1.

TECHNICAL FEATURES

ﺔﻴﻨﻔﻟا ﺺﺋﺎﺼﺨﻟا

1./1

ﺔﻣﺪﻘﻣ

BASICﻦﻴﻠﻴﺜﻴﻟﻮﺒﻟا ﻦﻣ ﺔﻋﻮﻨﺼﻤﻟا تﺎﺒﻴآﺮﺘﻟاو ﺮﻴﺳاﻮﻤﻠﻟ ﻊﻗﻮﻤﻟا ﻞﺧاد ﻲﺒآﺎﻨﺘﻟا مﺎﺤﻠﻟا تﺎﻨﻴآﺎﻣ ﻦﻣ ﺔﻠﺴﻠﺳ ﻲه)PE(ﻦﻴﻠﻴﺑوﺮﺑ ﻲﻟﻮﺒﻟاو)PP(ﻲﺘﻟا ىﺮﺧﻷا داﻮﻤﻟاو

ٍل ﺎ ﻋ ﻂﻐﺿ ﺖﺤﺗ نﻮﻜﺗ ﻲﺘﻟا ىﺮﺧﻷا ﻞﺋاﻮﺴﻟاو ﻩﺎﻴﻤﻟاو لﺎﻌﺘﺷﻼﻟ ﻞﺑﺎﻘﻟا زﺎﻐﻟا ﻞﻘﻨﻟ ﺔﺼﺼﺨﻤﻟا ةراﺮﺤﻟﺎﺑ نﺪﻠﺗ.

ﻣﻊﻴﻤﺟتﺎﻨﻴآﺎ

BASICﺎﻬﻧﺎﻜﻣﺈﺑPE 100جودﺰﻤﻟا ﻂﻐﻀﻟا ﺔﻘﻳﺮﻃ ماﺪﺨﺘﺳﺎﺑ.

ﺔﻣﺪﺨﺘﺴﻤﻟا ﺢﺋاﻮﻠﻟاو ﻦﻴﻧاﻮﻘﻠﻟ ﺎًﻘﻓو ،ﻦﻳﺪﻤﺘﻌﻤﻟاو ةﺮﻬﻤﻟا داﺮﻓﻷا ﻰﻠﻋ اًرﻮﺼﻘﻣ نﻮﻜﻳ ﺔﻠﺛﺎﻤﻤﻟا تﺎﻨﻴآﺎﻤﻟا ماﺪﺨﺘﺳا نﺄﺑ كﺮآﺬﻧ ﻦﺤﻧو.

INTRODUCTION

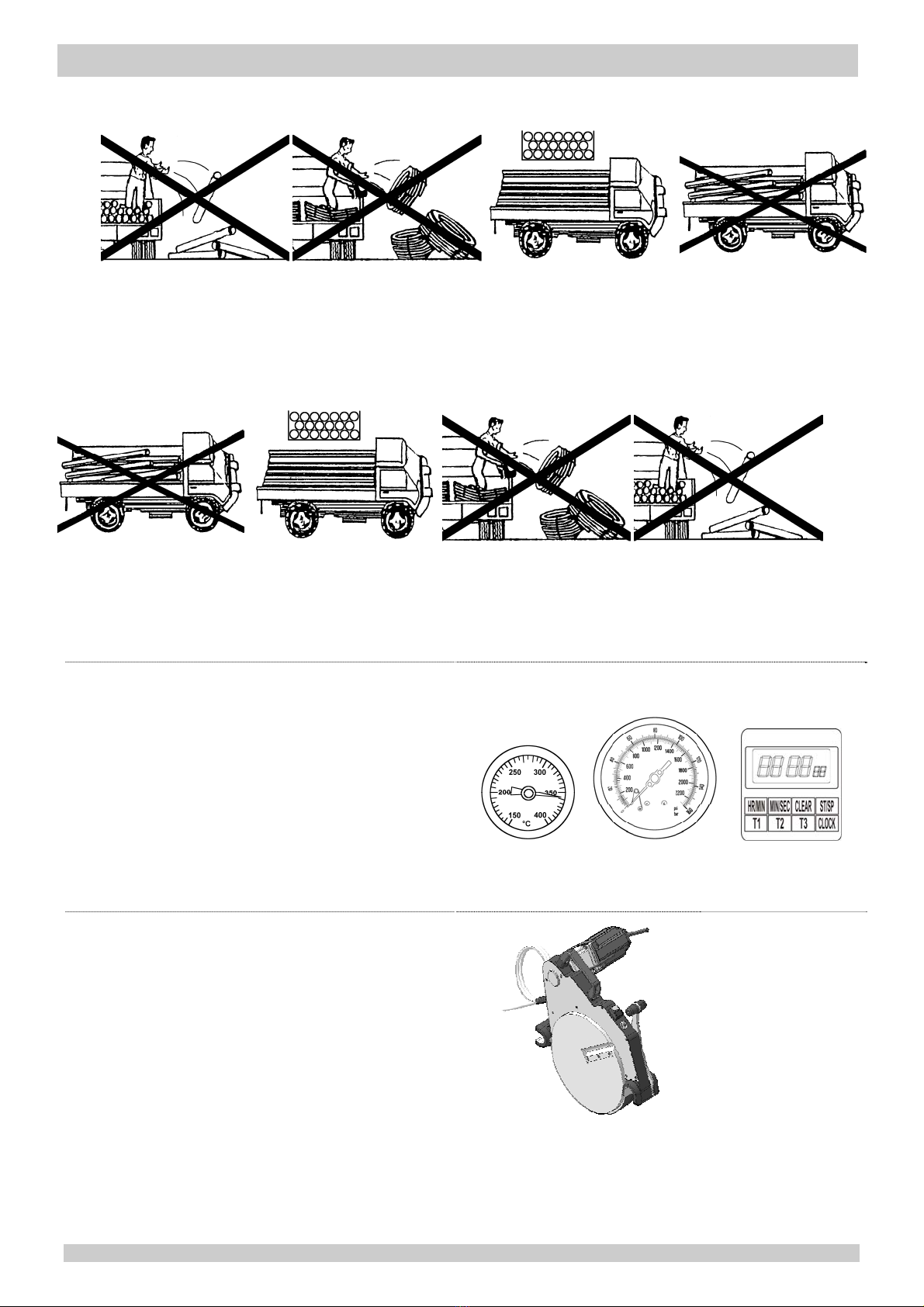

BASIC is a line of on-site butt welding machines for pipes and fittings in Polyethylene (PE), Polypropylene (PP), and other

thermoplastic materials intended for the transport of combustible gas, water, and other fluids under high pressure.

All BASIC machines can weld PE 100 with the Dual Pressure method.

We remind you that the use of such machines is limited to authorized skilled and certified personnel, in accordance with the

Legislation and Regulations in force.

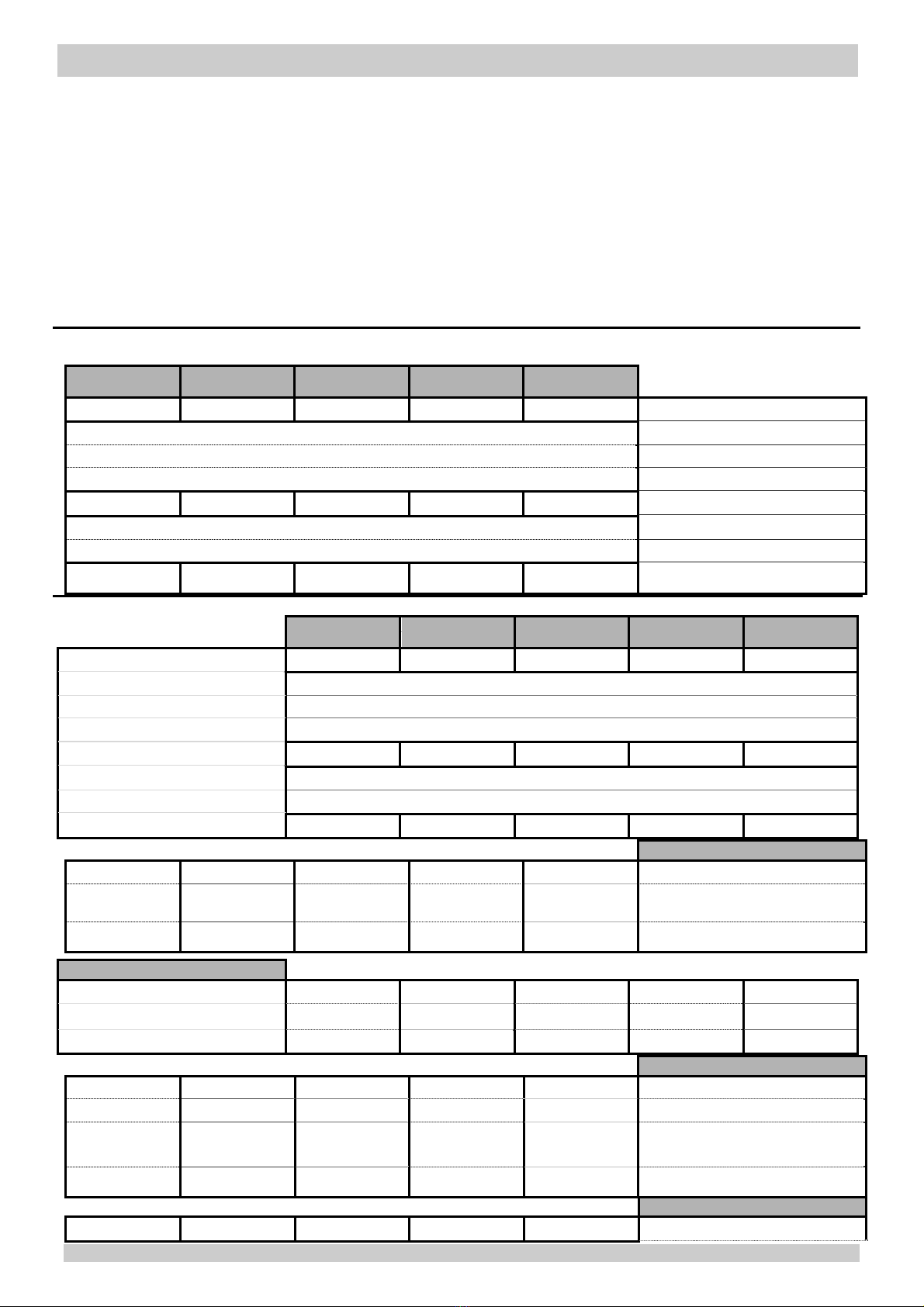

SPECIFICATIONS تﺎﻔﺻاﻮﻤﻟا

ﺺﺋﺎﺼﺨﻟا

BASIC 160 V1BASIC 200 V0BASIC 250 V1BASIC 315 V1BASIC 355 V0

220V220V220V220V220V

ﺮﻄﻘﻟا ىﺪﻣ]ﻢﻠﻣ[

∅40÷160∅63÷200∅75÷250∅90÷315∅125÷355

مﺎﺤﻠﻟ ﺔﻠﺑﺎﻗ داﻮﻣHDPE: PE 80 (MRS 8(وPE 100 (MRS 10(وPPﺘﻟا ىﺮﺧﻷا داﻮﻤﻟاوةراﺮﺤﻟﺎﺑ نﺪﻠﺗ ﻲ

ﺔﻄﻴﺤﻤﻟا ةراﺮﺤﻟا ﺔﺟرد قﺎﻄﻧ]ﺔﻳﻮﺌﻣ ﺔﺟرد[ﻦﻣ-5ﻰﻟإ+40)PE 100:ﻦﻣ0ﻰﻟإ+40(

ﺔﻗﺎﻄﻟا داﺪﻣإ

220بوﺎﻨﺘﻣ رﺎﻴﺗ ﻂﻟﻮﻓ60ﺰﺗﺮه

ﺔﺼﺘﻤﻤﻟا ﺔﻗﺎﻄﻠﻟ ﻰﺼﻗﻷا ﺪﺤﻟا]تاو[

22203220342044205750

لﺰﻌﻟا ﺔﺌﻓ

1:ﺔﻳﺎﻤﺤﻟا ﻞﺻﻮﻣ

ءﺎﺿﻮﻀﻟا ىﻮﺘﺴﻣ]ﻞﺒﺴﻳد)ﺒﻣأﺮﻴ[ (

Leq=79.2

نزﻮﻟا-ﺺﺋﺎﺼﺨﻟا ﻊﻴﻤﺟ ﻊﻣ ﺔﻨﻴآﺎﻤﻟا]ﻢﺠﻠآ[

70ماﺮﺟﻮﻠﻴآ)155

ًﻼ ﻃ ر(

93ماﺮﺟﻮﻠﻴآ)205

لﺎﻃرأ(

124ماﺮﺟﻮﻠﻴآ

)273.3ًﻼ ﻃ ر(

166ماﺮﺟﻮﻠﻴآ)366

ﻞﻃر(

-

FEATURES BASIC 160 V1 BASIC 200 V0 BASIC 250 V1 BASIC 315 V1 BASIC 355 V0

220V 220V 220V 220V 220V

Diameters range [ mm ] ∅40÷160 ∅63÷200 ∅75÷250 ∅90÷315 ∅125÷355

Weldable materials HDPE: PE 80 (MRS 8) and PE 100 (MRS 10), PP and other thermoplastics materials

Ambient temperature range [ ° C ] from -5 to +40 (PE 100: from 0 to +40)

Power supply 220VAC 60Hz

Maximum absorbed power [ W ] 2220 3220 3420 4420 5750

Isolation class 1: protection conductor

Noise level [ dB (A) ] Leq=79.2

Weight - machine with all features [kg] 70 Kg (155lb) 93 Kg (205 lb) 124 Kg (273.3 lb) 166 Kg (366 lb) -

ﻪﻴﺳﺎﺸﻟا

ﻲﻟﺎﻤﺟﻹا ﻊﻓﺪﻟا ﻢﺴﻗ]ﻢﺳ

2

[

1,9473,1565,8906,68014,130

عﺎﻔﺗرﻻا ﻖﻤﻌﻟا ضﺮﻌﻟا ،دﺎﻌﺑﻷا]ﻢﻠﻣ[

606x365x375ﻢﻠﻣ

)23.9x14.4x14.8

ﺔﺻﻮﺑ(

685×460×420ﻢﻠﻣ

)27x18.2x16.5ﺔﺻﻮﺑ(

850x470x400ﻢﻠﻣ

)33.5x18.5x15.7

ﺔﺻﻮﺑ(

981x586x520ﻢﻠﻣ

)38.6x23x20.5ﺻﻮﺑﺔ(

1077x510x715ﻢﻠﻣ

)42.4x20x28ﺔﺻﻮﺑ(

نزﻮﻟا]ﻢﺠﻠآ[

21ماﺮﺟﻮﻠﻴآ)46.3

ﺎًﻠﻃر(

39ماﺮﺟﻮﻠﻴآ)86

ًﻼ ﻃ ر(

63ماﺮﺟﻮﻠﻴآ)138.9

ًﻼ ﻃ ر(

86ماﺮﺟﻮﻠﻴآ)189.6

ًﻼ ﻃ ر(

100ماﺮﺟﻮﻠﻴآ

)220.5ًﻼ ﻃ ر(

CHASSIS

Overall thrust section [ cm2 ] 1,947 3,156 5,890 6,680 14,130

Dimensions W D H [ mm ] 606x365x375 mm

(23.9x14.4x14.8 in)

685×460×420 mm

(27x18.2x16.5 in)

850x470x400 mm

(33.5x18.5x15.7 in)

981x586x520 mm

(38.6x23x20.5 in)

1077x510x715 mm

(42.4x20x28 in)

Weight [ kg ] 21 Kg (46.3 lb) 39 Kg (86 lb) 63 Kg (138.9) 86 Kg (189.6 lb) 100 Kg (220.5 lb)

ةاﻮﺴﻤﻟا

ﺔﻴﻤﺳﻻا ةرﺪﻘﻟا]تاو[

1050105010501050900

ناروﺪﻟا ﺔﻋﺮﺳ]ﺔﻘﻴﻗﺪﻟا ﻲﻓ ةرود[

109109736722

عﺎﻔﺗرﻻا ﻖﻤﻌﻟا ضﺮﻌﻟا ،دﺎﻌﺑﻷا]ﻢﻠﻣ[

375×325×280ﻢﻠﻣ

)14.8x12.9x11ﺔﺻﻮﺑ(

-

440x450x380ﻢﻠﻣ

)17.3x17.7x15ﺔﺻﻮﺑ(

600×460×390ﻢﻠﻣ

)23.6x18.1x15.3

ﺻﻮﺑﺔ(

931x615x220ﻢﻠﻣ

)36.6x24.2x8.7

ﺔﺻﻮﺑ(

نزﻮﻟا]ﻢﺠﻠآ[

9ﻢﺠﻠآ)19.9ًﻼ ﻃ ر(

11ماﺮﺟﻮﻠﻴآ)24.2

ًﻼ ﻃ ر(

15ماﺮﺟﻮﻠﻴآ)33.1

ًﻼ ﻃ ر(

24ماﺮﺟﻮﻠﻴآ)53

ًﻼ ﻃ ر(

38ماﺮﺟﻮﻠﻴآ)83.8

ًﻼ ﻃ ر(

ﻦﻴﺨﺴﺘﻟا حﻮﻟ

ﺔﺼﺘﻤﻤﻟا ﺔﻗﺎﻄﻠﻟ ﻰﺼﻗﻷا ﺪﺤﻟا]تاو[

8001800200030003750