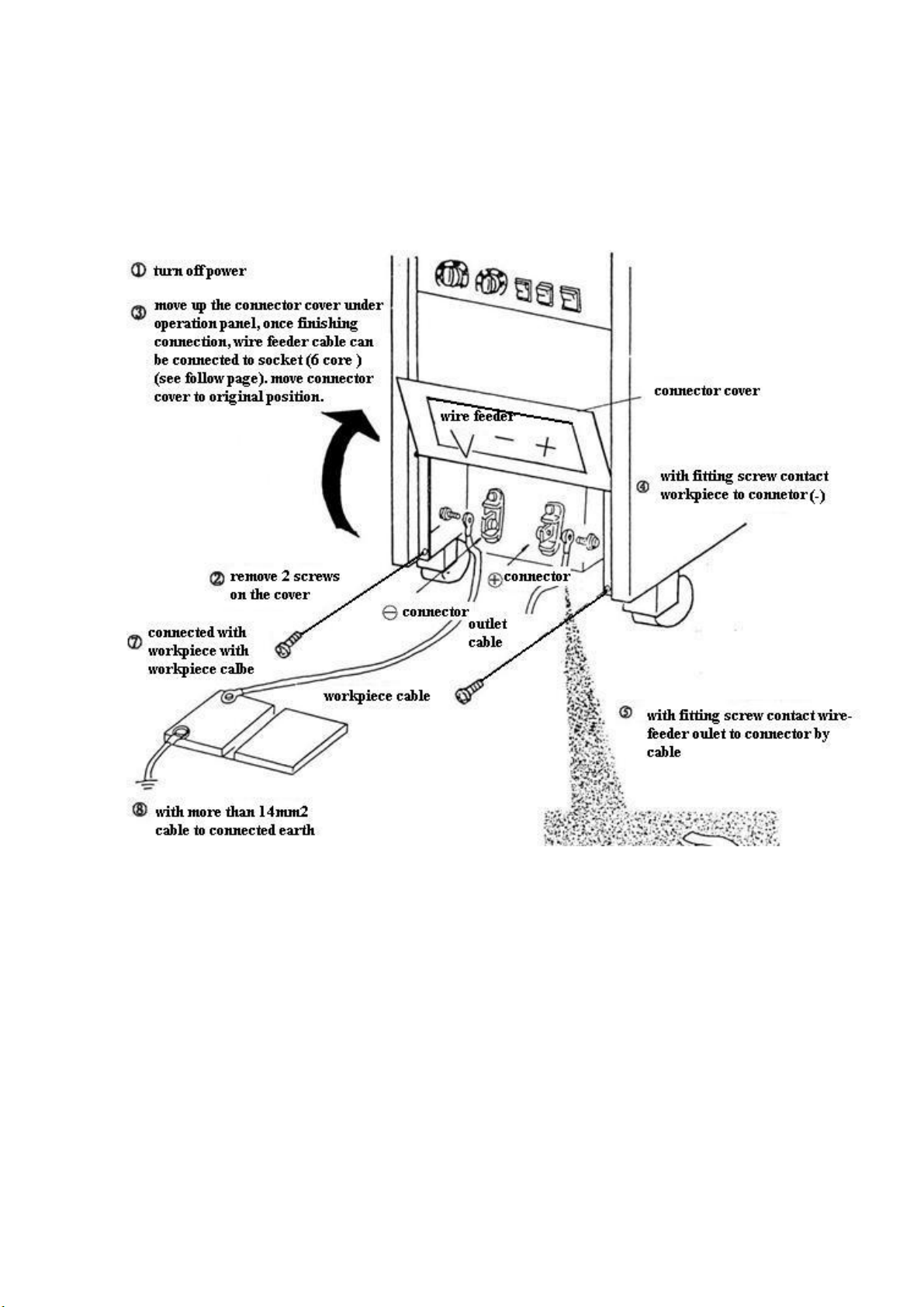

Connection and Grounding

Welding power connected with base metal and inlet cable

12

Welding power connection with wire-feeder and welding torch

Attention

Wire-feeder machine should match with welding machine and power source

If not match , the machine can not work and possibly be damaged .

Note: Information about welding torch 、wire-feeder and gas flow-meter, please refer

to page 29,page30.

13

Connection and Grounding

Gas cylinder and regulator

Note

Gas quality will effect to welding result, follows are some key points:

●CO2 welding must use CO2 gas.

●MAG welding must use MAG mixed gas(argon gas mixed with 5-20% CO2).

●CO2 and argon mixed, gas mix facility must be used(avoiding mixed mot well)

●Argon gas must be pure(purity 99.9% up).

14

OPERATION

1、Confirmation and preparation before operation

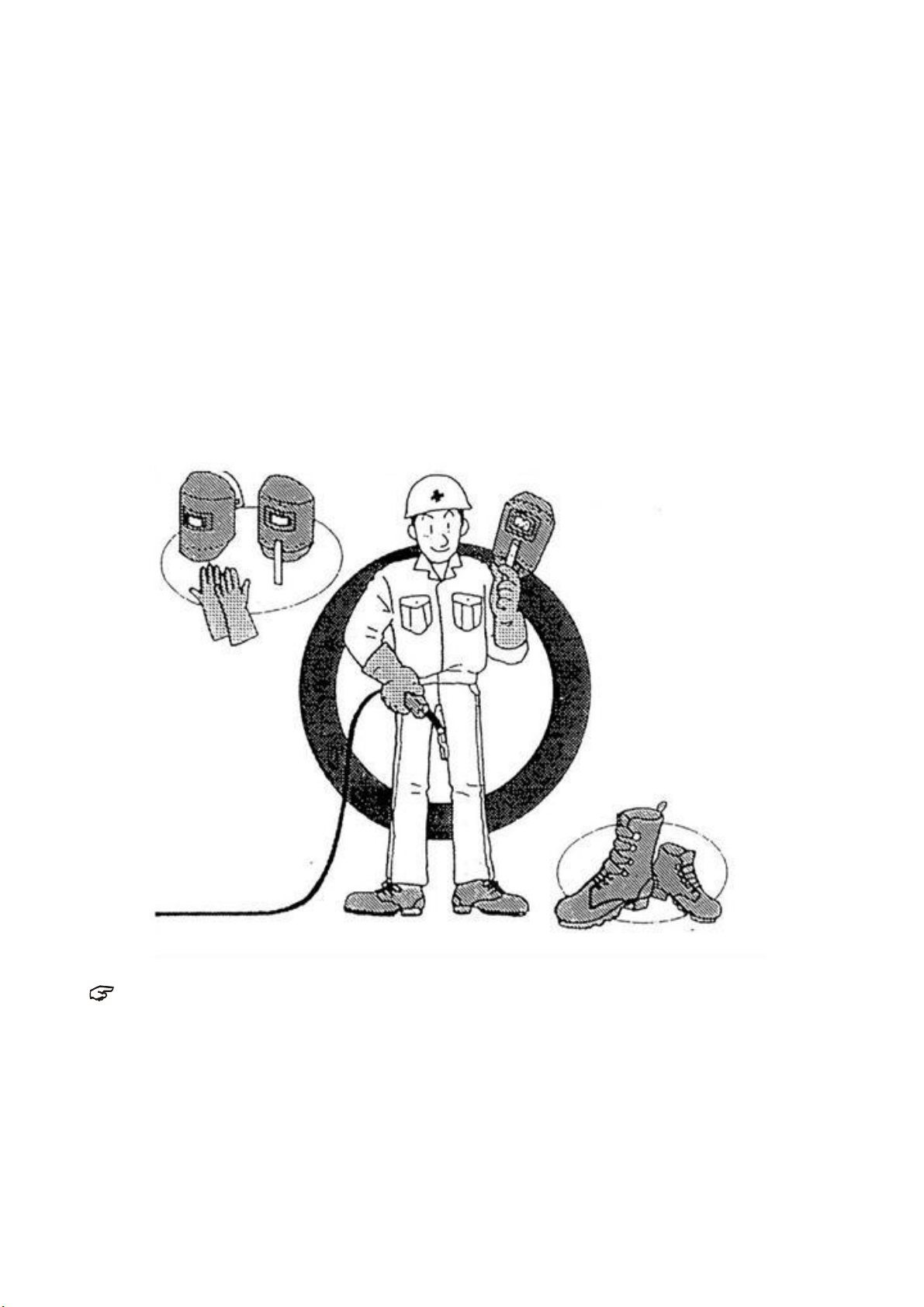

●Confirming to safety fitting and preparing

●Safety fittings

●For your naked eye and skill leather glove and safety boots should be dressed

well.

●must wear protection mask with shading and filting len.

Avoiding toxin gas(CO, ozone, oxidize nitrogen), ventilation system must be

employed.

●Check after connection

●check again and make sure all parts have been connected according to

connecting drawing

Note

Select suitable lens according to current and real situation while CO2 welding is

taken.

15

Confirmation and preparation before cooperation

Preparation before welding operation

■Switching and gas flow adjusting

16

Preparation before welding operation

■Install wire

17

Preparation before welding

■Slightly move for wire-feed

pressspot①-switch and wire-feeder

starts, until 15-20mm length of wire

out from nozzle, then loose switch

Note:

Thin wire is easily broken(like

Φ0.8 wire), please slow wire-feed

speed.

)

Note

Select wire roller,just according to wire dia. , not wire type.

When using cored wire,should adjust pressure of wire-feed arm,pressure should be

less than that of solid wire .

In addition, to cored wire, brand and process are different from each other,there may

be some difference in demanded pressure ,please note this point.

)

Safety warning

●For safety,after finishing job, all switches including distribution box and welding

power must be turned off(auto-switch or circuit breaker and electric leakage

protector)

●while slow wire-feeding,don't move close to nozzle to see if wire comes out .

●While welding,spatter is dangerous for operator's face and eye.

18

2、MMA operation(basic function and method)

●Welding with crater arc(self-location, crater arc action)

It is used to fill pit after welding, suitable for medium thickness sheet.

Welding with crater arc, funcation for filling welding pool at end and suitable for

medium thickness plate

Operatiing sequence

●Turn diversion switch to “crater arc on” position, press gun switch on/off two

times to take welding.

Work time diagram

As above said, with gun switch possible to lock automatically, once welding finish,

welding current reduce, crater arc is taken.

But, in welding process, when crater arc broken more than 0.5 seconds, lock will be

released automatically.

19

Welding without crater arc

This kind of welding is used for tack welding, instantaneous welding and thin sheet

welding.

Operation

●turn diversion switch to “without crater arc” position, “turn on”, “turn off” gun, arc

start or arc stop will be happened.

Work time diagram

This manual suits for next models

1

Table of contents

Other Hanshen Welding System manuals

Popular Welding System manuals by other brands

ESAB

ESAB Aristo Mig 3001i Service manual

EINHELL

EINHELL TC-FW 100 Original operating instructions

ESAB

ESAB Aristo Mig C3000i instruction manual

Clarke

Clarke 195TEC Operating & maintenance instructions

Cebora

Cebora 359 instruction manual

Parkside

Parkside PESG 120 A1 Assembly, operating and safety instructions