Hanshen HP80 Series User manual

0

OPERATION

MANUAL

IGBT INVERTER AIR PLASMA

CUTTING MACHINE

HP80/120/200 SERIES

ATTENTION

For safety guarantee,only the person with operating certificate or

expert skills can collocate,check,maintain,fix and repair the welder.

For safety guarantee,please completely read and understand the ditails

in this manual before using.

Keep the manual in convenient place for easy reading.

1

CATALOGUE

1、 CHARACTERISTICS &APPLICATIONS………………………2

2、 SAFETY ATTENTION …………………………………………3

3、 TECHNICAL PARAMETER……………………………………4

4、 INSTALLING&CONNECTION…………………………………5

5、 PREPARE FOR CUTTING……………………………………11

6、 DAILY MAINTAIN&CHECK…………………………………14

7、 FAULT REPAIR………………………………………………15

8、 CIRCUIT DIAGRAM……………………………………………18

2

1、 CHARACTERISTICS &APPLICATIONS

HP air plasma cutting machine series,can invert the working frequency DC of 50Hz into the

high frequency of 20KHz,with IGBT and soft switch technology,the application of PWM

technique,and reduce voltage,rectifies current and output a high DC power source and suitable

for cutting .The character is as follows:

The machine is projected by adopting entire-bridge inverter technique and with IGBT

elements.

1.Inverter frequency is above 20KHz by adopting PWM technique.

2.Can preset and continuous adjust the current ,suitable for different thickness work piece ,make

sure cutting quality and save energy.

3.Arc ignition of cutting machine is adopted with small flow of air and HF transfer arc method

for 100% arc ignition..

4.With over-heat 、over-current and arc starting protection.

Suitable for application

Such as carbon steel,alloy steel,nonferrous metals etc.

For operation in machinery industy,petroleum industry,ship building industry,vehicle

industry,electricity industry and decoration.

3

2、SAFETY ATTENTION

2.1 Avoid body event to assure safety operate obey the following

point:

a.The power item of input side、the location choosing、high-pressure gas use 、store and

supply ,welding products store and trash handling etc.please follow related laws or enterprise

standard.

b.Clothing wear and safty tools equip.To avoid eye inflammation and skin burn,please obey

related safty and healthy regulation ,please wear related protecting tools.

c. To avoid noxious gas and stifled(the welding soot and CO2 are harmful to body),must obey

related regulation regarding the soot handling.Installing partial exhausting equipment or use

effective breathing protecting equipment.

d. Can not operate without the weiding machine cover.

2.2 Avoid machine burning and fire

a. Avoid fire because of overheated, please keep 50cm distance between welding power and

the wall or combustibles.

b.Avoid fire because of spark.Forbid spark to touch the combustibles or enter the inspiration、

any open part of welding machine.

c.Avoid damaged by falling or break.During assemble welding machine in frame,to assure

security and avoid slipping ,please fasten the welding machine first.

d. Forbid to have gas piper or any seal can and pipe inside the welding machine.

2.3 Electric connecting item

a. Before connecting operating must turn off power and assure safty.

b. Forbid touch electric part or touch with wet glove.

c. Choose correct line type.

d. Avoid heavy touch on line and touch welding part.

e. Connect the line joint well,use insulating tape around bare wire.

f. Handle ground connection between machine cover and workpiece holder by professional

worker.

g. turn off power after finish welding.

4

3、 TECHNICAL PARAMETER

Table1、tec hni cal par ame ter

Model

Data

HP80

HP120

HP200

Rated input voltage(V)

3-Phase 50Hz

380

Rated input current(A)

14

26

54

Open voltage(V)

250

325

345

Range for cutting current (A)

30-80

30-120

30-200

Rated duty cycle(%)

Best cutting thicken

(carbon steel mm)

18

25

45

Max.cutting thickness

(carbon steel mm)

32

45

65

Shell protection degree

IP21S

Insulated class

F

Dimension(D×W×H mm)

640*335*670

690*335*670

700*350*660

Weight(Kg)

50

56

65

5

4、 INSTALLING&CONNECTION

4.1 Operate situation

Welding machine must put on flat 、cleaning and dry ground .Forbid to put the welding

machine on following situation:

a.Under hard sunshine and raining place.

b.With dusty and combustible gas place .

c.With harmful or caustic gas place.

d.With high temperature and steam place

e.Vibration and collision place.

f.The distance between other circumambience smaller than 50cm.

g.The temperature higher than +40℃or less than -10℃..

4.2 Ground connecting

Connect the machine’s ground connecting port to power’s ground connecting port and avoid

damaged by electric shock.

4.3 Ventilation

To assure welding quality must reduce the wind influence.If operate in seal space should

supply aeration equipmennt and avoid lack of oxygen.

4.4 Power and line

Table2、power and line (only for reference)

Model

HP80

HP120

HP200

Input power

3-Phase,AC 380V/ 50Hz

Capacity

Power

Above 14KVA

Above 26KVA

Above 26KVA

Engine

Two times than

14KVA

Two times than

26KVA

Two times than

26KVA

Input

protect

equipment

Fuse

30A

55A

55A

Leak

electricity

safeguard

machine

30A

55A

55A

Input cable(mm2)

≥6 mm2

≥10 mm2

≥10 mm2

Output cable(mm2)

≥16 mm2

≥25 mm2

≥25 mm2

Ground cable(mm2)

≥14 mm2

≥14 mm2

≥14 mm2

6

4.5 Connecting

a.The connecting must according to the table 2 requirement.

b.Turn off the cutting machine before connecting cable.

c.All joint must connect well ,use insulating tape around bare wire.

d.After connecting,put power cable cover on machine ,then fasten with screw(forbid to

operate with cover open)

e.To assure security forbid to input force on the cable.

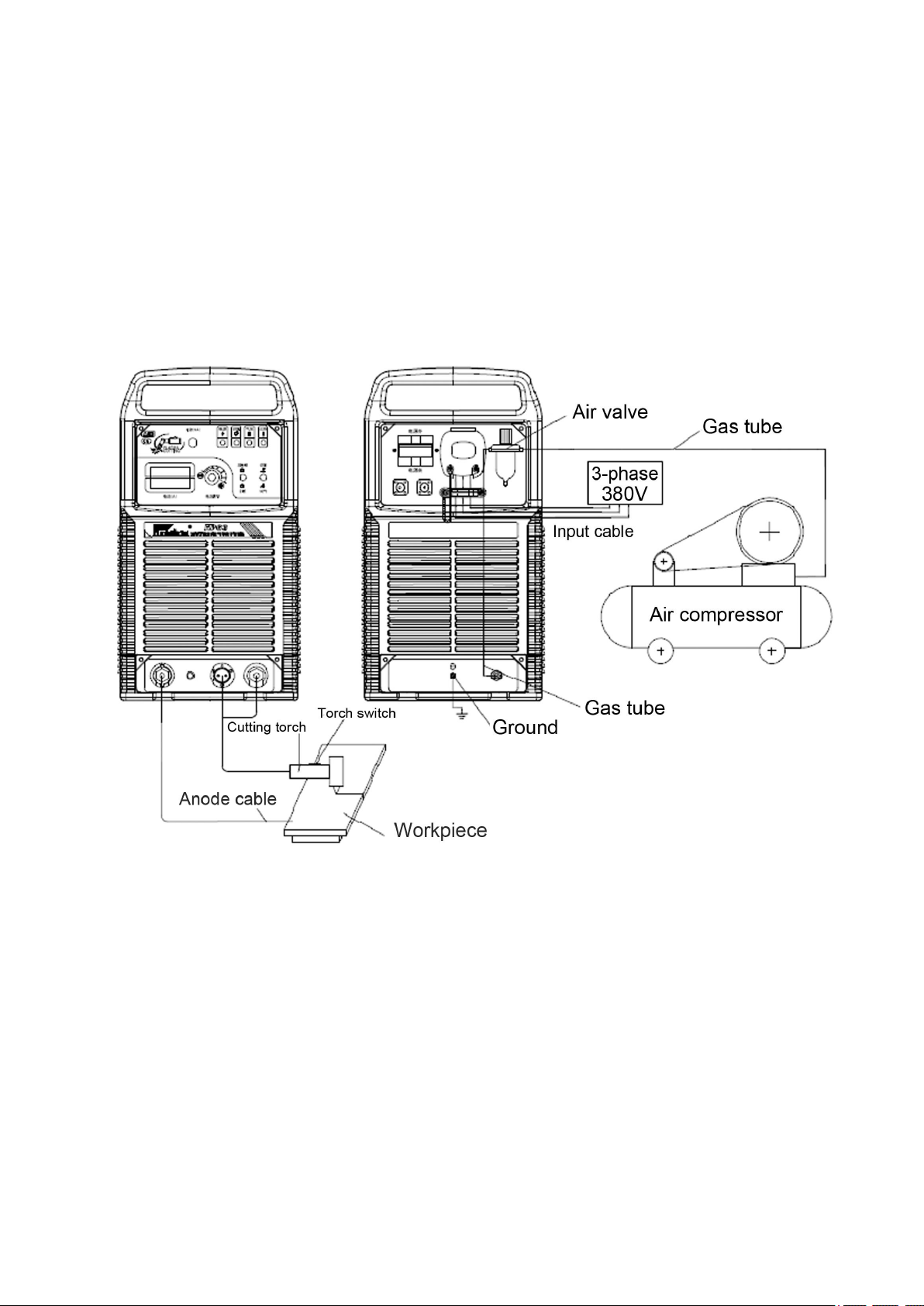

(FIG.1)HP63 connecting diagram

7

(FIG.2)HP80/120 connecting diagram

8

(FIG.3)HP200 connecting diagram

9

4.6 Front and back panel

电源关

电源开

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

(FIG.4)front and bank panel for HP63/HP80 /HP120

神

回水 水

电

接

口

口

接

电

气

电流调节

水冷

气冷试气

切割

自锁

非自锁

水压气压 过热切割电源

A

( )

电流

电源

( )

2A

2

2

0

I

U

X

eff

1

1

1max

~

~f

1

2

f

防护等级: 绝缘等级:

制造商:无锡汉神电气有限公司

生产厂:无锡汉神电气有限公司

地 址:江苏省无锡市锡山经济开发区芙蓉一路以北

R

IP21S F

进气

回水进水

电源关

电源开

① (+)

①②

⑥⑦

② (-)

割炬开关

起弧成功

IG B T 逆变式空气等离子切割机

引弧接口 -

+

R

汉

20

27

22

23

25

24

12111091

28

21

15

17

16

26

14

13

19

8

7

6

5

3

2

FUSE

18

(FIG.5)front and back panel for HP200

10

Table.3 Function

NO

Name

Function

1

Fuse

When short circuit,the fuse welt to protect control transformer

2

Current

Adjust cutting current

3

Digital meter

Indicate preset current when machine stand by,indicate welding current when

cutting

4

Torch(-)

Power cathode,to connect the tie-in of water cooling torch

5

Torch switch

Joint torch control connector

6

Starting arc

Connect torch starting arc line(HP63 has no this function)

7

Workpiece(+)

Power anode ,joint workpiece

8

Air switch

Automatic to turn off power when machine overload or get wrong,normally

this switch need to be turn on

9

Power

Power indicator,when cutting machine turn on ,the indicator will be light

10

Cutting

Cutting indicator ,will be linght when cutting torch turn on

11

Air pressure

Air pressure indicator ,when low than 0.2Mpa,cutting machine will stop work

12

Over-heat

Over-heat indicator ,when cutting machine is over-heat ,they can not work

13

Lock/Unlock

Transfor switch,when in“lock”,press torch switch to ignite arc ,can loosen

switch,cutting machine still go on cutting ,if press the torch switch

again ,cutting will stop

14

Air test/Cutting

When turn on air test,gas valve in cutting machine will be opened to check

gas flow rate,when turn on cutting,gas valve will be automaticly open and

supply gas when machine is cutting

15

Power box

Connect input cable

16

Control sign

Automaticly connect with cutting machine①② : torch switch ; ⑥⑦ :

successful to ignite arc

17

Output arc

Automaticly connect with cutting machine①:+,②:-

18

Fixed clamp

Fixed input cable

19

Air pressure

regulator

Adjust pressure of compressed air and to filter water in the air

20

Inlet of compressed

air

Connet gas tube and air pressure regulator to supply gas for cutting machine

21

Ground screw bolt

In order to make sure safety ,please ground connection with this screw bolt

22

Hydroelectric

interface

Power output (-),be used for connecting with Hydroelectric interface of

water –cooling cutting torch

23

Gas electric

interface

Power output(-),be used for connecting with gas electric interface of air-

cooling cutting torch or inlet connection of water- cooling cutting torch

24

Water pressure

Indicator of water pressure flow will be light when water pressure is

lower,and cutting machine will stop work.

25

Water return

Used for conecting with water return pipe’s lead arc of water-cooling cutting

torch

26

Water cooling/Air

cooling

According with cooling type of your cutting torch to chose corresponding

switch,when is “water-cooling”,if chose “water-cooling”torch need to make

sure under “water-cooling”condition,otherwise the cutting torch will be

damaged.

27

Water inlet

To link through water pipe and water outlet.

28

Water return

To link through water pipe and water return.

11

5、 PREPARE FOR CUTTING

5.1 Connect cutting machine

According with 4.5and FIG1、FIG 2、FIG 3 to connect with cutting machine

5.2 Cuttin g oper a ti o n

a. Turn on the power source ,cooling fan will be work as usual.

b. Turn on gas switch and put the switch to “air test”,then rotate air pressure regulator to chose

suitable gas flow rate.If air pressure low than0.2Mpa ,cutting machine will stop work,if

everything is ok, air pressure light will turn off,please put “air test/cutting “switch to

“cutting”at the same time.

Note:air pressure≥0.45~0.6MPa,flow rate ≥300L/min。

c. This cutting machine standard collocation adopt non-contact cutting torch.When cutting

machine ,nozzle will not meet workpiece due to if they get to each other, it’s easy to damage

electrode and nozzle. At this time,in order to control cutting torch height, we usually match

series of cutting tool、photoelectric follow up 、robot and CNC cutting machine tool.

Operation points as following:

a) Trolly the cutting torch to meet workpiece,and keep distance 2-5mm,make sure nozzle

axes apeak to surface of workpiece and don’t touch.( FIG6)

b) Turn on cutting switch ,ignite plasma arc ,cutting workpiece fully ,keep an even speed to

move along with cutting direction,Cutting speed is :base on cutting pierce,be fit for rapid

to cut ,if too slow will affect cutting quality even arc break off. Please control towing

angle in 10°(F6), cutting quality is perfect,if too fast won’t pierce,even spatter.

c) Generally speaking cutting from the edge of workpiece,when need to cut from the middle

of workpiece,if material thickness is≤5mm(stainless steel or carton steel,if other

material,need to cut back on cutting thickness),can directly cutting pierce.Method:put

cutting torch on starting point of cutting sew,make nozzle and workpiece an included

angle about 75°,then turn on torch switch,ignite arc to pierce workpiece,adjust torch axes

to apeak workpiece.But if material thickness≥5mm and need to cut in middle,please drill a

hole which diameter is ≥3mm,ignite arc to cut in hole.

d) If finish cutting ,unlock torch switch,break off plasma arc.compress air will be delayed

spurt to cooling cutting torch.After some minutes please move torch to finish cutting.

12

(FIG.6)cutting diagram

5.3 Cutting torch for installing、maintenance and replacement

Note:Before starting,please put the switch to“power off”on the machine.

(1)Installing cutting torch please reference FIG7.Plesae note must sure electrode is

tightened by spanner.

(2)Please replace nozzle on time when centre hole of nozzle is damaged(F8)

(3)Please replace electrode on time when electrode hafnium is damaged (F9)

(FIG.7)installing diagram

13

(FIG.8)nozzle burned diagram

(FIG.9)electrode burned diagram

(4)When gas tube、shield cap、cable is damaged,need to replace on time

(5)When you need dismantle the cutting torch,please demount bolt M3,then insulated

pipe ,at last is connect and transfer arc. When installing ,please take care every joint and

insulated pipe to make sure safety in igniting arc.

(6)Cutting torch and cable team can not touch high temperature workpiece.

14

6、DAILY MAINTAIN&CHECK

Safety warm:Before maintaining ,must cut off the power to avoid to be injured such aselectric

shock and burned,and please wait for 10 minutes then start to repair.

Table4 reference for maintain

ITEM

EVERY ONE OR TWO MONTH TO CHECK

AND MAINTAIN

1.Switch function for power

2.Cooling fan if is working

normally

3.If have unusual vibrate、noise

and smell

4.If cable connector is over-heat

5.Welding cable if is over-heat

6.Cable if is damaged

7.All cable connector if is loosen

1.Remove smudginess:

Make use compressed air to remove

smudginess,especially for inductance 、

transformer、transistor and PCB.

2.Repair for circuit diagram:

Check input ports ,output ports and exterior

cable

3.Check earth cable if is all right.

15

7、FAULT REPAIR

Inspector can check the machine follow table 5,and repair follow table 6.If the failure can not

be eliminated,please contact with manufactory.

ATTENTION:

1.Before the maintenance or repair,make sure the power is off to avoid electric shock.

2.The machine has tested before leaving factory,any modification is not be allowed.

3.During the inspection of wire connecting ,please don’t pull hard and change any connecting.

Table 5 Inspection item

Failure

Causing

Can not ignite arc

Power switch damaged or switch wire broken

The cable which connect with workpiece is

damaged ,or the clamp cable is damaged

Input power lack phase

Over loading,over heating or over current

protection

Input power cable loosing

Output cable connector loosing

Compressed air pressure is too low

Arc is unstable,or arc break frequently

Output cable connector loosing

Input power cable with bad connection

Decrease of output current

Input power is not between 330V~440V

Input power cable is too thin

Power capacity is low

16

Table 6 Inspection item

NO.

Failure

Causing

Solution

1

Turn on power,but

power indicator light

does not work

1、Indicator light damaged

Change

2、2A fuse damaged

Change

3、No input power

Repair

4、Lack of input powe

Repair

5、Power switch damaged

Change

6、Control PCB damaged

Repair

7、Control transformer

damaged

Repair

2

Switch on,power

indicator is light ,but the

fan does not work

1、Fan get stuck something

Eliminate the something

2、Fan capacity damaged

Change

3、Fan wire damaged

Repair

4、Fan is broken

Change or Repair

3

Switch on,power

indicator light on,fan

works,turn on the “air

test”,but no air flow

1、No input compressed air

Check air source and air pipe

2、“Adjusting air pressure

filter”error,pressure meter

shows zero,“air pressure

lack”indicator linght on

Readjust the air pressure

filter,method:turn “air

pressure filter”clockwise to

increase the pressure ,turn

anti-clockwise to decrease.

3、“Air test”switch damaged

Change

4、Main electromagnetism

valve

Repair or change

5、Air hose break or leak

Repair

4

Turn on “air

test”,nozzle fill with air,

turn on “cutting”,and

turn on the cutting

torch ,there is no air

1、Torch switch damaged or

switch wire damaged

Repair or change

2、Air valve QF1damaged

Change

3、Control PCB damaged

Repair

5

Turn on the cutting

torch,nozzle with

air .but torch does not

work

1、Input power lack phase

Repair

2、Input air flow is zero

Increase input air flow

3、Nozzle、electrode or

other parts damaged

Change

4、Torch damaged

Change

6

Kerf deflexion

1、Nozzle or electrode

damaged

Change

2、Nozzle and electrode does

not install correctly

Reinstalling

3、Cutting speed is too fast

Reduce cutting speed

4、Nozzle and cutting

material is out of the vertical

Adjusting

17

NO.

Failure

Causing

Solution

7

Setting cutting

thickness cannot be

achieved

1、Input voltage cannot get to

rated voltage

Inputting voltage

2、Input power supply capacity is

toosmall and cutting line

preesure is too big

Increase input power supply

capacity

3、Input compressure air pressure

is too low or too high

Adjusting the air pressure

4、Input air flow is too small,such

as preesure meter drops to

0.3Mpa during the

operation ,and pressure recover

after stop working

Increase the compressed air

flow to 300L/min;If the air

hose is small ,please change

the hosediameter to more

thanΦ8mm

5、Cutting speed is too fast

Reduce cutting speed

6、Nozzle burned

Change

7、Electrode has burned

Change

8、Nozzle size is not fitted

Change to the right size

9、Air hose or cutting cable

damaged

Repair or change

8

Kerf with wide

incision and poor

quality

1、Cutting speed is too slow

Adjusting speed

2、Nozzle and electrode burned

Change

3、material、thickness and option

of thickness have wrong position

Adjusting

4、Nozzle type is wrong and

diameter is too big

Change a right size one

9

Torch burned

1、Nozzle or electrode loosing

Fasten the nozzle or

electrode

2、Torch wire connector

loosing ,or cable /hose

damaged

Check on time

3、Torch connrctor with poor

insulation condition

Make sure the torch

connector with good

insulation

4、Shield cap of cutting torch has

been damaged

Change on time

5、Compressed air is over wet

Clear the water in “air

pressurevalve”,if the air wae

over wet ,please install

water flilter Lv1~2

6、Electrode burned

Change a new one

18

8、DIAGRAM CIRCUIT

Q F1

CN 13

97 97

105

87

86

50

52

51

52

52

50

51 3

2

1

4

3

2

1

97

731

2

CN 12

1

2

397

56

72

80

97

98

96

2

1

3

2

1

2

3

4

3

2

1

97

65

20

CN 9

CN 14CN 15

CN 3

CN 10

W

1

V

2

U

71

0. 25m H

70

~

~

~

BR1

RY 4

Q 3

C1- 9

C8

C2, 3

RY 1

RY 3

RY 2

S 1

C1

TV S1

8 4

8 5

Q 4 C10- 18

TV S2

8 6

8 7

Q 1

TV S1

8 0

8 1

Q 2

TV S2

8 2

8 3

L3

+

-

8 7

8 6

~ ~

FU SE

C8

TS

S4

68

67

66

1

2

3

CN 8 97

59

20

61

60

1

2

4

3

5

CN 6

CN 1

M1

~10 V

6

7

8

9

1

3

CT 1

380V

220V

0V

T1

FS

FH 7.8 20 .4 1 3

R1,2,3,4,5

L1

L2

B

A

R3

R4 R4

R3

97

96

1

3

2

3

4

5

97

2

1

CN 9

CN 10

CN 11

CN 8

85

84

8 5

8 4

1

3

CN 6

83

82

8 3

8 2

1

3

CN 4

81

80

8 1

8 0

1

3

CN 2

~19 V

~19 V

1

98 2

2

2

2

2

D 1

D 2

D 3

D 4

A

B

H GQ

R1

R2

R1

R2

~16 V

~16 V

~16 V

~16 V

~16 V

~16 V

~16 V

~16 V

94

95

1

3

CN 7

87 2

92

93

1

3

CN 5

85 2

90

91

1

3

CN 3

83 2

88

89

1

3

CN 1

81 2

TR1

C6 C7

CT 3

6T

993

105

1

101

102

97

106

100

104

103

97

97

64

63

97

1

2

4

3

5

CN 5

662

RP 1

4K 7

55

54 1

2

C9 C10

J1 J1-1

TR 2

57

97

1

2

CN 2

S3

+15V

-15V

OUT

GND

LE M

检气

焊接

自锁

非自锁

CN 11

2

3

1

T2

~24V

0V

380V

D1

D2

+'

50

R6

50

R7

50

R8

50

R9

C1 C2

C1 C2

100

R3

100

R4

100

R5

KM 1 -1

C7

C7 C6

2

R1

2

R2 R3 C 3 C 4

C1

C2

C5

2

R4

X1

X2 X3X4

X5

FH7.820.416

C

D

21

0V

110V

CN 4

QF2

KM 1

25V

S2

2

1

FH7.820.412

C

D

3 69

97

59

20

61

60

1

2

4

3

5

CN 1

586

切 割

气 压 水 压过 热

电 源

58 6

FH7.820.418

S5

7

气压开关

CN 7

200

201

FH7.820.296

50

R1

50

R2

FH7.820.294

FH7.820.323

FH7.820.327

FH7.820.327

H C- II- AP 2

H P -A P1

H P -A P2

H P -A P5

H P -A P4

H C- II- AP 8

H C- II- AP 8

HC-II-AP5

H C- II- AP 3

R 1 -2R 1 -1

FH4.702.051

FH4.702.048

-

+

1 2 3

1

2

3

4

5

6

7

115

116

115

116

115

116

71

69

TS

O K

This manual suits for next models

2

Table of contents

Other Hanshen Welding System manuals

Popular Welding System manuals by other brands

Miller

Miller Summit Arc 1000 owner's manual

Baileigh

Baileigh WP-1800F Operator's manual

FRONIUS

FRONIUS TransSteel 3500 Syn operating instructions

Telwin

Telwin TECNICA 190 TIG-MMA DC LIFT VRD manual

widos

widos 4000 WM Working Instructions Translation

CEVIK PRO

CEVIK PRO CE-TITANCEL 210 instruction manual