Hanshen MP350 Series User manual

1

OPERATION

MANUAL

DSP MULTIFUNCTION PULSE

WELDING MACHINE

MP350/500 series

A T T E N T I O N :

Be sure that all installation, operation, maintenance and repair

procedure are performed only by qualified individuals.

Read this operation manual completely before using this equipment.

Save this manual and keep it handy for quick reference pay more

attention to the safety instructions.

2

CATALOGUE

1、S A F E T Y R U L E S … … … … … … … … … … … … … … … … … … 3

2、S P E C I F I C A T I O N … … … … … … … … … … … … … … … … … 8

3、T E C H N I C A L P A R A M E T E R S … … … … … … … … … … … … 9

4、E Q U I P M E N T I N S T A L L A T I O N & C O N N E C T I O N … … … … 1 0

5、F U N C T I O N I N T R O D U C T I O N … … … … … … … … … … … … 1 2

6、W E L D I N G O P E R A T I O N … … … … … … … … … … … … … … 2 2

7、W E L D I N G M A T E R I A L S E L E C T I O N … … … … … … … … 3 5

8、D A I L Y M A I N T E N A N C E … … … … … … … … … … … … … … 3 6

9、C I R C U I T D I A G R A M … … … … … … … … … … … … … … … … 4 2

10、WIRING DIAGRAM FOR INTEGRATED WELDING MACHINE.......................44

3

1、SAFETY RULES

S a f e t y R u l e s

Please read the manual carefully before using the machine and

operating it correctly on this basis

This manual only for the installation, operation and maintenance

This operator should have received appropriate training

Please keep this manual or a copy to the welding machine operator

Installation, repair and maintenance personnel should also read the

operating instructions

Warning

Installation and maintenance of professional electrician to carry out

operations

Operation of electrical connections must disconnect the power

switch of the distribution box

Do not allow minors to close to the welding machine and welding

site

Note

The machine should be placed horizontal, the tilt angle should not

exceed 15°

Do not use this machine to thaw pipes.

A n e l e c t r i c s h o c k c a n b e fa t a l .

Be sure to turn off the power switch of the power distribution box

when wiring

Do not touch the exposed live parts

Do not touch the overheating parts produced by the current between

the welding and the workpiece with bare hands, or place parts of

body(or wet clothes)in the welding circuit to form a loop, when the

machine is working

Touching the electrodes of two power source at the same time may

cause electric shock damage

Do not loop any cables or other leads around your body or any parts of

your body

All cables and other leads must be firmly attached, undamaged,

properly insulated and adequately dimensioned. Immediately replace

any loose connections, scorched, damaged or under dimensioned

cables or other leads

In MIG/MAG welding, the welding wire, welding spool, the drive

rollers and all metal parts having a connection with the welding wire

are also live

The machine should be reliably grounded, and have the mains and the

machine supply leads checked regularly by a qualified electrician to

ensure that PE(protective earth)conductor is functioning correctly

Do not discharge the TIG torch when aiming at any part of the body

4

O v e r h e a t e d p a r t s m a y i n j u r e t h e sk i n

Do not touch the overheated welding position

Do not touch with bare hands the welding cable or welding clamp due

to the heat produced during operation. Welding slag in the weld

cooling may collapse from the surface. The operator and nearby

persons should wear goggles well and other protective equipment when

dealing with welded materials

W e l d i n g p r o c e s s m a y c a u s e f i r e o r

e x p l o s i o n

Spatter may ignite nearby combustibles. Combustible materials must

be at least 10 meters away from arc, or else must be covered over with

approved coverings

Have a suitable, approved fire extinguisher in the welding suit

Control the spatter from falling on clothes or the body

Do not perform welding in location that are at risk from fire or

explosion, or in enclosed tanks, barrels or pipes, unless the latter have

been prepared for welding in accordance with the relevant national and

international standards. Sparks and hot metal particles may also get

into surrounding areas through small crack and holes. Take suitable

measures here to ensure that there is no risk of injury

Welding must never be performed on containers which still have gases,

fuels, mineral oils etc. Traces of these substance left in the containers

are a major explosion hazard.

The fumes given off during welding contain gases and vapors are

harmful to health

Welding fumes may contain substances which may cause birth defects

and cancer

Do not inhale any fumes or noxious gases that are given off

Air circulation to maintain the welding site, welding site should be

proper ventilation exhaust soot facilities

The situation with insufficient ventilation should use a respirator mask

with an independent air supply

The harmful of welding fumes will depend on the following

components: the metals used in and for the workpiece, electrodes,

coating, cleaning and degreasing agents and the like

Lift up with forklift or hoist. When hoisting the machine by crane, only

use suitable manufacturer supplied lifting devices

Remove the cylinder and the wire feeder unit(MIG/MAG welder

units)before hoisting

When using a crane to lift, tie the rope around two handles at the same

time

5

When the welding wire emerges from the torch, there is a high risk of

injury (the wire may pierce the welder’s hand. injure his face and eyes)

For this reason, when feeder-inching etc., always hold away from your

body (machines with wire feeder)

Strong arc burns the eyes and skin

The UV rays generated by arc will damage skin and eyes, please wear

welding labor clothing when welding

Protect the eyes and face from UV, heat and flying sparks with an

appropriate safety shield containing appropriate regulation filter glass

Wear a pair of appropriate regulation goggles (with side guards) behind

the safety shield

C y l i n d e r s ma y h a v e a p o t e n t i a l r i s k o f

a n e x p l o s i o n

Protect shielding-gas cylinder from excessive heat, mechanical impact,

slag, naked flames, sparks and arcs

Place cylinders preferably away from the welding site and fasten them

firmly

Never hang a welding torch on a shielding-gas cylinder

Never perform welding on a pressurized shielding-gas cylinder

Use only shielding-gas cylinders that are suitable for the application in

question, together with matching, suitable accessories (pressure

regulator, hoses, fitting and hose clamp)

When opening the valve of a shielding-gas cylinder, always keep your

face away from the outlet nozzle

When the shielding-gas cylinder is not connected up, leave the cap in

place on the shielding-gas cylinder valve

E l e c t r o m a g n e t i c f i e l d ma y h a v e a c e r t a i n

d e g r e e o f h a z a r d

When current flows through a conductor or TIG welding, high

frequency arc is generated, which will induce an electromagnetic field

(EMF). When welding, the welding cable around will form the

electromagnetic fields

Electromagnetic fields may interfere with pacemakers and other medical

equipment, if the welders wear such equipment, please consult a doctor

before the welding operation

Electromagnetic field may cause as yet unknown damage to health, in

order to minimise electromagnetic damage, please try to do the

following points:

Keep the cables as short as possible

Arrange the cables so that they run close together (to prevent EMI

problems as well)

Do not arrange cables around the body

Try to ensure the cables connecting machines and workpiece are on the

same side of your body

6

●The electromagnetic fields may have some interference with radio

waves, computer, communications equipment and some other telecoms

equipment, the owner/operator is obliged to take all necessary measures

to prevent such interference.

To prevent the risk of scalding from accidental discharge of hot coolant,

before unplugging the connectors of coolant flow, switch off the

cooling unit first.

If need to use the machine under electricity environment, only use it

when the safety symbol □s is found in such environment.

R o t a t i o n o f t h e f a n ma y i n j u r e yo u r b o d y

Do not insert hands or fine material into the fan cover

Please ensure that the case has been covered before opening a welding

power

Do not let children go near the machine repair or maintenance places

7

The machine may only be used for jobs as defined by the “Intended

purpose”:

-The machine may only be used for the welding processes stated on

rating plate. Utilisation for any other purpose, or in any other

manner, shall be deemed to not be in accordance with the intended

purpose, the manufacturer shall not be liable for any damage

resulting from such improper use.

Accordance with ‘intended purpose’ also comprises:

-Completely read and follow all the instructions given in this manual

-Completely read and follow all the safety instructions and danger

warnings

-Performing all stipulated inspection and servicing work

The application must never be used for the following:

-Thawing pipes

-Charging batteries/accumulators

-Starting engines

The machine is designed to be used in industrial and workshop

environments. The manufacturer shall not be liable for any damage

resulting from using of the machine in residential premises

Likewise the manufacturer will accept no liability for defective or

faulty work results

Operation or storage of the power source outside the stipulated range is

deemed to not be in accordance with the intended use. The manufacturer

shall not be liable for any damage resulting from such.

Temperature range of ambient air:

-The use of ambient temperature:-10°C~+40°C

-Preservation and transport temperature:-25°C~+55°C

Relative atmospheric humidity:

-+40°C up to 50%

--20°C up to 90%

Ambient air:Free of dust, acids, corrosive gases or substances etc

The delivery of the printed text and images in this manual have been

checked. The company reserves the right to modify the instructions in

the case without notice. This manual does not mean that the user has

made any commitments and guarantees. We appreciate any advice

given.

8

2、SPECIFICATIONS

Hanshen MP series DSP welding machines are fully digitally controlled inverter power

source. Its core is the digital signal processor (DSP). The DSP centrally deals with the

welding data, controls and monitors the welding process, which gives a reliable, premium

performance and welding quality. Besides, there is an intellectualised parameters combination,

which uses the synergic mode, and is also capable of saving 100 welding expert database

process. It has largely simplified the operation, which could transform a beginner welder into

an expert.

MP series inverter pulse MIG/MAG welding machine combines all 5 welding methods

in 1:

1.The pulse (both double and single); 2. Constant voltage; 3. Arc hand; 4. Argon welding

and 5. Carbon arc air gouging welding.

Currently, the pulse welding method could be used to weld many materials such as

carbon steel and stainless steel, aluminum and its alloys, copper and its alloys and other non-

ferrous metal welding. The constant pressure welding method can be used for carbon steel

rich in argon and CO2gas shielded welding.

Advantages:

1) Fully digitally controlled system, accurate control of welding process, stable arc

length

2) Full Digital wire feeding control system, wire feeding is accurate and smooth

3) Built-in welding expert database system, automatic intelligent parameter combination

4) Friendly operation interface, multi adjustment methods, easy to master.

5) Less welding spatter and nice weld appearance.

6) It can store 100 sets of welding procedure, which saves operating time.

7) Special four steps function for welding thermal conductive metal, arc starting and arc

welding quality is premium.

8) With various interfaces, which can be used to dock the tailor made welding machine

(when using as a power source) and the welding robot (optional).

9) Soft switch inverter technology, which can enhance the reliability and energy saving.

10) Double pulse function can give beautiful scales striate weld appearance.

11) Can match the digital welding torch, adjustment faster and more convenient

(optional).

9

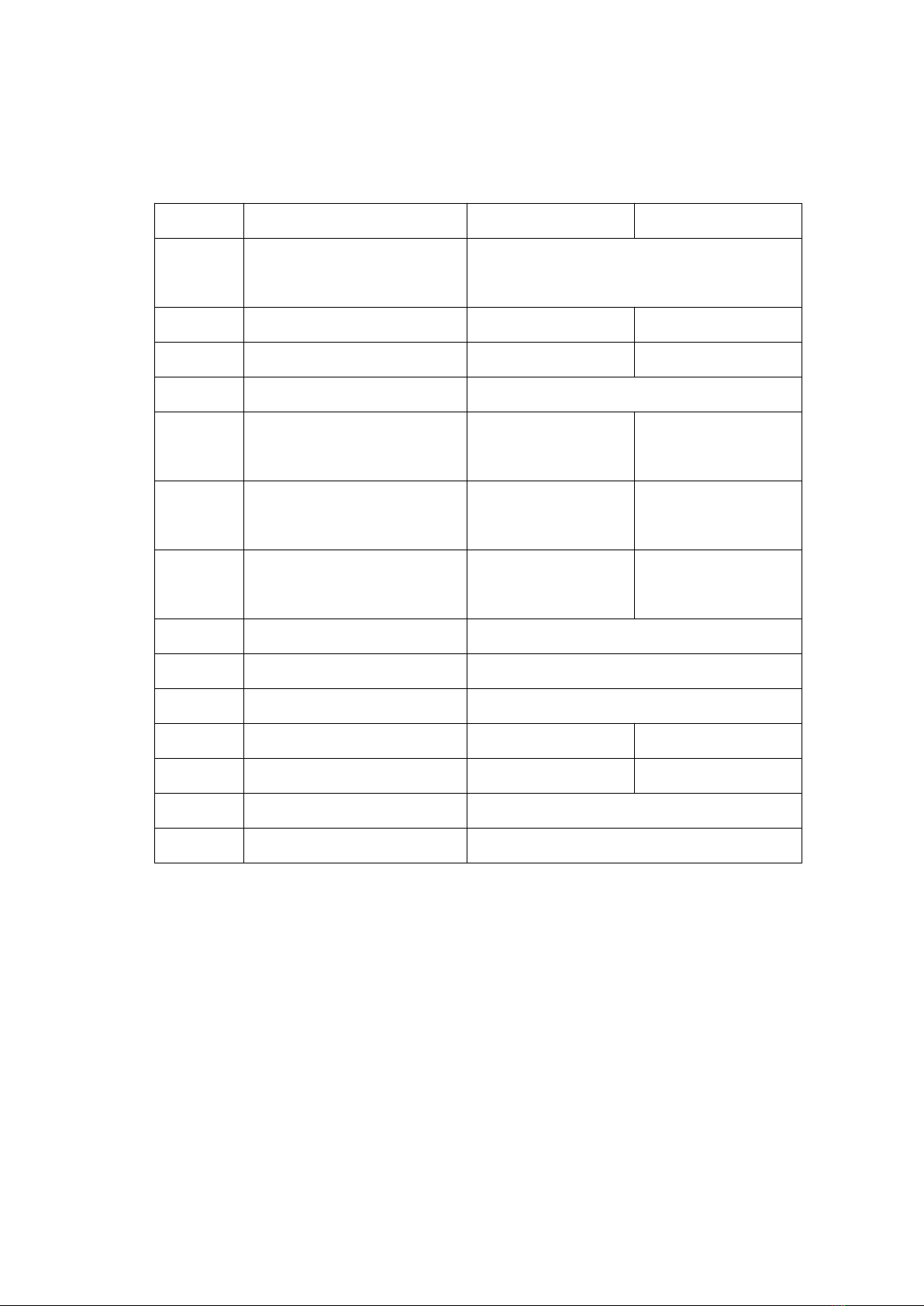

3、TECHNICAL SPECIFICATIONS

Table 1:Specifications

Specification

MP350

MP500

1

Power source

voltage/frequency

AC 3 phase 380V10% 50Hz

2

Rated power input

16.5KVA

24KVA

3

Rated input current

25A

36A

4

Rated duty cycle

60%

5

Range of rated output

current adjusting

20--350A

20-500A

6

Range of rated output

voltage adjusting

11--34V

11-40V

7

Output open circuit

voltage

58V

68V

8

Efficiency

≥85%

9

Efficiency factor

≥0.93

10

Wire diameter (mm)

Ф0.8、Ф1.0、Ф1.2、Ф1.6

11

Net weight (kg)

47

52

12

Dimension (mm)

690×335×720

690×335×720

13

Insulation class

F

14

Shield protection class

IP21S

10

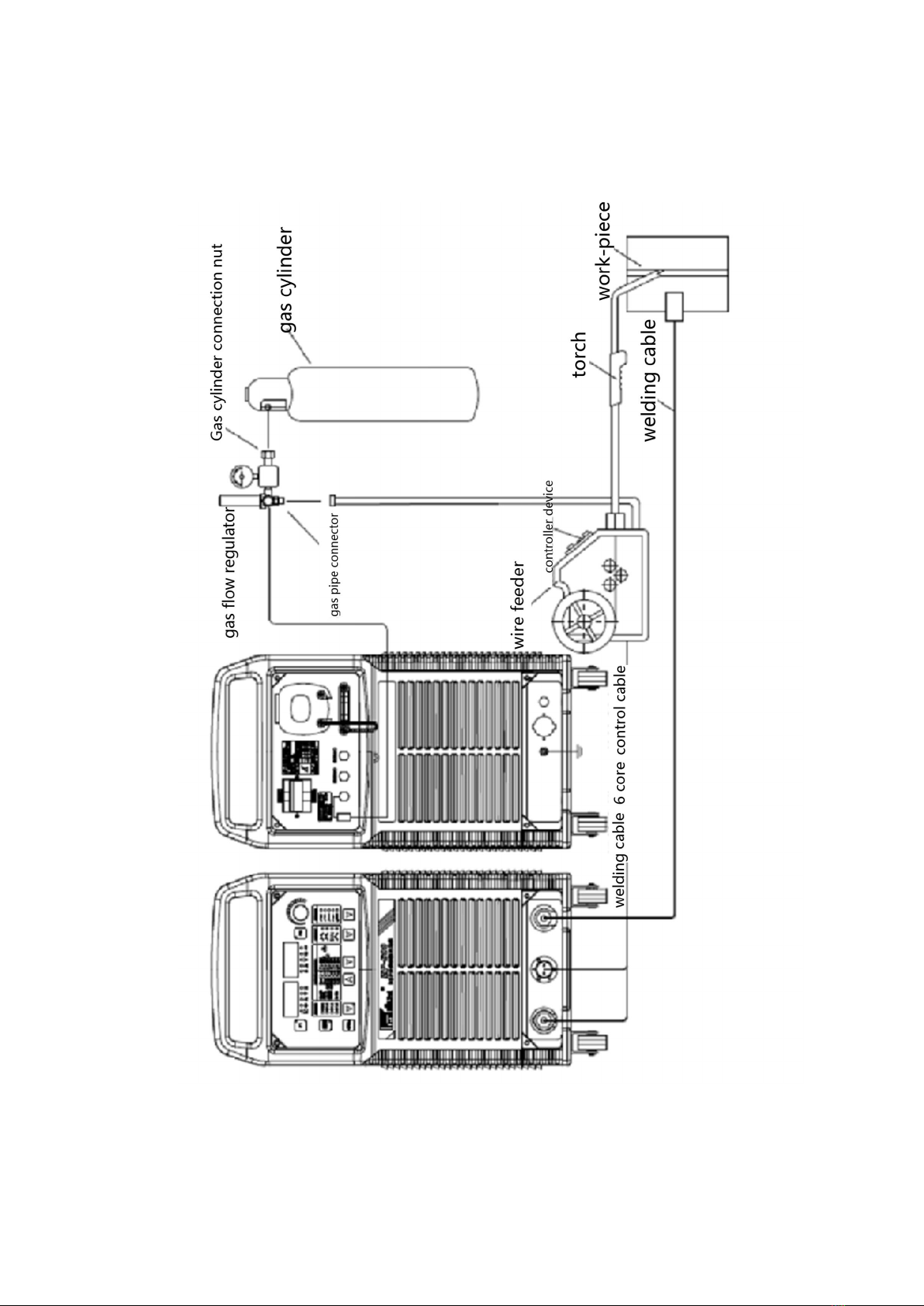

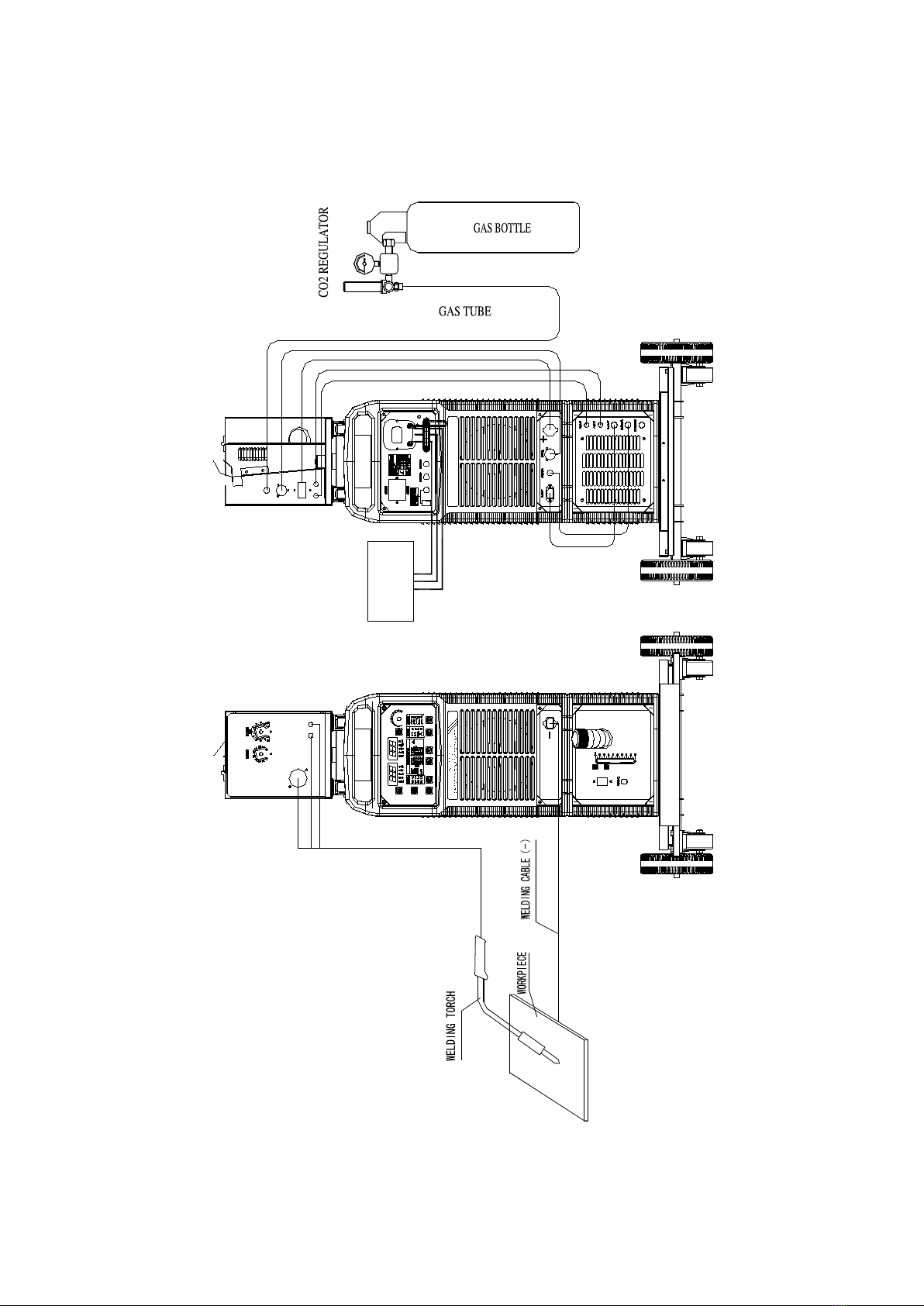

4、EQUIPMENT INSTALLATION & CONNECTION

4.1 Connection diagram (for example: melting pole welding)

11

3-415V

Fig.1:connection diagram

12

4.2 Safety tips

Note:

Please strictly stick to the following steps for installation and debugging

The operation of connecting the gas cylinders can only start after turning

off the power switch of distribution box.

Warning

Electric shock

may injure

body or may be

fatal

Welding process may cause fire

or explosion

Spatter may ignite nearby

combustibles. Combustible

materials must be at least 10m

away from the arc, or else must

be covered over with approved

coverings

Avoid spatter falling on the

clothes or the body

Be sure turn off the power

switch of the power

distribution box when wiring

Do not touch the exposed

live parts

The fumes given off during

welding is harmful to health

Do not inhale any fumes or

noxious

Clean up the oil spill on the

workpiece

Keep air circulation of

welding site

Welding station should be

equipped with exhaust smoke

and dust cleaning equipment

Strong arc burns the eyes and

skin

The UV rays generated by arc

will damage skin and eyes, please

wear welding labor clothing when

welding

Overheated parts may

injure the skin

Do not touch the

overheated welding position

Do not touch the welding

cable or welding clamp with

bare hands due to the welding

heat

High speed mobile content may

cause injury

Do not insert hands or fine

content into the fan cover

Please ensure the case has

been covered before opening a

welding power

To prevent eyes and skin injury, please follow

labor safety and health rules, wear the necessary

protective equipment

Operation should be in accordance with the

relevant work safety operating rules

13

5、FUNCTION INTRODUCTION

5.1 MP front panel structure

Fig 2:MP-500 front panel diagram

Table 2:

No.

Item

Function

1

Operation panel

Adjust parameters, function selection, etc. read instructions for

operation manual of MP series welding machine panel

2

Cathode output

connector

Through the output cable to connect the welding workpieces (gas

metal arc welding)

3

Control cable interface

Connecting wire feeder control cable

4

Anode output

connector

Connecting wire feeder welding cable (gas metal arc welding)

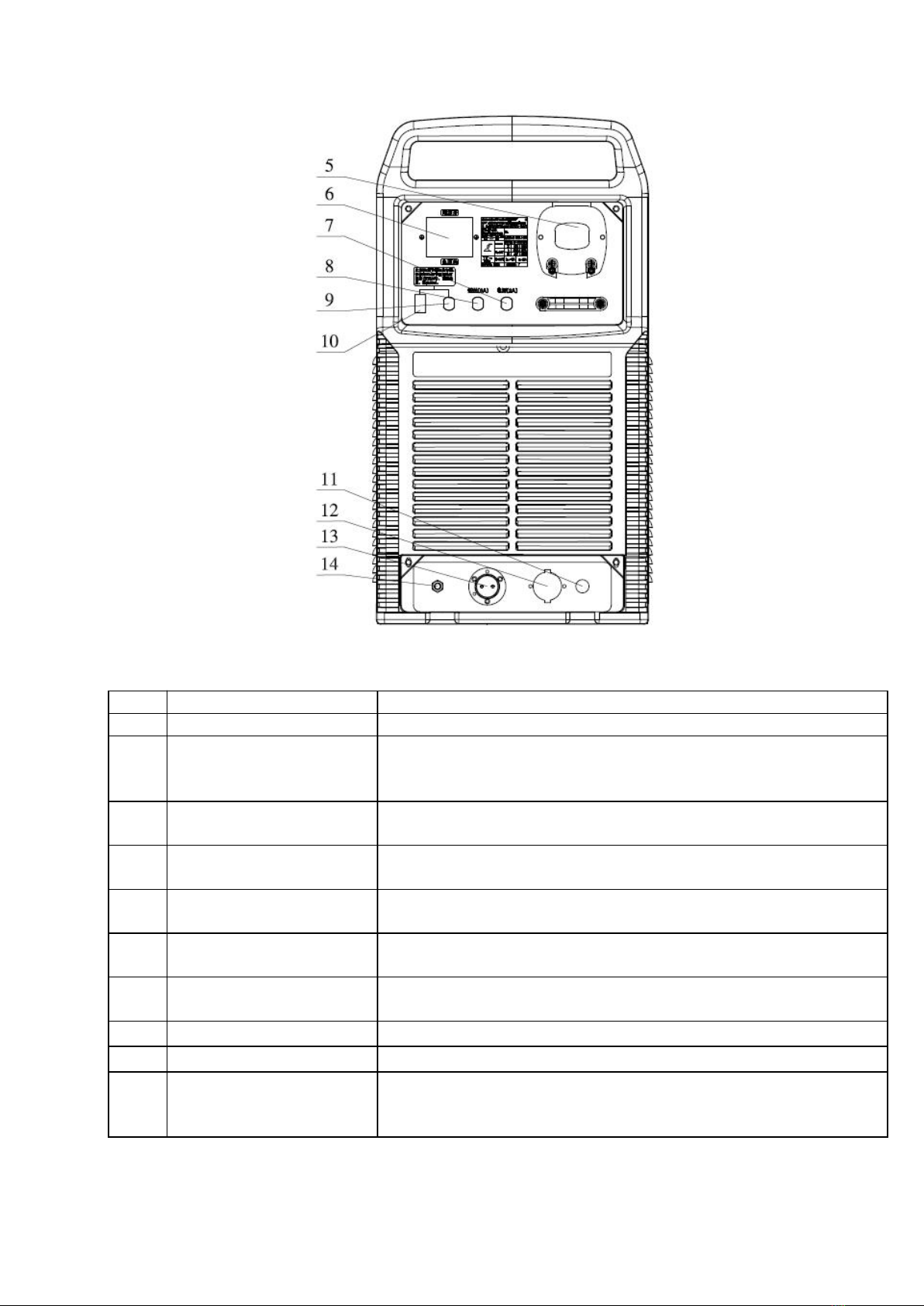

5.2 MP back panel structure

14

Fig3:MP-500 back panel diagram

Table 3

No.

Item

Function

5

Input power supply box

Used to connect the welding machine to 380V power supply

6

Air switch

This switch can automatically turn off power to protect the

welding machine during the overload or failure. In general, this

switch should be kept on

7

Control power fuse

When the control circuit short circuit occurs, this fuse will blow

to protect the voltage transformers, cooling fans and etc.

8

Wire feeder fuse

When the feeding circuit short circuit occurs, the fuse will blow

to protect the voltage transformer, cooling fan and etc.

9

Heating power fuse

When the heating regulator short circuit occurs, the fuse will blow

to protect control transformer ,cooling fan and etc

10

Heating output power

socket

Supply 36V heating regulator flowmeter

11

Water cooling switch

socket

Use for water cooling tank, water flow switch interface

(integrated machine)

12

Anode output connector

Connecting wire feeder cables (integrated machine)

13

Control cable connector

Connecting wire feeder control cables (integrated machine)

14

Grounding bolt

In order to ensure the personal safety, please be sure to use wires

to the bolt and reliable grounding, or reliable grounding line of

the input cable grounding.

5.3、Mp series control panel instructions

15

Fig4:MP series welding machine operation panel schematic diagram

1)Adjusting knob

Adjust the parameter values. When Indicator light is on, it means the knob can be used to

adjust the corresponding parameter of the project.

2)Indicator light of adjusting knob

When indicator light is on, it means the knob can adjust the parameters

3)Selection key F2

Choose to operate the parameters of the project:

- Arc length correction

- welding voltage

- job no. n0

4)indicator light of key F2

When F2 indicator light is on, it means that F2 key has been selected and it can adjust the

parameters

5)indicator light of job no. n0

Obtain the preset parameters stored based on the job number

16

6)indicator light of welding speed

When indicator light is on, the display screen on the right shows the preset welding speed

(cm/min)

7)indicator of welding voltage

When indicator light is on, right display shows preset or actual welding voltage

8)indicator light of arc length correction

When indicator light is on, the display screen on the right shows arc length correction

value

— indicates Arc length shorter

0 indicates Standard arc length

+indicates Arc length longer

9)indicator light of inner temperature

The function is the reserve function; it is not operational at the moment

10)The display screen on the right

Display related parameters

11)The display screen on the left

Display related parameters

12)indicator light of the arc force/arc lamp

When using pulse MIG/MAG welding, it is used to adjust the arc force

— indicates arc force decrease

0 indicates standard arc force

+indicates arc force increase

When MIG/MAG unifies DC welding, it changes the arc stiffness of the short circuit

transition.

— indicates hard and arc stability

0 indicates secondary arc

+Soft arc, little splash

13)indicator of feeding speed

When indicator light is on, left display shows the feeding speed (M/min)

14)indicator light of welding current

When indicator light is on, the display screen on the left shows preset or actual welding

current

15)indicator light of base metal thickness

17

When indicator light is on, the display screen on the left shows the preset base metal

thickness

16)indicator light of welding angle

When indicator light is on, the display screen on the leftshows welding angle size ‘a’

17)indicator light of F1

When indicator light is on, it means that F1 key has been selected and it can adjust the

parameters

18)selection key F1

Choose to operate the parameters of the project:

- feeding speed

- welding current

- arc force/arc stiffness

19)Invoking key

Obtain parameters stored in advance

20)indicator light of invoking key

When indicator light is on, it means it can obtain the preset parameters stored

21)storage key

Enter the settings menu or store parameters

22)indicator light of wire diameter

When indicator light is on, it means it can adjust wire diameter

23)selection key of wire diameter

Select suitable wire diameter

24)indicator light of implicit parameter menu

When indicator light is on, it means that can adjust implicit parameter

25)indicator light of wire materials and protective gas

When indicator light is on, it means the corresponding wire materials and protective gas

are selected

26)Wire material selection button up

Welding wire materials and protective gas upward selection.

27)Wire material selection button down

Welding wire materials and protective gas downward selection

28)indicator light of welding torch operation mode

When indicator light is on, it means the corresponding operation mode is selected

18

29)welding torch operation mode button

Select the welding torch operation mode

Table 4:welding torch operation mode

Mode

Remark

Two steps

Normal operation mode

Four steps

Locked operation mode

Special four steps

Up, crater arc adjustable

model

Spot welding

Automatically control

working time

30)indicator light of welding method

When indicator light is on, it means the corresponding welding method is selected

31)selection button of welding method

Table 5:welding method

Welding methods

Note

P-MIG

Pulse welding

MIG/MAG

Unified dc welding

STICK

Manual welding

TIG

Tungsten argon arc

welding

CAC-A

Carbon arc air gouging

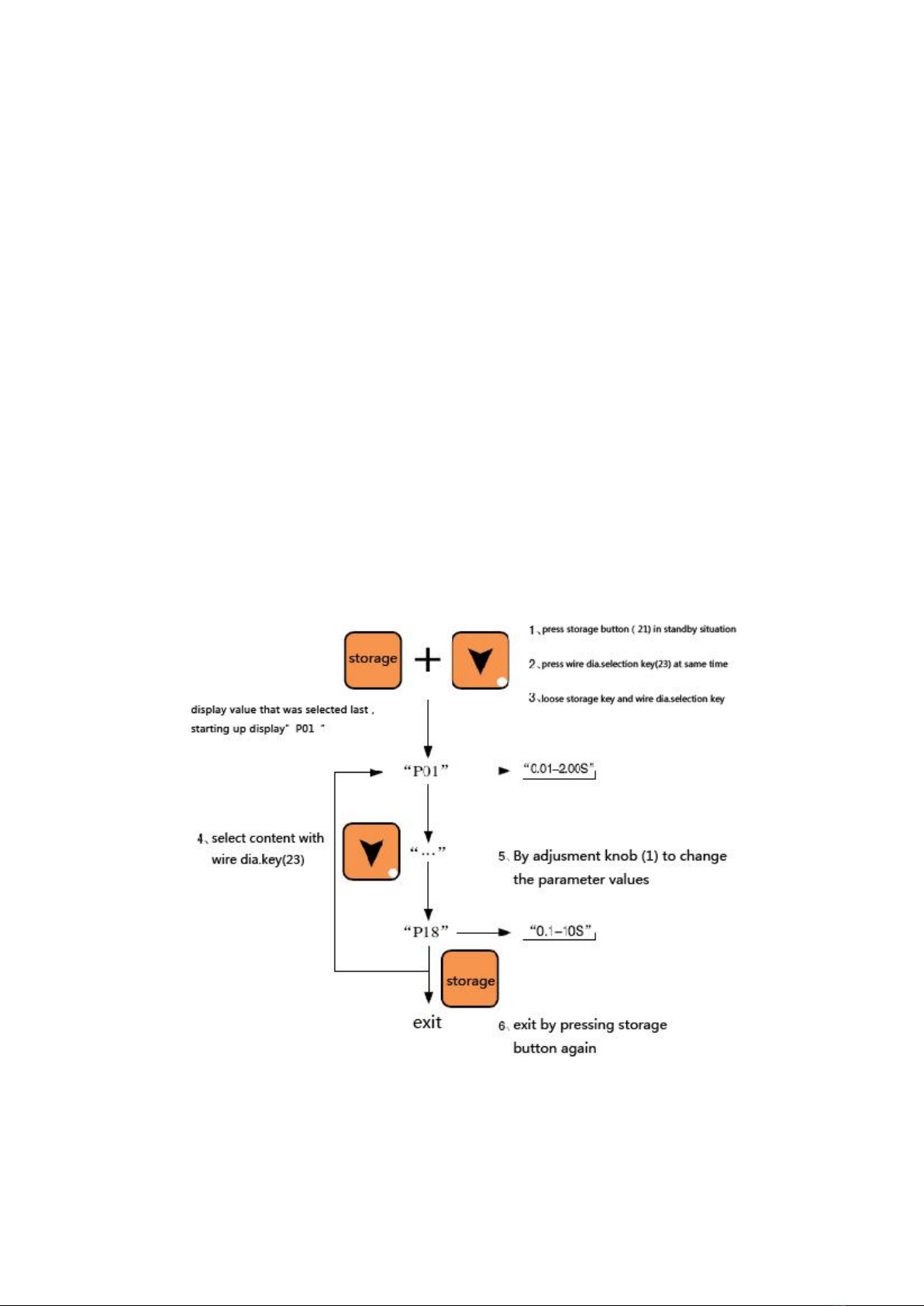

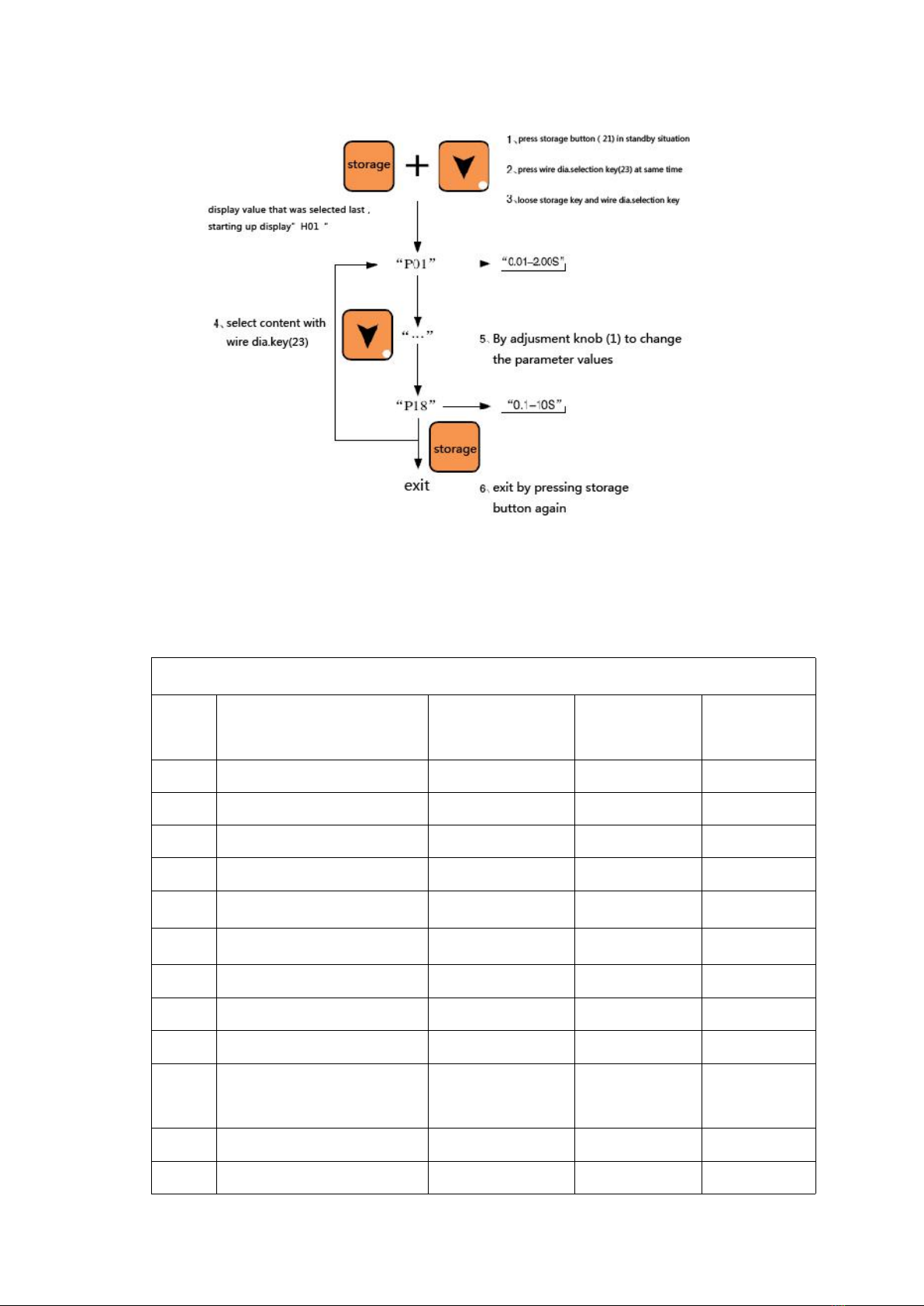

5.4 Implicit parameter adjustment

For implicit parameter adjustment method, see Fig5 and Fig6

At the same time press the store button (21) and the wire diameter selection key (23)

and then release, implicit parameter menu indicator (24) light is on, it means it has entered the

implicit parameter adjustment mode menu. Press the store button again (21) to exit the

implicit parameter menu adjustment mode; the implicit parameter menu indicator light is off.

19

Use the wire diameter selection button (23) and choose to modify the content. Use the

adjusting knob (1) to adjust to parameter values. P05, P06 item are available for F2 key

switch to display current percentage, arc length offsets, and can also use (1) to modify the

parameter values.

Detailed operation reference (Fig 5 and 6):

Fig 5:Implicit parameter operation schematic diagram (melting polar gas shielded welding )

20

Fig 6:Implicit parameter operation schematic diagram (electrode MMA welding )

5.5 Modify the content and the corresponding parameters as shown in table 6

Gas shielded welding way implicit parameter is as follows:

Item

Function

Setting range

Individual-use

Unit

Factory

setting

P01

Back to the burning time

0.01-2.00s

0.01s

0.08s

P02

Slow wire feeding speed

1.0-21.0 M/min

0.1 M/min

3.6 M/min

P03

time of Plenum ahead

0.1-10.0s

0.1s

0.20s

P04

time of Stop lagging gas

0.1-10.0s

0.1s

1.0s

P05

early specification

1-200%

1%

135%

P06

Are-receive specification

1-200%

1%

50%

P07

transient time

0.1-10.0s

0.1s

1.0s

P08

Spot welding time

0.5-5.0s

0.1s

2.0s

P09

Close-control

OFF/ON

――

OFF

P10

Selection of water

cooling

OFF/ON

――

OFF

P11

Double pulse frequency

0.5-5.0Hz

0.1Hz

OFF

P12

Strong pulse group arc

-50-+50

1

0

This manual suits for next models

1

Table of contents

Other Hanshen Welding System manuals

Popular Welding System manuals by other brands

SAF

SAF NERTABLOC TH 400 PW Safety instruction for use and maintenance

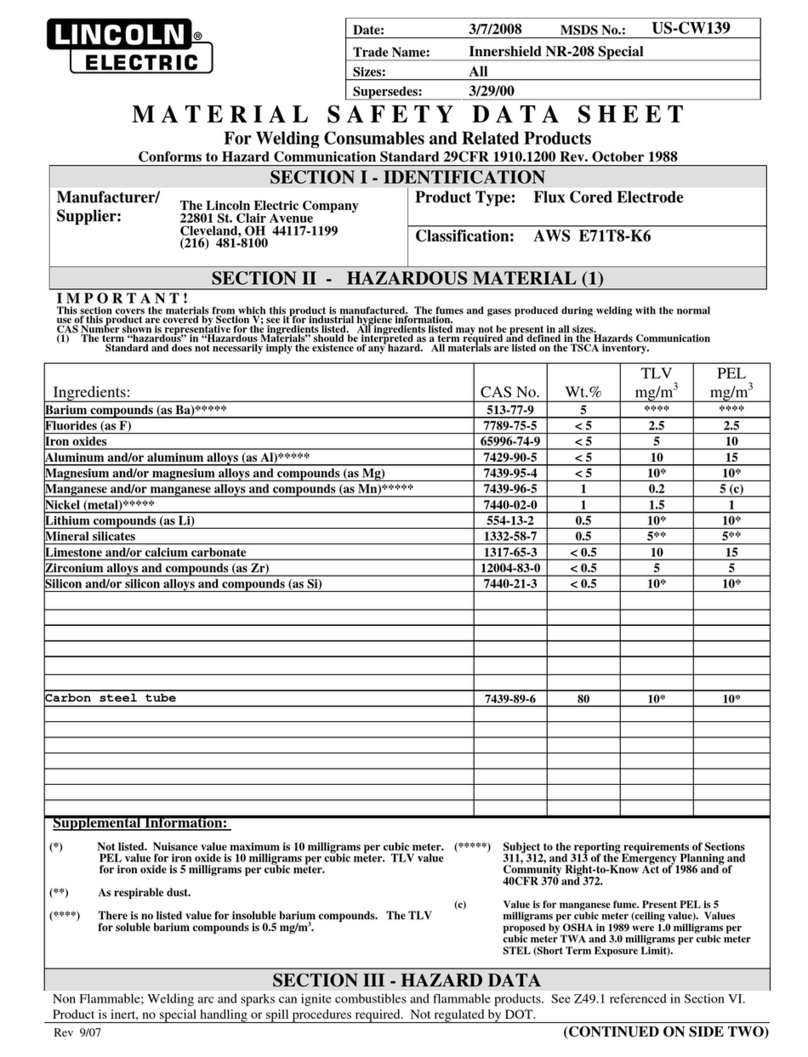

Lincoln Electric

Lincoln Electric LINC 405-S Operator's manual

Lincoln Electric

Lincoln Electric US-CW139 datasheet

Magmaweld

Magmaweld ID 500 M/MW PULSE user manual

Migatronic

Migatronic CMI 183i user guide

LORCH

LORCH M-Pro BasicPlus Operation manual