Hanshen TIG200P User manual

OPERATION

MANUAL

INVERTER DC PULSED

TUNGSTEN ARC WELDER

TIG200P

ATTENTION:

Be sure that all installation operation, maintenance and repair

procedures are preformed only by qualified individuals.

Read this operators manual completely before attempt to use

this equipment.

Save this manual and keep it well for quick reference pay more attention to the

safety instructions.

1

CATALOGUE

1. Characteristics & applications…………………………………….2

2. Safety attention……..……………………………………………...2

3. Range of welding parameters ……………………………………..4

4. Installing and connecting…… …………………………………....4

5. Prepare for welding………………………………………………..7

6. Weld-operating ………………….………………………………..10

7. Daily maintain & check…………………………………………...12

8. Trouble shoot…………………….…………………………….….12

9. Circuit diagram…………………….……………………………….16

2

1. CHARACTERISTICS & APPLICATIONS

This arc welder HT200P can invert the working frequency DC of 50Hz into the high frequency of

25KHZ, with built-in MOSFET from IR company and the application of PWM technique, and

reduces voltage, rectifies current and outputs a high DC power source fitting for welding. Its

functions include DC MMA, DC TIG welding and pulsed TIG welding.

Characteristics:

A. The output characteristics of welding are excellent and the welding current is calm.

B. Stability and dependability of the welder are much higher with application of contactless

circuit.

C. It is with rapid dynamic respond, calm arc, good welding line and nice welding

performance.

D. The functions are rich and its welding technology is good.

E. Arc igniting is stable and operation is easy with application of HF technique.

F. Its protection is perfect: with over-current and over-heat protection, slow startup of current

anti-strike.

G. The welder is much smaller, lighter and with high efficiency than ordinary welders.

Applications:

A: It can be used for welding all kinds of carbon steel, alloy steel, iron, stainless steel, copper,

titanium and their alloys.

B: it can be widely used in machinery industry, chemic industry, shipbuilding industry, vehicle

industry, decoration industry, etc.

2. SAFETY ATTENTION

A: Followi ng attenti ons should be observe d for safety guara n tee

(1).Confirm the followings such as supply power connected from your side, the spot for welder’s

installing, high-pressure gas, storage of workpiece and the treatment of rubbish according to your

national laws or your company’s standards.

(2).Dressing and safety protecting articles

In order to protect your eyes and skin, please wear the protecting articles according to your relevant

rules.

(3).On spot of welding

3

To avid from the injure and hurt by smoke and bad gas, the exhaust equipments ought to be

installed or useful breath apparatus should be used, depending on your rules. (4). Don’t open up

the welder or use it in open position.

B: Avoid burn i n g or fire

(1).Avoid burning from over-heat:

Keep the welder from the wall for more than 30cm and from combustible articles for more than

50cm.

(2). Avoid burning from spark

Keep spark far away from tinder or open holes.

(3). Avoid welder from impact or falling

Fasten the welder by fixed bolts.

(4). Don’t weld the tubes with gas or hermetic tubes and vessels.

(5). Don’t hang the torch on the gas bottle or touch the bottle with electrode.

C: Atten t ion while conn ectin g

(1). Only after disconnection of power and safety ensuring, the connection of welder can be

operated.

(2). Don’t touch the parts with electricity or wear the wet broken gloves.

(3). The cables should be selected according to the appointed standard.

(4). Don’t place the heavy on cables.

(5). The cables should be well connected and the bare electric parts ought to be well wrapped with

insulation.

(6). Only electrician with certificate can do grounding of welder or workpiece.

(7). The power of all equipments should be turned off while not using.

D: Atten t ion to HF

Arc of this welding machine is ignited by HF. To avoid electromagnetism hurt, we should:

(1). The welding cables should be shortened as possible.

(2). Place the cables nearly to the floor or ground with extending position.

(3). Place the cables of work-piece and cables of torch in parallel.

(4). The grounding of work-piece can’t be used together with other machines.

4

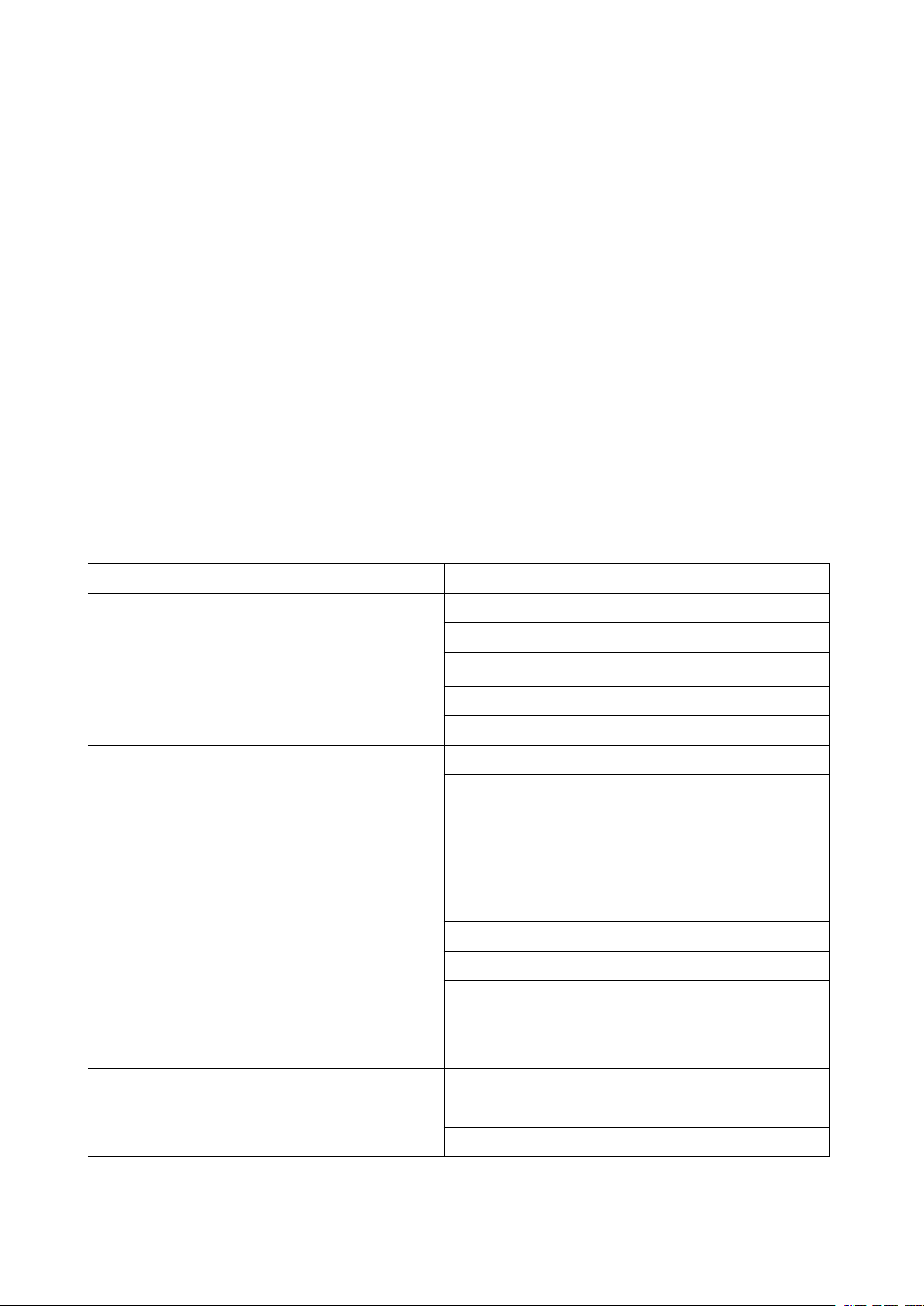

3. RANGE OF WELDING PARAMETERS

table 1. the range of welding parameters

TIG200P

TIG

MMA

Rated input voltage(V)

1-Phase,220V±10 %,50/60Hz

Rated input current(A)

17.5

Rated input capacity(KVA)

6.6

Rated output current(A)

200

160

Rated load voltage(V)

18

26.4

Idle voltage(V)

≤113

≤113

Rated duty cycle(%)

35

Crest current(A)

10~200

10~160

Base current(A)

8~200

/

Pulse frequency (Hz)

0.5~200

/

Pulse rate

0.1~0.9

/

Post flow time(s)

1~10

/

dimensions(W×D×H mm)

430×195×380

Weight(Kg)

18

4. INSTALLING & CONNECTING

(1).PO S ITION FOR USING

place the welder on the dry, clean and solid smooth ground.

The following spots are not allowed:

a. the place under the sunshine and rain.

b. the spot with dust, flammable gas or oil gas.

c. the spot with harmful or caustic gas.

d. the spot with high-humidity steam.

e. easy impacting spot.

f. The distance between each other less than 30cm.

g. the spot with surrounding temperature higher than +40℃ or less than -10℃.

Model

Parameter

Item

5

(2). GROUND I NG

Connect the welder’s grounding end with the grounding line of switchboard, or ensure the

grounding of input power cables connected with the grounding line of switchboard.

(3).VEN T ILA TI ON

Reduce the influence from wind as possible for ensuring the welding quality. But the enough

ventilation should be supplied for preventing the lack of oxygen ,when weld is operated in close

space.

(4).PO W ER SUPPL Y EQUIPM ENT & CON N ECTIO N S

table 2. power supply equipment & connections

mode

TIG200P

Input voltage(V)

1-phase,220±10%

Capability (KVA)

≥7.5

Input cable(m ㎡)

3*2.5

Output cable(m ㎡)

16

(5).GAS FO R WE L DING

The pure argon should be selected for welding quality and no gas leak after connection.

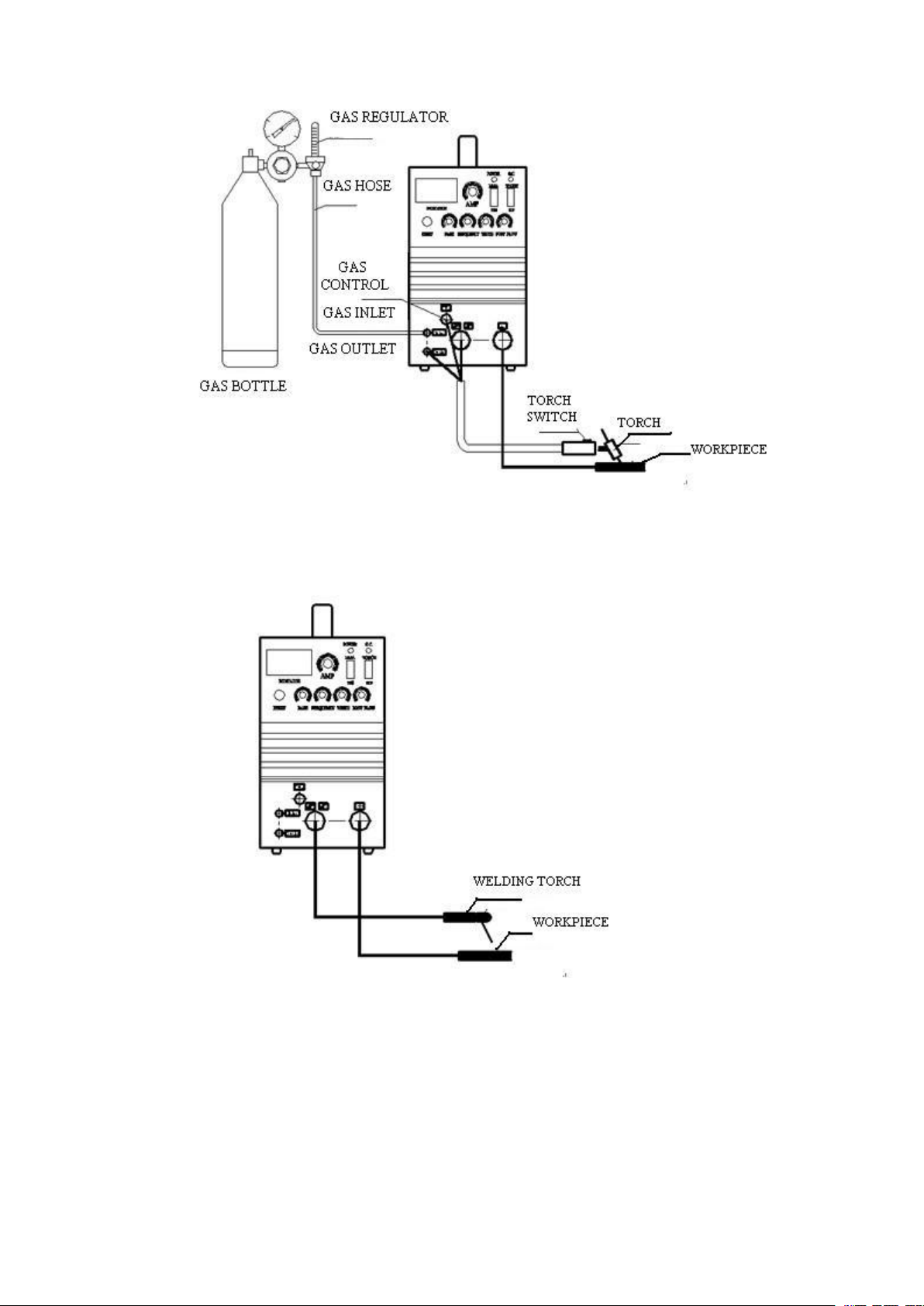

(6).CON N ECTI O N

a. Ensure the welder’s switch closed while connecting.

b. All tubes are in good position for preventing gas from leaking.

c. All bare wires should be wrapped with insulating tapes.

6

p i c t u r e 1 . c o n n e c t i o n f o r T I G w e l d i n g

p i c t u r e 2 . c o n n e c t i o n f o r M M A w e l d i n g

7

5. PREPARE FOR WELDING

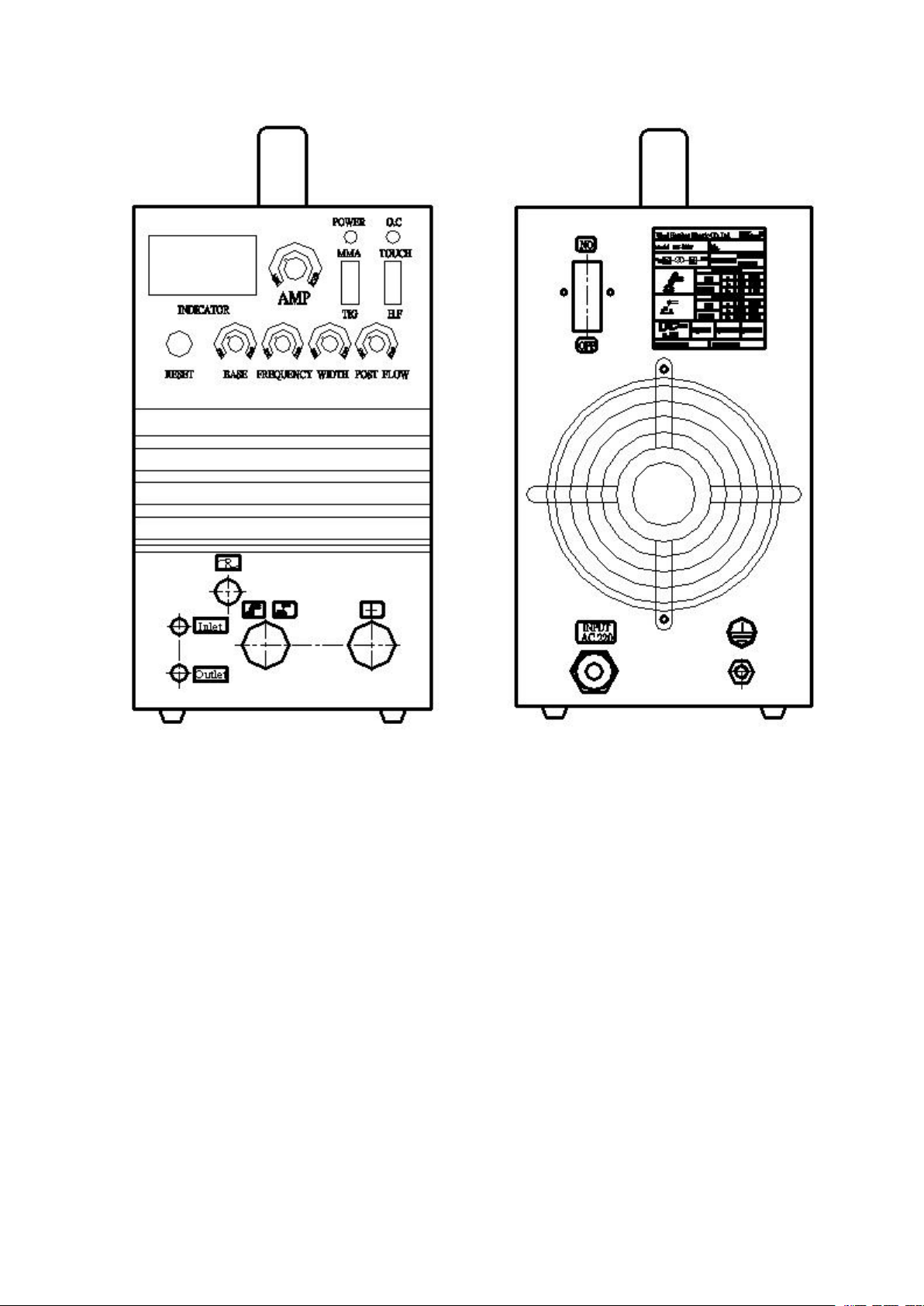

p i c t u r e 3 F R O N T P A N E L p i c t u r e 4 R E A R P A N E L

(1).WELDER CONNECTION

Connect the welder according to the pictures1-3 and the requirements in 4.6 for welding.

ATTENTION: input voltage should be 1-phase, 220V.

(2).TUNGSTEN, PORCELAIN SPIGOT & ARGON FLUX

Select the proper tungsten, spigot and argon flux according to the lists 3-5 on the base of welding

material and its thickness.

8

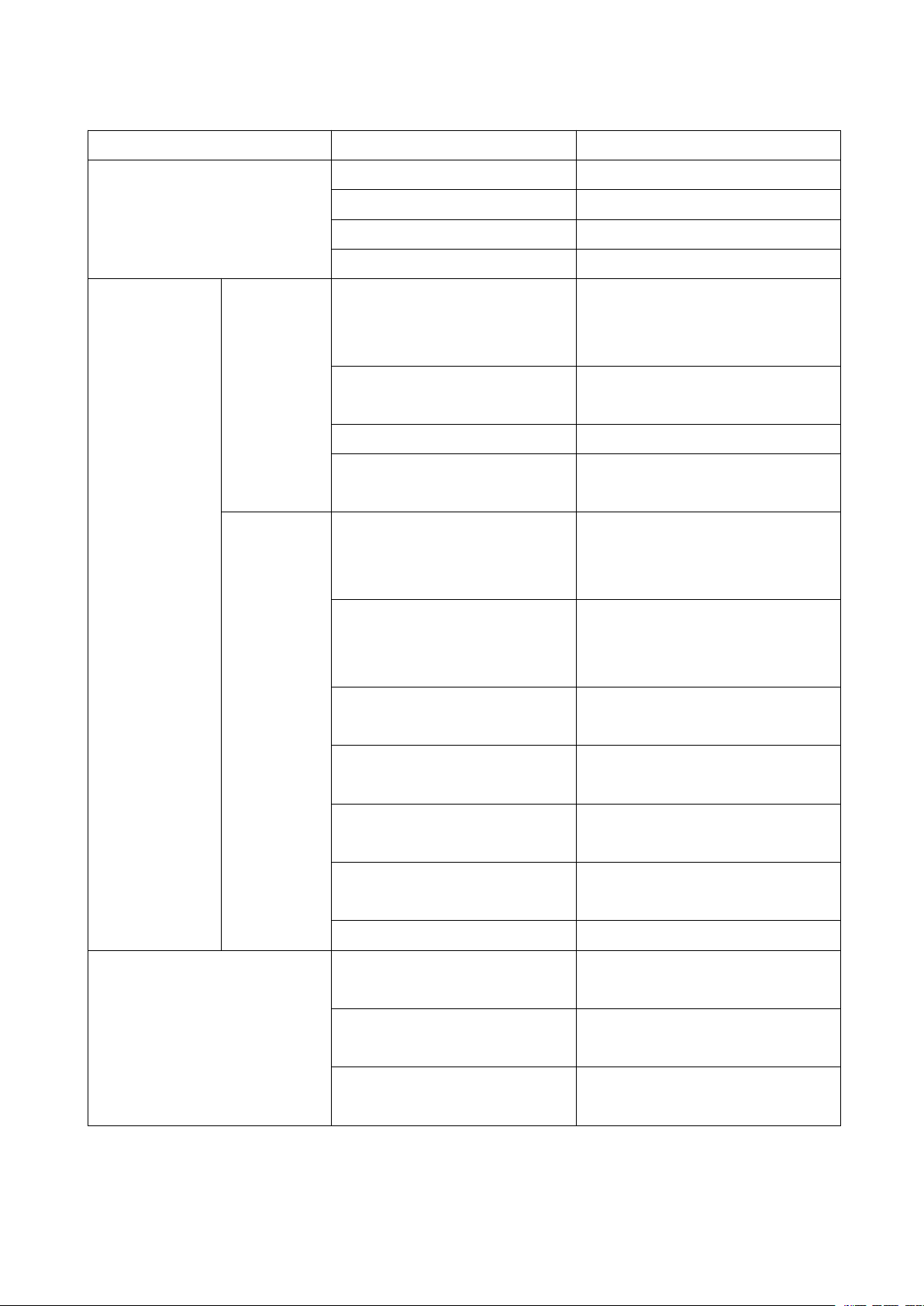

List3、reference of tungsten

Current range

tungsten dia.

(mm)

Allowe d rang e of curren t(A)

Pu re tu n gsten

Th o rium tungs t en,

cerium tungst en

1. 0

10 ~80

10 ~80

1. 6

40 ~130

60 ~130

2. 0

75 ~160

10 0 ~160

2. 4

15 0 ~200

15 0 ~200

The end of tungst en oug ht to be sharp (ap pr ox im at el y 20 ° )in sm all curre nt.

The end of tungst en oug ht to be mill ed as a co ne wit h fl at ro of in lar ge cu rrent.

List4. welding parameter of stainless steel

Workpiece

thickness

(mm)

Tungsten

dia.

(mm)

Filling Wire

dia.

(mm)

Welding

current

(A)

Argon flux

(L/min.)

groove

condition

Nozzle dia.

(mm)

0.4

1.0~1.6

1.0

8~20

3~4

A or B

4~9 . 5

0.6

1.0~1.6

1.0

20~40

4~5

A or B

4~9 . 5

1.0

1.0~1.6

1.6

30~60

4~5

A or B

4~9 . 5

1.6

1.6~2 . 4

1.6

60~10 0

4~5

B

6~10

2.4

1.6~2.4

1.6~2.4

100~130

4~7

B

6~10

3.2

2.4~3 . 2

2.4~3 . 2

140~20 0

6~8

B

8~13

A B

P i c t u r e 5 . g r o o v e c o n d i t i o n

L i s t 5 . r e f e r e n c e f o r M M A

Stick dia.(mm)

2.0

2.5

3.2

4.0

Welding current(A)

30-60

50-100

80-160

120-200

9

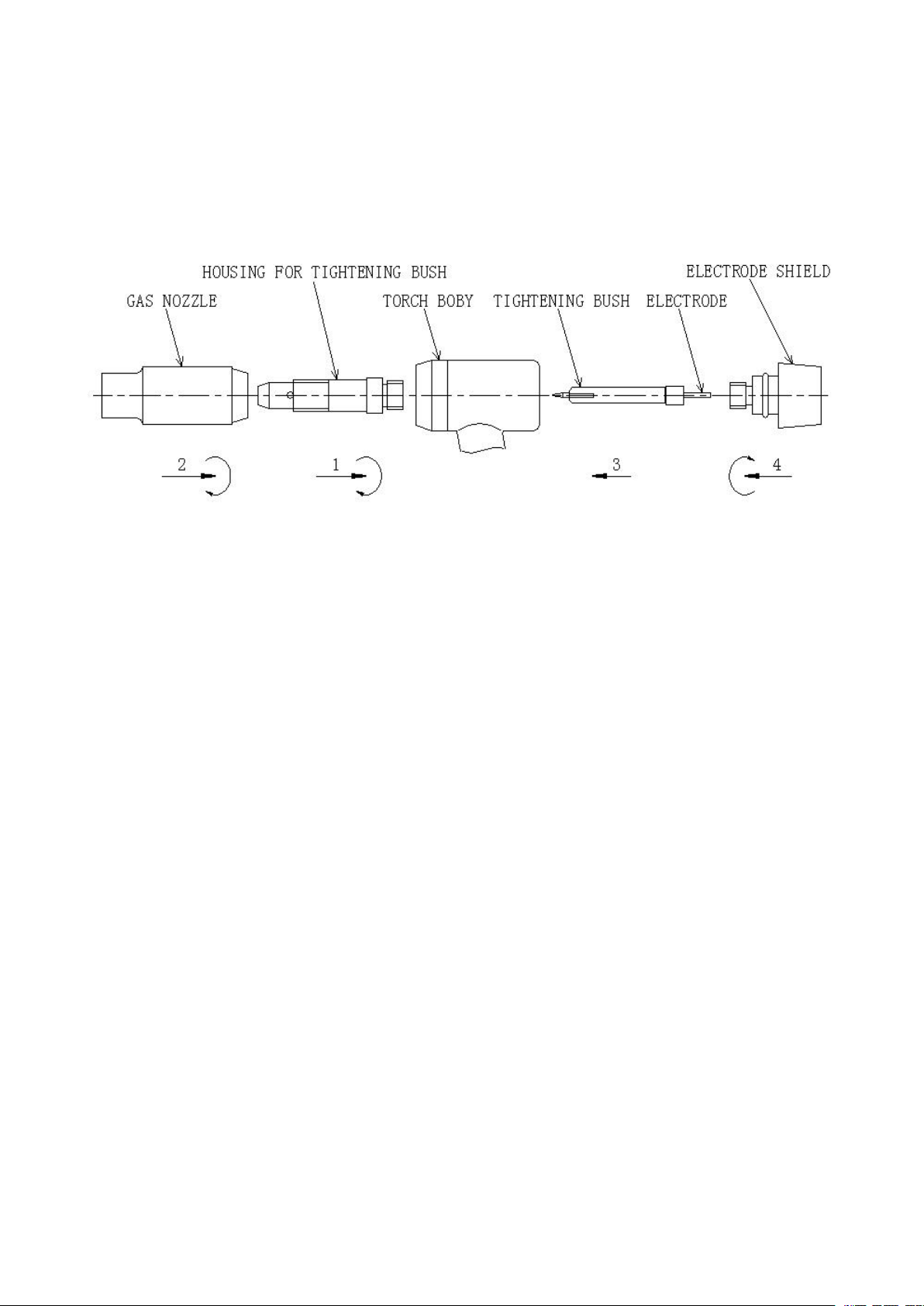

(3).TORCH

Instal l the torch acc o rding to list 5.

P i c t u r e 6 . s t r u c t u r e o f t o r c h

(4).WELDING MODE SELECTION & WELDING PARAMETERS

SETTING

Select the proper welding mode on the base of materials and its thickness, and set the proper

welding parameters referring to list3, 4, 5.

The details include:

a. Set the power-supply switch on the state of “power on”. When the power indicator turns light

and the fan runs, it means the machine has been normally started.

b. Selection of welding mode:

①MMA welding:

Turn the switch “MMA/TIG” to position “MMA”, and rotate the “base current” knob to the end

in clock-wise direction.

②AC TIG welding:

Turn the switch “MMA/TIG” to position “TIG”, and rotate the “base current” knob to the end in

clock-wise direction.

③Pulsed TIG welding:

Turn the switch “MMA/TIG” to position “TIG”, and adjust the “base current” knob in order to set

the current in a proper value less than summit current(“base current” is also named “stand-by

10

current”, it is always selected in a lesser value which can protect arc not breaking).

c. Open up the valve of argon bottle and adjust the flowmeter to the needed value.

d. Set post flow gas time:

Adjusting post flow gas time means that argon gas can be turned off later for a proper time after

welding being finished and arc being broken. It can more really protect the workpiece and guarantee

the quality of welding. The detail operation is: adjust the “post flow gas time” knob and select

needed value among 1-10 seconds according to the value of welding current (summit current).

Generally speaking, the bigger welding current or the higher welding quality is, the longer post

flow gas is; otherwise, the smaller or the lower is, the shorter is for saving gas.

The more the “post flow gas time” knob is rotated in clock-wise direction, the more post flow gas

time is increased.

6. WELDER OPERATING

MMA welding:

After all switches and knobs are checked in correct situation on the base of item 5.4, adjust “current

adjusting” knob according to thickness of workpiece, select the proper welding current and rods,

then begin to formally weld.

AC TIG welding:

a. According to item 5.4 check whether all switches and knobs are in correct situation.

b. After rotating the knob “base current” to the end in clock-wise direction, select the proper

welding current by adjusting knob “current adjust”.

c. Press the switch on torch and ignite arc by HF. The arc is automatically extinguished after

loosening the torch switch. The post-flow time can be adjusted among 1-10 seconds. Close

the argon bottle and turn off the welder after welding.

11

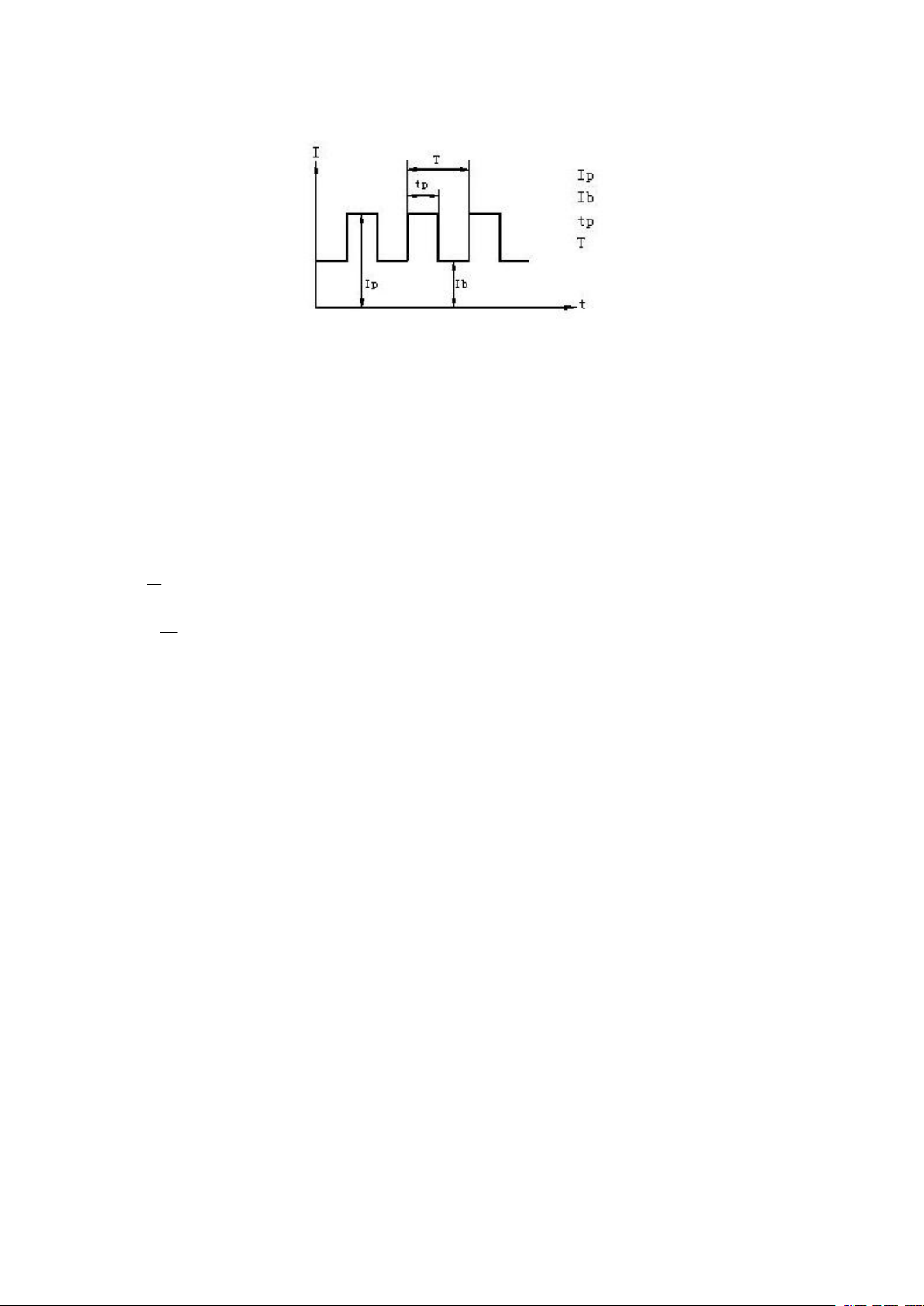

Pulsed TIG welding

P i c t u r e 7 . p u l s e r e l a t i o n

IP—summit current

Ib—base current

tp—width time of summit current

T—period of pulse

f=

T

1

,it can be adjusted among 0.5~200Hz.

D=

T

tp

,it can be adjusted among 0.1~0.9.

The bigger the pulse ratio is, the wider and deeper the welds are; otherwise, the narrower and less

deep.

The higher the pulse frequency is, the more dense the welding waves will become; otherwise, the

less dense.

Operation method:

The welds of a workpiece can be precisely controlled on the pulsed TIG welding mode, every

welding point can be heated up and cooled down quickly, the possibility of producing cracks can be

decreased. It is suitable for welding workpieces, which are of different heat conductivity and

thickness, and thin plates and ultra thin plates (of 0.4mm). As long as “base current” is kept below

“crest current”, the pulsed TIG welding effect can be achieved. A smaller volume of “base current”

(also referred to as “arc maintaining current”), is usually selected, as far as arc is maintained; the

selection of the pulse ratio (tp/T) depends on heat input, which is reflected on a weld’s width and

depth. 0.3 ~ 0.7 of the ratio is generally chosen. Pulse frequency is selected according to the

welding speed and the thickness of welding plates.

Apart from the above, operate the machine in the same way as on the AC TIG welding mode.

12

7. DAILY MAINTENANCE & EXAMINATION

Regular maintenance and examination can guarantee the machine in good work condition. When

the machine is not in use for a long time, it should be regularly and periodically (once two months)

examined in the state of electrification in order to ensure the machine dry and avoid the components

disabled or the parameters changed. The outer connections can be checked only after the power

supply is disconnected. Before inner circuitry and connections are checked, disconnect the power

supply and wait for 5 minutes for fully discharging from capacitor in machine in order to ensure

safety.

list 6: reference for examination

Item of circuitry examination

Regular examination for 1 or 2 months

1. Function of power switch

2. If the running of cooling fun is in normal

condition

3. If exists unwonted libration, noise or

smell

4. If the tie-in of welding cable is singularly

hot

5. If welding cable is singularly hot

6. If the cable is hurt

7. If all tie-ins of strikes are loose

1. Eliminate dirtiness

eliminate dirtiness by compressed air,

especially the dirtiness from reactor,

transformer, power transistor and PCB.

2. Examine the connections of electrocircuit:

Check the connections of input and output

sides, outer connecting lines, and screw

down the loose parts and eliminate rust to

guarantee the connections in good

condition.

3. Check if the grounding line is in good

condition.

4. Check the discharging clearance and make

it clean.

13

8.TROUBLES EXAMINATION & REPAIR

The overhauler can examine and repair the machine according to table 8 after examining it on the

base of list 7. Please contact the seller or the producer if the malfunctions still have not been

eliminated.

ATTENTION:

1. Because inner electrocircuit can produce high voltage which can hurt people, so before

maintenance and overhaul must turn off the switch in switchboard. Inner electrocircuit only can

be overhauled after 5 min. after power supply has been disconnected from welding machine.

2. The machine has been accurately adjusted before leaving from factory, so strictly prohibit any

modifying and change.

3. Check whether the circuitries are in correct connection. In order to avoid troubles do not

energize hard and change its position at will while connecting.

List7: overhauling items

Trouble phenomena

Trouble causes

No arc exists

Torch switch is useless

Power switch is broken

The cable to switch is disconnected

The cable to workpiece is disconnected

The cable of torch is broken

Starting arc is not good or jarless

Connecting tie-in is loose

Argon gas is not pure

The tungsten electrode is no good fixed or its

quality is no good

Surface of welding line is no good

Dunghill or grease exists on the surface of

workpiece

Argon gas is not pure

Flux of argon gas is not enough

Dunghill exists on the surface of tungsten

electrode

Post flow gas time is too short

Tungsten electrode wastes hard

Current is too great or tungsten electrode is too

thin

Argon gas is not pure

14

List 8

Troubles

Possible causes

Eliminate methods

Fun does not work after

turning on the power switch

Power does not exist

Check input power

Power switch is broken

Change power switch

Disconnection inside machine

Check inside connecting

The fun is broken

Change fun

Trouble of

arc-igniting

No voice of

HF

discharging

exists inside

machine

Torch switch or “arc control”

jack is broken or its

connection is no good

Check the condition of switch or

jack and its connection

220V/125V transformer is

disconnected or broken

Check transformer and its

connecting

Can not close J2(4123) relay

Check relay

High voltage box or capacitor

is broken

Check High voltage box or

capacitor

Voice of HF

discharging

exists inside

machine

Overheat protection or

overflow protection

Turn off the mcahine for a few

minutes and retry

Tungsten electrode is far

away from workpiece

Keep the distance of 2-3mm

between tungsten electrode and

workpiece

Tungsten electrode is not

sharp or is broken

Sharpen tungsten electrode

Tungsten electrode is bad

fixed or its quality is bad

Refix or change good tungsten

electrode

Welding current is too low or

workpiece is too dirty

Enlarge current or clean

workpiece

Discharging clearance of Arc

ignition unit is dirty

Clean clearance with sand paper

or alcohol

Output rapid diode is broken

Change diode

HF can not be turned off

Torch switch or arc control

wire is short- circuited

Check switch and jack

Relay J2(4123) in

AP-WSM(2) board is broken

Change relay J2(4123)

B3(339)in board AP1 is

broken

Change B3(339) or board AP1

15

Troubles

Possible causes

Eliminate methods

No argon flows out after

pressing the torch switch

Switch of argon bottle or

flowmeter doesn’t open up

Open up these two switches

Gas tube is jammed or broken

Check tube

Gas valve is broken

Change valve

Can’t close relay J3(4123) in

board AP1

Change relay J3(4123) or board

AP1

Can’t adjust welding current

Potentiometer for adjusting

current is broken or wire is

disconnected

Change potentiometer or

connect wire

B1 in board AP1 is broken

Change B1 or board AP1

Rated output current is

reduced

Input voltage is too low

Ensure the normal voltage

Input wire is too thin

Change power supply wire

Capability of power supply is not

enough

Ensure the capability of power

supply more than the maximal

power of machine in normal

work condition

Function “pulsed TIG

welding” does not exist

One of the base current, summit

current or pulse frequency

potentiometers is broken

Check and change the broken

potentiometers

M1(4011),N1(555),B1(339) in

board AP1 is broken

Change M1(4011),N1(555),

B1(339) or board AP1

Inverter tube (IGBT) is

broken

Work in over loading condition

for a long time

Change IGBT

Work in over voltage or under

voltage condition for a long time

Change IGBT and ensure the

normal input voltage

Output commutation diode

is broken

Work in great current condition

for a long time or environment

temperature is too high

Change broken diode and

improve work condition

Frequent burnout of diode is

caused by the large discharging

space of arc-igniting unit.

Adjust the discharging space to

1.0-1.2mm

16

9. CIRCUIT DIAGRAM

Table of contents

Other Hanshen Welding System manuals

Popular Welding System manuals by other brands

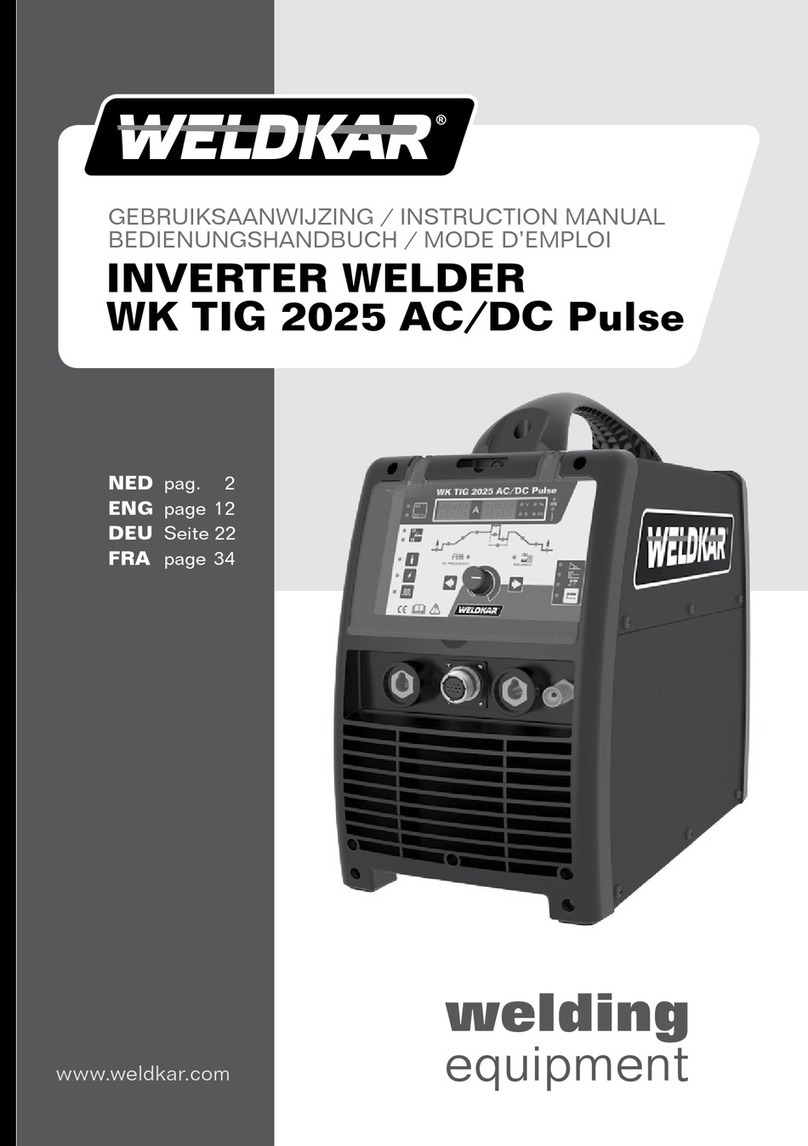

WELDKAR

WELDKAR WK TIG 2025 AC/DC Pulse instruction manual

Chicago Electric

Chicago Electric 62719 Owner's manual & safety instructions

Lincoln Electric

Lincoln Electric PRECISION TIG 375 IM909 Operator's manual

Leister

Leister HEMTEK ST operating instructions

Sealey

Sealey SUPERMIG230 instruction manual

Munsch

Munsch GM-50-FU operating instructions