Hanshen HC350D User manual

OPERATION

MANUAL

IGBT INVERTER MULTIFUNCTION

WELDING MACHINE

HC350D/500D/650D

ATTENTION:

Be sure that all installation operation, maintenance and repair are

performed only by qualified personnel.

You are advised to read this operation manual thoroughly before using

the equipment. Keep this manual for future reference and safety

information.

-1-

CONTENT

1. Characteristics…………………………………………………...2

2. Safety ……………………………………………………………3

3. Technical parameters ……………………………………………4

4. Installation and connection………………………………………5

5. Function introduction……………………………………………9

6. Operation………………………………………………………..12

7. Daily maintenance and trouble shooting ……………………….16

8. Circuit diagram………………………………………………….18

-2-

1、CHARACTERISTICS

HC-D series welding machine have CO2 and MMA function (if make use

appointed welding torch, also can bring about simple TIG function). HC-D

series machine can be used widely in various fields. Its characteristics are as

following:

1.1 With high quality for welding

Adopted high-quality and advanced control circuit, with good dynamic

response, and it can easier achieve nice-looking weld slot.

1.2 With obvious electricity saving

Adopted inverter technology and voltage equalization, can deeply reduces

the input capacity, meanwhile saving electricity.

1.3 With presetting function

The welding current and voltage can be preset in advance, and it is easy to

be read via digital display meter. It is more useful for beginner.

1.4 With lighter weight and smaller dimension

Compared with rectifier/thyristor model welding machine, HC-D series

machine 1/3 of rectifier machine, and its weight is 1/4 of rectifier machine.

So it is more convenient for outside working.

1.5 With less splash

With wave-form control technique, the splash while welding is deeply

reduced. and suitable for welding from all position.

1.6 With high ratio of arc ignition

The arc ignition ratio can be reached 100% via special ignition circuit.

1.7 For MMA usage

The arc-ignition current can be adjusted while welding, and the welding

rod is not easy to be agglutinated with workpiece. With arc force circuit

design, the arc characteristics can be adjusted according to welding

technology. The welding is stable and with less splash.

1.8 With stable welding process

Adopt high-speed feedback circuit,welding system can be anti-interference

and resistance network fluctuation,thus realize the stable welding process

-3-

2、SAFETY

Please observe the following safety information for your own safety:

2.1 Avoidance of accident

A. Ensure that you operate the equipment with the power source of correct

voltage as provided by your country;

B. Ensure that you comply with the laws of your country on position for

welder’s installation, high-pressure gas, storage of materials and

treatment of rubbish…etc;

C. Ensure that you wear the safety equipment and dress for the protection

of your eyes and skin;

D. Ensure that there is proper ventilation on place of welding to prevent

injury or hurt by smoke and gas exhaustion;

E. Do not open the DOS shell of the welder or use it in open position.

2.2 Prevention from burn and fire

A. Always keep the welder with a distance 30cm away from the wall and

50cm away from any combustible articles;

B. Keep sparks away from tinder or the open holes;

C. Fasten the welder properly with fixed bolts if it is to be installed on high

position for use;

D. Do not weld tubes, hermetic tubes or vessels through which combustion

gas is traveling.

2.3 Usage

A. Always disconnect the welder if the welder is not in use;

B. Do not touch any electrical components in the welder;

C. Do not wear wet or torn gloves when using the welder;

D. Always select correct cables for use with the welder and always ensure

that correct cables are property connected to the welder;

E. Replace all worn cables or wrap the worn cables with insulation tape

for temporary use;

F. Do not place heavy object or any glass of water on the welder. If you

spill water or any liquid into the welder, immediately unplug the welder

and have it checked by a qualified personnel before using it any further;

G. Always ensure that all electrical or ground connection is carried out by

a licensed electrician.

-4-

3、TECHNICAL PARAMETERS

table 1 technical parameters

model

parameter

HC350D

HC500D

HC650D

Rated input voltage (V)

3 Phase/380V/50Hz

Rated input current (A)

25

36

56

Rated input capacity (KVA)

16.5

23.8

37

Rated output current(A)

CO2: 80-350

MMA: 30-350

CO2:100-500

MMA:50-400

CO2:100-650

MMA:50-650

Rated output voltage (V)

CO2:18-32

MMA:22-34

CO2:19-39

MMA:22-36

CO2:19-44

MMA:22-44

Open Circuit Voltage(V)

CO2:54

MMA:54

CO2:64

MMA:64

CO2:64

MMA:64

Rated duty cycle

60

wire diameter for CO2/MAG

1.0、1.2mm

1.2、1.6mm

1.2、1.6mm

Shell protection degree

IP21S

Insulation grade

F

Dimension

(L×W×H mm)

615*325*610

(steel)

640*335*670

(plastic)

665*325*610

(steel)

690*335*670

(plastic)

695*360*820

(steel)

Weight(KG)

45(steel)

47(plastic)

48(steel)

52(plastic)

66(steel)

-5-

4、INSTALLATION AND CONNECTION

4.1 Position for use

Always place the welder on a dry, clean and solid ground for use. Avoid the

following places when use the machine:

A. under sunshine or rain;

B. place with dust, flammable gas or oil;

C. place with harmful or caustic gas;

D. place with high humidity steam;

E. place with poor ventilation;

F. place with temperature higher than 40℃ or less than -10℃;

G. The distance between the welder and the wall is less than 50cm.

4.2 Grounding

Connect the welder’s grounding end with the grounding line of switchboard,

or ensure the grounding of input power cables connected with the grounding

line of switchboard.

4.3 Ventilation

Reduce the influence from blowing wind to ensure good welding quality.

When welder is operated in enclosed place, ensure that there is proper

ventilation to prevent injury or hurt by smoke and gas exhaustion or lack of

supply of oxygen.

4.4 Power and Line

Table 2 Power and line

Power

3 Phase AC(380V)50HZ

Model

HC350D

HC500D

HC650D

capacity

power

≥ 15KVA

≥ 25KVA

≥ 36KVA

engine

2 times than

15KVA

2 times than

25KVA

2 times than

36KVA

Input

Protect

equipment

fuse

25A

40A

60A

leak electricity

safeguard

machine

25A

40A

60A

line

cross section

area

Input power

≥ 6mm2

≥ 12mm2

≥ 16mm2

Output power

≥ 35mm2

≥ 50mm2

≥ 70mm2

Ground line

≥ 14mm2

≥ 14mm2

≥ 14mm2

please install the leak electricity safeguard machine when operating in wet place、

iron place and iron frame.

please mating with appointed wire feeder to weld.

-6-

4.5 Connection

A. All connection must be according to the request on List 2.

B. All joint must be connected well, use insulating tape to wrape the bare wire.

C. After connection must assemble the cover of power supply and fasten it by

screw(never operate the machine while the cover is open)

D. For safety, never put weight or add force onto the cable.

FIG 1 CO2/MAG

-7-

For alkaline electrode

神

R

汉IGBT逆变式多功能焊机

-

+送丝机

手工焊

气保焊焊接

检气

收弧无

收弧有

弧特性收弧电流

(推力调节)(电流调节)(引弧电流)

软硬

收弧电压

异常

控制

电流显示电压显示

For acidic electrode

神

R

汉IGBT逆变式多功能焊机

-

+送丝机

手工焊

气保焊焊接

检气

收弧无

收弧有

弧特性收弧电流

(推力调节)(电流调节)(引弧电流)

软硬

收弧电压

异常

控制

电流显示电压显示

FIG 2 MMA

-8-

神

R

汉IGBT逆变式多功能焊机

-

+送丝机

手工焊

气保焊焊接

检气

收弧无

收弧有

弧特性收弧电流

(推力调节)(电流调节)(引弧电流)

软硬

收弧电压

异常

控制

电流显示电压显示

FIG 3 TIG

Note:

If need TIG, please use appointed welding torch(which can control argon

gas flow and on-off);when in MMA,adopt simple contact arc way;if need

to break arc,please drive up the welding torch to do it)

Distribution box

3-380V

CO2 REGULATOR

GAS

BOTTLE

GAS TUBE

INPUT CABLE

WORK PIECE

WELDING

TORCH

≥14MM2

≥14MM2

-9-

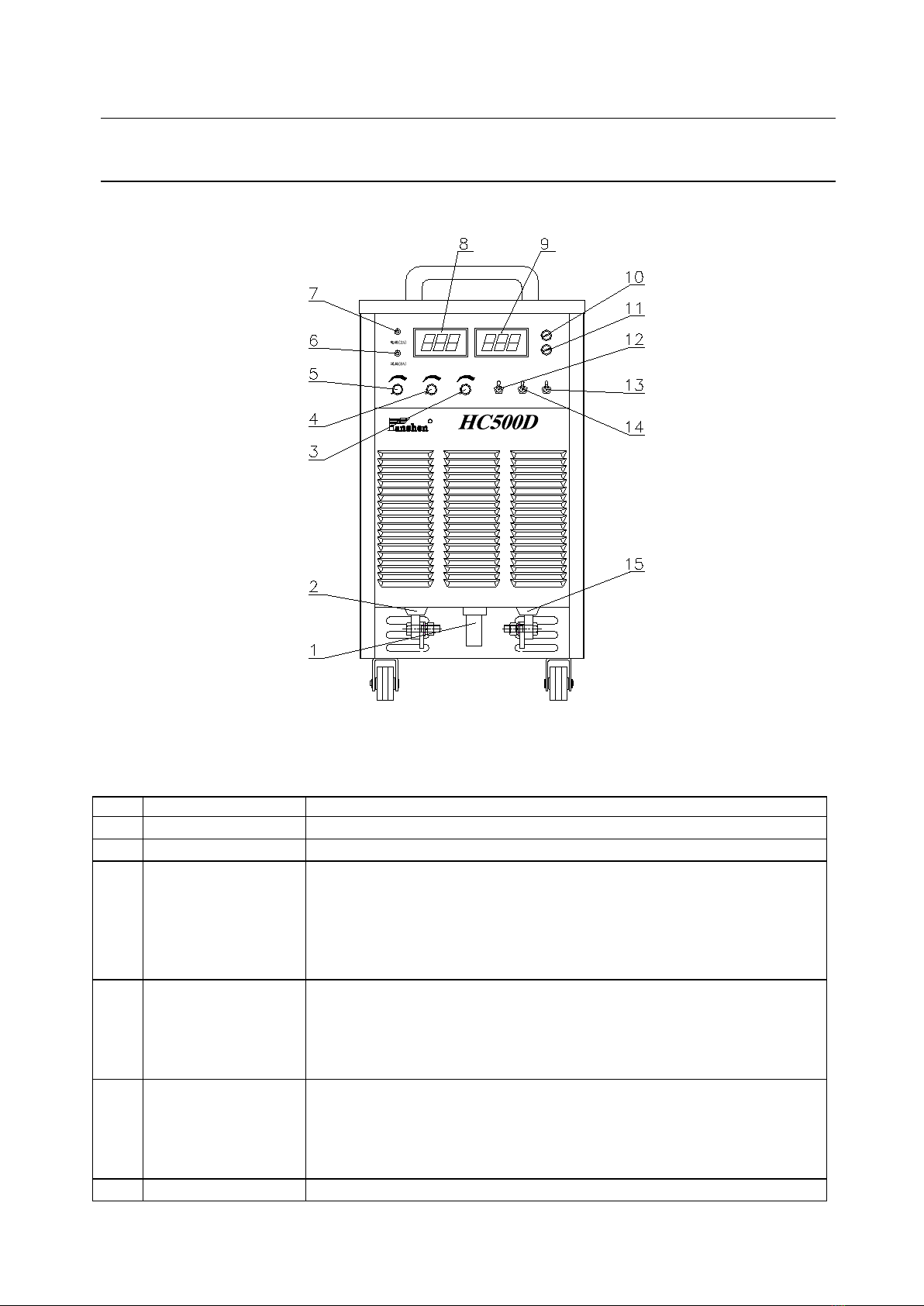

5、FUNCTION

5.1 Front Panel

神

R

汉IGBT逆变式多功能焊机

-

+送丝机

手工焊

气保焊焊接

检气

收弧无

收弧有

弧特性收弧电流

(推力调节)(电流调节)(引弧电流)

软硬

收弧电压

异常

控制

电流显示电压显示

FIG 4

Table 3 Function on front panel

NO

NAME

FUNCTION

1

Wire feeder connect

For wire feeder control cable

2

+

For connection with wire feeder welding cable

3

CO2:arc character

MMA:arc force

current

GMAW Condition:Arc characteristic adjustment knob When do CO2

Arc Welding, it could change welding stability, penetration and spatter loss

coefficient.

MMA Condition:arc force current adjustment knob When do MMA, it is

used to change arc stiffness.

4

CO2:crater arc

current

MMA:adjust current

GMAW Condition:Crater current adjustment knob for adjusting the size

of crater current in ‘Crater On’ mode

MMA Condition:Welding current adjustment knob for adjusting the size

of output current

5

CO2:crater arc

voltage

MMA:arc start

current

GMAW Condition:Crater Voltage Adjustment Knob When do CO2 Arc

Welding, adjust the size of crater voltage in ‘Crater On’ mode

MMA Condition:Striking Current Adjustment Knob When do MMA, it

is used to change arc start current

6

Wire feeding (8A)

Wire-feeder fuse. The fuse is broken for protecting control transformer while

-10-

wire feeding circuit is short.

7

Power(2A)

Power fuse. The fuse is broken for protecting control transformer while

control electric circuit is short.

8

Voltage indicator

For output voltage adjust while welding

9

Current indicator

For welding current/output current adjust

10

Control

Indicate welding machine if is on or off

11

O.C

Abnormity indicator. If the indicator lights, the inner circuit is abnormal and

machine stops working.

12

Crater Arc

(ON/OFF)

Crater arc selection.

For CO2 welding while it is on “arc off” position, press the torch switch

for welding and loosen torch switch for welding stop, and this model is

suitable for short-time welding.

For GMAW welding while it is on “arc on” position, press the torch switch

and after arc ignition can loosen the torch switch, the normal welding can be

continued. Press the torch switch again, the arc will be reduced into a less

value which is set by adjusting the knob on front panel, and the weld will be

stop if you loosen the torch switch now. It is suitable for long-time welding.

13

MMA/CO2

Function switch,to chose working condition

14

Gas test/Weld

Gas test/weld selection. On “gas test” position can check the flux of CO2 or

argon; on “weld” position the machine works normally.

15

-

For connection with workpiece.

5.2 Back Panel

R

~

3

电源开

2

1ff

X

eff

1

2

I

2

1max

U

0

1

绝缘等级: F

电源关 ~

防护等级: IP21S

请勿他用。保险丝8A。

2

2

CO 调节器加热用电源(交流36V),

此为CO 调节器加热专用。仅作为

FIG 5

-11-

Table 5 Function on back panel

NO.

NAME

FUNCTION

1

Grounding Bolt

Connect this bolt for reliable grounding via wire or connect the input power supply

for reliable grounding.

2

Cooling Fan

For cooling inner calorific parts inside machine

3

Heating Fuse

(8A)

The fuse will be broken down for protecting transformer while the regulator is

short circuit.

4

Power supply for

heating

For supplying DC 36V to regulator(cannot be used for other places, otherwise,

bear your own consequences)

5

Power Switch

Be automatic power-off when welding machine is overload or malfunction.

Generally, the switch is to pull to the connection and to close or cut off input

power supply.

6

Nameplate

For description of parameters. Refer to it while operating

7

Power Cable Box

For connect with power supply in 380V

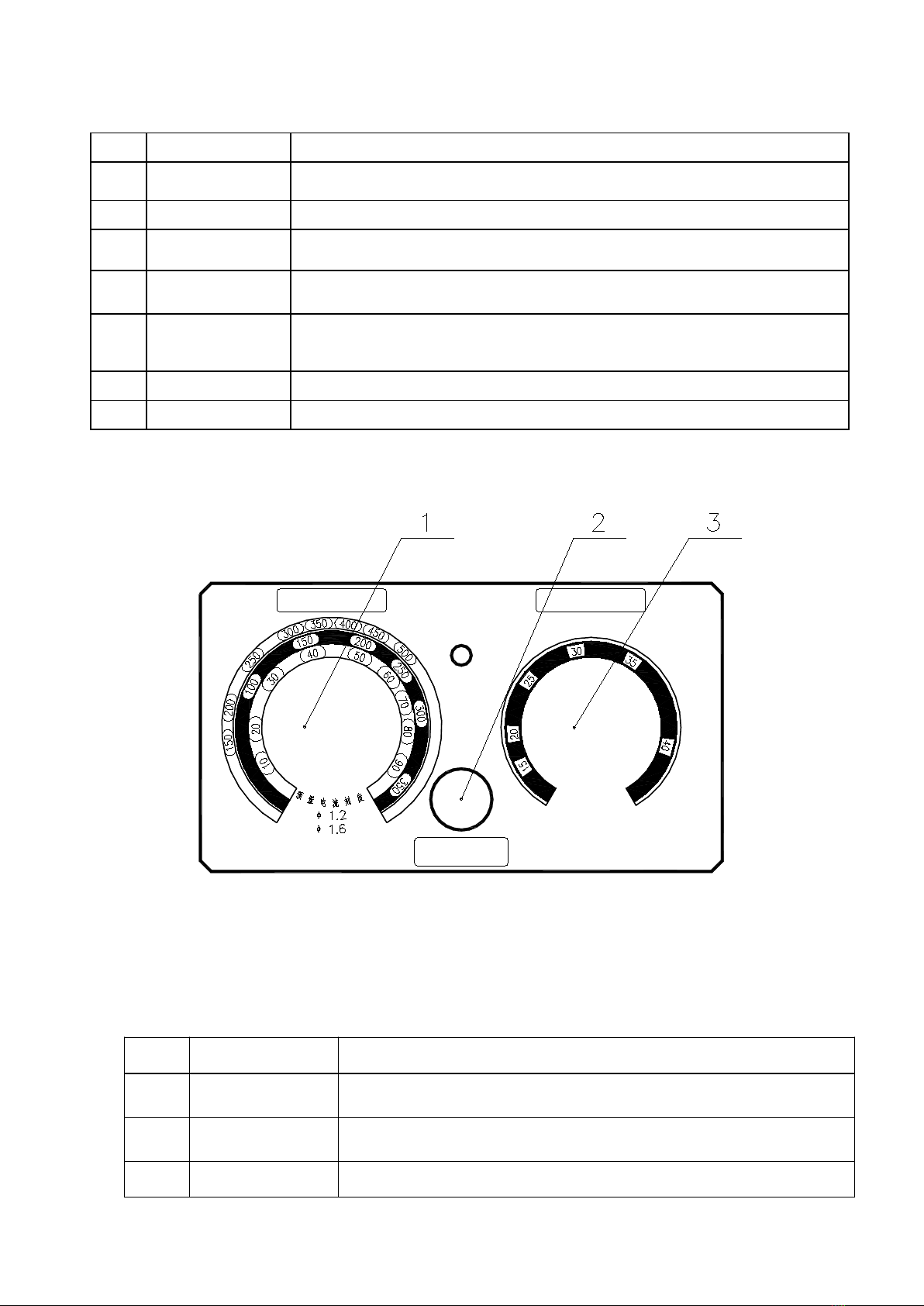

5.3 Wire Feeder Control Panel

AV

手 动 送 丝

I N C H I N G

WELDING VOLT.ADJ.

电 压 调 整

WELDING CUR.ADJ.

电 流 调 整

FIG 6 Control Panel for Wire Feeder

Table 6 Function for Control Panel of Wire Feeder

NO

NAME

FUNCTION

1

Current Adjust

For welding current adjust. The relative value of current is shown

from 10 to 100 by scale while presetting current.

2

Feeding Wire by

Manual

For feeding the wire into torch before welding.

3

Voltage Adjust

For welding voltage adjustment.

-12-

6、OPERATION

6.1 GMAW operation

6.1.1 Preparation

(1)Connect machine according to FIG 1.

(2)Open up the middle panel, shift“MMA/TIG/CO2”swith onto “CO2”model.

(3)Switch on the power supply MCB, the machine’s “power”indicator turns

light, cooling fan begins running and regulator turns heating.

(4)Select suitable wire for work piece, and select suitable wire-feeding roller

and contact lip of torch according to wire diameter.

(5)Press “feed sire by manual”knob and adjust “welding current” knob for

feeding the wire into torch.

(6)Shift “gas test/weld”switch onto“gas test”position, adjust regulator valve

for suitable flow value. After gas test shift the switch onto “weld” position.

6.1.2 Welding Operation

6.1.2.1 Spot welding or short welding

(1) Shift “crater arc on/off”onto “off” position

(2) Adjust “welding current” and “welding voltage” onto suitable value

according to welding technology (FIG 7 refer to GMAW technology

criterion).

(3) Press torch switch for welding, loosen torch switch for stop welding.

6.1.2.2 Long welding or welding in large current

(1)Shift “crater arc on/off” onto “on” position.

(2)Adjust “welding current”, “welding voltage”, “crater current” and “crater

voltage” according to welding technology.

(3)Press torch switch for arc ignition, then the machine goes onto normal

welding position. Here the welder can loosen torch switch for continuous

welding. If wants to stop welding, press torch switch again, now the

machine turns onto “crater arc” position, and the output current is

decreasing. After loosening the torch switch the welding stops.

(4)During welding process, adjust “Arc Characteristics” knob could change

arc stability, penetration and spatter loss coefficient.

6.2 SMAW Operation

6.2.1 Preparation

(1) Connect machine according to FIG 2.

(2) Shift “MMA/TIG/CO2” switch onto “MMA” model.

(3) Switch on the power supply MCB, the machine’s “power” indicator turns

light, cooling fan begins running.

(4) Select suitable electrode according to work piece.

-13-

6.2.2 Welding Operation

(1) Adjust “welding current onto suitable value according to work piece

thickness and electrode diameter (refer to Table 8)”. Could adjust striking

arc current properly to ensure reliable striking arc.

(2) The machine uses inverter control by adjust “arc force” to control

stiffness of arc and change metal transfer process to ensure welding

process running stably.

(3) While welding on all position, adjust “arc force” value bigger to avoid

conglutination between electrode and work piece; while welding in large

current or flat welding, adjust “arc force” value smaller or onto zero

position to decrease splash.

6.3 GTAW operation

6.3.1 Preparation

(1) Connect machine according to FIG 3.

(2) Shift “MMA/TIG/CO2” switch onto “MMA” model.

(3) Switch on the power supply MCB, the machine’s “power” indicator turns

light, cooling fan begins running.

(4) Select suitable dock needle and filler wire according to work piece.

(5) Adjust welding torch flow switch and select suitable flow. Shift switch

onto “off” position when not use.

6.3.2 Welding Operation

(1)Adjust “welding current” onto suitable value according to work piece

thickness(refer to table 9)

(2)The operation is : contact tungsten with work piece, press torch switch,

scratch work piece and uplift torch, the arc is ignited. Uplift torch when arc

is broken, elongate arc, force to broke arc.

-14-

6.4 Technology

Table 7 GMAW technical requirement (for reference only)

Thickness

(m m)

Wire

Diamete

r

( mmΦ)

Bottom

Clearance

G

(mm)

Welding

Current

(A)

Welding

Voltage

(V)

Weldin

g Speed

(cm/mi

n)

Operate

Clearance

(mm)

Gas

Flow

(L/min

)

L

O

W

S

P

E

E

D

0.8

0.8,0.9

0

6070

1616.5

5060

10

10

1.0

0.8,0.9

0

7585

1717.5

5060

10

1015

1.2

0.8,0.9

0

8090

1718

5060

10

1015

1.6

0.8,0.9

0

95105

1819

4550

10

1015

2.0

1.0,1.2

00.5

110120

1919.5

4550

10

1015

2.3

1.0,1.2

0.51.0

120130

19.520

4550

10

1015

3.2

1.0,1.2

1.01.2

140150

2021

4550

1015

1015

4.5

1.0,1.2

1.01.5

170185

2223

4050

15

15

6.0

surface

1.2

1.21.5

230260

2426

4050

15

1520

inner

1.2

1.21.5

230260

2426

4050

15

1520

9.0

surface

1.2

1.21.5

320340

3234

4050

15

1520

inner

1.2

1.21.5

320340

3234

4050

152

1520

F

A

S

T

S

P

E

E

D

0.8

0.8,0.9

0

89

16.5

120

10

15

1.0

0.8,0.9

0

100

17

120

10

15

1.2

0.8,0.9

0

110

18

120

10

15

1.6

1.0,1.2

0

160

19

120

10

15

2.0

1.0,1.2

0

180

20

80

15

15

2.3

1.0,1.2

0

200

22

100

15

20

3.2

1.2

0

240

25

100

15

20

Thick

ness

(mm)

Welding

Length

(mm)

Wire

Diameter

(mm)

Welding

Current

(A)

Weldin

g

Voltage

(V)

Weldin

g Speed

(cm/min)

Weldi

ng

Distanc

e (mm)

Posit

ion A

or B

Gas

Flow(L/

min)

L

O

W

S

P

E

E

D

1.0

2.53

0.8,0.9

7080

1718

5060

10

A

1015

1.2

33.5

0.9,1.0

8590

1819

5060

10

A

1015

1.6

33.5

1.0,1.2

100110

1819.5

5060

10

A

1015

2.0

33.5

1.0,1.2

115125

19.520

5060

10

A

1015

2.3

33.5

1.0,1.2

130140

19.521

5060

10

A

1015

3.2

3.54

1.0,1.2

150170

2122

4550

15

A

1520

4.5

4.55

1.0,1.2

180200

2324

4045

15

A

1520

6

55.5

1.2

230260

2527

4045

20

A

1520

8,9

67

1.2,1.6

270380

2935

4045

25

B

2025

F

A

S

T

S

P

E

E

D

12

78

1.2,1.6

300380

3235

3540

25

B

2025

1.0

22.5

0.8,0.9

140

1920

150

10

A

15

1.2

3

0.8,0.9

140

1920

110

10

A

15

1.6

3

1.0,1.2

180

2223

110

10

A

1520

2.0

3.5

1.2

210

24

110

15

A

20

2.3

3.5

1.2

230

25

100

20

A

25

3.2

3.5

1.2

260

27

100

20

A

25

4.5

4.5

1.2

280

30

80

20

B

25

6

5.5

1.2

300

33

70

25

B

25

-15-

thickness

(mm)

Welding

Diameter

(mm)

Welding

Current

(A)

Welding

Voltage

(V)

Welding

Speed

(cm/min)

Welding

Distance

(mm)

Position

A,B or

C

Gas Flow

(L/min)

L

O

W

S

P

E

E

D

0.8

0.8,0.9

6070

1617

4045

10

A

1015

1.2

0.8,0.9

8090

1819

4550

10

B

1015

1.6

0.8,0.9

90100

1920

4550

10

B

1015

2.3

0.8,0.9

100130

2021

4550

10

C

1015

1.0,1.2

120150

2021

4550

10

C

1015

3.2

1.0,1.2

150180

2022

3545

1015

C

1015

4.5

1.2

200250

2426

4050

1015

C

1015

F

A

S

T

S

P

E

E

D

2.3

3.2

1.2

220

24

150

15

B or C

25

300

26

250

15

B or C

25

Thickness

(mm)

Welding

Diameter

(mm)

Welding

Current

(A)

Welding

Voltage

(V)

Welding

Speed

(cm/min)

Welding

Distance

(mm)

Gas

Flow

(L/min)

L

O

W

S

P

E

E

D

1.6

0.8,0.9

6575

1617

4045

10

1015

2.3

0.8,0.9

80100

1920

4045

10

1015

3.2

1.0,1.2

130150

2022

3540

1015

1015

4.5

1.0,1.2

150180

2123

3035

1015

1015

Table 8 relation of electrode & welding current for SMAW (for reference only)

For alkaline electrode 507(GB E5015,AWS E7015 ,JIS D5015)

Rod Diameter(mm)

2.5

3.2

4.0

5.0

5.8

Welding Current(A)

60~90

90~120

140~180

170~210

210~260

For acidic electrode 422(GB E4303,AWS E6013 ,JIS D4303)

Rod Diameter(mm)

2.0

2.5

3.2

4.0

5.0

5.8

Welding Current(A)

40~70

70~90

90~130

160~210

220~270

260~310

-16-

Table 9 for GTAW (for reference only)

Work piece

thickness

(mm)

Tungsten

Diameter

(mm)

Wire Diameter

(mm)

Welding

Current

(A)

Clearance

(mm)

Groove

Condition

0.6

1.0~1.6

1.0

20~40

1

(1) (2)

1.0

1.0~1.6

1.6

30~50

1

(1) (2)

1.5

1.0~1.6

1.6

50~80

1

(2)

2.5

1.6~2.4

1.6~2.4

70~100

1

(2)

3.0

1.6~2.4

1.6~2.4

100~130

1~2

(2) (3)

4.0

2.4

1.6~2.4

120~160

2~3

(3) (4)

5.0

2.4~3.2

2.4~3.2

130~200

2~3

(3) (4)

6.0

2.4~3.2

2.4~3.2

150~240

3~4

(4)

8.0

3.2~4.0

3.2~4.0

180~31 5

4~5

(4)

(3)

(1)

(4)

(2)

-17-

7、DAILY MAINTENANCE AND TROUBLE SHOOTING

Warning:

Only after switching off the power supply and ensuring safety, the welding

machine can be opened up for check. Otherwise it may cause electric shock or

burn and other safety accidents

7.1 Attention :

a. Connect cable to port well. Any damage can influence the stability when

welding.

b. Forbid the bare cable and port to be touched by other metal, avoid short

circuit.

c. Avoid breaking the cable.

d. Avoid knocking or heavy weight.

e. Keep good ventilation.

f. Daily maintenance is not enough. In order to keep excellent performance,

periodic maintenance and checking and cleaning the inside components

is necessary.

g. In normal condition, there will be quantity of spark mote and oil dust.

Check and clean in every three months.

h. Check cables including the adjusting button and spares in panel regularly.

i. Change contact tube and wire feeder wheel and clear wire feeder pipe

regularly.

7.2 Trouble Shooting

NO

TROUBLE

POSSIBLE CAUSE

REPAIR

01

Switch on but indicator light

does not work

(1)Air switch could be out of

order.

(2)Power fuse is blown.

(1)change the controller

(2)change fuse

02

air switch on back panel

breaks.

(1)Air switch cannot work.

(2)IGBT mould is damaged

(3)3 phase commutate bridge is

damaged

(4)control PCB damaged

(1)change controller

(2)change IGBT mould

(3)change 3 phase

commutate bridge

(4)change panel

03

Too hot when welding

(1)over-load operating for long

time

(1)operate within load

04

Cannot adjust current

(1)controller cable of wire feeder

is damaged or control PCB is

damaged.

(2)the connection wire of current

divider may be damaged

(3)control PCB is damaged

(1)change

(2)fasten

(3)change

05

Unstable arc, big spatter

(1)wrong procedure

(2)contact tip wear

(1)correct procedure

(2)change contact tube

07

CO2 regulator does not work

(1)CO2 regulator is damaged

(1)change

-18-

(2)heating cable is broken

(3)fuse melts

(2)repair

(3)change 8A fuse

07

switch on the torch and can

feed wire but without gas

flow

(1)control PCB is damaged

(2)electromagnetism valve is

damaged

(1)change

(2)change

08

Wire feeder does not work

(1)gun switch is damaged

(2)feeder cable is broken

(1)change

(2)repair

7.3 Fixing

Normal Fixing:

a) Fuse melts, change fuse. If failure persists after change, switch off power

and consult manufacturer.

b) PCB Problem: Contact with manufacturer or dealer.

c) Other spare parts failure, check and change

d) Other: check whether there is wrong connection or loose connection.

7.4 After-sale Service

a) Check according to normal checking list.

b) Contact manufacturer if require technical support.

c) Please furnish the following information:

- Your name、address、contact number。

- Machine model and type

- Details of trouble or problem.

-19-

8、CIRCUIT DIAGRAM

送丝机电路

M

-

+

SSJ

QF

CZ2

CN9

97 97

105

87

86

45

6 12 3

38

38

47

115

115

61

115

67 1

2

3

4

5

6

7

8

76

75

15

74

73 1

2

3

4

5

CN8

1

2

3

4

5

6

7

8

52

52

50

50

51

51

34

35

49

115

48

98

97

96

3

2

1

3

2

1

1

1

2

3

4

71

70

15

33

CN7

~27.4V

~36V

CN5

1

2

115

40

CN1

CN10

CN3

W

V

U

~

~

~

BR1

RY4

Q1

5C1-6

C12

D1-3

D4-6

3-7R1,2 3-7C1

R1

4C1

4C2

C8,9

RY1

RY3

RY2

S1

C3

C2

C1

8TVS1

8 4

8 5

Q3 5C10-15

8TVS2

8 6

8 7

Q2

8TVS1

8 0

8 1

Q4

8TVS2

8 2

8 3

L4

10T/0.042mH

+

-

FL

500A/75m V

8 7

8 6

~ ~

RP3

47K

FUSE2

2A

C13

CBB61-1UF/500VAC

FUSE1

8A 9D29D1

A

15A502

V9R1

TS

IPB

RJ

~ ~

RP2

收弧电流

56

208

RP1

收弧电压

115

200

201

1

2

3

4

5

CN6

16

14

60

191

190

1

2

4

3

5

6

CN4

L1

L2

S3

S2

T2:FH4.702.002E

CN2

S3:收弧有/收弧无(图中为收弧有状态)

S2:焊接/检气(图中为检气状态)

电源

过热

CT2

M1-电压表 M2-电流表

弧特性

~10V

~19V

~19V

6

7

8

9

1

3

CT1

热继电器

FUSE3

8A

~27.4V

~27.4V

415V

380V

220V

0V

0V

T1:FH4.702.056

FS

20T

3T

3T

12T

DC24V

200FZY6-S/220V

JUC-17F-80℃±5

4K7

4K7

5R1,2,3,4,5

C4,5,6,7

L2

L3

5T

L1

B

A

8R3

8R4 8R4

8R3

97

96

1

3

2

3

4

5

97

2

1

CN5

CN6

CN7

CN4

85

84

8 5

8 4

1

3

CN3

83

82

8 3

8 2

1

3

CN2

81

80

8 1

8 0

1

3

CN1

~19V

~19V

1

98 2

2

2

2

2

3D1

3D2

3D3

3D4

3R1

A

B

HGQ

3-7R3,4 3-7C2

TR1

C10 C11

CT3

6T

993

1052

101

102

97

106

100

104

103

380V

415V

主控板AP1

HC-Ⅱ -AP1

FH7.820.292E

驱动板

HC-Ⅱ -AP 2

FH7.820.293C

电容板1

HC-Ⅱ -AP 5

FH7.820.296C

IGBT驱动吸收板

HC-Ⅱ -AP 8

FH7.820.327B

IGBT驱动吸收板

HC-Ⅱ -AP 8

FH7.820.327B

输出整流吸收板

HC-Ⅱ -AP 7

FH7.820.326A

输出整流吸收板

HC-Ⅱ -AP 7

FH7.820.326A

HC-Ⅱ -AP 4

FH7.820.295B

输出保护吸收板

指示灯板

HM-Ⅱ - AP 4

FH7.820.351

电流采样板

HC-Ⅱ -AP 3

FH7.820.294C

1

2

378

79

S4 S4:手工焊/气保焊(图中为手工焊状态)

This manual suits for next models

2

Table of contents

Other Hanshen Welding System manuals

Popular Welding System manuals by other brands

ADA INSTRUMENTS

ADA INSTRUMENTS IronWeld 160 operating manual

Kemppi

Kemppi KempArc Pulse 350 operating manual

HERKULES

HERKULES HES 150 T Original operating instructions

WELDING INDUSTRIES

WELDING INDUSTRIES Weldmatic 200i Operator's manual

Miller

Miller Intellifire 204 owner's manual

EWM

EWM TR-0102 operating instructions